Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Peter Tang and Version 1 by Kinga Korniejenko.

Geopolymers belong to the group of the fastest-growing polymeric materials. The interest in these inorganic ceramic materials is constantly growing. This is a result of their properties, including acid resistance, porosity, low drying shrinkage, as well as high strength, due to which geopolymers are widely investigated for potential application in the construction industry (e.g., repairing roads, bridges, or other infrastructure). The range of potential applications of geopolymers can be increased by improving the properties of the components.

- geopolymer nanocomposites

- sustainable development

- inorganic nanoparticles

- carbon nanotubes

- graphene

- nanoclay

1. Introduction

Geopolymers belong to the group of the fastest-growing polymeric materials. The interest in these inorganic ceramic materials is constantly growing. This is a result of their properties, including acid resistance, porosity, low drying shrinkage, as well as high strength, due to which geopolymers are widely investigated for potential application in the construction industry (e.g., repairing roads, bridges, or other infrastructure) [1,2,3][1][2][3]. Importantly, geopolymers are also used as a substitute for Portland cement. Compared to Portland cement, geopolymers are cheaper, and their fabrication releases less carbon dioxide [4,5][4][5].

The use of geopolymers in wastewater treatment (for removing heavy metals) [6,7,8,9][6][7][8][9], soil stabilization [10], carbon capture and storage [11], or as protective coatings [12,13][12][13] is also being investigated. Furthermore, studies on the application potential of these materials for biomedical purposes including tissue engineering [14] or drug delivery systems [15] have also been performed.

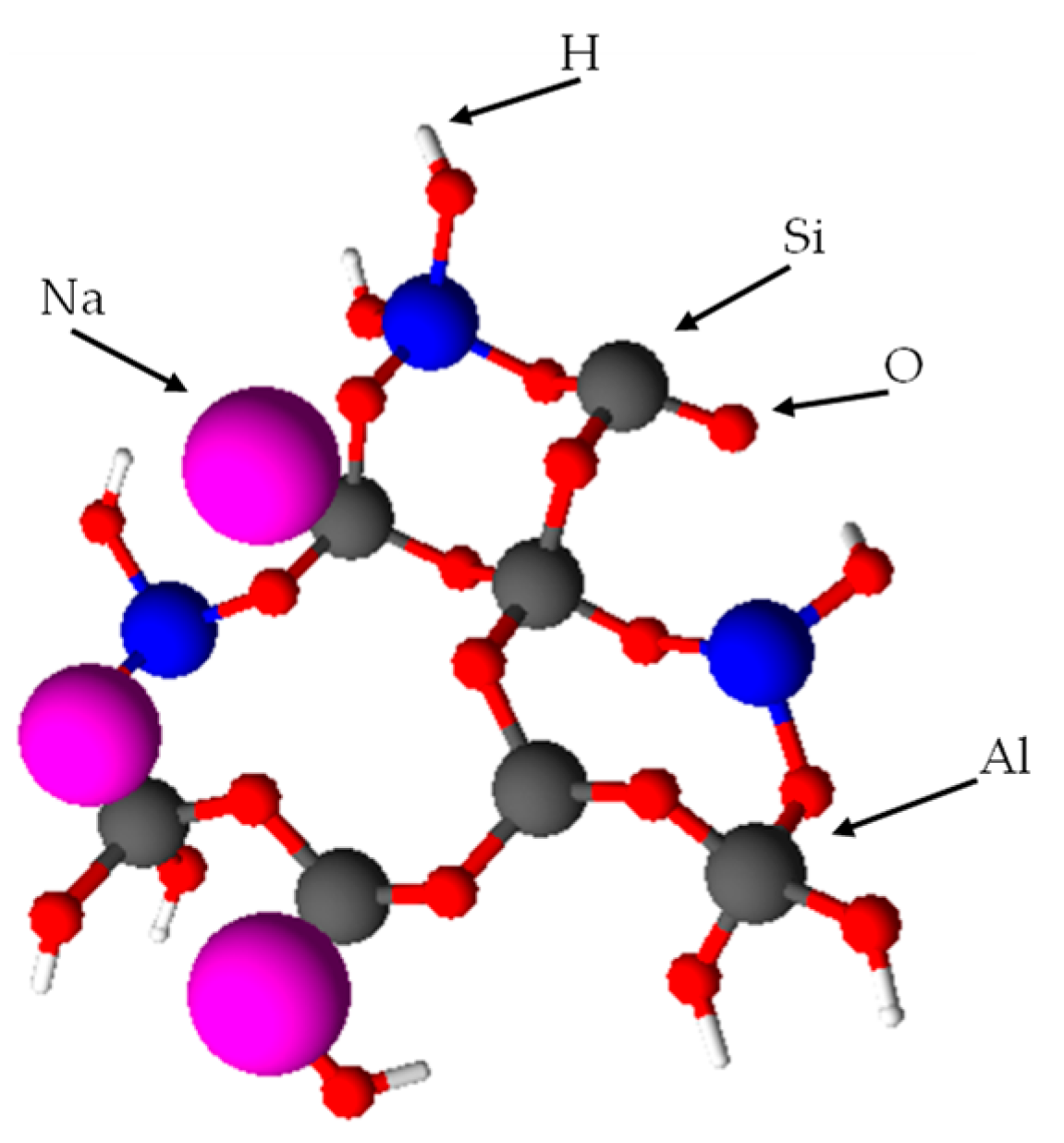

The structure of geopolymers consists of networks of inorganic molecules combined by means of covalent bonds. The scheme of the geopolymer framework is presented in Figure 1.

Due to the increasing demand for these materials as well as placing ever higher demands on them, many investigations are being performed to develop geopolymers showing the most beneficial physicochemical properties. Particular attention is paid to studies on geopolymer nanocomposites; the term “geopolymer nanocomposite” refers to the hybrid material made up of a combination of a geopolymer matrix and a nanosized modifying agent. It was demonstrated in many literature reports that the incorporation of various nanomaterials into geopolymer matrices results in significant improvement of their functional properties, including, e.g., compressive strength and stiffness [17,18][17][18].

