The oil and gas (O&G) sector is a critical energy infrastructure to a Nation’s welfare. As developed as the O&G industry may seem, its aging infrastructure gradually shows numerous challenges to keep up with the growing energy demand, increasing operation costs, and environmental concerns. A robust O&G infrastructure that is risk-free, reliable, and resilient towards expected or unexpected threats can offer an uninterrupted supply of O&G to downstream stakeholders, competitive prices to customers, and better environmental footprints. With the shift towards renewable energy, the notion of sustainable development should be firmly embedded in O&G infrastructure and operations to facilitate the smooth transition towards future renewable energy generation.

- energy

- oil

- gas

- infrastructure

- sustainability

- risk

1. Introduction

2. O&G Infrastructure and Challenges

2.1. Overview of O&G Infrastructure

O&G infrastructure is very expansive, and its operations are highly complex. Most O&G infrastructure can be generally separated into three main levels: upstream, midstream, and downstream [11][22]. The O&G upstream level focuses on exploration and production (E&P) operations. Exploration efforts include geographical surveys in search of potential oil and gas fields, while production (such as drilling and operating oil wells) is carried out to extract crude oil or raw natural gas to the surface [23][24]. The midstream level includes long-distance transportation and storage facilities from upstream suppliers to downstream distributors or customers [22]. The O&G transportation can be carried out with various means, such as pipelines, rail freight, trucks, oil tankers, or inland barges [25]. Storage facilities vary based on the product stored. Crude oil and refined oil are usually stored in above ground tanks or temporarily stored in tanker ships when land storage is at capacity [26]. Underground storage, such as depleted reservoirs, is more suitable for natural gas [27].2.2. Sustainability and Sustainable Development

In the late 1980s, the United Nations (U.N.) World Commission on Environment and Development was chaired by Gro Harlem Brundtland (former Norwegian Prime Minister), and was focusing on the importance of sustainable economic development without draining natural resources or harming the environment [28]. The concept of sustainability or sustainable development has become more prevalent in today’s practice [20], with the primary objective of ensuring the Earth is inhabitable for future generations. The term ‘sustainable development’ is often interchangeably used with the broader concept of ‘sustainability.’ Ruggerio (2021) has presented a comprehensive review of theoretical definitions and the differences between the two concepts [29]. In other instances, sustainability is often regarded as a long-term goal, while sustainable development refers to the many pathways to becoming sustainable [29][30]. Sustainability is commonly known to have three interconnected dimensions (pillars/elements/facets) encompassing social, economic, and environmental factors (goals/objectives) [31]. Sustainable development seems contradictory to the property of non-renewable energy, inherently due to its limited natural resources. There are still many debates about defining, quantifying, realizing, and measuring sustainable development or sustainability in energy applications or the O&G industry. However, these topics will not be elaborated on further. In the O&G industry, the answer is straightforward, whereas the implementation is not. The limited O&G natural resources must be sustained for as long as possible or at least until the next generation of renewable energy takes over. The goal of sustainability can be accomplished by incorporating various sustainable development practices into all aspects of O&G infrastructure and operations. However, this is not an easy task, as many challenges are present in the O&G industry.2.3. Multidimensional Challenges

The O&G industry faces significant challenges when it comes to balancing conflicting objectives in the pursuit of long-term sustainability. Meeting the increasing demand for oil and gas with limited natural resources is a primary challenge, alongside the need to increase production while reducing operating costs and adhering to environmental policies to minimize contamination and pollution. Despite increasing attention focused on the transition of O&G industries to sustainable development, the complexity of O&G infrastructure and operations make achieving sustainable development challenging. Numerous theories, concepts, and methods are proposed with this transition, but practical implementation has proven difficult and remains unresolved due to social and market mechanisms of sustainable development [32].

Considering only three dimensions: sustainability, O&G operations, and O&G infrastructure. For each dimension, there are multiple elements and sub-dimensions. As the long-term goal, the sustainability dimension has social, economic, and environmental pillars [31]. The day-to-day operations of the O&G industry depend on physical infrastructure, cyberinfrastructure (computing, internet-of-things), and humans (operators, policymakers) [33][34]. The O&G infrastructure has three major levels (upstream, midstream, and downstream) [22].

