Nanolubricants are the name given to the dispersion of nanoparticles in a base oil, and has attracted researchers due to its potential application. In addition to being used in the tribology field, nanoparticles are also used for medical, space, and composites purposes. The addition of nanoparticles in base oils is promising because it enhances specific tribological characteristics including wear-resistance and friction, and the most important reason is that the majority of them are environmentally friendly.

- Nanolubricants

- Nanoparticles

- Tribological characteristics

- Friction

- Wear

1. Nanolubricants and Base Oils

1.1. Nanolubricants

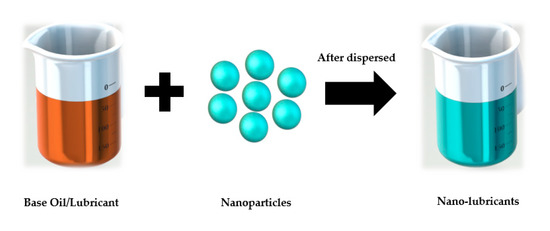

From here the use of nanoparticles/nanomaterials as lubricant additives are known as nanolubricants. Typically, their diameter particle size is between 1 and 100 nm. In laboratory tests, the use of nanolubricants in base oils or coatings promotes a significant reduction of friction and wear, which exhibits interesting tribological properties. Nanolubricants can be synthesized by the one-step method or two-step method. For the one-step method, the nanolubricants directly formulate through a chemical process. In the two-step method, the first procedure is the nanomaterials are synthesized in dry powder form by either physical or chemical methods, and the second procedure is to disperse them into base oil by mixing techniques with or without dispersants or surfactants [1]. An illustration of nanolubricants synthesis is shown in Figure 1.

1.2. Base Oils

Lubricants are classified into three physical appearances: solid, semisolid, and liquid form. Generally, lubricants are synthesized from three different types of base oils. They are mineral oil, synthetic oil, and biolubricant. The American Petroleum Institute (API) classified lubricant base oil quality and the necessary information of different groups of base oils under API 1509 [2]. Groups I–III base oils are refined from crude oil. Group IV base oils are fully synthetic oils made by polyalphaolefins (PAO). Group V base oils are those oils not found in groups I–IV categories. This group includes other base oils such as silicone, organophospahtes, polyalkyleneglycol (PAG), polyolester, and biolubricants.

Mineral oil is refined from crude oil by fraction distillation. The chemical composition of mineral oil is classified into paraffinic, naphthenic, and aromatic. Paraffinic contains primarily paraffin straight-chain hydrocarbon, naphthenic hydrocarbons are in the cyclic structures with no unsaturated bonds, and aromatic hydrocarbon also has a cyclic structure derived from benzene [3][4]. Mineral oil is the economic base oil and also serves as a common lubricant widely used in industry but harms both the environment and health. Typically, they are used in engines, gears, and bearings, etc.

Synthetic oil is artificially made from hydrocarbons or other chemicals. This lubricant can be manufactured by chemically modifying petroleum products instead of using whole crude oil. The formulation of synthetic oil provides superior properties over mineral oils, including the ability to lubricate in extremely low or high temperatures and offers better wear protection [4]. In addition, synthetic oils also provide several economic benefits including reducing energy consumption and maintenance costs, and improving energy efficiency, etc. Additionally, synthetic lubricants are designed to fulfil the high demands of modern machinery [5]. Conversely, a few synthetic oils may also cause harm to the environment [6].

Biolubricant is mainly made from vegetable oils such as sunflower, coconut, Jatropha, rapeseed, and palm while fusel oil is also acceptable for biolubricant production. Synthetic esters and petroleum products that fulfil biodegradability and toxicity criteria can also be used to manufacture biolubricants [7]. Biolubricant base stocks are the primary factor that decides the properties of biolubricants. The properties include physicochemical properties, renewability, and degradability. Among these properties, tribological properties are the most critical criterion. Moreover, biolubricants are an alternative source due to their widespread sources, and they are also renewable, biodegradable, and eco-friendly. Biolubricants offer several advantages over mineral oil, and it has high lubricity, high viscosity index, high flash point, low volatility, and high dispersion [8][9].

2. Various Types of Nanoparticles as Lubricant Additives

Based on the chemical composition, nanoparticles consist of metal, metal oxide, sulphide, nanocomposites, carbon nanoparticle, and rare earth compounds. According to Dai et al. [10], metal-containing nanoparticles are the subject of most of the studies carried out, and they occupy 72% of the reviews. In contrast, studies that focused on carbon nanoparticles, nanocomposites, and rare earth compounds accounted for just 7%, 6%, and 7%, respectively.

2.1. Metal

Form here the metallic NPs have a small particle size, high surface area, low melting point, and low shear strength. They provide excellent tribological performance and self-repairing function as lubricant additives [11], including Cu, Bi, Sn, Fe, Ni, Al, Pd, Co, Zn. The lubrication mechanism of metallic NPs can be categorized into (a) the surface properties will be changed and separate two friction surfaces with the formation of tribofilms, hence provide promising tribological performance; (b) NPs roll between two friction surface leading to the reduction of friction and wear; (c) heat and pressure generated during operation, leading to the compaction of NPs on the wear track, with this phenomenon considered as a repair or sintering effect [10].

Padgurskas et al.[12] investigated the tribological properties of Fe, Cu, and Co NPs and their mixture as lubricant additives on SAE 10 mineral oil. They reported that the use of nanoCu is the most effective NPs to reduce friction and wear both alone or as a mixture, and the mixture of NPs is more effective than pure NPs. Asadauskas et al.[13] conducted a comparative study of tribological properties of Cu, Fe, and Zn NPs between vegetable oil (rapeseed oil, soy oil, canola oil, and olive oil), mineral oil, and synthetic oil. They reported that without NPs, synthetic oil obtained the lowest wear, and with the addition of NPs, nanoFe evidenced better dispersion stability than nanoCu and nanoZn. NanoFe improved the wear resistance of rapeseed oil, while nanoZn reduced wear and smoothened scars in mineral oil.

The addition of nano-bismuth in light and heavy base oil resulted in wear reduction from 535 to 454 μm and 651 to 563μm, friction reduction from 0.091 to 0.052 and 0.074 to 0.047 [14]. The addition of nanoCu in paraffin oil resulted in a reduction of friction (23%) and wear (26%) [11]. An investigation of the tribological properties of nanoNi in PAO6 reported a reduction of 7–30% in wear and 5–45% in friction [15]. Furthermore, the addition of nanoAl increased load carrying capacity and improved friction and wear [16].

2.2. Metal Oxide

Various metal oxides have been used as lubricant additives, including TiO2, CuO, ZnO, Al2O3, Fe3O4, ZnAl2O4. The lubrication mechanism of metal oxide NPs is similar to the metallic NPs, including rolling effect, sintering and repair effect, and tribofilm formation.