2. Nanomaterials as Modifiers of Geopolymer Composites

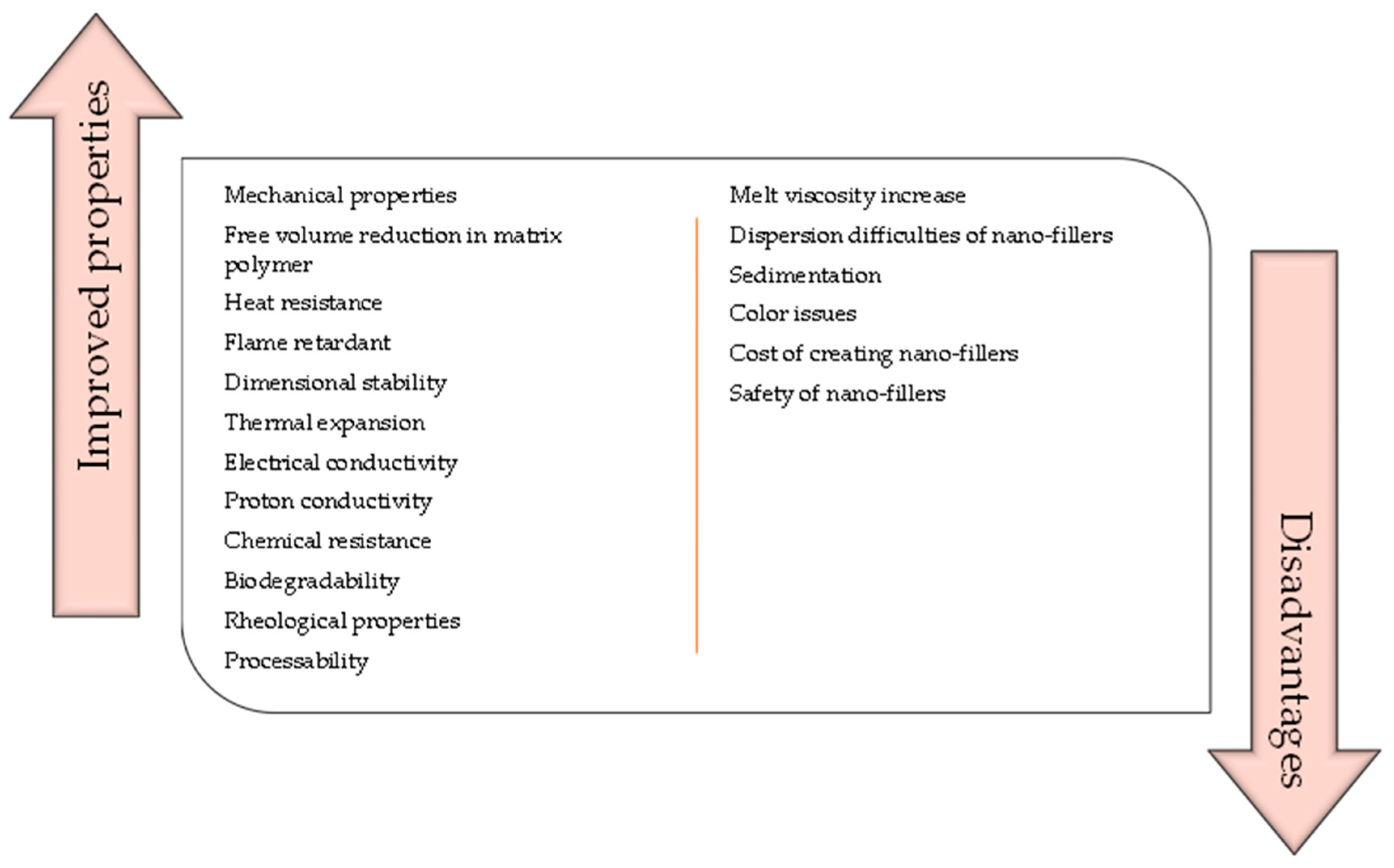

Geopolymerization occurs by mixing a mineral or waste material with an alkaline solution as a function of time and temperature. By adding nanoparticles to the matrix, the alkaline solution is immobilized and the pores between the grains of the raw material are filled, the so-called filler effect [19]. Nanoadditives increase the binding strength of the mixture and participate in pozzolanic reactions, which cause the formation of hydrates of calcium silicates [20]. The following nanoadditives were investigated in geopolymer matrices: nanosilica [21[21][22],22], nanocellulose [23[23][24][25],24,25], nanoaluminum [26], nanographite [27], and nano-CaCO3 [28]. The performance of geopolymer composites largely depends on the uniform distribution of nanoadditives in the matrix and their reaction with the matrix. Among these nanoparticles, nanosilica and nanocellulose are the most popular in research due to their unique properties. Nanocellulose seems to be an excellent reinforcing agent in various types of materials, especially in composites. The use of nanocellulose to replace, for example, synthetic fibers, leads to the production of a more environmentally friendly material. Nanocellulose, due to its origin and availability, can be successfully used in materials at low concentrations up to several %, due to the interaction between the matrix, e.g., polymer, and nanoparticles [29]. The use of nanoadditives in geopolymer matrices has a large impact on the proper-ties of the finished material. The basic type of properties most often determined in geo-polymers are mechanical properties, namely compressive strength and bending strength [36][30]. Research shows that the addition of nano-SiO2 to 2% wt. increases the compressive strength by up to 80% compared to geopolymer based on unmodified fly ash cured at room temperature [37][31]. Subsequent studies with the addition of nanosilica were carried out on geopolymer samples with a metakaolin matrix. Also, an improving effect of the nanoadditive on compressive strength was demonstrated, both for mortar cured at 80 °C (increase by 40%) and at 20 °C (increase by 56%), compared to the material without nanosilica introduced into the mix [38][32]. A limitation in the constructional use of geopolymers is their quasi-brittle cracking. Therefore, along with the introduction of nano-SiO2, scientists introduce various types of fibers into the geopolymer matrix to improve the structural properties and durability of geopolymers [30][33]. Thus, the introduction of a combination of PVA fibers and nanosilica particles to the fly ash and the activator increased the compressive strength (by 26% on average) and the fracture toughness compared to the reference sample [39][34]. The use of the addition of aluminum nanooxide to improve mechanical strength also brings good results. Research by Phoo-ngernkham et al. showed that for 1% wt. of nano-Al2O3 content, the compressive strength of geopolymer paste with fly ash increases by about 43%. Optimally, to maintain the best strength, it is not to exceed the addition of 3% wt. of nanoparticles [40][35]. A positive effect on the strength properties was also noted for calcium carbonate nanoparticles, especially for thermal hardening of the geopolymer for 24 h (increase in strength by approx. 60%) [41][36]. Research on geopolymers can take place at various stages of the process of their creation. One of these is the course of geopolymerization. In its course, nanoparticles can have different effects. The addition of nanosilica to fly-ash-based geopolymers increases the activity of the matrix material, and thus accelerates the geopolymerization process, increasing the length of the C–S hydrogen gel chain, which gives the effect of filling with small particles. Finally, the fly ash and nano-SiO2 geopolymerize to form a three-site reticular inorganic gel material with Si–Al–O cross-linking [42][37]. The higher the nano-SiO2 content, the shorter is the setting time. This is mainly due to the unique “surface effect” of nano-SiO2. The high surface area of nano-SiO2 has high activity and surface energy, which enriches the surrounding free phase on the surface of the nanomaterial, thus accelerating the geopolymerization process. At the same time, the concentration of monomers such as -OSi(OH)3-, -OSi(OH)2O- in the system accelerates the hydration and condensation hardening of fly ashes [43][38]. For construction materials, the important properties are resistance to freezing and propagation. It is no different in the case of geopolymer materials, where this property can be determined on the basis of the coefficient of loss of geopolymer compressive strength [44][39]. Most of the current research [3,18][3][18] on geopolymers reinforced with various nanomaterials is at an early stage, and little research has focused on their value for engineering applications and their sustainable aspects. Moreover, dynamic properties and properties after increased temperature are important for the safety of concrete structures. However, the current research [18,45][18][40] results focus on the static mechanical properties of nano-SiO2- and nanocellulose-modified geopolymer composites, and little research concerns dynamic mechanical properties and properties after elevated temperature. Therefore, further research on the dynamic properties of nanocomposites before and after their treatment with elevated temperature is needed to accelerate the development of geopolymers enriched with nanoadditives and increase their utility value. Nanocomposite materials show both advantages and disadvantages [6,7,8][6][7][8] which are presented in Figure 2.

