You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 4 by Jessie Wu and Version 3 by Behrouz Abnar.

Friction stir welding (FSW) is an effective solid-state joining process that has the potential to overcome common problems correlated with conventional fusion welding processes. FSW is used for the joining of metallic materials, in particular Al alloys (non-heat-treatable and heat-treatable). The heat produced by the friction between the rotating tool and the workpiece material generates a softened region near the FSW tool.

- friction stir welding

- mechanical

- heat

1. Introduction

Friction stir welding (FSW) is a widely used solid-state joining process for metals and alloys developed at The Welding Institute (TWI) in 1991. During the FSW process, a rotating tool is inserted into the interface between two workpieces, which is then traversed along the welding line. The rotating tool is usually composed of a pin and a shoulder. The applied plastic deformation and heat-induced by friction between the rotating tool and workpiece lead to the formation of a solid-state weld [1,2,3,4,5][1][2][3][4][5]. Although FSW is applicable for various metals [6[6][7][8][9][10],7,8,9,10], it is mostly used in the joining of Al alloys [1,11,12,13,14][1][11][12][13][14]. FSW of Al alloys has many advantages compared with conventional fusion welding processes (e.g., MIG and TIG). These include finer microstructure, better dimensional stability, lower processing defects, reduced residual stresses, and superior mechanical properties [3,15,16][3][15][16].

Non-heat-treatable Al alloys, which are also called strain-hardened or work-hardened alloys, include a group of alloys that are usually strengthened via cold work and/or solid solution hardening. The various combinations of additions used for these alloys are shown in Table 1 [3,17,18][3][17][18]. Temper designations for the alloys strengthened by strain hardening consist of an H followed by two or more digits (e.g., AA3103-H13). The first digit following the H indicates whether the strain-hardened alloy has been thermally treated, and the digit following the H1, H2, and H3 (e.g., H1xx, H2xx, or H3xx conditions) indicates the degree of the applied strain hardening. Furthermore, the letter “O” is used to present the annealed conditions by which the lowest strength is achieved [19,20][19][20].

| Non-Heat-Treatable Aluminum Series |

Common Alloys (Number) |

Alloy System | Tensile Strength Range (MPa) |

|---|---|---|---|

| 1xxx | 1050, 1060, 1100 | Pure Al | 70–175 |

| 3xxx | 3003, 3004, 3105 | Al-Mn | 140–280 |

| 5xxx | 5005, 5052, 5056, 5083, 5086, 5454, 5456, 5657, 5754 | Al-Mg | 140–380 |