3. Risk, Reliability, and Resilience

3.1. Risk Analysis, Assessment, and Management Framework

The pipeline transportation system is essential to the O&G industry, allowing for the safe and efficient movement of crude oil, natural gas, and refined petroleum products over long distances. However, as with any infrastructure, the pipelines that make up this system are subject to wear and tear over time, leading to various risks and hazards. One of the major concerns in recent years has been the aging of these pipelines, which has highlighted corrosion as a significant threat. Corrosion can lead to leaks and bursts in the pipeline, which can cause harm to other stakeholders and the environment. Mitigating this risk requires careful consideration and an integrated risk framework considering the risks threatening the pipeline network. The framework generally starts with identifying the hazard (failure or threat), estimating and evaluating the impact, and mitigating the adverse effects by taking appropriate corrective measures [12][13]. Depending on the type and severity of threats or hazards, the decision-makers can take various risk control approaches to eliminate, reduce, mitigate, transfer, or resolve the risks [35]. However, it should be noted that there is always the possibility that a system may fail not due to risk propagation, but from poor decision-making outcomes. A risk framework in the O&G pipeline network identifies probable system failure causes, such as corrosion, cracks or leaks, digging, excavation, or operational errors [16][36]. In cases where a threat is identified, detected, or has occurred, appropriate corrective measures should be taken to control the risk and to ensure the pipeline is in working condition without any critical impact on downstream stakeholders [37]. For pipeline networks, the primary objective of risk management is to decrease the failures or limit their severity in case of occurrence [13]. Risk assessment is a subset of risk management and is preceded by analyzing the risk to measure its severity. In probabilistic terms, the risk level of a particular hazard can be quantified by taking the product of the risk likelihood and the risk impact. Methods for risk assessment in most O&G applications can be broadly categorized into three groups: qualitative methods (or index modeling), quantitative methods (or probabilistic methods), and hybrid methods. There are many types of possible risks in O&G applications: operational risks, human factor risks, environmental risks, technology risks, schedule risks, and others. In addition to a risk framework or matrix, other aspects of O&G infrastructure and operations need to be analyzed to gain a more profound knowledge of how risk can occur, its impact, and how it can be controlled, mitigated, or resolved. To ensure that the O&G industry always delivers its intended value to the downstream stakeholders, it is best that stakeholders from all levels can understand how O&G infrastructure and operation may fail to perform as required. However, this may not always be possible, given the complexity of the O&G infrastructure and operation. Thus, risk analysis, assessment, and management should be incorporated into sustainable development practices to identify, analyze, and prioritize risks and to ensure that the likelihood of unintended events occurring, and their impact is minimized, monitored, and controlled. This effort, in turn, will promote sustainability in the long run.3.2. Reliability Analysis

O&G pipeline reliability may be defined as delivering oil or gas products safely using a detailed medium in the required quality and quantity and within a definite time. If the operational reliability of the pipeline network is not monitored, there will always be a potential threat to users and to the environment. Operational reliability can be evaluated by determining the mean time between failures (MTBF) and identifying its cause in a system operation [38]. Reliability is one of the crucial attributes of any complex system. The concept of reliability can be defined as the ability of units or systems to perform a specific function within a specific time and circumstance [39].

According to reliability theory [40], the reliability of a system or component over time, R(t), can be expressed as the probability of the system, P(t), performing its intended function until time T. The reliability index, R, holds a maximum value of 1, meaning the system is 100% reliable. The reliability of a system changes over time R(t) and can be quantified based on its probability of failure (when the system fails before time T), denoted as P(T ≤ t), as shown in Equation (1).