Figure 2.

Selected advantages and disadvantages of nanocomposites.

3. Geopolymer Nanocomposites Reinforced with Selected Nanomaterials

3.1. Geopolymer Nanocomposites Reinforced with Carbon Nanotubes

Geopolymer nanocomposites reinforced with carbon nanotubes (CNTs) have gained significant attention in recent years due to their unique mechanical, thermal, and electrical properties. Carbon nanotubes are cylindrical carbon molecules that have exceptional mechanical, electrical, and thermal properties. In this subsection, the synthesis, properties, and applications of CNT-containing geopolymer nanocomposites are described. There are two main approaches used to these nanocomposites: in situ and ex situ methods. In situ methods involve the addition of carbon nanotubes during the synthesis of the geopolymer matrix. In turn, ex situ processes involve the addition of pre-synthesized carbon nanotubes to the geopolymer matrix. In situ methods are advantageous because they result in a more homogeneous distribution of CNTs within the geopolymer matrix. However, they require careful control of the synthesis parameters, such as pH and temperature, to prevent the degradation of the carbon nanotubes. Ex situ methods are easier to control, but the dispersion of the carbon nanotubes within the geopolymer matrix is not as uniform [48,49,50][41][42][43]. Geopolymer nanocomposites with CNTs show excellent mechanical properties, including high tensile strength, compressive strength, and flexural strength. The addition of carbon nanotubes improves the fracture toughness and reduces the brittleness of the geopolymer matrix. The high aspect ratio of carbon nanotubes also enhances the load transfer between the matrix and the reinforcement [51,52,53][44][45][46]. Additionally, CNT-containing geopolymer nanocomposites have superior thermal properties compared to traditional composites. The addition of carbon nanotubes enhances the thermal conductivity of the geopolymer matrix, which is important for applications such as thermal management. The thermal stability of the geopolymer matrix is also improved by the addition of carbon nanotubes. The described nanocomposites also demonstrate excellent electrical properties, including high electrical conductivity and low dielectric constant. These properties make them suitable for applications such as electromagnetic shielding and energy storage [54,55,56][47][48][49]. Geopolymer nanocomposites containing CNTs have potential applications in various industries, including aerospace, automotive, and construction. In the aerospace industry, these materials can be used to manufacture lightweight, high-strength components. In the automotive industry, they can be used to manufacture components with improved fuel efficiency and reduced emissions. In the construction industry, they can be used to manufacture high-strength, durable building materials. Overall, this type of nanocomposite is a promising class of materials with superior mechanical, thermal, and electrical properties. The addition of carbon nanotubes enhances the properties of geopolymer matrices, making them suitable for a wide range of applications. However, further research is needed to optimize the synthesis parameters and to investigate the long-term stability of these materials [57,58,59,60][50][51][52][53].3.2. Geopolymer Nanocomposites Containing Graphene and Graphene Oxide