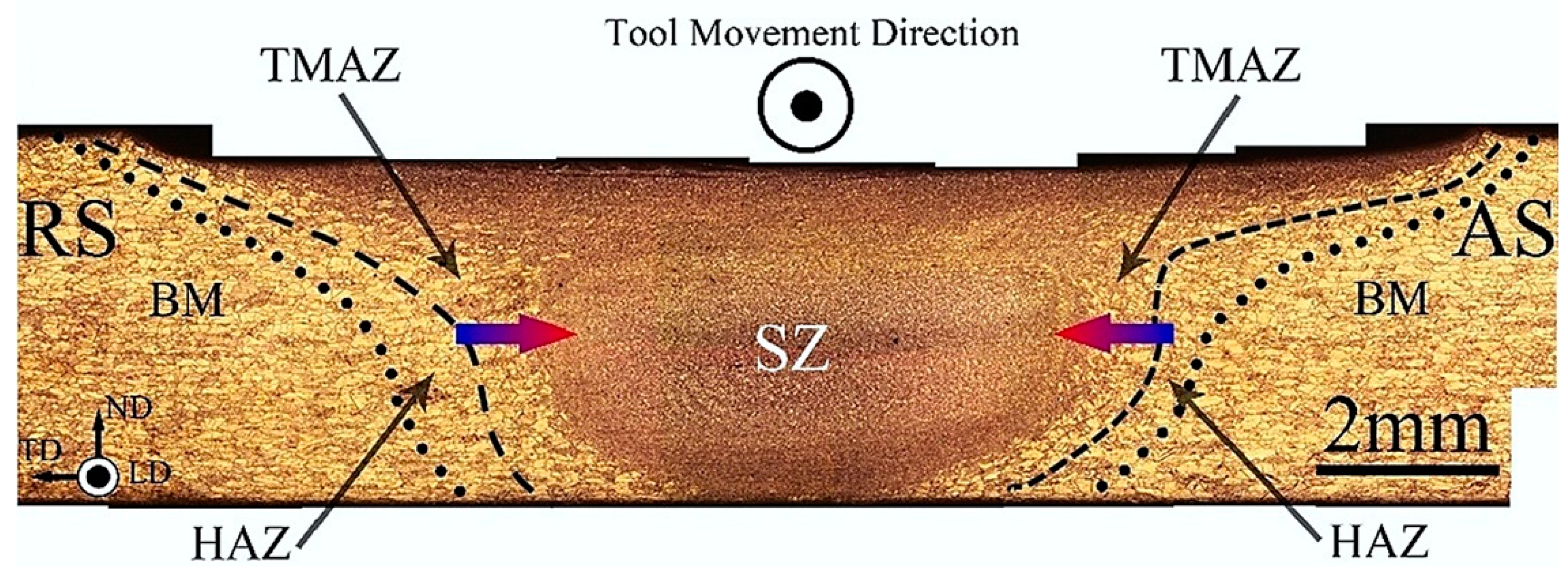

The plastic flow applied by the rotating pin leads to stirring and mixing of material around the weld zone, while friction between the tool and the workpiece provides the main contribution to heat generation [3,22,23][3][21][22]. The generated heat activates softening mechanisms by which the mechanical properties of the weld area are deteriorated compared to the base metal [1,24,25,26,27,28][1][23][24][25][26][27]. Overall, four distinct macrostructural zones can be identified in the FSWed joints, including: heat-affected zone (HAZ), thermomechanical affected zone (TMAZ), stir zone (SZ), and base metal (BM) [29][28]. Figure 1 shows a common cross-section of FSWed joints [29][28].

In non-heat-treatable, work-hardened Al alloys, the softened region leads to considerable deterioration in the tensile properties, hardness, and fatigue resistance of the FSWed joints. Recovery and recrystallization are the principle softening mechanisms [31,37,38][29][30][31]. Unlike the heat-treatable alloys, applying the post-weld heat treatment does not work and can significantly deteriorate the mechanical properties of the FSW joints of the strain-hardened Al alloys [17,38,41,42][17][31][32][33].

Several efforts have been made to identify and introduce novel processing routes which can improve the mechanical properties of FSWed joints of non-heat-treatable Al alloys. The first practical approach is the optimization of FSW parameters, including rotational and traverse speeds, welding tool geometry, tool tilt angle, and plunge depth. Minimizing heat generation by applying higher traverse speeds and/or lower rotational speeds seems to be a successful solution for alleviating the softening problems. However, there are concerns about insufficient heat generation which can lead to different types of defects in the weld area where the mechanical properties of the joints can be remarkably reduced [1,22,43,44][1][21][34][35]. Unfavorable residual stress, distortion, and high surface flash are also negative effects of the excessive heat input that mostly affect the fatigue performance of FSWed joints [2,26,45,46][2][25][36][37]. Therefore, an appropriate combination of traverse and rotational speeds is required to achieve a defect-free joint with minimum heat input.

Another important FSW parameter is tool geometry, which plays a key role in localized heating and material flow and can remarkably influence the tensile properties, hardness, and fatigue life. Designing appropriate tool geometry is necessary to control the heat input of the FSW joint. The common tool pin design consists of a cylindrical and tapered/conical pin that can be with or without thread [12,47,48,49][12][38][39][40]. By designing an appropriate tool pin design, it is possible to fabricate FSWed joints with symmetrical mechanical properties.

Furthermore, the tool tilt angle is associated with the effective transfer of material from the front to the back of the pin. Its effect on the formation or disappearance of defects, peak temperature, the material flow, and changing the shapes of the nugget zone has also been shown. The tool tilt angle depends on the tool pin design and the degree of its mixing during FSW. In addition, surface defects that are mainly responsible for fatigue crack initiation are affected by tool tilt angle [44,50,51][35][41][42]. The plunge depth is another factor that affects the surface quality of the joints. Plunge depths that are either too shallow or too deep can negatively affect the weld quality (e.g., by insufficient plastic deformation, lack of penetration, local thinning, and excessive flash) [2,27,52][2][26][43].