R(t) = P(T > t) = 1 − P(T ≤ t)

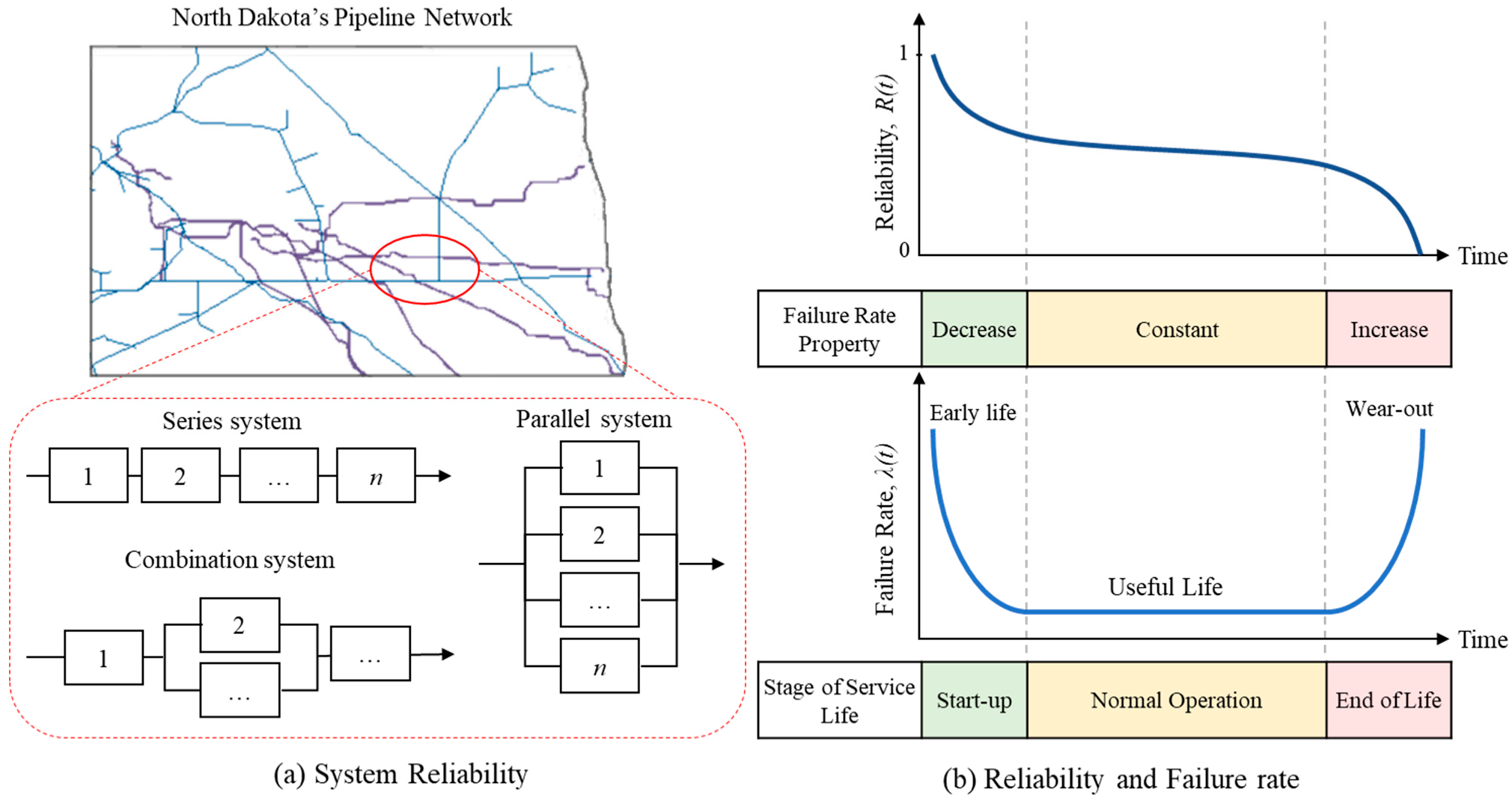

Many past studies have been conducted to assess the reliability of O&G infrastructure systems. Ahmad et al. [41] described the reliability analysis of a pipeline system as a three-step process: (i) division of a pipeline into segments and construction of its corresponding reliability block diagram (RBD)s, (ii) reliability assessment of the individual segments, and (iii) evaluation of the reliability of the overall pipeline system based on the RBD and the individual segment reliability. A single or one-direction supply pipeline can be modeled as a series RBD [42]. However, the pipeline systems can also be a combination of series and parallel RBDs with either reserved components or subsystems [43]. Figure 1 shows that part of the pipeline system can be deconstructed into either a series, a parallel, or a combination of series and parallel structures. It should be noted that the complexity of the analysis increases with the number of components considered as part of the system.

