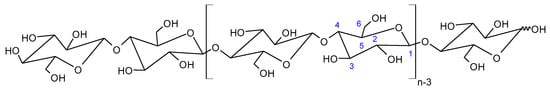

The supramolecular structure of cellulose is responsible for its insolubility in water and in a large number of organic solvents. The supramolecular structure can be defined by the degree of crystallinity, crystallographic parameters, crystallite dimensions and presence of defects, structural indices of amorphous domains, and dimensions of fibrillar formations

[13]. The physicochemical properties of cellulose are established by a particular hierarchical order in supramolecular structure and organization. The molecular structure conveys cellulose with its distinguishing properties, such as chirality, hydrophilicity, degradability, and extensive chemical variability, introduced by the high donor reactivity of the –OH groups

[12]. One of the explanations for the stability of cellulose is that it exists generally in the form of crystals that have broad van der Waals attractive forces, as well as hydrogen bonds

[14][15][16][14,15,16].

2. Nature Materials

Millions of years of natural selection have resulted in the design of cellulose-based structures that combine structure–function and are an inspiration for the production of synthetic materials.

TIn this section

, we describe

s some key examples of structures found in nature with unique characteristics, such as support, coloration, and movement. Plants present one interesting feature: the outer layer known as the cuticle, made of lipids embedded on a typically hydrophobic polymeric matrix

[17][76], which can confer several properties to the plant. One of the most recognized examples is the self-cleaning mechanism present in the common lotus leaf. The micro- and nanostructured surface of the lotus leaf provides a highly effective antiadhesive effect, allowing the plant to protect itself against contamination

[17][76]. Plants can also comprise, at different scales, anisotropic cellulose structures that are responsible for color and/or movement. These interesting features of plants inspired and continue to inspire scientists and engineers to pursue new biomimetic and actuating materials/devices that can change, for example, color and/or shape

[18][77]. The majority of the colors that plants exhibit are due to pigments and dye molecules that are ephemeral and disappear with time

[19][20][78,79]. Another approach used in the plant kingdom to exhibit lively and attractive colors is accomplished by the interaction of light with ordered structures at the micron and nanoscale

[21][80], defined as structural color. Iridescent colors, similar to the interference colors observed in soap bubbles or thin soap films

[22][23][81,82], are colors that differ with the observing angle or lighting geometry; these features can also be observed in plants and result from ordered structures existing in the plants

[24][83].

Micro- and nanofibers produced by plants are fundamental elements that assist in vital functions, for example, reproduction or weight support. Climbing plants are a notable example of organisms that use filaments as support; these structures are designated as tendrils. Darwin reported in 1865 that tendrils can create 2D structures (spirals) if they do not find a support point or 3D structures (helices) if they do

[25][90]. Micro-nano-helical structures can also be found in water and the nutrient transport system and can be isolated from the leaves of different plants. For example, in

Agapanthus africanus and

Ornithogalum thyrsoides, the filaments are tightly coiled and present the same cellulosic skeleton but with different mechanical properties and surface morphology. These differences were revealed by the texture observed in nematic liquid crystal droplets pierced by these microfilaments

[26][91].

The seed-dispersal method of the true rose of Jericho,

Anastatica hierochuntica, a desert plant, is correlated with the water-absorption-driven motion of the entire dead skeleton. The dead branches, which consist of dead cellulosic tissue, present a curling motion in the presence of water, allowing the fruit valves to open and release seeds. The closing process is associated with the rapid drying of the xylem vessels existent on the upper side of the stem

[27][28][98,99]. The spike moss

Selaginella lepidophyla also presents a water-driven motion, due to a different response to water by the inner and outer stems of the spike moss. This type of movement is vital for plant survival, since it avoids photoinhibitory and thermal damage being a mechanism that overcomes stress due to sun radiation, high temperatures, and water scarcity. The water-driven movement of the stems can occur for several cycles without structural impairment. Water loss within the internal capillary spaces of parallel cellulose fibers in the cell walls, and the consequent shrinking of the cell wall is the driving force responsible for stem curling

[29][100].

3. Cellulose Biomimetic Fiber in Functional Materials

In this topic, the production of biomimetic fiber and fiber-based cellulosic materials that have attracted significant attention within the scientific community will be presented. The main strategy of biomimetic materials is to observe and understand the function of unique structures present in nature, and then use that knowledge to obtain similar structures and functionality. Jiang et al.