The incorporation of reinforcement nano- or microparticles in the microstructure of non-heat-treatable Al alloys can improve the mechanical strength of the stir zone, provided that an appropriate ratio of rotational and traverse speeds is chosen. In addition to the rotational and traverse speeds, the number of FSW passes and direction of the multi-passes are important variables that affect the FSWed joint quality in the presence of reinforcement particles [53,54,55][44][45][46]. The reinforcement particles can be ceramic-based particles, that are intrinsically hard, or intermetallic compounds formed in the microstructure by in situ reaction between metal powder and aluminum matrix. The homogeneous distribution of the reinforcement particles in the aluminum matrix is critical to have high strength FSWed joints [56,57][47][48].

The use of artificial cooling (e.g., water) during the course of the FSW process can minimize heat input and the associated softening effect [2]. Underwater friction stir welding (UFSW) improves the mechanical properties of joints by preventing grain coarsening in different weld zones, especially in the HAZ. Using water cooling may require revising the welding parameters of the conventional FSW processes (e.g., rotational speed) to obtain high-quality defect-free joints [58,59][49][50]. Water cooling media can greatly improve the fatigue performance of FSWed joints by controlling residual stresses and distortions [25,60][24][51].

Several other measures have been suggested to improve the quality of FSWed joints of work-hardened Al alloys. Surface defects, which act as the site of fatigue crack initiation, can be removed and replaced by favorable compressive residual stress and applying suitable surface treatments [61,62][52][53]. The Bobbin tool FSW was developed to solve the insufficient tool penetration in conventional tool FSW [26,63][25][54]. Furthermore, using Cu backing as a cooling agent was introduced to FSW of Al alloys to improve hardness, tensile properties, and fatigue life [64,65][55][56]. Double-sided FSW is an efficient method for joining Al thicker plates, which maximizes symmetry and minimizes the root flaws [10,66][10][57].

2. Application

FSW is extensively used in many industries (e.g., shipbuilding, marine, aerospace, railway vehicles, and automotive sectors) in joining non-heat-treatable Al-based products [13,67,68,69,70,71][13][58][59][60][61][62]. Although the FSW process is mostly used in butt welds, other joint designs such as spot welds and T-joint welds are also being performed. In most cases, FSW is applied for large-scale products that are welded by setting the workpiece on a worktable. Even though the applications are in a one-dimensional form, the facility is under development to conduct FSW in a three-dimensional form [2,72,73][2][63][64]. The following are some common examples of FSW, which imply the strong need for FSW use in various industrial sectors.

2.1. Marine

One of the main applications of FSW is in shipbuilding, where it is often used for joining the boat’s hulls and its stiffeners, decking, bulkheads, and superstructure made from corrosion resistant AA5XXX aluminum alloys, such as AA5086, AA5454, AA5456, AA5059, and AA5383 AA5083 products [74,75,76][65][66][67]. In addition, the FSW process is used to join honeycomb panels which have been developed with a high noise-absorbing coefficient for the walls of the ship cabin. In shipbuilding construction, prefabricated panels fabricated by FSW lead to reduced problems for retaining highly skilled welders, thus reducing labor costs. [67,68,77,78][58][59][68][69]. Furthermore, a portable prototype FSW machine has been recently used in manufacturing the bow section of a new type of ocean viewer vessel made from the AA5083-H321 alloy [67,78][58][69].

2.2. Aerospace

The various advantages of the FSW process, such as the weight of the structure, the strength of the joint (particularly fatigue performance), and finished cost, led to interest from the aerospace industry [2,78,79,80][2][69][70][71]. Various joining processes, especially FSW, are performed to join the main structural areas in a transport aircraft, namely fuselage and pressure cabins, wings, and empennage (horizontal and vertical stabilizers). The engineering properties required for these structures are strength, stiffness, fatigue crack growth, fracture toughness, and corrosion [81][72]. FSW is used in the manufacturing of aircraft (A3xxx Airbus series) for the production of longitudinal joints in the fuselage, links, and central container of the wing [68][59].