3.3. Resilience Assessment

4. O&G Sustainable Development and the 3Rs

4.1. Conceptual Relationship and the Holistic 3Rs

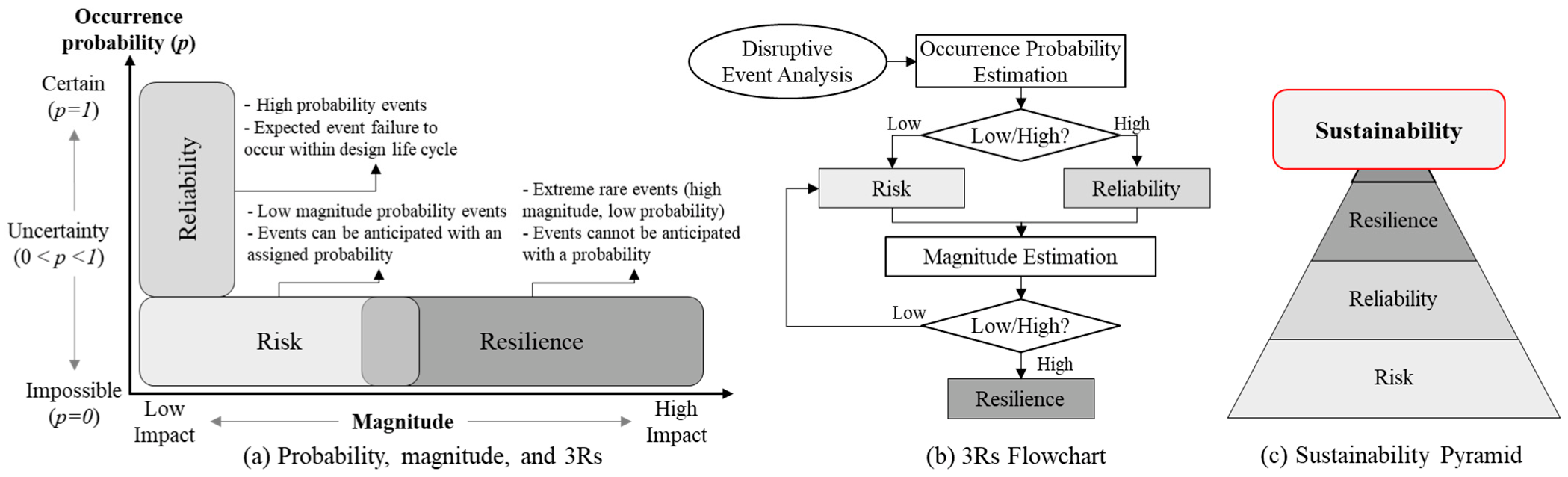

Based on the probability of occurrence (p) and the magnitude of impact. Risk is generally known as the probability of occurrence of an unexpected event or outcome [48]. In risk, the possible outcome events can be anticipated quantitatively with an assigned probability. However, the actual outcome is unknown until the event occurs. Thus, a risk control plan can be formulated beforehand to account for all the possible outcomes. Since there is a pre-mitigation plan in place, typically the negative magnitude of an outcome can be reduced to a low-magnitude probability event if the outcome occurs. Reliability concerns the probability of a failure event expected to occur within the design life cycle. Thus, the occurrence probability is higher compared to the risk. To increase reliability, maintenance or redundancy is often approached [14][49]. Resilience is more commonly associated with extreme, rare, and uncertain events where its occurrence and impact cannot be quantified with an assigned probability [50]. For resilience, failure is often expected and cannot be mitigated, although the occurrence probability of this outcome is often low (Figure 2).

4.2. Sustainable Development and the 3Rs

To reduce the complexity of the multi-faceted sustainable development, the fundamental matrix for sustainable development suggested a targeted 3Rs effort to the social, economic, and environmental pillars of sustainability. This fundamental matrix looks at the direct and immediate impacts of a particular activity or process on the environment, economy, and society. For example, social risk will emphasize reducing risks generated by the O&G sectors, such as human rights violations or poor labor conditions, health, and safety. Social reliability focuses on the ability of O&G to consistently provide a reliable energy supply to the community while minimizing the negative impacts on society. Social resilience aims to build a resilient community to withstand and recover from the negative social impact caused by the O&G operations or failures. These fundamental effects can often be measured and quantified, and they may include factors such as emissions, water usage, land use changes, operational costs, and other indices for measuring social welfare.