Alves et al. [17] studied the tribological behavior of ZnO and CuO in vegetable oil (sunflower and soybean), synthetic oil, and mineral oil. They found that the addition of CuO in synthetic oil improves tribological properties, ZnO mineral-based lubricants exhibit excellent friction and wear reduction, while the addition of NPs in vegetable oil were not beneficial for wear reduction. The addition of TiO2 in water-based lubricant exhibits excellent tribological performance [18][19], while in engine oil SAE 20W 40, wear showed significant reduction and friction reduced by 50% [20]. Luo et al. [21] investigated the tribological properties of Al2O3 in pure lubricating oil with two types of tribometer. They reported that through the four-ball tribometer, the average coefficient of friction (COF) reduction is 17.61% and 41.75% reduction for wear scar diameter (WSD). Friction is reduced by 23.92% by using a thurst-ring tribometer. This is because of the formation of a protective film on the contact surface and rolling effect. One should note, however, that the addition of Al2O3 had a detrimental impact on PAO and SAE75W-85 [22].

2.3. Metal Sulphides

2.3. Metal Sulphides

Metal sulphides have been widely used for decades, as solid or liquid lubricant additives, including MoS2, WS2, FeS, CuS. It has been confirmed that nanoMoS2 in liquid lubricants is better than microMoS2 due to the smaller particles size for friction reduction [23]. MoS2 as a lubricant additive in dioctyl sebacate results in more friction and wear reduction than microMoS2 because of the extra formation of a solid and complex absorption film on the contact surface [24]. Fullerene-like NPs (IF) are the layered compounds with a hollow polyhedral structure. The addition of IF-MoS2 and IF-WS2 in PAO could significantly improve tribological properties [25]. Gulzar et al. [26] studied the tribological properties of chemical modified palm oil with the addition of MoS2 and CuO, wherein nanoMoS2 showed better tribological properties than nanoCuO. An interesting study discussed the anti-friction ability of nanoFeS with 20–200nm particle size as engine oil lubricant additive [27]. COF significantly decreases with the addition of nanoFeS and shows persistent anti-friction behavior under dry sliding.

2.4. Carbon-Based Nanoparticles

From here use of carbon-based NPs as lubricant additives is still an innovation. These include diamond, graphene, and graphite. Peng et al. reported that diamond NPs in paraffin oil exhibit excellent tribological properties due to the formation of a protective film, which separates the friction surface [

From here use of carbon-based NPs as lubricant additives is still an innovation. These include diamond, graphene, and graphite. Peng et al. reported that diamond NPs in paraffin oil exhibit excellent tribological properties due to the formation of a protective film, which separates the friction surface [

]. It should be noted that changes of adhesion to abrasion wear mechanism improve the tribological behavior of PAO with an optimum concentration of 0.2 wt% diamond NPs [

29].

].

The lubrication mechanism of graphite NPs can be the mending effect, the formation of tribofilm, and rolling effect. Gupta et al. [30] reported the highest tribological performance of improvement up to 80% by graphite with dispersant. The enhancement of AW properties is related to the combination of formation of tribofilm and mending effect, and the tribofilm formation mechanism contributes to EP enhancement. Sivakumar et al. [31] reported graphite oxide as the lubricant additives which are synthesized by the waste carbon sources, that reduce friction wear and surface roughness by up to 21.1%, 18.5%, and 42.3%, respectively.

Graphene is highlighted out of all the NPs due to its unique properties, including excellent mechanical, physical, and electrical properties. Further, graphene has been used in various applications, and is frequently named a “supermaterial” or “all-in-one material” in the world of material science [32]. The improvement of friction and wear is up to 80% and 33% with the addition of graphene in engine oil and the enhancement is related to the ball-bearing effect and ultimate strength properties of graphene [33]. A comparative study between modified natural flake graphite and modified graphene platelets in SN350 base oil has been conducted by Lin et al. The results showed that modified graphene platelets have better tribological properties [34]. Graphene by exfoliation should also be mentioned [35][36]. The ocradecylamine reduced graphene oxide nanolubricants in boundary regime and hydrodynamics regime has been evaluated by Vats et al. The results showed that the COF reduced by 61.8% and 75% in those regimes and WSD significantly decreased by 92.5% in the boundary regime [37]. Besides, the viscosity of these nanolubricants improved by 60% through flow analysis.

2.5. Nanocomposites

2.5. Nanocomposites

These are multicomponent materials, including WC-Al2O3/graphene platelets, Cu/graphene oxide, TiO2/SiO2, Ag/graphene, graphite oxide/Cu, and Al2O3/TiO2, etc. Due to the synergistic effect of the combination of NPs, nanocomposites usually provide better performance than single NPs. One should note that the nanocomposites which include graphene exhibit excellent tribological performance [38][39][40][41]. The tribological properties of WC-Al2O3/graphene platelets has been investigated. The test under 40 and 60N load show that the COF incorporated with graphene is 40.4% and 33.3% lower than test carried out without graphene. Further, the addition of graphene changes from significant abrasive wear to minor abrasive wear [42].It is of interest to study tribological properties of TiO2/SiO2 NPs in palm TMP ester, even without the use of surfactant, because the dispersion stability is stable and also effective in friction and wear reduction. At the same time, the surface is enhanced by the mending and polishing effect [43].Composites of Cu-MoS2 and Ag-MoS2 reduce the COF and essentially improve wear resistance [44]. Copper/carbon nanotube nanocomposite results in a reduction of friction and wears by up to 23.7% and 33.5%, respectively [45]. Both studies report that the improvement of lubrication is related to the synergistic effect of nanocomposites.

2.6. Rare Earth Compounds

Rare earth compounds can be used as lubricating additives or doped to other NPs. Typically, the lubrication mechanism of rare earth compounds is the formation of a tribofilm or absorption film. La-doped Mg/Al layered double hydroxide NPs modified by sodium dodecyl sulfate show better friction properties than those without modification in diesel engine oil CD 15W–40. The lubrication mechanism has been concluded as the formation of tribofilm on the friction surface leading to friction reduction [46]. Cerium oxide provides excellent tribological properties even in titanium complex grease or lithium grease [47][48]. Furthermore, the tribological properties of rare earth compounds such as LaF3 and CeVO4 have also been investigated [49][50].

3. Parameters of Nanoparticles Affect The Tribological Properties

3.1. Concentration of Nanoparticles

Concentration is one of the most critical factors that affect the tribology characteristics of nanolubricants. In most cases, the addition of NPs in the lubricant is useful in reducing friction and wear. There is also no ideal concentration, even with the addition of below 1 wt% concentration NPs [51] or above 2 wt% concentration NPs [19], but adding more NPs in the lubricant does not mean any concomitant increased reduction in friction and wear. Still, there is an optimum concentration for maximum reduction of friction and wear. Rajubhai et al. [52] investigated tribological characteristics of copper NPs in Pongamia oil with different concentrations of 0.025, 0.05, 0.075, and 0.1 wt% with the results revealing that 0.075 wt.% is the optimum concentration with minimum evidence of friction and wear. Shaari et al. [24] reported that an addition of 0.1 wt.% TiO2 in palm oil exhibits the lowest friction and wear. Stephen et al. [53] investigated the tribological effect of graphene in palm oil with the addition of 25, 50, and 100ppm and reported that 50ppm is the optimum concentration. Zhang et al. [54] added Sn and Fe in macs base oil with concentrations of 0.1, 0.5, and 1.0 wt%, with the results showing that optimum concentration of both nanoparticles is 1.0 wt%, although Sn was more effective in friction reduction and Fe more effective in wear reduction. The addition of MoS2 in coconut oil and paraffin oil was investigated by Koshy et al. [55]. The optimum concentration of MoS2 obtained from these base oils is slightly different. The optimum concentration of coconut oil is 0.53 wt%. In comparison, paraffin oil is 0.58 wt%. This investigation can show that the optimum concentration of nanoparticle is related to the base oil too. Furthermore, Alves et al. [17] added an optimum concentration of 0.5 wt% nanoCuO and nanoZnO to investigate tribological properties in mineral oil, PAO, sunflower oil, and soybean oil, but this research contains a contradiction on their experiment results. Azman et al. [25] added an optimum concentration of 0.34 wt% nanoCuO in palm kernel oil. The results show that friction and wear is reduced by 56% and 48%, respectively.