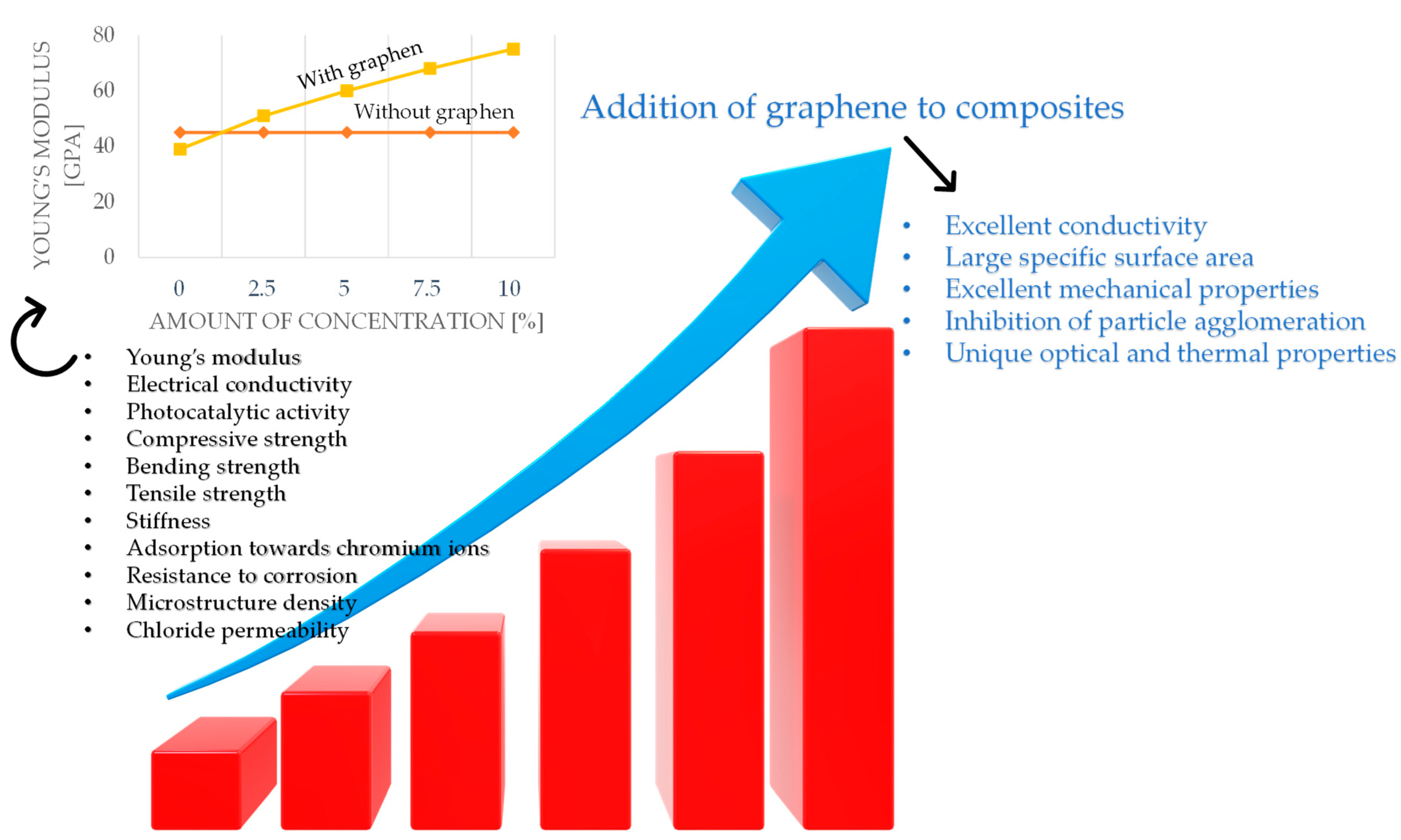

Geopolymer nanocomposites containing graphene and graphene oxide have been extensively studied in recent years due to their unique properties and potential applications in various industries. Graphene and graphene oxide are two-dimensional carbon-based materials that have excellent mechanical, electrical, and thermal properties. Several methods are used to synthesize geopolymer nanocomposites containing graphene and graphene oxide, including in situ and ex situ methods, which involve the addition of graphene or graphene oxide during the synthesis of the geopolymer matrix (in situ) and the addition of pre-synthesized graphene or graphene oxide to the geopolymer matrix (ex situ). More uniform distribution of graphene or graphene oxide within the composite matrix is achieved via in situ processes which, in turn, require strict control of the process conditions (temperature, pH etc.) [61,62,63,64,65][54][55][56][57][58]. Geopolymer nanocomposites with graphene and graphene oxide exhibit excellent mechanical properties, including high tensile strength, compressive strength, and flexural strength. The addition of graphene or graphene oxide improves the fracture toughness and reduces the brittleness of the geopolymer matrix. The high aspect ratio of graphene or graphene oxide also enhances the load transfer between the matrix and the reinforcement. Importantly, such nanocomposites demonstrate superior thermal properties, enhanced thermal conductivity, and thermal stability compared to composites without these nanoadditives. Moreover, graphene and graphene oxide nanocomposites exhibit excellent electrical properties, including high electrical conductivity and low dielectric constant, which make them useful in terms of their application in electromagnetic shielding and energy storage [66,67,68,69,70][59][60][61][62][63]. The overall influence of graphene on selected physicochemical characteristics of geopolymers is illustrated in Figure 3.

Figure 3.

The impact of graphene on selected characteristics of geopolymers.

3.3. Geopolymer Nanocomposites Reinforced with Nanoclay

Geopolymer nanocomposites reinforced with nanoclay are a type of material that has gained significant attention in recent years. These composites combine the benefits of geopolymer technology, such as high strength and durability, with the reinforcing effects of nanoclay particles, resulting in improved mechanical, thermal, and chemical properties. The synthesis of geopolymer nanocomposites reinforced with nanoclay can be achieved using various methods, although the most common is the in situ method, where nanoclay particles are added during the synthesis of the geopolymer matrix [75,76][68][69]. Geopolymer nanocomposites containing nanoclay demonstrate improved mechanical properties such as enhanced strength, stiffness, and toughness. This is due to the high aspect ratio of the nanoclay particles, which reinforce the geopolymer matrix by acting as a physical barrier against crack propagation. The addition of nanoclay particles also improves the thermal stability of the geopolymer matrix, making it suitable for high-temperature applications. Additionally, the presence of nanoclay particles can improve the chemical resistance of geopolymer nanocomposites, providing protection against chemical degradation [77,78][70][71]. Importantly, nanoclay-containing geopolymer nanocomposites have applications in the construction, automotive, and aerospace, industries. In the construction industry, these materials can be used to manufacture high-strength, durable building materials, such as pipes and panels. In turn, in the aerospace industry, they can be used to manufacture lightweight components for aircraft and space vehicles. In the automotive industry, they can be used to manufacture components with improved fuel efficiency and reduced emissions [79,80,81][72][73][74]. Despite the numerous benefits of geopolymer nanocomposites reinforced with nanoclay, there are still some challenges that need to be addressed. One of the primary challenges is the cost of producing these materials, as nanoclay particles are relatively expensive. Furthermore, the optimization of the synthesis parameters, such as pH and temperature, is crucial to ensure consistent and reproducible results [82,83][75][76]. In the future, research will focus on the development of more cost-effective methods for producing the described geopolymer nanocomposites. Additionally, further research is needed to investigate the long-term stability of these materials under various environmental conditions, such as exposure to UV radiation and humidity. The development of new applications for geopolymer nanocomposites reinforced with nanoclay will also be an area of focus in the coming years. Geopolymer nanocomposites with nanoclay are a promising class of materials with improved mechanical, thermal, and chemical properties. These materials have the potential for various applications in the construction, aerospace, and automotive industries. Although there are still some challenges that need to be addressed, the development of cost-effective methods for producing these materials and the investigation of their long-term stability will drive future research in this field [84,85,86][77][78][79].3.4. Geopolymer Nanocomposites with Magnetic Nanoparticles

The incorporation of magnetic nanoparticles into geopolymer nanocomposites has added a new dimension to the potential applications of these materials, making them suitable for a range of innovative technologies, including drug delivery, environmental remediation, and magnetic separation. The synthesis of geopolymer nanocomposites with magnetic nanoparticles can be achieved using both in situ and ex situ approaches [61][54]. Geopolymer nanocomposites with magnetic nanoparticles exhibit improved magnetic properties such as enhanced magnetic susceptibility, magnetic field response, and magnetic saturation. This is due to the presence of magnetic nanoparticles, which are capable of responding to external magnetic fields. Additionally, the incorporation of magnetic nanoparticles does not significantly affect the mechanical, thermal, and chemical properties of geopolymer nanocomposites [87,88,89][80][81][82]. Magnetic-nanoparticle-containing geopolymer nanocomposites have the potential for various applications in the fields of drug delivery, environmental remediation, and magnetic separation. In the field of drug delivery, these materials can be used as drug carriers, which can be magnetically guided to specific sites in the body. In the field of environmental remediation, they can be used to remove contaminants from water and soil by magnetically separating them from the environment. In the field of magnetic separation, they can be used to separate and purify magnetic materials from non-magnetic materials [90,91][83][84]. In spite of the many benefits of the described nanocomposites, there are still some challenges that need to be addressed. One of the primary challenges is the optimization of the synthesis parameters, such as pH and temperature, to ensure consistent and reproducible results. Additionally, the cost of producing these materials needs to be reduced to make them more economically feasible [92,93,94][85][86][87]. In the future, research will focus on the development of more cost-effective methods for producing geopolymer nanocomposites with magnetic nanoparticles. Additionally, further research is needed to investigate the long-term stability of these materials under various environmental conditions, such as exposure to humidity and corrosive environments. The development of new applications for geopolymer nanocomposites with magnetic nanoparticles will also be an area of focus in the coming years. Geopolymer nanocomposites with magnetic nanoparticles constitute an interesting class of materials showing enhanced magnetic properties, which makes them appropriate for a range of innovative technologies. However, the development of cost-effective methods for producing these materials and the investigation of their long-term stability will drive future research in this field. The potential applications of these materials in drug delivery, environmental remediation, and magnetic separation make them an exciting area of research in the field of materials science [95,96,97][88][89][90].3.5. Geopolymer Nanocomposites Reinforced with Titanium Dioxide Nanoparticles

