Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Conner Chen and Version 1 by Inês Santos Afonso.

Vegetable oils have been used as metalworking fluids (MWFs) for many years, particularly in small-scale metalworking operations and in industries where environmental regulations are strict. Before the development of modern MWFs, vegetable oils were one of the most common lubricants used for metalworking tools. The use of vegetable oils can be traced back to ancient civilizations such as Egypt, Greece, and Rome, where olive oil was commonly used to lubricate metal tools and weapons.

- vegetable oil

- metalworking fluids

- lubricants

1. Introduction

Lubricants play a crucial role in various industrial processes, including metalworking and machining. However, the widespread use of petroleum-based lubricants has been linked to negative environmental impacts, including groundwater contamination and air pollution. Metalworking fluids (MWFs) are a type of lubricant that are widely used in machining operations, and the majority of these fluids are mineral oil-based. Despite their benefits in enhancing productivity and manufacturing quality, MWFs pose significant environmental and health hazards, therefore, researchers and tribologists are exploring alternatives to petroleum-based MWFs, including vegetable-based lubricants [1].

Vegetable-based lubricants are gaining attention as an ecofriendly alternative to petroleum-based lubricants due to their renewability, biodegradability, and lower toxicity [2]. Many researchers are exploring the use of various vegetable oils as potential candidates for metalworking fluids. For instance, Pereira et al., investigated the use of canola oil-based cutting fluids with the addition of alumina nanoparticles for machining stainless steel samples. Their study found that the addition of nanoparticles improved the lubricity of the canola oil-based fluid, resulting in reduced tool wear and improved surface finish [3].

Another study from Marichelvam et al., investigated the use of soybean oil-based cutting fluid with an environmentally friendly additive for machining of aluminum alloys. The study found that the soybean oil-based fluid with the additive provided better cooling and lubrication compared to conventional mineral oil-based fluids, resulting in improved surface finish and reduced tool wear [4].

Moreover, researchers have explored the use of waste vegetable oil as a potential feedstock for bio-based lubricants. Kurre and Yadav examined the potential of waste cooking oil as a feedstock for the production of bio-based lubricants, and they discovered that the waste cooking oil-based lubricant showed good lubrication properties and could be a potential candidate for industrial applications [5].

In addition to vegetable oils, researchers have also explored the use of bio-based esters as potential candidates for metalworking fluids. A study published in 2018 investigated the use of bio-based esters derived from renewable sources such as palm oil and rapeseed oil as metalworking fluids, founding out that the bio-based esters showed good lubrication properties and had the potential to replace petroleum-based MWFs [6].

The development of ecofriendly alternatives to petroleum and mineral-based lubricants is an area of active research. Vegetable-based lubricants, including those derived from waste vegetable oil and bio-based esters, have shown promise as potential candidates for metalworking fluids. Future research in this area could lead to the development of more sustainable and environmentally friendly lubricants for industrial applications.

One of the main openings in the available research about vegetable oils used for metalworking fluids is the lack of a comprehensive understanding of the underlying mechanisms of lubrication, which makes it difficult to predict and optimize the performance of vegetable oil-based lubricants. While there has been a significant amount of research done on the tribological properties of vegetable oils and their derivatives, there are still many unanswered questions about the specific mechanisms involved in the lubrication process. In addition, there is a need for more research on the long-term durability and stability of vegetable oil-based lubricants under a variety of operating conditions, including high temperatures and pressures. This will be critical in order to develop lubricants that can compete with petroleum-based products in terms of performance and durability. Finally, there is also a need for more research on the environmental impacts of vegetable oil-based lubricants, including their biodegradability and toxicity to aquatic organisms. Overall, there is still much work to be done in order to fully realize the potential of vegetable oils as a sustainable and environmentally-friendly alternative to petroleum-based lubricants.