3.2. Size of Nanoparticles

NP size is an important parameter that directly affects the tribological performance of nanolubricants. The smaller the particle size, the easier it is to penetrate the rubbing surface. The reaction is dependent on the surface-to-volume ratio and the particle size determines the hardness of NPs, which conversely affects the tribological properties [56]. For nanomaterials with a size range of 100nm or higher, a decrease in particle size corresponds with an increase in the hardness. This is due to the Hall–Petch regime. In contrast, for particle sizes usually below 10nm, a decrease in particle size This explanation is called the inverse Hall–Petch regime. If the hardness of NPs is higher than the hardness of tribo-pair materials, this will result in indentation and scratches [57]. Peña-Parás et al. [22] reported that 8-9 Mohs hardness of nanoAl2O3 higher than the metal substrate causes the NPs in base oil re-agglomeration and abrasion. Thus, the size and hardness of NPs should be considered in the preparation of nanolubricants.

Furthermore, the ratio of root mean square (RMS) roughness of the lubricated material surface to the NPs radius is essential in selecting suitable NPs size. Nanolubricants must keep providing the lubrication on the contact zone during operation to protect the material surface. For this reason, if the NP size is larger than the gap between asperities, the NPs could not fill in the contact zone, potentially leading to inadequate lubrication.

To obtain stable nanolubricants, the NPs must homogeneously disperse in the base oil. Therefore, the dispersion stability is a function of NP size, which is considered a crucial factor in the preparation of nanolubricants. The dispersion stability can be determined by the sedimentation rate and calculated by using Stokes’ law:

Vz=(2(ρNP- ρF )gr^2)/9μ

where, Vz is settling velocity, ρNP is the mass density of NPs, ρF is the mass density of fluid, g is gravity, r is the radius of NPs, and μ is dynamic viscosity.

Based on the Stokes’ law, smaller particle size indicates better dispersion stability and results in achieving stable nanolubricants. Chen et al. [58] evaluated the tribological properties of Ni-based nanolubricants with 7.5, 13.5, and 27.5 nm of diameter. They reported that Ni-based nanolubricants with 7.5nm diameter exhibited effective anti-wear ability compared to another two. The investigation by Su et al. [59] demonstrated that graphite-based nanolubricants with smaller particle sizes are more effective in improving tribological performance at the same volume fraction.

3.3. Morphology of Nanoparticles

The shape of NPs is vital in the preparation of nanolubricants, because it is relevant to the pressure experienced by NPs through loading. NPs have five types of form: spherical, granular, onion, sheet, and tube. Most NPs are in the spherical shape, followed by granular, sheet, onion, and tube. After nucleation, to achieve equilibrium, the particle crystalline structures tend to change, and the surface energy will be minimized. NPs form in spherical shape if there is isotropic surface energy [10]. Normally, spherical shape NPs favor the rolling mechanism, it will act as ball-bearing roll between the friction surfaces. Mostly spherical shaped nanoAl2O3 act as ball bearing and lead to improving load capacity, friction, and wear reduction [21] and nearly spherical shaped nanoCu show improvement in tribological properties from SEM and EDS analysis [60]. In addition, the relationship between the shape of NPs contact to the lubricated surface are important too. Spherical shaped NPs result in point contact with surface(s) through loading. The line contact is related to nanosheets, yet nanoplatelets are planar contact [56].

Onion morphology has an external spherical shape and internal lamellar structure. Stability of the onion morphology corresponds to the tribological performance. If it is stable, it will be similar to the spherical morphology, or else it becomes sheet morphology by exfoliating. The advantage of onion-shaped NPs is a lack of dangling bonds [10]. The presence of dangling bonds generates high local energy, which could affect some physical properties of NPs. Therefore the reaction of NPs with the environment is easier or reduces the energy by agglomeration [61]. Since dangling bonds are absent in onion morphology, the reaction between particles and environment will be weakened, which results in less particles attaching to the substrate. The sheet-like NPs consist of graphene, ZrP, hBN, and transition metal dichalcogenides. Lubrication in this case is about the exfoliation between adjacent layers by sliding and leading to friction reduction.

Furthermore, in addition to NP morphology affecting tribological properties, the internal nanostructure is also a factor. The tribological properties of WS2 nanorod as nanoadditives in mineral oil has been investigated [62]. They also compared the tribological properties of WS2 nanorod with 2H-WS2 (mix layer). WS2 nanorod lubricant shows better tribological properties with the formation of a thin tribofilm on the substrate, followed by 2H-WS2 and base oil. Tribological performances had been improved by liquid-phase exfoliation graphene as an additive in SAE 10W-30 oil. Another study explained the layered structure of transition metal dichalcogenides in friction reduction with the formation of tribofilm [63]. Compared to the typical transition metal dichalcogenides, IFNPs consist of layered compounds with a hollow polyhedral structure. Hence, this results in excellent lubrication with three lubrication mechanisms: rolling, sliding, and exfoliation [64]. The significant improvement of tribological performance of the metallic substrates is with the addition of IF-MoS2 [65]. Rabaso et al. [66] reported the benefits of using IF-MoS2 including size and morphology, which does not affect the tribological performance, and is more effective than bulk h-MoS2. In investigating how to obtain further improvement in the tribological performance of IF-NPs, Yadgarov et al. [67] doped the IF-MoS2 with rhenium and reported that it obtained a better result than IF-MoS2.

3.4. Dispersion Stability of Nanoparticles

The high surface area to volume ratio in NPs leads to high surface energy. High surface area means the molecular attraction is strong and causes the particles to agglomerate. The aggregation of NPs results in sedimentation and also a loss of tribological improvement ability. Thus, the dispersion stability of NPs is strongly desirable for reliable lubrication performance. Stability is defined as the NPs not agglomerating at a significant rate. Several methods can enhance dispersion stability. The currently proposed methods are ultrasonic agitation, high-shear mixing, homogenizing, ball milling, and magnetic force agitation [68]. Various studies have mentioned the method that they used for dispersion including magnetic stirrer [14][69], ultrasonic probe agitation [33], homogenization by triple-roller mill [70] and planetary ball mill [50], ultrasonic bath agitation [24], ultrasonic shaker agitation [20][71], high shear homogenizer [72], and mix method [27][35][73]. According to the literature, the majority of researchers use ultrasonic agitation for NPs dispersion, even though some of them just mentioned ultrasonication for dispersion or failed to mention any method at all. Zhao et al. [35] reported that graphene disperses in base oil with similar dispersion stability leading to eliminating the factor that affects lubrication properties. Furthermore, dispersion duration is also an important parameter to reduce or control agglomerations. It has been concluded that with the increase of mixing time, the size of NPs aggregates decreases by using magnetic force agitation [74]. The dispersion duration was carried out by the researchers as short as 5 min [54], and as long as 8 h [23], while the majority dispersion duration is 30min or 1h.