Since the social, economic, and environmental influences often cannot be entirely distinguished from one another, the fundamental matrix for sustainable development can be further expanded to include the coupling effect from the individual sustainability pillar. This will result in a coupling matrix between the sustainability pillars and the 3Rs, which consist of: (1) social-economic risk, socio-environmental risk, and eco-economic risk, within the risk framework, (2) social-economic reliability, socio-environmental reliability, and eco-economic reliability, within the reliability approach, and (3) social-economic resilience, socio-environmental resilience, and eco-economic resilience, within the resilience concept. The coupling matrix considers the indirect or long-term impacts of an activity or processes toward achieving sustainability. It should be noted as more coupling matrices are considered, the complexity of sustainable development increases.

5. Conclusions

Sustainable development in the O&G industry requires a balance between economic growth, energy security, and social and environmental concerns. It has proposed a novel approach to achieving sustainable development by introducing the holistic 3Rs concept and its influence on the industry. By integrating the 3Rs approach with the three pillars of sustainability, ithis paper has identified a fundamental and coupling matrix that can help reduce the complexity of sustainable development in practice. The contributions of this paperentry extend beyond the O&G industry and can be applied to other critical infrastructures to build a better future for future generations. This paperentry also suggests future research directions that require collaborative efforts from technology researchers, policymakers, and practitioners. The perspectives presented in this paper offer a fresh and valuable contribution to the field of sustainable development.

References

- Natural Gas Explained. About U.S. Natural Gas Pipelines 2022. Available online: https://www.eia.gov/energyexplained/natural-gas/natural-gas-pipelines.php (accessed on 15 January 2023).

- Dorian, J.P.; Franssen, H.T.; Simbeck, D.R. Global challenges in energy. Energy Policy 2006, 34, 1984–1991.

- Shafiee, S.; Topal, E. When will fossil fuel reserves be diminished? Energy Policy 2009, 37, 181–189.

- Sajid, M.J.; Yu, Z.; Rehman, S.A. The coal, petroleum, and gas embedded in the sectoral demand-and-supply Chain: Evidence from China. Sustainability 2022, 14, 1888.

- Sukumaran, K. Impact of Human Activities Inducing and Triggering of Natural Disasters. In A System Engineering Approach to Disaster Resilience; Springer: Berlin/Heidelberg, Germany, 2022; pp. 17–31.

- Allen, D.T. Emissions from oil and gas operations in the United States and their air quality implications. J. Air Waste Manag. Assoc. 2016, 66, 549–575.

- Ming, A.; Rowell, I.; Lewin, S.; Rouse, R.; Aubry, T.; Boland, E. Key Messages from the IPCC AR6 Climate Science Report; IPCC: Geneva, Switzerland, 2021.

- Pörtner, H.-O.; Roberts, D.C.; Poloczanska, E.; Mintenbeck, K.; Tignor, M.; Alegría, A.; Craig, M.; Langsdorf, S.; Löschke, S.; Möller, V. Summary for Policymakers; IPCC: Geneva, Switzerland, 2022.

- Yodo, N.; Wang, P.; Rafi, M. Enabling resilience of complex engineered systems using control theory. IEEE Trans. Reliab. 2017, 67, 53–65.

- U.S. Energy Information Administration. Month Energy Review January 2023. Available online: https://www.eia.gov/totalenergy/data/monthly/pdf/mer.pdf (accessed on 15 January 2023).

- Mojarad, A.A.S.; Atashbari, V.; Tantau, A. Challenges for sustainable development strategies in oil and gas industries. In Proceedings of the International Conference on Business Excellence, Bucharest, Romania, 22–23 March 2018; pp. 626–638.

- Hariri-Ardebili, M.A. Risk, Reliability, Resilience (R3) and beyond in dam engineering: A state-of-the-art review. Int. J. Disaster Risk Reduct. 2018, 31, 806–831.