2. Vegetable Oils as Lubricants

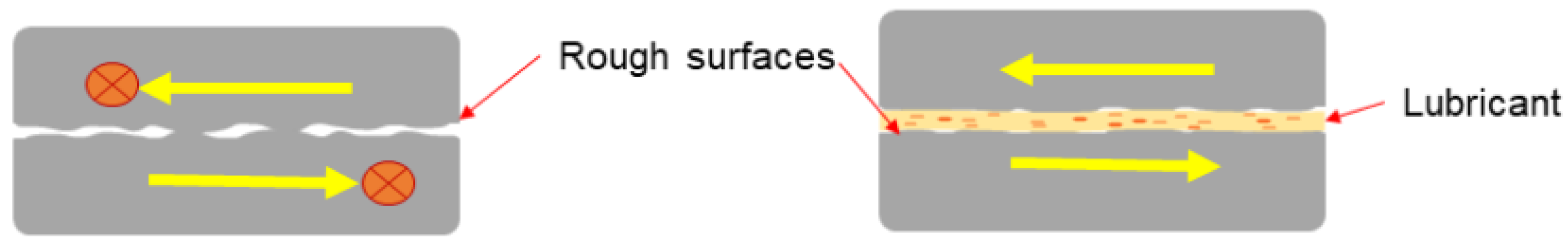

A lubricant is a substance that is used to reduce friction and wear between two sliding surfaces, playing an essential role in maintaining the health and longevity of machines and equipments [7]. It forms a thin layer of protection between the two surfaces, reducing friction and wear (Figure 1), protecting against corrosion and rust, and helping to dissipate heat. Lubricants are used in a wide variety of applications, including automotive engines, hydraulic systems, industrial machinery, and marine equipment [8].

Figure 1. Schematic diagram representing the role of lubricants in reducing friction and wear. The image on the left demonstrates two rough surfaces with high friction, creating sliding resistance. The image on the right demonstrates how adding lubricant creates a thin film that produces more accessible sliding conditions [7].

There are several different types of lubricants, each one with unique properties and applications. The most common types of lubricants include mineral oil, synthetic oil, and grease. Mineral oil is a petroleum-based lubricant that is commonly used in engines, hydraulic systems, and gearboxes. It is relatively inexpensive and widely available. However, it can break down over time and can be susceptible to oxidation [9]. Synthetic oil is made from chemical compounds and is designed to be more stable and longer-lasting than mineral oil. It can perform well in extreme temperatures and high-pressure applications [10]. Synthetic oil is commonly used in industrial equipment, turbines, and aircraft engines. Grease is a semi-solid lubricant that is composed of a base oil and a thickening agent. It is used in areas where a liquid lubricant may not be practical, such as in bearings or open gears. Grease is often used in automotive and marine applications [11]. Other types of lubricants include biodegradable lubricants, which are designed to be environmentally friendly, and food-grade lubricants, which are used in the food industry.

Lubricants have several properties that must be considered when selecting the right lubricant for a particular application, that include viscosity, pour point, flash point, and oxidation stability [12]. Viscosity is the measure of a lubricant’s resistance to flow. A high viscosity lubricant will be thicker and provide more protection against wear and tear. However, it may also cause more friction and generate more heat. A low viscosity lubricant will flow more easily and generate less heat, but it may not provide as much protection against wear [13]. Pour point is the temperature at which a lubricant will begin to solidify. A high pour point lubricant may not be suitable for colder temperatures, as it may become too thick and fail to provide adequate lubrication [14]. Flash point is the temperature at which a lubricant will ignite when exposed to a flame. This property is important for safety considerations and can help prevent accidents [15]. Oxidation stability is the lubricant’s ability to resist chemical reactions with oxygen over time. A lubricant with good oxidation stability will last longer and protect against wear and tear better [16].

A wide variety of lubricants are available, each with its own unique properties and applications. Selecting the right lubricant for a particular application is essential to ensure the longevity and efficiency of an equipment. Several factors should be considered when selecting a lubricant, including the type of equipment being used, the operating conditions, the load and speed of the equipment, and the type of surface materials in contact. Regular maintenance, including inspection and cleaning of the lubricant system, is also essential for optimal performance [17]. Lubricants can also have a significant impact on the environment, and it is essential to consider their environmental impact when selecting a lubricant. Biodegradable lubricants, which are designed to break down in the environment, are available and should be used in areas where environmental impact is a concern. In addition, proper disposal of used lubricants is essential to prevent environmental damage [11].