In addition, it is not only the dispersion methods that can reduce the agglomeration of NPs. The surface functionalization has developed to enhance dispersion stability. These include electrostatic stabilization and steric stabilization. Electrostatic stabilization is when the ionic surfactants have been absorbed on the NPs surface, while steric stabilization is achieved by applying a polymer or surfactant coat on the NPs surface. The surface-functionalized NPs should have better lubrication compared to bare NPs. The former prevents material transfer that leads to avoiding direct contact and cold-welding between shearing surfaces. Additionally, a rigid internal core and soft external shell in the hybrid structure of functionalized NPs allows for high load carrying capacity and does not reduce the lubrication [57]. Hence, surface-functionalized NPs provide more benefit compared to bare NPs.

The surface functionalization technique and related studies will be discussed. Surface modification is one of the methods to enhance dispersion stability. The common modification agent such as oleic acid is widely used in various studies to enhance dispersion stability [16][34][75]. In addition, other modification agents have been studied. NanoCu has been surface modified using a mixture of resin, methylbenzene, and amine compound, and the prevention of agglomeration and good oil-dispersion ability has been confirmed [76]. NanoCu surface modification by methyl-methyl acrylate provides a benefit in reducing friction and wear [77]. The surface-modified nanoPd by tetrabutylammonium chains results in the extension of loading parts life and electrical conduction [78][79]. One should note that dual modified CuO by sodium oleate (SOA) and alkylphenol polyoxyethylene ether disperse in water, resulting in excellent dispersion stability and improvement in lubricity [80]. Another noted study showed that the surface-capped triangle Cu nanoplates prepared by cetytrimethylammonium bromide (CTAB) were effective in wear loss reduction (82%) and friction reduction (12%) by the formation of tribofilm at the interface of the parts [70].

Furthermore, the second method is to use a surfactant to enhance dispersion stability. Surfactants can also be considered as a dispersant, and using this method is easier and more economical than the surface modification method because the surfactant can be directly added in nanolubricants. Still, the cons of using surfactants have a limitation on thermal conductivity enhancement. Used surfactants include oleic acid [73][76][81], sodium-dodecyl [82], sorbitol monooleate (SPAN 80) [62][72][83], and polyisobutylene succinimide (PIBSI) [30]. Demas et al. [84] studied the dispersion stability of nanoBN and nanoMoS2 by using five types of surfactant. They proved that using a surfactant not only benefits in suspending the NPs, but also decreases friction and wear by itself. Four types of dispersant have been selected to explore the dispersion stability and influence of EP properties in API Group III 150N base oil with or without hBN particles [85]. All dispersants impart their dispersion stability and influenced tribological properties of oil. One should note that 1% dispersant did not influence EP properties of oil, and 5% dispersant shows more improvement of dispersion stability along with a 10% EP performance increase. The EP performance increased by up to 30% by adding the hBN particle.

3.4.1 Methods to Analyze Dispersion Stability of Nanolubricants

There are a number of ways to evaluate the dispersion stability of nanolubricants. These include the sedimentation method, zeta potential analysis, spectral absorbency analysis, and metallographic micrograph stability test [56]. In addition, the centrifugal method has also been mentioned [80].

The sedimentation method is the easiest method to determine the stability of nanolubricants because only the observation of the nanolubricants is involved, and it is usually conducted after nanoparticles disperse in the lubricant. During the stability analysis, a photograph of the test nanolubricants is taken. However, the drawback of this method is the long duration required. Furthermore, the environmental conditions and volume should be fixed for all test samples to obtain precision results, and any relocation or disturbance has to be avoided during this analysis. The duration of this analysis is usually in the range of days to months. The dispersion stability of CuO in palm kernel oil has been researched, revealing that it fully sediments at day 16 [25]. Wu et al. reported significantly less precipitated La(OH)3/RGO in diesel engine oil after 28 days [39]. A comparative study of graphite with or without dispersant in API Group III 150N base oil should be mentioned, with 1wt% PIBISI the stability of nanolubricant remained stable for up to 50 days. In comparison, without dispersant, stability only lasts 6-7 days [30]. In contrast, including 1wt% sorbitan monooleate as a dispersant in graphite-PAO4 lubricant, graphite fully sediments after 3 days [83]. Hence, the duration of this stability analysis is due to the different combination of lubricants and NPs, and the analysis is considered complete when the NPs fully sediment or the dispersion stability lasted for a long time.

Spectral absorbency analysis is the most efficient method to evaluate the dispersion stability of nanolubricants. Ultraviolet-visible (Uv-vis) absorption spectroscopy measurements are used in this method to characterize the stability of a variety of materials in lubricants quantitatively. This measurement is a reliable method to evaluate the dispersion stability of nanolubricants. It has the characteristic absorption bands in the wavelength range of 190-1100nm [68]. Xia et al. [86] reported the wavelength of absorbance of TiO2 nanolubricant in the range of 250-500nm and maximum absorbance at 378nm. In addition, the quantitative concentration of nanofluids will be provided through this measurement, due to the linear relation of supernatant nanoparticles concentration to the absorbency [68]. Thus, this is an advantage of using this method. Furthermore, for this analysis, different test durations have been reported by researchers. Xia et al. [86] carried out the spectral absorbency analysis over 72 h for oil in water enriched with , showing that stability is over 80%. Similarly, Gulzar et al. [26] conducted this analysis over 72 h for nanoCuO and nanoMoS2 lubricant. Song et al. [75] showed the absorbance spectrum of three different temperature modified nanoZnAl2O4 lubricants over 140 h. A comparative study revealed the optical absorbance spectral behavior of engine oil enriched with nanocomposite Al2O3/TiO2 in four different durations: 48, 168, 336, and 1000 h [48].

The zeta potential measurement also known as the surface charge analysis, is a technique used to determine the colloidal stability of nanoparticles. This method shows the zeta potential difference between the dispersion medium and the stern layer of fluid attached to the dispersed nanoparticle [68]. Typically, the range of zeta potential is from +100 to −100 mV, and it is related to the colloidal stability of nanolubricants. Thus, high zeta potential means electrically stabilized, while low zeta potential means dispersion instability due to the absence of a force to prevent the agglomeration of particles. In addition, if the zeta potential value is in the range of 0 to ±5mV, the particle will tend to flocculation or coagulation, and ±10 to ±30mV is considered as incipient instability. However, ±25 mV is the arbitrary value that decides the dispersion stability, in the range of ±40 to ±60 mV results in good stability, and greater than ±60 mV is excellent stability [87]. Luo et al. [21] reported that the modified Al2O3 nanolubricant has the average zeta potential value of 25.1 mV. The modified nanoCuO has a higher dispersion stability six times that of the unmodified nanoCuO in water [80].