2.3. Railway

The use of FSW is also increasing in the railway vehicle industry and is an ideal process for butt welding of lengthy longitudinal extruded section profiles for high-speed trains [82,83][73][74]. In train and tram structures, FSW is now used for roof panels, car-body, and railway wagons, which are made from longitudinal hollow Al extrusions [78,84,85][69][75][76].

2.4. Automotive

The FSW of different Al alloys has been extensively used in the automotive industry for the high-volume production of vehicle components for years due to the high integrity of the technique [51,72][42][63]. Among the innovations used in joining aluminum alloy body panels, prototype frames, and structural components in automobiles are FSW and friction stir spot welding (FSSW) [86][77].

References

- Mishra, R.S.; Ma, Z. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78.

- Threadgill, P.; Leonard, A.; Shercliff, H. Friction stir welding of aluminium alloys. Int. Mater. Rev. 2009, 54, 49–93.

- Ma, Z.; Feng, A.; Chen, D.; Shen, J. Recent advances in friction stir welding/processing of aluminum alloys: Microstructural evolution and mechanical properties. Crit. Rev. Solid State Mater. Sci. 2018, 43, 269–333.

- Akinlabi, E.T.; Mahamood, R.M. Solid-State Welding: Friction and Friction Stir Welding Processes; Springer: Cham, Switzerland, 2020.

- AWS A3.0M/A3.0; Standard Welding Terms and Definitions; Including Terms for Adhesive Bonding, Brazing, Soldering, Thermal Cutting, and Thermal Spraying, 13th ed.; American Welding Society: Miami, FL, USA, 2020; p. 190.

- Ke, W.; Oliveira, J.; Ao, S.; Teshome, F.; Chen, L.; Peng, B.; Zeng, Z. Thermal process and material flow during dissimilar double-sided friction stir spot welding of AZ31/ZK60 magnesium alloys. J. Mater. Res. Technol. 2022, 17, 1942–1954.

- Oliveira, J.P.; Duarte, J.; Inácio, P.; Schell, N.; Miranda, R.; Santos, T.G. Production of Al/NiTi composites by friction stir welding assisted by electrical current. Mater. Des. 2017, 113, 311–318.

- Costa, A.M.S.; Oliveira, J.; Pereira, V.; Nunes, C.A.; Ramirez, A.J.; Tschiptschin, A.P. Ni-based Mar-M247 superalloy as a friction stir processing tool. J. Mater. Process. Technol. 2018, 262, 605–614.

- Aliha, M.; Kalantari, M.; Ghoreishi, S.; Torabi, A.; Etesam, S. Mixed mode I/II crack growth investigation for bi-metal FSW aluminum alloy AA7075-T6/pure copper joints. Theor. Appl. Fract. Mech. 2019, 103, 102243.

- Cam, G.; Mistikoglu, S. Recent developments in friction stir welding of Al-alloys. J. Mater. Eng. Perform. 2014, 23, 1936–1953.

- Mathers, G. The Welding of Aluminium and Its Alloys; Woodhead Publishing: Abington, UK, 2002.

- Rai, R.; De, A.; Bhadeshia, H.; DebRoy, T. Friction stir welding tools. Sci. Technol. Weld. Join. 2011, 16, 325–342.

- Eren, B.; Guvenc, M.A.; Mistikoglu, S. Artificial intelligence applications for friction stir welding: A review. Met. Mater. Int. 2021, 27, 193–219.

- Xu, W.; Wu, X.; Ma, J.; Lu, H.; Luo, Y. Abnormal fracture of 7085 high strength aluminum alloy thick plate joint via friction stir welding. J. Mater. Res. Technol. 2019, 8, 6029–6040.

- Taban, E.; Kaluc, E. Microstructural and mechanical properties of double-sided MIG, TIG and friction stir welded 5083-H321 aluminium alloy. Kov. Mater. 2006, 44, 25.

- Paik, J.K. Mechanical properties of friction stir welded aluminum alloys 5083 and 5383. Int. J. Nav. Archit. Ocean. Eng. 2009, 1, 39–49.