- Shahriar, A.; Sadiq, R.; Tesfamariam, S. Risk analysis for oil & gas pipelines: A sustainability assessment approach using fuzzy based bow-tie analysis. J. Loss Prev. Process Ind. 2012, 25, 505–523.

- Yodo, N.; Wang, P. Resilience modeling and quantification for engineered systems using Bayesian networks. J. Mech. Des. 2016, 138, 031404.

- Davila-Frias, A.; Yodo, N.; Le, T.; Yadav, O.P. A deep neural network and Bayesian method based framework for all-terminal network reliability estimation considering degradation. Reliab. Eng. Syst. Saf. 2023, 229, 108881.

- Afrin, T.; Yodo, N. Resilience assessment of repair strategies against localized attacks for infrastructure protection. In Proceedings of the 2019 Annual Reliability and Maintainability Symposium (RAMS), Orlando, FL, USA, 28–31 January 2019; pp. 1–7.

- Cimellaro, G.P.; Villa, O.; Bruneau, M. Resilience-based design of natural gas distribution networks. J. Infrastruct. Syst. 2015, 21, 05014005.

- Tan, X.; Fan, L.; Huang, Y.; Bao, Y. Detection, visualization, quantification, and warning of pipe corrosion using distributed fiber optic sensors. Autom. Constr. 2021, 132, 103953.

- Yodo, N.; Afrin, T.; Yadav, O.P.; Wu, D.; Huang, Y. Condition-based monitoring as a robust strategy towards sustainable and resilient multi-energy infrastructure systems. Sustain. Resilient Infrastruct. 2022, 8, 170–189.

- Afrin, T.; Yodo, N. A Hybrid Recovery Strategy toward Sustainable Infrastructure Systems. J. Infrastruct. Syst. 2022, 28, 04021054.

- Kondrasheva, N.K.; Eremeeva, A.M. Production of biodiesel fuel from vegetable raw materials. J. Min. Inst. 2023.

- Al-Janabi, Y.T. An overview of corrosion in oil and gas industry: Upstream, midstream, and downstream sectors. In Corrosion Inhibitors in the Oil and Gas Industry; Wiley: Hoboken, NJ, USA, 2020; pp. 1–39.

- Hanga, K.M.; Kovalchuk, Y. Machine learning and multi-agent systems in oil and gas industry applications: A survey. Comput. Sci. Rev. 2019, 34, 100191.

- Davies, R.J.; Almond, S.; Ward, R.S.; Jackson, R.B.; Adams, C.; Worrall, F.; Herringshaw, L.G.; Gluyas, J.G.; Whitehead, M.A. Oil and gas wells and their integrity: Implications for shale and unconventional resource exploitation. Mar. Pet. Geol. 2014, 56, 239–254.

- Strogen, B.; Bell, K.; Breunig, H.; Zilberman, D. Environmental, public health, and safety assessment of fuel pipelines and other freight transportation modes. Appl. Energy 2016, 171, 266–276.

- Coburn, T.C. Oil and Gas Infrastructure. In The Oxford Handbook of Energy Politics; Oxford Academic: Oxford, UK, 2020; p. 99.

- Bai, M.; Song, K.; Sun, Y.; He, M.; Li, Y.; Sun, J. An overview of hydrogen underground storage technology and prospects in China. J. Pet. Sci. Eng. 2014, 124, 132–136.

- Borowy, I. Defining Sustainable Development for Our Common Future: A History of the World Commission on Environment and Development (Brundtland Commission); Routledge: Oxfordshire, UK, 2013.

- Ruggerio, C.A. Sustainability and sustainable development: A review of principles and definitions. Sci. Total Environ. 2021, 786, 147481.

- World Commission on Environment and Development. Our Common Future; United Nations: New York, NY, USA, 1987; Volume 10, pp. 1–300.

- Purvis, B.; Mao, Y.; Robinson, D. Three pillars of sustainability: In search of conceptual origins. Sustain. Sci. 2019, 14, 681–695.

- Litvinenko, V.; Tsvetkov, P.; Molodtsov, K. The social and market mechanism of sustainable development of public companies in the mineral resource sector. Eurasian Min. 2020, 2020, 36–41.