54. Conclusions

Tribology is a science that has a close relationship with the development of physics. This field is already involved in the microscale and nanoscale, both of which influence lubrication, friction, wear, and sliding mechanisms. The tribological characteristics and lubrication mechanism of various types of nanoparticles as lubricant additives were reviewed here. The present review also covered the parameters of nanoparticles that affect the tribological properties, the dispersion method, techniques on enhancing dispersion stability, and nanolubricants characterization. Even though a lot of research studies have been done, the most crucial challenge is to prepare and maintain homogenous and good stability nanolubricants for a long duration. Thus, the stabilization of nanoparticles in various base oils must be investigated using multiple modification techniques.

The size, concentration, and morphology of nanoparticles are relevant to the improvement of tribological characteristics. However, the methods to determine the correlation between these factors are still lacking, but it is still promising. Besides, it is essential to discover the optimum concentration of nanoparticles in base oils. This would not only exhibit the maximum improvement but also save in terms of the cost of production. Thus, the authors recommend here the use of simulation software to optimize the concentration of nanoparticles in base oils which exhibit excellent tribological properties.

Based on the literature, there are two techniques for enhancing the dispersion stability of nanolubricants. Surface modification seems to provide more effective stabilization of nanolubricants, and it does not significantly affect the fuel properties of nanolubricants. In addition, ultrasonication is an auxiliary method in the previously mentioned techniques.

Overall, a majority of extant studies reported that nanoparticles enriched with lubricating oils improved tribological performance. The lubrication mechanism of nanoparticles cannot be fully yet understood since the mechanism is complex, and it contains various types of nanoparticles. However, for environmental protection purposes, the formulation of environmentally friendly nanolubricants is essential, which does not contain sulfur or phosphorus and will not affect the improvement of tribological properties.

References

- A.K. Rasheed; M. Khalid; W Rashmi; T.C.S.M. Gupta; A. Chan; Graphene based nanofluids and nanolubricants – Review of recent developments. Renewable and Sustainable Energy Reviews 2016, 63, 346-362, 10.1016/j.rser.2016.04.072.

- INSTITUTE, A. P. 2019. APPENDIX E -API BASE OIL INTERCHANGEABILITY GUIDELINES FOR PASSENGER CAR MOTOROILS AND DIESEL ENGINE OILS. In: INSTITUTE, A. P. (ed.).

- Speight, James G. Handbook of Industrial Hydrocarbon Processes. Chapter 3 Hydrocarbons from crude oil; Elsevier: Amsterdam, The Netherlands, 2020; pp. 95-142.

- Stachowiak, Gwidon W. ;Batchelor, Andrew W. Engineering Tribology (Third edition). Chapter 3 Lubricants and Their Composition; Elsevier: Amsterdam, The Netherlands, 2006; pp. 51-101.

- Wu, Margaret, M.; Ho, Suzzy C.; Forbus, T. Rig. Practical Advances in Petroleum Processing. Synthetic Lubricant Base Stock Processes and Products; Springer: New York, NY, USA, 2006; pp. 553-577.

- Paulina Nowak; Karolina Kucharska; Marian Kamiński; Ecological and Health Effects of Lubricant Oils Emitted into the Environment. International Journal of Environmental Research and Public Health 2019, 16, 1-9, 10.3390/ijerph16163002.

- H.M. Mobarak; E. Niza Mohamad; H.H. Masjuki; M.A. Kalam; K.A.H. Al Mahmud; M. Habibullah; A.M. Ashraful; The prospects of biolubricants as alternatives in automotive applications. Renewable and Sustainable Energy Reviews 2014, 33, 34-43, 10.1016/j.rser.2014.01.062.

- Jumat Salimon; Nadia Salih; Emad Yousif; Biolubricants: Raw materials, chemical modifications and environmental benefits. European Journal of Lipid Science and Technology 2010, 112, 519-530, 10.1002/ejlt.200900205.

- Carlton J. Reeves; Arpith Siddaiah; Pradeep L. Menezes; A Review on the Science and Technology of Natural and Synthetic Biolubricants. Journal of Bio- and Tribo-Corrosion 2017, 3, 11, 10.1007/s40735-016-0069-5.

- Wei Dai; Bassem Kheireddin; Hong Gao; Hong Liang; Roles of nanoparticles in oil lubrication. Tribology International 2016, 102, 88-98, 10.1016/j.triboint.2016.05.020.

- Guangbin Yang; Zhanming Zhang; Shengmao Zhang; Laigui Yu; Pingyu Zhang; Yanchao Hou; Preparation and characterization of copper nanoparticles surface-capped by alkanethiols. Surface and Interface Analysis 2013, 45, 1695-1701, 10.1002/sia.5309.

- J. Padgurskas; Raimundas Rukuiža; Igoris Prosyčevas; Raimondas Kreivaitis; Tribological properties of lubricant additives of Fe, Cu and Co nanoparticles. Tribology International 2013, 60, 224-232, 10.1016/j.triboint.2012.10.024.

- Svajus Asadauskas; Raimondas Kreivaitis; Gedvidas Bikulčius; Asta Grigucevičienė; J. Padgurskas; Tribological effects of Cu, Fe and Zn nano-particles, suspended in mineral and bio-based oils. Lubrication Science 2015, 28, 157-176, 10.1002/ls.1307.

- Mariela Florescastaneda; E. Camps; M. Camacho-López; S. Muhl; Emilio Agusto Alvarez Garcia; Maria Eugenia Prado Figueroa; Bismuth nanoparticles synthesized by laser ablation in lubricant oils for tribological tests. Journal of Alloys and Compounds 2015, 643, S67-S70, 10.1016/j.jallcom.2014.12.054.

- R. Chou; Antolín Esteban Hernández Battez; J.J. Cabello; J.L. Viesca; A. Osorio; A. Sagastume; Tribological behavior of polyalphaolefin with the addition of nickel nanoparticles. Tribology International 2010, 43, 2327-2332, 10.1016/j.triboint.2010.08.006.

- De‐Xing Peng; Yuan Kang; Shih‐Kang Chen; Fu‐Chun Shu; Yeon‐Pun Chang; Dispersion and tribological properties of liquid paraffin with added aluminum nanoparticles. Industrial Lubrication and Tribology 2010, 62, 341-348, 10.1108/00368791011076236.

- Salete Martins Alves; B.S. Barros; Marinalva Ferreira Trajano; Kandice Suane Barros Ribeiro; Edja Iandeyara Freitas Moura; Tribological behavior of vegetable oil-based lubricants with nanoparticles of oxides in boundary lubrication conditions. Tribology International 2013, 65, 28-36, 10.1016/j.triboint.2013.03.027.

- Hui Wu; Jingwei Zhao; Wenzhen Xia; Xiawei Cheng; Anshun He; Jung Ho Yun; Lianzhou Wang; Han Huang; Sihai Jiao; Li Huang; et al.Suoquan ZhangZhengyi Jiang A study of the tribological behaviour of TiO 2 nano-additive water-based lubricants. Tribology International 2017, 109, 398-408, 10.1016/j.triboint.2017.01.013.