- Davis, J.R. Aluminum and Aluminum Alloys; ASM International: Novelty, OH, USA, 1993.

- Mondolfo, L.F. Aluminum Alloys: Structure and Properties; Butterworth-Heinemann: London, UK, 2013.

- Kaufman, J.G. Introduction to Aluminum Alloys and Tempers; ASM Handbook: Novelty, OH, USA, 2000.

- Cayless, R. Alloy and Temper Designation Systems for Aluminum and Aluminum Alloys; ASM International: Novelty, OH, USA, 2013.

- Djurdjanovic, M.; Mijajlovic, M.; Milcic, D.; Stamenkovic, D. Heat generation during friction stir welding process. Tribol. Ind. 2009, 31, 8.

- Schmidt, H.; Hattel, J.; Wert, J. An analytical model for the heat generation in friction stir welding. Model. Simul. Mater. Sci. Eng. 2003, 12, 143.

- Fujii, H.L.H.; Nogi, K. Tensile Properties of A Friction Stir Welded Thin-Sheet of 1050-H24 Aluminum Alloy. Charact. Control. Interfaces High Qual. Adv. Mater. 2012, 146, 129–136.

- Peel, M.; Steuwer, A.; Preuss, M.; Withers, P. Microstructure, mechanical properties and residual stresses as a function of welding speed in aluminium AA5083 friction stir welds. Acta Mater. 2003, 51, 4791–4801.

- Meng, X.; Huang, Y.; Cao, J.; Shen, J.; dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2021, 115, 100706.

- Ogunsemi, B.; Abioye, T.; Ogedengbe, T.; Zuhailawati, H. A review of various improvement strategies for joint quality of AA 6061-T6 friction stir weldments. J. Mater. Res. Technol. 2021, 11, 1061–1089.

- Laska, A.; Szkodo, M. Manufacturing parameters, materials, and welds properties of butt friction stir welded joints—Overview. Materials 2020, 13, 4940.

- Heidarzadeh, A.; Mironov, S.; Kaibyshev, R.; Çam, G.; Simar, A.; Gerlich, A.; Khodabakhshi, F.; Mostafaei, A.; Field, D.; Robson, J. Friction stir welding/processing of metals and alloys: A comprehensive review on microstructural evolution. Prog. Mater. Sci. 2021, 117, 100752.

- Liu, H.; Fujii, H.; Maeda, M.; Nogi, K. Mechanical properties of friction stir welded joints of 1050–H24 aluminium alloy. Sci. Technol. Weld. Join. 2003, 8, 450–454.

- Threadgill, P. Terminology in friction stir welding. Sci. Technol. Weld. Join. 2007, 12, 357–360.

- Abnar, B.; Kazeminezhad, M.; Kokabi, A. Effects of heat input in friction stir welding on microstructure and mechanical properties of AA3003-H18 plates. Trans. Nonferrous Met. Soc. China 2015, 25, 2147–2155.

- Xu, W.; Liu, J.; Chen, D.; Luan, G.; Yao, J. Improvements of strength and ductility in aluminum alloy joints via rapid cooling during friction stir welding. Mater. Sci. Eng. A 2012, 548, 89–98.

- Khorrami, M.S.; Kazeminezhad, M.; Kokabi, A. Thermal stability during annealing of friction stir welded aluminum sheet produced by constrained groove pressing. Mater. Des. 2013, 45, 222–227.

- Kulekci, M.K.; Şik, A.; Kaluç, E. Effects of tool rotation and pin diameter on fatigue properties of friction stir welded lap joints. Int. J. Adv. Manuf. Technol. 2008, 36, 877–882.

- Li, H.; Gao, J.; Li, Q. Fatigue of friction stir welded aluminum alloy joints: A review. Appl. Sci. 2018, 8, 2626.

- Bussu, G.; Irving, P. The role of residual stress and heat affected zone properties on fatigue crack propagation in friction stir welded 2024-T351 aluminium joints. Int. J. Fatigue 2003, 25, 77–88.

- James, M.; Bradley, G.; Lombard, H.; Hattingh, D. The relationship between process mechanisms and crack paths in friction stir welded 5083-H321 and 5383-H321 aluminium alloys. Fatigue Fract. Eng. Mater. Struct. 2005, 28, 245–256.