[30][120] prepared cellulose membranes that can present a variety of predetermined deformations in the presence of moisture. Thin cellulose membranes from balsa wood fibers through a series of procedures that include chemical, mechanical, and heat treatment were prepared. The high humidity response presented by the thin membrane is due to a self-maintained moisture gradient induced by an asymmetric design of the membrane surfaces, strengthened by the hygroscopic swelling of the cellulose matrix. The

scautho

lars designed and built a hydro-driven robot hand using these cellulose membranes. The hydro-driven robot hand could controllably grab and release objects 40 times heavier than its weight. The high capability of load uptake is attributed to the fairly rigid cellulose elements in the membranes. These results are presented as a good option to achieve new smart structures and devices, such as flexible robots and self-unfolding structures produced from an environmentally friendly and recyclable source

[30][120].

The scientific community has shown increased interest in the manufacture of electrospinning fibers. Using this process, it is possible to produce membranes and three-dimensional constructions with a wide range of polymers of different sizes and shapes and small pores. The fibers have diameters in the submicron range, and the surface area is remarkably high. Cao et al.

[31][121] reported that it is possible to produce fiber-based nanoporous membranes that mimic spider webs using jute cellulose nanocrystals (CNCs) in their composition. For this purpose, different polyacrylonitrile (PAN), crosslinked polyvinyl alcohol (PVA), and silica membranes were produced using electrospinning. The electrospun membranes were later immersed in a solution of dodecyl trimethyl ammonium bromide (DTAB) and jute CNCs. The membranes obtained were produced using a low-energy consumption method and presented pores in the submicron range, very useful for ultrafiltration

[31][121]. Later, also inspired by spider webs, Wang et al.

[32][122] manufactured a fiber-based membrane composed of 48% functionalized sulfhydryl cellulose (SC) and polyacrylonitrile (PAN). The reusable membrane produced via electrospinning presented a great water–oil separation capability. To increase the concentration of cellulose nanocrystals that could be used, functionalized sulfhydryl cellulose nanocrystals were also added to the membrane composition. This strategy made it possible to manufacture ultrathin and porous membranes with better mechanical properties and with a separation efficiency of 99.9%

[32][122].

Electrospinning membranes have also begun to be used in tissue engineering with the aim of mimicking the extracellular matrix (ECM) to restore, maintain, or improve tissue function. Cellulose acetate membranes, produced using electrospinning, capable of mimicking this three-dimensional structure were reported by Han et al.

[33][125]. These membranes will help in cell differentiation, tissue, and organ growth and also facilitate the cellular response

[34][126]. Over the years, electrospun fibers of cellulose acetate combined with other polymers such as gelatin

[35][127], polycaprolactone

[36][128], polyvinyl alcohol

[37][129], zein

[38][130], and polyurethane

[39][131] have been used in the field of wound-healing applications.

4. Biomimetic Cellulosic Active Films

The development of nature-inspired materials with a focus on functionality and response to an external stimulus has been reported for several years. A one-step method to produce monolayer cellulose-based Janus-like membranes with reversible behavior of the micro-/nanostructures and solvent-responsive properties was reported by Liu and coworkers

[40][136]. The structural difference among the top and bottom surfaces, due to the anisotropic self-assembly of cellulose nanocrystals, enables the solvent-responsive curling of the film in different solvents with a rapidly reversible bending motion for many cycles

[40][136]. Gevorkian et al.

[41][137] reported a planar single-layer cellulose-based hydrogel with anisotropic structures. Shear-induced-orientation cellulose nanocrystals resulted in anisotropic mechanical and swelling properties of the cellulose hydrogel. Multiple complex 3D shapes from the same hydrogel were prepared according to the degree of its structural anisotropy

[41][137]. Inspired by the plant movements triggered by the water content within nano- and mesoscale cellulose fibrillar structures, Wang and coworkers

[42][138] developed a thin film of cellulose nanofibrils (CNFs) that presents humidity-controlled reversible actuation. To mimic the water-dependent curling and blooming of the glory flower, the

scautho

lars prepared a four-petal CNF film “flower” that gradually folded the petals and that bloomed and recovered its original shape as a consequence of the presence or absence of moisture, respectively.

Freestanding, flexible, and porous moisture-driven actuators inspired by

M. pudica and pine cone were reported by Zhu et al.

[43][139]. The active films consisted of poly (vinyl alcohol-

co-ethylene) nanofibers and cellulose nanocrystals. The films prepared were applied to switches, soft robots, and humidity regulation. The locomotion of the actuator produced could be adjusted by cutting the film in different directions, and is a reflection of the orientation of the CNC existing in the film. The film could bend to an angle of 180° and recover its shape in less than 1 s for more than 100 cycles when the environment moisture decreased

[43][139].