- Hui Wu; Jingwei Zhao; Xiawei Cheng; Wenzhen Xia; Anshun He; Jung-Ho Yun; Shuiquan Huang; Lianzhou Wang; Han Huang; Sihai Jiao; et al.Zhengyi Jiang Friction and wear characteristics of TiO 2 nano-additive water-based lubricant on ferritic stainless steel. Tribology International 2018, 117, 24-38, 10.1016/j.triboint.2017.08.011.

- Meena Laad; Deepalekshmi Ponnamma; Kishor Kumar Sadasivun; Tribological Studies of Nanomodified Mineral based Multi-grade Engine Oil . International Journal of Applied Engineering Research 2017, 12, 2855-2861.

- Ting Luo; Xiaowei Wei; Xiong Huang; Ling Huang; Fan Yang; Tribological properties of Al2O3 nanoparticles as lubricating oil additives. Ceramics International 2014, 40, 7143-7149, 10.1016/j.ceramint.2013.12.050.

- Laura Peña-Parás; Jaime Taha-Tijerina; Lorena Garza; Demófilo Maldonado-Cortés; Remigiusz Michalczewski; Carolina Lapray; Effect of CuO and Al 2 O 3 nanoparticle additives on the tribological behavior of fully formulated oils. Wear 2015, 332-333, 1256-1261, 10.1016/j.wear.2015.02.038.

- N.W.M. Zulkifli; M.A. Kalam; H.H. Masjuki; Robiah Yunus; Experimental Analysis of Tribological Properties of Biolubricant with Nanoparticle Additive. Procedia Engineering 2013, 68, 152-157, 10.1016/j.proeng.2013.12.161.

- Mohd Zulfadhli Shaari; N. R. Nik Roselina; Salmiah Kasolang; Koay Mei Hyie; Mardziah Che Murad; Mimi Azlina Abu Bakar; INVESTIGATION OF TRIBOLOGICAL PROPERTIES OF PALM OIL BIOLUBRICANT MODIFIED NANOPARTICLES. Jurnal Teknologi 2015, 76, 69-73, 10.11113/jt.v76.5654.

- Nurul Farhanah Azman; Syahrullail Samion; Mohamad Nor Hakim Mat Sot; Investigation of tribological properties of CuO/palm oil nanolubricant using pin-on-disc tribotester. Green Materials 2018, 6, 30-37, 10.1680/jgrma.17.00026.

- M. Gulzar; H H Masjuki; M Varman; M A Kalam; Riaz Ahmad Mufti; Nwm Zulkifli; Robiah Yunus; Rehan Zahid; Improving the AW/EP ability of chemically modified palm oil by adding CuO and MoS2 nanoparticles. Tribology International 2015, 88, 271-279, 10.1016/j.triboint.2015.03.035.

- Lu Hai Zhou; Xi Cheng Wei; Zi Jian Ma; Bin Mei; Anti-friction performance of FeS nanoparticle synthesized by biological method. Applied Surface Science 2017, 407, 21-28, 10.1016/j.apsusc.2017.02.182.

- D.X. Peng; Yansheng Kang; R.M. Hwang; Shyhshyong Shyr; Y.P. Chang; Tribological properties of diamond and SiO2 nanoparticles added in paraffin. Tribology International 2009, 42, 911-917, 10.1016/j.triboint.2008.12.015.

- Ankush Raina; Ankush Anand; Lubrication performance of synthetic oil mixed with diamond nanoparticles: Effect of concentration. Materials Today: Proceedings 2018, 5, 20588-20594, 10.1016/j.matpr.2018.06.438.

- Manoj Kumar Gupta; Jayashree Bijwe; A complex interdependence of dispersant in nano-suspensions with varying amount of graphite particles on its stability and tribological performance. Tribology International 2020, 142, 105968, 10.1016/j.triboint.2019.105968.

- Bose Sivakumar; Nisha Ranjan; Ramaprabhu Sundara; M. Kamaraj; Tribological properties of graphite oxide derivative as nano-additive: Synthesized from the waster carbon source. Tribology International 2020, 142, 105990, 10.1016/j.triboint.2019.105990.

- Josphat Phiri; Patrick Gane; Thad C. Maloney; General overview of graphene: Production, properties and application in polymer composites. Materials Science and Engineering: B 2017, 215, 9-28, 10.1016/j.mseb.2016.10.004.

- Varrla Eswaraiah; Venkataraman Sankaranarayanan; Sundara Ramaprabhu; Graphene-Based Engine Oil Nanofluids for Tribological Applications. ACS Applied Materials & Interfaces 2011, 3, 4221-4227, 10.1021/am200851z.

- Jinshan Lin; Liwei Wang; Guohua Chen; Modification of Graphene Platelets and their Tribological Properties as a Lubricant Additive. Tribology Letters 2010, 41, 209-215, 10.1007/s11249-010-9702-5.

- Jun Zhao; Junyuan Mao; Yingru Li; Yongyong He; Jianbin Luo; Friction-induced nano-structural evolution of graphene as a lubrication additive. Applied Surface Science 2018, 434, 21-27, 10.1016/j.apsusc.2017.10.119.

- Xinbo Wang; Yafei Zhang; Zhongwei Yin; Yanjie Su; Yanping Zhang; Jun Cao; Experimental research on tribological properties of liquid phase exfoliated graphene as an additive in SAE 10W-30 lubricating oil. Tribology International 2019, 135, 29-37, 10.1016/j.triboint.2019.02.030.

- Bhavya Nidhi Vats; Monika Singh; Evaluation of tribological properties of graphene oxide dispersed paraffin oil. Materials Today: Proceedings 2020, 25, 557-562, 10.1016/j.matpr.2019.06.376.

- Yuan Meng; Fenghua Su; Yangzhi Chen; Synthesis of nano-Cu/graphene oxide composites by supercritical CO2-assisted deposition as a novel material for reducing friction and wear. Chemical Engineering Journal 2015, 281, 11-19, 10.1016/j.cej.2015.06.073.

- Bo Wu; Hui Song; Chuan Li; Ruhong Song; Tianming Zhang; Xianguo Hu; Enhanced tribological properties of diesel engine oil with Nano-Lanthanum hydroxide/reduced graphene oxide composites. Tribology International 2020, 141, 105951, 10.1016/j.triboint.2019.105951.

- Li Wang; Peiwei Gong; Wei Li; Ting Luo; Bingqiang Cao; Mono-dispersed Ag/Graphene nanocomposite as lubricant additive to reduce friction and wear. Tribology International 2020, 146, 106228, 10.1016/j.triboint.2020.106228.

- Chaoliang Gan; Ting Liang; Wen Li; Xiaoqiang Fan; Minhao Zhu; Amine-terminated ionic liquid modified graphene oxide/copper nanocomposite toward efficient lubrication. Applied Surface Science 2019, 491, 105-115, 10.1016/j.apsusc.2019.06.141.