Geopolymer nanocomposites reinforced with nanoparticles, such as titanium dioxide (TiO2), have been developed to enhance their mechanical, thermal, and chemical properties. The synthesis of geopolymer nanocomposites reinforced with TiO2 can be achieved using the same approaches as in the case of the nanocomposites described in previous subsections of this paperntry, i.e., ex situ and in situ [98][91]. Geopolymer nanocomposites containing TiO2 nanoparticles exhibit improved mechanical, thermal, and chemical properties such as enhanced flexural strength, compressive strength, thermal stability, and resistance to chemical attack. This is due to the presence of TiO2 nanoparticles, which act as reinforcement agents, filling the gaps between the geopolymer matrix and improving its mechanical properties. Additionally, the incorporation of TiO2 nanoparticles can improve the photocatalytic activity of geopolymer nanocomposites. These nanocomposites have the potential for various applications in the fields of construction, environmental remediation, and energy storage. In the field of construction, these materials can be used to produce high-performance, durable building materials, such as concrete and mortar. In the case of environmental remediation, they can be used to remove contaminants from water and soil by photocatalytic degradation, while in the area of energy storage, they may be applied to produce high-performance supercapacitors [99,100,101][92][93][94]. Considering further studies on these nanocomposites, aspects such as pH and temperature employed during their synthesis should be investigated so as to obtain desirable results. Furthermore, their long-term stability and durability under various conditions also need to be verified. In the future, research will focus on the development of more cost-effective methods for producing geopolymer nanocomposites reinforced with TiO2. Additionally, further research is needed to investigate the effects of TiO2 particle size, shape, and surface modification on the properties of geopolymer nanocomposites. So far, the incorporation of TiO2 in geopolymer matrix has shown to improve the mechanical properties such as compressive strength, flexural strength, and fracture toughness. This improvement is due to the enhanced interfacial bonding between the geopolymer matrix and TiO2 particles. Additionally, TiO2 improves the thermal stability of geopolymer nanocomposites [102,103,104][95][96][97]. In conclusion, geopolymer nanocomposites reinforced with TiO2 have shown significant potential for various applications in the fields of construction, biomedicine, and environmental remediation. The development of these materials will undoubtedly contribute to the advancement of materials science, particularly in the search for sustainable and eco-friendly materials [105,106][98][99].3.6. Geopolymer Nanocomposites Reinforced with Nanosilica

The addition of nanoparticles, such as nanosilica, to geopolymer matrices has been studied to improve their properties further. Nanosilica can be synthesized using various methods, including sol-gel, precipitation, and hydrothermal methods. The most commonly used method for the synthesis of nanosilica is the sol-gel method, which involves the hydrolysis and condensation of silicon alkoxides. The resulting nanosilica particles can then be incorporated into geopolymer matrices using in situ or ex situ methods [61][54]. Incorporation of nanosilica into geopolymer matrices has been shown to improve their mechanical, thermal, and chemical properties. The incorporation of nanosilica increases the density and reduces the porosity of the geopolymer matrix, resulting in improved mechanical properties such as compressive strength, flexural strength, and fracture toughness. Nanosilica also enhances the thermal stability of geopolymers and improves their chemical resistance, making them more resistant to acid and alkali attack. As a result, the addition of nanosilica to geopolymer matrices has expanded their potential applications in various fields, such as construction, energy, and environmental remediation. In the field of construction, geopolymer-based composites reinforced with nanosilica have been shown to produce high-performance materials, such as mortar and concrete. In the energy sector, geopolymer-based materials reinforced with nanosilica can be used for energy storage, such as supercapacitors. In environmental remediation, geopolymer-based composites reinforced with nanosilica have been used to remove heavy metals and organic pollutants from contaminated water [107,108,109,110][100][101][102][103]. Importantly, introduction of nanosilica into geopolymer matrices has been shown to improve their chemical, mechanical, and thermal properties. The incorporation of nanosilica increases the density and reduces the porosity of the geopolymer matrix, resulting in improved mechanical properties such as compressive strength, flexural strength, and fracture toughness. Additionally, the improved thermal stability and chemical resistance make nanosilica-modified geopolymer matrices suitable for a wide range of applications in construction, energy storage, and environmental remediation [111,112,113,114][104][105][106][107]. Despite the potential benefits, there are still challenges that need to be addressed. With continued research, it is likely that nanosilica-modified geopolymer matrices will become even more versatile and cost-effective, making them a promising alternative to traditional cement-based materials. Overall, the addition of nanosilica to geopolymer matrices shows great promise for enhancing the properties and expanding the potential applications of these inorganic materials [115,116][108][109]. Geopolymers are ceramic materials obtained from mineral raw materials such as fly ash or slag. Nanomaterial additives are used to improve the mechanical and thermal properties of geopolymers. The mechanism of action of nanomaterial additives on the structure and properties of geopolymers is complex and depends on the type of nanomaterial, its concentration, the method of introduction into the geopolymer structure, and the conditions during production and curing. In research conducted by De Silva et al. [175][110], the addition of carbon nanotubes to a geopolymer mixture increased its compressive and flexural strength by approximately 29% and 21%, respectively. Similar results were obtained by using silica nanoparticles [176][111] and aluminum oxide [177][112]. Nanomaterial additives can affect the structure of geopolymers by increasing the number of crosslinking bonds, reducing porosity, and improving homogeneity. In addition, nanomaterials can affect the phase structure of geopolymers and their thermal decomposition [178][113]. However, it is worth noting that the results of studies on the impact of nanomaterials on the properties of geopolymers are varied and not always clear. The introduction of nanomaterials into geopolymer mixtures requires further research and optimization of production processes to obtain materials with desired properties.References

- Novotný, J.; Jaskevic, M.; Mamon, F.; Mareš, J.; Horký, R.; Houška, P. Manufacture and Characterization of Geopolymer Coatings Deposited from Suspensions on Aluminium Substrates. Coatings 2022, 12, 1695.

- Cong, P.; Cheng, Y. Advances in geopolymer materials: A comprehensive review. J. Traffic Transp. Eng. 2021, 8, 283–314.

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90.

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267.

- Ren, B.; Zhao, Y.; Bai, H.; Kang, S.; Zhang, T.; Song, S. Eco-friendly geopolymer prepared from solid wastes: A critical review. Chemosphere 2021, 267, 128900.

- Wang, S.; Liu, B.; Zhang, Q.; Wen, Q.; Lu, X.; Xiao, K.; Ekberg, C.; Zhang, S. Application of geopolymers for treatment of industrial solid waste containing heavy metals: State-of-the-art review. J. Clean. Prod. 2023, 390, 136053.

- Grba, N.; Baldermann, A.; Dietzel, M. Novel green technology for wastewater treatment: Geo-material/geopolymer applications for heavy metal removal from aquatic media. Int. J. Sediment Res. 2023, 38, 33–48.

- Zhang, X.; Zhou, X.; Moghaddam, T.B.; Zhang, F.; Otto, F. Synergistic effects of iron (Fe) and biochar on light-weight geopolymers when used in wastewater treatment applications. J. Clean. Prod. 2021, 322, 129033.

- Aouan, B.; Alehyen, S.; Fadil, M.; El Alouani, M.; Saufi, H.; El Herradi, E.H.; El Makhoukhi, F.; Taibi, M. Development and optimization of geopolymer adsorbent for water treatment: Application of mixture design approach. J. Environ. Manag. 2023, 338, 117853.

- Nawaz, M.; Heitor, A.; Sivakumar, M. Geopolymers in construction—Recent developments. Constr. Build. Mater. 2020, 260, 120472.

- Freire, A.L.; José, H.J.; de Fátima Peralta Muniz Moreira, R. Potential applications for geopolymers in carbon capture and storage. Int. J. Greenh. Gas Control 2022, 118, 103687.

- Wang, A.; Fang, Y.; Zhou, Y.; Wang, C.; Dong, B.; Chen, C. Green Protective Geopolymer Coatings: Interface Characterization, Modification and Life-Cycle Analysis. Materials 2022, 15, 3767.

- Hamidi, R.M.; Siyal, A.A.; Luukkonen, T.; Shamsuddin, R.M.; Moniruzzaman, M. Fly ash geopolymer as a coating material for controlled-release fertilizer based on granulated urea. RSC Adv. 2022, 12, 33187–33199.

- Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Bone Tissue Applications: Recent Advances and Future Perspectives. Polymers 2023, 15, 1087.

- Forsgren, J.; Pedersen, C.; Strømme, M.; Engqvist, H. Synthetic geopolymers for controlled delivery of oxycodone: Adjustable and nanostructured porosity enables tunable and sustained drug release. PLoS ONE 2011, 6, e17759.

- Titirici, M.M.; White, R.J. Geopolymers: A paradigm shift in sustainable chemistry. Chem. Soc. Rev. 2021, 50, 5836–5858.

- Zhang, C.; Khorshidi, H.; Najafi, E.; Ghasemi, M. Fresh, mechanical and microstructural properties of alkali-activated composites incorporating nanomaterials: A comprehensive review. J. Clean. Prod. 2023, 384, 135390.

- Xie, T.; Fang, C. Nanomaterials Applied in Modifications of Geopolymer Composites: A Review. Aust. J. Civ. Eng. 2019, 17, 32–49.

- Huseien, G.F.; Hamzah, H.K.; Sam, A.R.M.; Khalid, N.H.A.; Shah, K.W.; Deogrescu, D.P.; Mirza, J. Alkali-activated mortars blended with glass bottle waste nano powder: Environmental benefit and sustainability. J. Clean. Prod. 2020, 243, 118636.

- Faheem, M.T.M.; Abdullah, M.M.a.; Hussin, K.; Binhussain, M.; Ghazali, C.M.R.; Izzat, A. Application of Clay-Based Geopolymer in Brick Production: A Review. Adv. Mater. Res. 2013, 626, 878–882.

- Zhang, P.; Li, Q.; Wang, J.; Shi, Y.; Ling, Y. Effect of PVA fiber on durability of cementitious composite containing nano-SiO2. Nanotechnol. Rev. 2019, 8, 116–127.

- Zhang, P.; Ling, Y.; Wang, J.; Shi, Y. Bending resistance of PVA fiber reinforced cementitious composites containing nano-SiO2. Nanotechnol. Rev. 2019, 8, 690–698.

- Tay, C.H.; Mazlan, N.; Wayayok, A.; Basri, M.S.; Mustafa, M.; Abdullah, A. Nanocellulose reinforced zeolite based geopolymer concrete: Density analysis through response surface methodology. Mater. Today Proc. 2022, 66, 2873–2882.

- Rahmawati, C.; Aprilia, S.; Saidi, T.; Aulia, T.B. Current development of geopolymer cement with nanosilica and cellulose nanocrystals. J. Phys. Conf. Ser. 2021, 1783, 12056.

- Sudalaimani, K.K.; Vijayakumar, C.T.; Saravanakumar, S.S. Effect of bio-additives on physico-chemical properties of fly ash-ground granulated blast furnace slag based self-cured geopolymer mortars. J. Hazard. Mater. 2019, 361, 56–63.

- Shaikh, F.U.A.; Hosan, A. Effect of Nano Alumina on Compressive Strength and Microstructure of High Volume Slag and Slag-Fly Ash Blended Pastes. Front. Mater. 2019, 6, 90.

- Chougan, M.; Ghaffar, S.H.; Jahanzat, M.; Albar, A.; Mujaddedi, N.; Swash, R. The influence of nano-additives in strengthening mechanical performance of 3D printed multi-binder geopolymer composites. Constr. Build. Mater. 2020, 250, 118928.

- Alomayri, T. Performance evaluation of basalt fiber-reinforced geopolymer composites with various contents of nano CaCO3. Ceram. Int. 2021, 47, 29949–29959.

- Muhammad, Y.K.; Ans, A.R.; Zia, U.A.; Waqas, A.; Hassan, A. Recent advances in nanocellulose-based different biomaterials: Types, properties, and emerging applications. J. Mater. Res. Technol. 2021, 14, 2601–2623.

- Korniejenko, K.; Figiela, B.; Miernik, K.; Ziejewska, C.; Marczyk, J.; Hebda, M.; Cheng, A.; Lin, W.-T. Mechanical and Fracture Properties of Long Fiber Reinforced Geopolymer Composites. Materials 2021, 14, 5183.

- Deb, P.S.; Sarker, P.K.; Barbhuiya, S. Effects of nano-silica on the strength development of geopolymer cured at room temperature. Constr. Build. Mater. 2015, 101, 675–683.

- Zidi, Z.; Ltifi, M.; Zafar, I. Synthesis and attributes of nano-SiO2 local metakaolin based-geopolymer. J. Build. Eng. 2021, 33, 101586.

- Guo, X.; Shi, H. Durability and pore structure of nano-particle-modified geopolymers of waste brick powder-class C fly ash. Chin. J. Mater. Res. 2017, 31, 110–116.

- Xu, S.L.; Malik, M.A.; Qi, Z.; Huang, B.T.; Li, Q.H.; Sarkar, M. Influence of the PVA fibers and SiO2 NPs on the structural properties of fly ash based sustainable geopolymer. Constr. Build. Mater. 2018, 164, 238–245.

- Phoo-ngernkham, T.; Chindaprasirt, P.; Sata, V.; Hanjitsuwan, S.; Hatanaka, S. The effect of adding nano-SiO2 and nano-Al2O3 on properties of high calcium fly ash geopolymer cured at ambient temperature. Mater Des. 2014, 55, 58–65.

- Durak, U.; Karahan, O.; Uzal, B.; İlkentapar, S.; Atiş, C.D. Influence of nano SiO2 and nano CaCO3 particles on strength, workability, and microstructural properties of fly ash-based geopolymer. Struct. Concr. 2021, 22, 352–367.

- Meng, T.; Ahmed, S.; Dai, D.; Yu, Y. Effects of load types and critical molar ratios on strength properties and geopolymerization mechanism. Rev. Adv. Mater. Sci. 2021, 60, 216–222.

- Liu, X.; Peng, Z.; Pan, C.; Hu, X.; Wan, C.; Yang, H. Mechanical properties and microscopic analysis of nano-silica modified fly ash geopolymer. Mater. Rev. 2020, 34, 22078–22082.

- Marczyk, J.; Ziejewska, C.; Korniejenko, K.; Łach, M.; Marzec, W.; Góra, M.; Dziura, P.; Sprince, A.; Szechyńska-Hebda, M.; Hebda, M. Properties of 3D Printed Concrete–Geopolymer Hybrids Reinforced with Aramid Roving. Materials 2022, 15, 6132.

- Singh, N.B.; Saxena, S.K.; Kumar, M. Effect of nanomaterials on the properties of geopolymer mortars and concrete. Mater. Today Proc. 2018, 5, 9035–9040.

- Duxson, P.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S. The role of inorganic polymer technology in the development of green concrete. Cem. Concr. Res. 2007, 37, 1590–1597.

- Provis, J.L.; Duxson, P.; van Deventer, J.S. The role of alkali-activated materials in sustainable construction. Mater. Today 2011, 14, 394–401.

- Zhu, W.; Wang, Q.; Zhang, Y.; Chen, D. Carbon nanotube reinforced geopolymer composites: A review. Mater. Des. 2015, 65, 653–678.

- Tang, W.; Lu, X.; Qi, T. Preparation and characterization of carbon nanotube/Geopolymer nanocomposites with high mechanical properties. Ceram. Int. 2019, 45, 24858–24863.