References

- Luna, F.M.T.; Cavalcante, J.B.; Silva, F.O.N.; Cavalcante, C.L. Studies on Biodegradability of Bio-Based Lubricants. Tribol. Int. 2015, 92, 301–306.

- Fox, N.J.; Stachowiak, G.W. Vegetable Oil-Based Lubricants—A Review of Oxidation. Tribol. Int. 2007, 40, 1035–1046.

- Pereira, O.; Martín-Alfonso, J.E.; Rodríguez, A.; Calleja, A.; Fernández Valdivielso, A.; Lacalle, L. Sustainability Analysis of Lubricant Oils for Minimum Quantity Lubrication Based on Their Tribo-Rheological Performance. J. Clean. Prod. 2017, 164, 1419–1429.

- Marichelvam, M.K.; Manimaran, P.; Khan, A.; Geetha, M. Development of Eco-Friendly Cutting Fluid for Machining of AISI 1010 Steel in Automotive Industry. Sustainability 2022, 14, 9414.

- Kurre, S.K.; Yadav, J. A Review on Bio-Based Feedstock, Synthesis, and Chemical Modification to Enhance Tribological Properties of Biolubricants. Ind. Crops Prod. 2023, 193, 116122.

- Talib, N.; Rahim, E.A. Experimental Evaluation of Physicochemical Properties and Tapping Torque of Hexagonal Boron Nitride in Modified Jatropha Oils-Based as Sustainable Metalworking Fluids. J. Clean. Prod. 2018, 171, 743–755.

- Marlinda, A.R.; Thien GS, H.; Shalid, M.; Ling, T.Y.; Hashem, A.; Chan, K.Y.; Johan, M.R. Graphene as a Lubricant Additive for Reducing Friction and Wear in Its Liquid-Based Form. Lubricants 2023, 11, 29.

- Khanna, N.; Shah, P.; Sarikaya, M.; Pusavec, F. Energy Consumption and Ecological Analysis of Sustainable and Conventional Cutting Fluid Strategies in Machining 15–5 PHSS. Sustain. Mater. Technol. 2022, 32, e00416.

- Bhushan, B. Solid Lubricants and Self-Lubricating Films. In Modern Tribology Handbook; CRC Press: Boca Raton, FL, USA, 2000; p. 1760. ISBN 9780429126727.

- Jarfors, A.E.W.; Castagne, S.J.; Danno, A.; Zhang, X. Tool Wear and Life Span Variations in Cold Forming Operations and Their Implications in Microforming. Technologies 2016, 5, 3.

- Fan, M.; Yang, D.; Wang, X.; Liu, W.; Fu, H. DOSS—Based QAILs: As Both Neat Lubricants and Lubricant Additives with Excellent Tribological Properties and Good Detergency. Ind. Eng. Chem. Res. 2014, 53, 17952–17960.

- Salimon, J. Improvement of Pour Point and Oxidative Stability of Synthetic Ester Basestocks for Biolubricant Applications. Arab. J. Chem. 2017, 5, 193–200.

- Wang, C.-C.; Hafner, A.; Kuo, C.-S.; Hsieh, W.-D. An Overview of the Effect of Lubricant on the Heat Transfer Performance on Conventional Refrigerants and Natural Refrigerant R-744. Renew. Sustain. Energy Rev. 2012, 16, 5071–5086.

- Wang, J.-L. Pour Point. In Encyclopedia of Tribology; Wang, Q.J., Chung, Y.-W., Eds.; Springer: Boston, MA, USA, 2013; pp. 2673–2678. ISBN 978-0-387-92897-5.

- Mitusova, T.N.; Nikolaeva, V.G.; Veretennikova, T.N. Influence of Flash Point of Diesel Fuel on Its Potential Production Volume. Chem. Technol. Fuels Oils 1985, 21, 279–280.

- Murru, C. Oxidative Stability of Vegetal Oil-Based Lubricants. ACS Sustain. Chem. Eng. 2021, 9, 1459–1476.

- Johnson, M. Lubricant Selection: Function and Composition. Available online: https://www.stle.org/images/pdf/STLE_ORG/BOK/LS/Gears/LubricantSelection_FunctionandComposition_tltarticle_April08.pdf (accessed on 1 March 2023).

More