- Xiaoxiao Zhang; Shigen Zhu; Tianyu Shi; Hao Ding; Yunfeng Bai; Ping Di; Yilan Luo; Preparation, mechanical and tribological properties of WC-Al2O3 composite doped with graphene platelets. Ceramics International 2020, 46, 10457-10468, 10.1016/j.ceramint.2020.01.045.

- M. Gulzar; H.H. Masjuki; M. A. Kalam; M. Varman; N. W. M. Zulkifli; R. A. Mufti; R. Zahid; R. Yunus; Dispersion Stability and Tribological Characteristics of TiO2/SiO2 Nanocomposite-Enriched Biobased Lubricant. Tribology Transactions 2016, 60, 670-680, 10.1080/10402004.2016.1202366.

- Vladimir V An; E. Anisimov; V. Druzyanova; N. Burtsev; Ivan A. Shulepov; M. Khaskelberg; Study of tribological behavior of Cu-MoS2 and Ag-MoS2 nanocomposite lubricants.. SpringerPlus 2016, 5, 72, 10.1186/s40064-016-1702-y.

- Zhiqiang Wang; Ruirui Ren; Haojie Song; Xiaohua Jia; Improved tribological properties of the synthesized copper/carbon nanotube nanocomposites for rapeseed oil-based additives. Applied Surface Science 2018, 428, 630-639, 10.1016/j.apsusc.2017.09.207.

- Shuo Li; Haojing Qin; Ranfang Zuo; Zhimin Bai; Friction properties of La-doped Mg/Al layered double hydroxide and intercalated product as lubricant additives. Tribology International 2015, 91, 60-66, 10.1016/j.triboint.2015.06.012.

- Qiang He; Anling Li; Yachen Guo; Songfeng Liu; Yong Zhang; Linghao Kong; Tribological properties of nanometer cerium oxide as additives in lithium grease. Journal of Rare Earths 2018, 36, 209-214, 10.1016/j.jre.2017.09.004.

- Tiejun Shen; Daxi Wang; Jimmy Yun; Qinglian Liu; Xinghua Liu; Zhongxiao Peng; Tribological properties and tribochemical analysis of nano-cerium oxide and sulfurized isobutene in titanium complex grease. Tribology International 2016, 93, 332-346, 10.1016/j.triboint.2015.09.028.

- Xiao Hou; Jie He; Laigui Yu; Zhiwei Li; Zhijun Zhang; Pingyu Zhang; Preparation and tribological properties of fluorosilane surface-modified lanthanum trifluoride nanoparticles as additive of fluoro silicone oil. Applied Surface Science 2014, 316, 515-523, 10.1016/j.apsusc.2014.07.171.

- Fengzhen Liu; Xin Shao; Yibin Yin; Limin Zhao; Zhuwei Shao; Xuehua Liu; Xianhua Meng; Shape controlled synthesis and tribological properties of CeVO4 nanoparticles aslubricating additive. Journal of Rare Earths 2011, 29, 688-691, 10.1016/s1002-0721(10)60523-6.

- K Thirumalai Kannan; S Rameshbabu; Tribological behavior of modified jojoba oil with graphene nanoparticle as additive in SAE20W40 oil using pin on disc tribometer. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 2017, 39, 1842-1848, 10.1080/15567036.2017.1376006.

- Virwal Harsh Rajubhai; Yashvir Singh; Ketan Suthar; Aadesh Rajendra Surana; Friction and wear behavior of Al-7% Si alloy pin under pongamia oil with copper nanoparticles as additives. Materials Today: Proceedings 2020, 25, 695-698, 10.1016/j.matpr.2019.08.149.

- Kiu Stephen Sie Kiong; Suzana Yusup; Chok Vui Soon; Taufiq Arpin; Syahrullail Samion; Ruzaimah Nik Mohamad Kamil; Tribological Investigation of Graphene as Lubricant Additive in Vegetable Oil. Journal of Physical Science 2017, 28, 257-267, 10.21315/jps2017.28.s1.17.

- Songwei Zhang; Litian Hu; Dapeng Feng; Haizhong Wang; Anti-wear and friction-reduction mechanism of Sn and Fe nanoparticles as additives of multialkylated cyclopentanes under vacuum condition. Vacuum 2013, 87, 75-80, 10.1016/j.vacuum.2012.07.009.

- Chacko Preno Koshy; Perikinalil Krishnan Rajendrakumar; Manu Varghese Thottackkad; Evaluation of the tribological and thermo-physical properties of coconut oil added with MoS 2 nanoparticles at elevated temperatures. Wear 2015, 330-331, 288-308, 10.1016/j.wear.2014.12.044.

- M. Gulzar; H.H. Masjuki; M. A. Kalam; M. Varman; N. W. M. Zulkifli; R. A. Mufti; Rehan Zahid; Tribological performance of nanoparticles as lubricating oil additives. Journal of Nanoparticle Research 2016, 18, 1-25, 10.1007/s11051-016-3537-4.

- Igor E. Uflyand; Vladimir A. Zhinzhilo; Victoria E. Burlakova; Metal-containing nanomaterials as lubricant additives: State-of-the-art and future development. Friction 2019, 7, 93-116, 10.1007/s40544-019-0261-y.

- Yanfen Chen; Yujuan Zhang; Shengmao Zhang; Laigui Yu; Pingyu Zhang; Zhijun Zhang; Preparation of Nickel-Based Nanolubricants via a Facile In Situ One-Step Route and Investigation of Their Tribological Properties. Tribology Letters 2013, 51, 73-83, 10.1007/s11249-013-0148-4.

- Yu Su; Le Gong; Dandan Chen; An Investigation on Tribological Properties and Lubrication Mechanism of Graphite Nanoparticles as Vegetable Based Oil Additive. Journal of Nanomaterials 2015, 2015, 1-7, 10.1155/2015/276753.

- J.L. Viesca; Antolín Esteban Hernández Battez; R. González; R. Chou; J.J. Cabello; Antiwear properties of carbon-coated copper nanoparticles used as an additive to a polyalphaolefin. Tribology International 2011, 44, 829-833, 10.1016/j.triboint.2011.02.006.

- Calestani, Davide. Characterization of the physical and chemical properties of engineered nanomaterials; Elsevier: Amsterdam, The Netherlands, 2019; pp. 31-57.

- L.L. Zhang; J.P. Tu; H.M. Wu; Y.Z. Yang; WS2 nanorods prepared by self-transformation process and their tribological properties as additive in base oil. Materials Science and Engineering: A 2007, 454, 487-491, 10.1016/j.msea.2006.11.072.

- Hugh Spikes; Friction Modifier Additives. Tribology Letters 2015, 60, 1-26, 10.1007/s11249-015-0589-z.

- Ofer Tevet; Palle Von-Huth; Ronit Popovitz-Biro; Rita Rosentsveig; H. Daniel Wagner; Reshef Tenne; Friction mechanism of individual multilayered nanoparticles. Proceedings of the National Academy of Sciences 2011, 108, 19901-19906, 10.1073/pnas.1106553108.