- Kalemba-Rec, I.; Kopyściański, M.; Miara, D.; Krasnowski, K. Effect of process parameters on mechanical properties of friction stir welded dissimilar 7075-T651 and 5083-H111 aluminum alloys. Int. J. Adv. Manuf. Technol. 2018, 97, 2767–2779.

- Janeczek, A.; Tomków, J.; Fydrych, D. The influence of tool shape and process parameters on the mechanical properties of AW-3004 aluminium alloy friction stir welded joints. Materials 2021, 14, 3244.

- Singh, K.; Singh, G.; Singh, H. Review on friction stir welding of magnesium alloys. J. Magnes. Alloys 2018, 6, 399–416.

- Dialami, N.; Cervera, M.; Chiumenti, M. Effect of the tool tilt angle on the heat generation and the material flow in friction stir welding. Metals 2018, 9, 28.

- Lohwasser, D.; Chen, Z. Friction Stir Welding: From Basics to Applications; Woodhead Publishing: Cornwall, UK, 2009.

- Iqbal, M.P.; Vishwakarma, R.K.; Pal, S.K.; Mandal, P. Influence of plunge depth during friction stir welding of aluminum pipes. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020.

- Rastabi, S.A.; Mosallaee, M. Effects of multipass friction stir processing and Mg addition on the microstructure and tensile properties of Al 1050 alloys. Int. J. Miner. Metall. Mater. 2022, 29, 97–107.

- Arora, H.; Singh, H.; Dhindaw, B. Composite fabrication using friction stir processing—A review. Int. J. Adv. Manuf. Technol. 2012, 61, 1043–1055.

- Sharma, V.; Prakash, U.; Kumar, B.M. Surface composites by friction stir processing: A review. J. Mater. Process. Technol. 2015, 224, 117–134.

- Abnar, B.; Kazeminezhad, M.; Kokabi, A. The effect of Cu powder during friction stir welding on microstructure and mechanical properties of AA3003-H18. Metall. Mater. Trans. A 2014, 45, 3882–3891.

- Huang, G.; Hou, W.; Li, J.; Shen, Y. Development of surface composite based on Al-Cu system by friction stir processing: Evaluation of microstructure, formation mechanism and wear behavior. Surf. Coat. Technol. 2018, 344, 30–42.

- Wahid, M.A.; Siddiquee, A.N. Review on underwater friction stir welding: A variant of friction stir welding with great potential of improving joint properties. Trans. Nonferrous Met. Soc. China 2018, 28, 193–219.

- Tan, Y.; Wang, X.; Ma, M.; Zhang, J.; Liu, W.; Fu, R.; Xiang, S. A study on microstructure and mechanical properties of AA 3003 aluminum alloy joints by underwater friction stir welding. Mater. Charact. 2017, 127, 41–52.

- Lombard, H.; Hattingh, D.; Steuwer, A.; James, M. Effect of process parameters on the residual stresses in AA5083-H321 friction stir welds. Mater. Sci. Eng. A 2009, 501, 119–124.

- Lomolino, S.; Tovo, R.; Dos Santos, J. On the fatigue behaviour and design curves of friction stir butt-welded Al alloys. Int. J. Fatigue 2005, 27, 305–316.

- Feng, A.; Chen, D.; Ma, Z. Microstructure and low-cycle fatigue of a friction-stir-welded 6061 aluminum alloy. Metall. Mater. Trans. A 2010, 41, 2626–2641.

- Padhy, G.; Wu, C.; Gao, S. Friction stir based welding and processing technologies-processes, parameters, microstructures and applications: A review. J. Mater. Sci. Technol. 2018, 34, 1–38.

- Liu, F.; Fu, L.; Chen, H. High speed friction stir welding of ultra-thin AA6061-T6 sheets using different backing plates. J. Manuf. Process. 2018, 33, 219–227.

- Kulkarni, B.; Pankade, S.; Andhale, S.; Gogte, C. Effect of backing plate material diffusivity on microstructure, mechanical properties of friction stir welded joints: A Review. Procedia Manuf. 2018, 20, 59–64.