- Rovnaníková, P.; Kovářík, T. Structural characterization of carbon nanotubes and carbon nanotube-reinforced geopolymer composite. J. Mater. Sci. 2021, 56, 4694–4712.

- Li, X.; Li, Y.; Chen, J.; Chen, Y. Mechanical and electrical properties of carbon nanotube/geopolymer nanocomposites. J. Mater. Sci. 2018, 53, 7536–7547.

- Wang, L.; Li, Z.; Zhang, C. Preparation and characterization of carbon nanotube reinforced geopolymer nanocomposites with enhanced mechanical and thermal properties. Materials 2019, 225, 450–461.

- Wang, Y.; Chen, C.; Zhao, Z.; Zhang, L.; Li, Y. Synthesis and properties of carbon nanotube reinforced geopolymer composites. J. Mater. Sci. 2018, 53, 13461–13475.

- Wang, X.; Yang, X.; Hu, S.; Feng, D. Carbon nanotube-reinforced geopolymer composites for high-temperature applications: A review. Compos. B Eng. 2020, 183, 107658.

- Qian, X.; Lu, L.; Yan, H.; Huang, Y. Enhanced mechanical and thermal properties of carbon nanotube-geopolymer composite by pre-treatment. Constr. Build. Mater. 2019, 206, 468–477.

- Liu, Y.; Chen, Z.; Zhu, M.; Lu, C.; Chen, G.; Huang, X. Preparation and properties of carbon nanotube/geopolymer nanocomposites. J. Alloys Compd. 2020, 816, 152559.

- Wang, L.; Li, Z.; Zhang, C. Thermal and electrical properties of carbon nanotube reinforced geopolymer nanocomposites. Constr. Build. Mater. 2020, 234, 117409.

- Yang, Y.; Song, L.; Chen, F. Preparation and properties of carbon nanotube-geopolymer composites for energy storage applications. J. Mater. Sci. 2019, 54, 9341–9354.

- Davidovits, J. Geopolymers: Inorganic polymeric new materials. J. Therm. Anal. 1991, 37, 1633–1656.

- Zhu, W.; Huang, L.; Wang, X.; Yao, Q.; Wang, D. In-situ and ex-situ approaches to graphene-reinforced geopolymer composites: A review. Compos. B Eng. 2017, 15, 223–231.

- Duan, P.; Liu, J.; Li, W.; Yu, Q.; Lu, Z. Mechanical properties of graphene/geopolymer nanocomposites: A review. Compos. B Eng. 2019, 175, 107032.

- Abdollahnejad, Z.; Rafiee, M.A. Graphene-geopolymer nanocomposites: A review. J. Mater. Sci. 2018, 53, 12081–12101.

- Kriegel, R.; Ferrari, A.; Nistico, R. The influence of graphene and graphene oxide on the properties of geopolymer composites. Materials 2017, 10, 1440.

- Singh, D.; Singh, N.B.; Singh, M. Geopolymer/graphene oxide nanocomposites: A review. Mater. Sci. Energy Technol. 2021, 4, 1–12.

- Della, V.P.; Kyzas, G.Z.; Ochando-Pulido, J.M. Green synthesis of graphene oxide/alginate composite for highly efficient removal of copper ions. J. Clean. Prod. 2016, 113, 553–560.

- Kong, L.; Chen, J.; Lu, J. Geopolymer reinforced with graphene oxide–phosphate glass composite fibres. Compos. Part A Appl. 2018, 109, 188–195.

- Alam, M.S.; Islam, M.R. Influence of graphene oxide on the properties of geopolymer composites. J. Mater. Sci. Res. 2017, 6, 39–50.

- Liu, J.; Duan, P.; Yu, Q.; Li, W.; Lu, Z. Preparation and properties of graphene oxide–geopolymer nanocomposites: A review. Adv. Appl. Ceram. 2021, 120, 294–309.

- Sanjuán, M.Á.; Sanjuán, M.Á.; Martinez-Ramirez, S.; Garcia-Lodeiro, I.; Palomo, A. Graphene oxide geopolymer composites with advanced properties. Nanomaterials 2019, 9, 1011.

- Zuo, X.; Zuo, X.; Li, W.; Li, M.; Li, Z.; Wang, H.; Ding, J.; Chen, Y. A review of graphene-based geopolymers: Synthesis, properties and applications. Adv. Appl. Ceram. 2020, 119, 1–20.

- Eftekhari, Y.; Eftekhari, Y.; Shirvani, M.; Javidi, M.; Zargar, M. Graphene oxide/epoxy/geopolymer ternary nanocomposite coating for protection of steel in corrosive environments. J. Mater. Sci. 2018, 53, 8647–8663.

- Jia, D.; Jia, D.; Chen, Y.; Li, Y.; Wang, Y.; Ye, Q.; Zhang, Y.; Song, X. Geopolymer composite with graphene oxide: Properties and microstructure. J. Alloys Compd. 2018, 746, 327–334.

- Pacheco-Torgal, F.; Jalali, S. Nanotechnology: Advantages and drawbacks in the field of construction and building materials. Constr. Build. Mater. 2011, 25, 582–590.

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; van Deventer, J.S. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933.

- Provis, J.L.; van Deventer, J.S. Geopolymers: Structures, Processing, Properties and Industrial Applications; Woodhead Publishing: Sawston, UK, 2009; pp. 1–484.

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329.

- Wong, L.S. Durability Performance of Geopolymer Concrete: A Review. Polymers 2022, 14, 868.

- Morsy, M.S.; Alsayed, S.H.; Abd Elaleem, H.; Elchalakani, M. Recent trends in geopolymer concrete: A review. Constr. Build. Mater. 2020, 231, 117174.

- Zainudin, N.H.; Razak, R.A.; Jamaludin, S.B. A review on recent progress in geopolymer nanocomposites. J. Nanomater. 2019, 27, 650–673.

- Li, H.; Xiao, J.; Ou, J.; Wang, D. Microstructure of geopolymer prepared from circulating fluidized bed combustion (CFBC) bottom ashes. J. Cent. South Univ. Technol. 2005, 12, 769–773.

- Zhang, Z.; Liu, Y.; Chen, Q.; Zhang, L.; Lu, C. Enhancing the properties of fly ash-based geopolymer by adding nanoclay. J. Build. Eng. 2019, 25, 100764.

- Zhang, Z.; Liu, Y.; Chen, Q.; Zhang, L.; Lu, C. Properties and microstructure of geopolymer composite modified by hybrid reinforcement of basalt fiber and nanoclay. Constr. Build. Mater. 2018, 189, 525–533.

- Salehi, S.; Shekarchi, M. Effects of nanoclay on mechanical properties of geopolymer composites containing microcrystalline cellulose. Constr. Build. Mater. 2019, 201, 447–454.

- Nath, P.; Kumari, A. Synthesis and characterization of geopolymer-based nanocomposite reinforced with modified montmorillonite. J. Build. Eng. 2019, 21, 141–148.

- Zhang, M.; Ruan, C.; Liu, Q.; Yang, X. Magnetic properties of CoFe2O4 nanoparticles prepared by sol-gel method. J. Magn. Magn. Mater. 2016, 416, 76–81.