- Rital Rosentsveig; A. Gorodnev; N J Feuerstein; H. Friedman; Andrzej Zak; N. Fleischer; Johny Tannous; Fabrice Dassenoy; Reshef Tenne; Fullerene-like MoS2 Nanoparticles and Their Tribological Behavior. Tribology Letters 2009, 36, 175-182, 10.1007/s11249-009-9472-0.

- Pierre Rabaso; Fabrice Ville; Fabrice Dassenoy; Moussa Diaby; Pavel Afanasiev; Jérôme Cavoret; Béatrice Vacher; Thierry Le Mogne; Boundary lubrication: Influence of the size and structure of inorganic fullerene-like MoS2 nanoparticles on friction and wear reduction. Wear 2014, 320, 161-178, 10.1016/j.wear.2014.09.001.

- Lena Yadgarov; Vincenzo Petrone; Rita Rosentsveig; Yishai A Feldman; Reshef Tenne; A. Senatore; Tribological studies of rhenium doped fullerene-like MoS2 nanoparticles in boundary, mixed and elasto-hydrodynamic lubrication conditions. Wear 2013, 297, 1103-1110, 10.1016/j.wear.2012.11.084.

- Wei Yu; Huaqing Xie; A Review on Nanofluids: Preparation, Stability Mechanisms, and Applications. Journal of Nanomaterials 2011, 2012, 1-17, 10.1155/2012/435873.

- Sudeep P. Ingole; Archana Charanpahari; Amol B Kakade; S.S. Umare; D.V. Bhatt; Jyoti Menghani; Tribological behavior of nano TiO2 as an additive in base oil. Wear 2013, 301, 776-785, 10.1016/j.wear.2013.01.037.

- Jing Wang; Xiaochuan Guo; Yan He; Mingjun Jiang; Rong Sun; The synthesis and tribological characteristics of triangular copper nanoplates as a grease additive. RSC Advances 2017, 7, 40249-40254, 10.1039/c7ra07252j.

- Vijaykumar S. Jatti; T. P. Singh; Copper oxide nano-particles as friction-reduction and anti-wear additives in lubricating oil. Journal of Mechanical Science and Technology 2015, 29, 793-798, 10.1007/s12206-015-0141-y.

- Qingming Wan; Yi Jin; Pengcheng Sun; Yulong Ding; Rheological and tribological behaviour of lubricating oils containing platelet MoS2 nanoparticles. Journal of Nanoparticle Research 2014, 16, 2386, 10.1007/s11051-014-2386-2.

- Bao-Sen Zhang; Bin-Shi Xu; Yi Xu; Fei Gao; Pei-Jing Shi; Yi-Xiong Wu; CU nanoparticles effect on the tribological properties of hydrosilicate powders as lubricant additive for steel–steel contacts. Tribology International 2011, 44, 878-886, 10.1016/j.triboint.2011.03.002.

- A. Moshkovith; Vladislav Perfiliev; A. Verdyan; I. Lapsker; Ronit Popovitzbiro; Reshef Tenne; L. Rapoport; Sedimentation of IF-WS2 aggregates and a reproducibility of the tribological data. Tribology International 2007, 40, 117-124, 10.1016/j.triboint.2006.02.067.

- Xiaoyun Song; Shaohua Zheng; Jun Zhang; Wei Li; Qiang Chen; Bingqiang Cao; Synthesis of monodispersed ZnAl2O4 nanoparticles and their tribology properties as lubricant additives. Materials Research Bulletin 2012, 47, 4305-4310, 10.1016/j.materresbull.2012.09.013.

- He-Long Yu; Yi Xu; Pei-Jing Shi; Bin-Shi Xu; Xiao-Li Wang; Qian Liu; Tribological properties and lubricating mechanisms of Cu nanoparticles in lubricant. Transactions of Nonferrous Metals Society of China 2008, 18, 636-641, 10.1016/s1003-6326(08)60111-9.

- Pei Jing Shi; H.L. Yu; Hong Mei Wang; B.S. Xu; Tribological Behaviour of Surface Modified Copper Nanoparticles as lubricating Additives. Physics Procedia 2013, 50, 461-465, 10.1016/j.phpro.2013.11.072.

- Manuel-David Abad; J.C. Sánchez-López; Tribological properties of surface-modified Pd nanoparticles for electrical contacts. Wear 2013, 297, 943-951, 10.1016/j.wear.2012.11.009.

- L. Kolodziejczyk; D. Martínez-Martínez; T. C. Rojas; A. Fernández; J.C. Sánchez-López; Surface-modified Pd nanoparticles as a superior additive for lubrication. Journal of Nanoparticle Research 2006, 9, 639-645, 10.1007/s11051-006-9124-3.

- Peipei Yang; Xiuchen Zhao; Ying Liu; Xianhua Lai; Preparation and Tribological Properties of Dual-Coated CuO Nanoparticles as Water Based Lubricant Additives. Journal of Nanoscience and Nanotechnology 2016, 16, 9683-9689, 10.1166/jnn.2016.12394.

- Wei Zhang; Ming Zhou; Hongwei Zhu; Yu Tian; K.L. Wang; Jinquan Wei; Fei Ji; Xiao Li; Zhen Li; Peng Zhang; et al.Dehai Wu Tribological properties of oleic acid-modified graphene as lubricant oil additives. Journal of Physics D: Applied Physics 2011, 44, 1-4, 10.1088/0022-3727/44/20/205303.

- Yuan Meng; Fenghua Su; Yangzhi Chen; Supercritical Fluid Synthesis and Tribological Applications of Silver Nanoparticle-decorated Graphene in Engine Oil Nanofluid. Scientific Reports 2016, 6, 31246, 10.1038/srep31246.

- Zu-Chuan Zhang; Zhen-Bing Cai; Jin-Fang Peng; Min-Hao Zhu; Comparison of the tribology performance of nano-diesel soot and graphite particles as lubricant additives. Journal of Physics D: Applied Physics 2015, 49, 045304, 10.1088/0022-3727/49/4/045304.

- Nicholaos G. Demas; Elena V. Timofeeva; Jules L. Routbort; George R. Fenske; Tribological Effects of BN and MoS2 Nanoparticles Added to Polyalphaolefin Oil in Piston Skirt/Cylinder Liner Tests. Tribology Letters 2012, 47, 91-102, 10.1007/s11249-012-9965-0.

- M. Gupta; Jayashree Bijwe; Kadiyala Ajay Kumar; Tribo-Investigations on Oils With Dispersants and Hexagonal Boron Nitride Particles. Journal of Tribology 2017, 140, 031801, 10.1115/1.4038105.

- Wenzhen Xia; Jingwei Zhao; Hui Wu; Sihai Jiao; Xianming Zhao; XiaoMing Zhang; Jianzhong Xu; Zhengyi Jiang; Analysis of oil-in-water based nanolubricants with varying mass fractions of oil and TiO 2 nanoparticles. Wear 2018, 396-397, 162-171, 10.1016/j.wear.2017.02.031.

- Kumar, Ajeet; Dixit, Chandra Kumar. Methods for characterization of nanoparticles. In Advances in Nanomedicine for the Delivery of Therapeutic Nucleic Acids; Woodhead Publishing: Cambridge, UK,, 2017; pp. 43-58.