- Yang, C.; Zhang, J.; Ma, G.; Wu, L.; Zhang, X.; He, G.; Xue, P.; Ni, D.R.; Xiao, B.L.; Wang, K.S. Microstructure and mechanical properties of double-side friction stir welded 6082Al ultra-thick plates. J. Mater. Sci. Technol. 2020, 41, 105–116.

- Kallee, S. Application of friction stir welding in the shipbuilding industry. In Proceedings of the International Conference Lightweight Construction, London, UK, 24–25 February 2000.

- Shtrikman, M. Current state and development of friction stir welding Part 3. Industrial application of friction stir welding. Weld. Int. 2008, 22, 806–815.

- Lohwasser, D. Welding of Airframes by Friction Stir. In Proceedings of the Third International Symposium on Friction Stir Welding, Kobe, Japan, 27–28 September 2001.

- Magalhães, V.; Leitão, C.; Rodrigues, D. Friction stir welding industrialisation and research status. Sci. Technol. Weld. Join. 2018, 23, 400–409.

- Bhardwaj, N.; Narayanan, R.G.; Dixit, U.; Hashmi, M. Recent developments in friction stir welding and resulting industrial practices. Adv. Mater. Process. Technol. 2019, 5, 461–496.

- Hori, H.; Hino, H. Application of friction stir welding to the car body. J. Light Met. Weld. Constr. 2002, 40, 12–17.

- Gite, R.A.; Loharkar, P.K.; Shimpi, R. Friction stir welding parameters and application: A review. Mater. Today Proc. 2019, 19, 361–365.

- Wahid, M.A.; Siddiquee, A.N.; Khan, Z.A. Aluminum alloys in marine construction: Characteristics, application, and problems from a fabrication viewpoint. Mar. Syst. Ocean. Technol. 2020, 15, 70–80.

- Prabha, K.A.; Putha, P.K.; Prasad, B.S. Effect of tool rotational speed on mechanical properties of aluminium alloy 5083 weldments in friction stir welding. Mater. Today Proc. 2018, 5, 18535–18543.

- Hosseinabadi, O.F.; Khedmati, M.R. A review on ultimate strength of aluminium structural elements and systems for marine applications. Ocean. Eng. 2021, 232, 109153.

- Kumagai, M.; Tanaka, S. Properties of aluminum wide panels by friction stir welding. In Proceedings of the First International Symposium on Friction Stir Welding, Thousand Oaks, CA, USA, 14–16 June 1999.

- Kallee, S. Industrial Applications of Friction Stir Welding. In Friction Stir Welding; Woodhead Publishing: Sawston, UK, 2010; pp. 118–163.

- Arbegast, W.J. Application of Friction Stir Welding and related technologies. In Friction Stir Welding and Processing; ASM international: Novelty, OH, USA, 2007; pp. 273–308.

- Shah, P.H.; Badheka, V.J. Friction stir welding of aluminium alloys: An overview of experimental findings–process, variables, development and applications. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1191–1226.

- Eswara Prasad, N.; Wanhill, R.J.H. Aluminium alloys for aerospace applications. In Aerospace Materials and Material Technologies: Volume 1: Aerospace Materials; Springer: Singapore, 2017; pp. 29–52.

- Skillingberg, M.; Green, J. Aluminum applications in the rail industry. Light Met. Age Chic. 2007, 65, 8.

- Sun, X.; Han, X.; Dong, C.; Li, X. Applications of aluminum alloys in rail transportation. In Advanced Aluminum Composites and Alloys; Dobrzański, L.A., Ed.; Intechopen: London, UK, 2021; Volume 9, pp. 251–268.

- Kawasaki, T.; Makino, T.; Masai, K.; Ohba, H.; Ina, Y.; Ezumi, M. Application of friction stir welding to construction of railway vehicles. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2004, 47, 502–511.

- Thomas, W.; Nicholas, E. Friction stir welding for the transportation industries. Mater. Des. 1997, 18, 269–273.

- Benedyk, J. Aluminum Alloys for Lightweight Automotive Structures, in Materials, Design and Manufacturing for lightweight Vehicles; Woodhead Publishing: Sawston, UK, 2010; pp. 79–113.

More