- Zhang, Y.; Li, J. Review of magnetic nanoparticles preparation techniques and their applications in biomedicine. J. Nanomater. 2017, 26, 521–537.

- Yang, K.; Xu, H.; Cheng, Y.; Zhang, X. Magnetic nanoparticles for enhanced drug delivery in cancer therapy. Curr. Drug Metab. 2017, 18, 447–456.

- Wu, M.; Gu, Y.; Yu, C.; Fu, J. Magnetic nanoparticle-based drug/gene delivery systems. Chem. Rev. 2017, 117, 8388–8462.

- Hossain, S.; Bose, S.; Cho, J.; Choi, H. Nano/micro hybrid composites: Synthesis, properties and applications. RSC Adv. 2017, 7, 27440–27461.

- Yildirim, O.; Al-Sayah, M.H.; Kitis, M. Magnetic nanoparticle-based advanced nanocomposites for environmental remediation applications: A review. J. Environ. Chem. Eng. 2017, 5, 5737–5763.

- Wang, S.; Chen, H.; Yu, H.; Sun, H. Magnetic nanocomposites for environmental remediation. J. Hazard. Mater. 2015, 283, 329–343.

- Muflikhun, M.; Fitriana, N.; Widayatno, W.B. Recent advances in magnetic nanocomposites for environmental remediation: A review. J. Environ. Chem. Eng. 2020, 8, 103763.

- Ghasemzadeh, K.; Shojaei, A.F.; Yazdani, B.; Motamedi, H. Synthesis and Characterization of Geopolymer Composites Reinforced with Nano-SiC Particles. J. Inorg. Organomet. Polym. Mater. 2019, 29, 1397–1407.

- Chakraborty, S.; Sahoo, P.; Roy, A. Geopolymer nanocomposites: A review of recent developments. J. Mater. Sci. 2021, 56, 2485–2511.

- Tao, F.; Li, Z.; Zhang, J.; Liu, H. A review of the recent progress in synthesis, properties, and applications of magnetic geopolymer composites. Prog. Mater. Sci. 2020, 109, 100616.

- Zhang, Z.; Yao, X.; Liu, J. Geopolymer: A review of the synthesis methods, properties and applications. Mater. Sci. Eng. B 2018, 236, 114–126.

- Kumar, A.; Kumar, P.; Singh, R.K. Geopolymer Nanocomposites and Its Applications. Nanomaterials 2020, 52, 197–223.

- Palomo, A.; Krivenko, P.; Garcia-Lodeiro, I.; Kavalerova, E. Geopolymers based on natural resources: Fly ash. Procedia Mater. Sci. 2014, 4, 114–123.

- Bernal, S.A.; Provis, J.L.; Rose, V.; van Deventer, J.S. Progress in understanding alkali-activated materials. Cem. Concr. Res. 2013, 78, 110–125.

- Tchakouté, H.K.; Elimbi, A.; Djangang, C.N.; Kamseu, E.; Leonelli, C. Assessment of the pozzolanic activity of kaolin waste for the production of geopolymer cements. Appl. Clay Sci. 2014, 97, 245–250.

- Zhou, Y.; Ye, G.; Zhang, Y.; Wang, D. The role of alkali concentration in the formation of TiO2-geopolymer nanocomposites with enhanced mechanical properties. Mater. Sci. Eng. A 2018, 731, 444–452.

- Yip, C.K.; Lukey, G.C.; Provis, J.L.; van Deventer, J.S. Effect of calcium silicate sources on geopolymerisation. Cem. Concr. Res. 2008, 38, 554–564.

- Li, C.; Li, L.; Li, J.; Li, J.; Wang, H. Preparation and properties of geopolymer composites reinforced by Al2O3 and TiO2. J. Aust. Ceram. 2020, 56, 301–307.

- Xu, H.; Zhu, Y.; Zhang, H.; Gao, X.; Shu, X. Development of a novel TiO2-geopolymer photocatalyst for degradation of organic pollutants. J. Environ. Chem. Eng. 2020, 8, 104236.

- Provis, J.L.; Duxson, P.; van Deventer, J.S.J. The role of particle technology in developing sustainable construction materials. Adv. Powder Technol. 2009, 20, 387–394.

- Xu, H.; van Deventer, J.S.J. The geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266.

- Zhang, Z.; Provis, J.L.; Reid, A.; Wang, H.; Li, H. Geopolymers for immobilization of Cr(VI)-contaminated soil: Immobilization efficiency and leaching behavior. Environ. Sci. Technol. 2012, 46, 12224–12232.

- Nematollahi, B.; Sanjayan, J.G.; Shaikh, F.U.A. Effects of nano-silica addition on properties of geopolymers cured in ambient condition. Constr. Build. Mater. 2014, 50, 231–239.

- Provis, J.L.; Bernal, S.A.; Duxson, P.; van Deventer, J.S.J. Geopolymers as precursors to strengthened and stabilized mining waste. J. Hazard. Mater. 2009, 162, 1319–1327.

- Bernal, S.A.; Provis, J.L.; Walkley, B.; San Nicolas, R.; Gehman, J.D.; Brice, D.G.; Kilcullen, A.R.; Duxson, P.; van Deventer, J.S.J. Gel nanostructure in alkali-activated binders based on slag and fly ash, and effects of accelerated carbonation. Cem. Concr. Res. 2012, 42, 432–444.

- Gharzouni, A.; Damidot, D.; Jauberthie, R.; Benhassaine, A.; Qiao, Y. Influence of silica fume on the properties of fly ash-based geopolymer concrete. Constr. Build. Mater. 2012, 27, 241–245.

- Wu, C.; Zhang, Y.; Zeng, J.; Lu, J.; Chen, Z.; Zhang, Y. Preparation and properties of inorganic polymer concrete modified with nano-SiO2. Mater. Des. 2013, 47, 720–726.

- Li, Y.; Li, W.; Yu, Q.; Li, W.; Zhang, J. Effect of nanosilica on the properties of fly ash-based geopolymer. Constr. Build. Mater. 2012, 29, 548–554.

- Chindaprasirt, P.; Rattanasak, U.; Sirivivatnanon, V. Influence of fly ash fineness on the chloride penetration of concrete. Constr. Build. Mater. 2007, 21, 356–361.

- De Silva, R.T.; Yu, L.; Wang, D.; Chen, X.; Liu, Y.; Zhang, Z. Carbon nanotube reinforced geopolymer composites: An experimental study on mechanical and electromagnetic interference shielding properties. J. Clean. Prod. 2018, 198, 661–670.

- Qian, Z.; Li, H.; Li, Y.; Chen, Y.; Chen, C.; Chen, X. Effect of SiO2 nanoparticles on the microstructure and mechanical properties of fly ash-based geopolymer. J. Mater. Sci. 2017, 52, 9172–9185.

- Li, Y.; Qian, Z.; Li, H.; Chen, Y.; Chen, C.; Chen, X. Effect of Al2O3 nanoparticles on the mechanical and thermal properties of fly ash-based geopolymer composites. Constr. Build. Mater. 2017, 154, 278–289.

- Ismail, I.; Kumar, S.; Bernal, S.A.; Provis, J.L.; van Deventer, J.S.J. Effects of nano-SiO2 on geopolymer cement properties: A review. Constr. Build. Mater. 2019, 229, 116969.

More