Inspired by stomata, the structure existing in plant leaves responsible for the control of the rate of gas exchange, Hou et al.

[44][145] prepared a bilayer intelligent hydrogel film. The

scautho

lars presented a one-step casting strategy to produce an N-isopropylacrylamide/clay gel reinforced with a bacterial cellulose network. The anisotropic swelling promoted by the bilayer structure provided a rapid temperature-induced tunable shape modification with reversible behavior. As result, a bionic leaf stoma was built where the vapor could pass and fill the space above to achieve moisture circulation, as well as temperature and air balance.

5. Cellulosic Printed 3D Structures

Traditional fabrication technologies struggle to accurately reproduce or imitate the complex structures existing in nature, which have specific mechanical, hydrodynamic, optical, and electrical properties. Three-dimensional (3D_ printing is reported as a suitable technology to fabricate structures with complex and arbitrary geometry

[45][46][146,147]. The classification standards of the American Society for Testing and Materials (ASTM) define seven categories in 3D printing technology: powder bed fusion molding (PBF), material extrusion molding (ME), binder injection molding (BJ), photopolymerization curing, material inject forming (MJ), direct energy deposition (DED), and sheet lamination (SL)

[47][48][148,149].

In 2019, Kam et al.

[49][150] reported a method called direct cryo writing (DCW) that combines freeze casting and 3D printing in a single step. The

scautho

lars used an aqueous mixture of cellulose nanocrystals and xyloglucan to produce an aerogel with an internal structure mimicking plant cell walls. Directly printing onto a cold platform enables the direct post-processing of the resulting 3D-printed aerogel with aligned structures via lyophilization. DCW allows obtaining structures with a low solid content coupled with controlled porosity and tunable architecture, making this method suitable for the production of custom-designed biological scaffolds

[49][150].

Three-dimensional (3D) bioprinting of a hierarchical nano- to macrofibrillary artificial human tissue with high resolution and integrity was reported by Mendes et al.

[50][151]. The

scautho

lars developed a nanocomposite bioink of platelet lysate hydrogel reinforced by cellulose nanocrystals, presented as suitable to print dynamic and personalized 3D living constructs that mimic the structure and composition of native tissues

[50][151].

6. Cellulosic 4D-Printed Responsive Materials

Four-dimensional (4D) printing is a one-step process, where time is considered the fourth dimension, in which the properties of the printed materials allow morphing a 1D strand or 2D surface into a 3D shape, or converting a 3D shape into another 3D shape, in response to an external stimulus such as the presence of water

[51][156]. This technique was first introduced in 2013 by Skylar Tibbits at a TED conference

[52][157]. As mentioned above, 4D printing can produce dynamic structures with adjustable shapes, properties, or functionality

[53][54][158,159]. The 4D printing market is predicted to reach USD 510 million in the 2022–2030 period

[55][160]. Gladman et al.

[56][161] printed a series of functional folding-flower architectures using a biomimetic composite hydrogel with nanofibrillated cellulose. The printed material successfully reproduces the complex architecture of the orchid

Dendrobium helix. The materials used present encoded anisotropy that promotes the appearance of an intricate shape when the printed structure is immersed in water

[56][161]. Throughout the printing process, when the ink flows, fibril arrangement is induced, and anisotropic stiffness and longitudinal swelling are introduced in the structure. The printed programmable bilayer architecture enables petals to be closed or twisted upon swelling according to the orientation of the printed layers

[56][161].

7. Conclusions

Stimuli-responsive nature-inspired cellulose-based materials have paved the way for a wide variety of applications, namely in actuators, sensors, soft robotics, biomedicine, tissue engineering, and smart fabrics. Cellulose and cellulose derivatives are easily available and low-cost polymers that have been widely used in commercial applications. Here, it showed that cellulose and cellulose-based materials are excellent candidates to mimic the structures and functions existing in some plants and animals. The development of stable and innovative active materials/devices requires: (1) a full understanding of the underlying mechanisms after being exposed to external stimuli; (2) tunable fabrication of the smart cellulose-based materials; and (3) evaluation and continuous improvement of the active materials/devices performance regarding the desired sensitivity, specificity, and stability.