- Fataliyev, T.K.; Mehdiyev, S.A. Analysis and new approaches to the solution of problems of operation of oil and gas complex as cyber-physical system. Int. J. Inf. Technol. Comput. Sci. 2018, 10, 67–76.

- Zingirian, N. Cyber-Physical Application for the Safety and Security Enforcement in Oil and Gas Transportation. In Proceedings of the IFIP International Internet of Things Conference, Virtual, 4–5 November 2021; Springer: Berlin/Heidelberg, Germany, 2021.

- Yodo, N.; Goethals, P.L. Cybersecurity Management via Control Strategies for Resilient Cyber-Physical Systems. In Proceedings of the IIE Annual Conference, Orlando, FL, USA, 18–21 May 2019; Institute of Industrial and Systems Engineers: Peachtree Corners, GA, USA, 2019; pp. 1584–1589.

- Han, Z.Y.; Weng, W.G. Comparison study on qualitative and quantitative risk assessment methods for urban natural gas pipeline network. J. Hazard. Mater. 2011, 189, 509–518.

- Singh, R. Pipeline Integrity: Management and Risk Evaluation; Gulf Professional Publishing: Houston, TX, USA, 2017.

- Kwestarz, M. The Application of W. Kent Muhlbauer’s Model for The Risk Assessment of District Heating Networks. IOSR J. Mech. Civ. Eng. 2017, 14, 65–73.

- Zio, E. Reliability engineering: Old problems and new challenges. Reliab. Eng. Syst. Saf. 2009, 94, 125–141.

- Bilintion, R.; Allan, R. Reliability Evaluation of Engineering System; Springer: Berlin/Heidelberg, Germany, 1992; Volume 10.

- Ahmad, W.; Hasan, O.; Tahar, S.; Hamdi, M.S. Towards the formal reliability analysis of oil and gas pipelines. In Proceedings of the International Conference on Intelligent Computer Mathematics, Coimbra, Portugal, 7–11 July 2014; pp. 30–44.

- Zhang, Z.; Shao, B. Reliability evaluation of different pipe section in different period. In Proceedings of the 2008 IEEE International Conference on Service Operations and Logistics, and Informatics, Beijing, China, 12–15 October 2008; pp. 1779–1782.

- Soszynska, J. Reliability and risk evaluation of a port oil pipeline transportation system in variable operation conditions. Int. J. Press. Vessel. Pip. 2010, 87, 81–87.

- Petit, F.; Bassett, G.; Black, R.; Buehring, W.; Collins, M.; Dickinson, D.; Fisher, R.; Haffenden, R.; Huttenga, A.; Klett, M. Resilience Measurement Index: An Indicator of Critical Infrastructure Resilience; Argonne National Lab: Argonne, IL, USA, 2013.

- Yodo, N.; Arfin, T. A resilience assessment of an interdependent multi-energy system with microgrids. Sustain. Resilient Infrastruct. 2021, 6, 42–55.

- Benevolenza, M.A.; DeRigne, L. The impact of climate change and natural disasters on vulnerable populations: A systematic review of literature. J. Hum. Behav. Soc. Environ. 2019, 29, 266–281.

- Watson, J.-P.; Guttromson, R.; Silva-Monroy, C.; Jeffers, R.; Jones, K.; Ellison, J.; Rath, C.; Gearhart, J.; Jones, D.; Corbet, T. Conceptual Framework for Developing Resilience Metrics for the Electricity Oil and Gas Sectors in the United States; Technical Report; Sandia National Laboratories: Albuquerque, NM, USA, 2014.

- Aven, T.; Renn, O.; Rosa, E.A. On the ontological status of the concept of risk. Saf. Sci. 2011, 49, 1074–1079.

- O’Connor, P.; Kleyner, A. Practical Reliability Engineering; John Wiley & Sons: Hoboken, NJ, USA, 2012.

- Sweetapple, C.; Astaraie-Imani, M.; Butler, D. Design and operation of urban wastewater systems considering reliability, risk and resilience. Water Res. 2018, 147, 1–12.

- Ayyub, B.M. Infrastructure resilience and sustainability: Definitions and relationships. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2020, 6, 02520001.