Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Chaojun Ren.

A stable life support system in the spacecraft can greatly promote long-duration, far-distance, and multicrew manned space flight. Therefore, controlling the concentration of CO

2

in the spacecraft is the main task in the regeneration system. The electrocatalytic CO

2

reduction can effectively treat the CO

2

generated by human metabolism. This technology has potential application value and good development prospect in the utilization of CO

2

in the space station.

- carbon dioxide

- electrocatalytic reduction

- electrocatalyst

- electrolyte

- reactor design

- spacecraft life support system

1. Introduction

With the continuous development of human science and technology, space exploration will face unprecedented opportunities and challenges [1,2,3,4,5][1][2][3][4][5]. Currently, realizing the recycle of materials in closed space stations is the best solution to solve the problem of water (H2O) and oxygen (O2) resupply faced by human activities, which not only can extend the duration of manned missions and reduce transportation costs, but also is a prerequisite for interstellar migration [6,7,8,9,10][6][7][8][9][10]. As the end product of human respiration and metabolic processes, carbon dioxide (CO2) carries a large amount of oxygen [11,12,13][11][12][13]. Therefore, recovering O2 from waste CO2 is an important way to achieve resource recycling and reduce transportation costs for medium- and long-term manned extraterrestrial missions [14,15,16,17,18][14][15][16][17][18].

The concentration of CO2 in the space station directly affects the life and health system of the astronauts [19]. To reduce the concentration of CO2 (<0.5%) and maintain the balance of air components, it is necessary to treat the CO2 emissions at 0.7–1.0 kg per person per day. How to better transform and recycle CO2 in the space station has become the focus of researchers [20,21,22,23][20][21][22][23]. The methods of CO2 transformation can be classified into two categories: physical absorption and chemical conversion [24,25][24][25]. The chemical conversion mainly includes thermochemistry, photocatalytic reduction, electrocatalytic reduction, and photoelectrocatalytic reduction [26,27,28,29][26][27][28][29]. Chemical conversion can capture and immobilize CO2 or convert it into useful low-carbon fuels, such as CO, CH4, HCOOH, CH3OH, etc. [30,31,32,33,34][30][31][32][33][34].

2. The Mechanism of Electrocatalytic Reduction of CO2

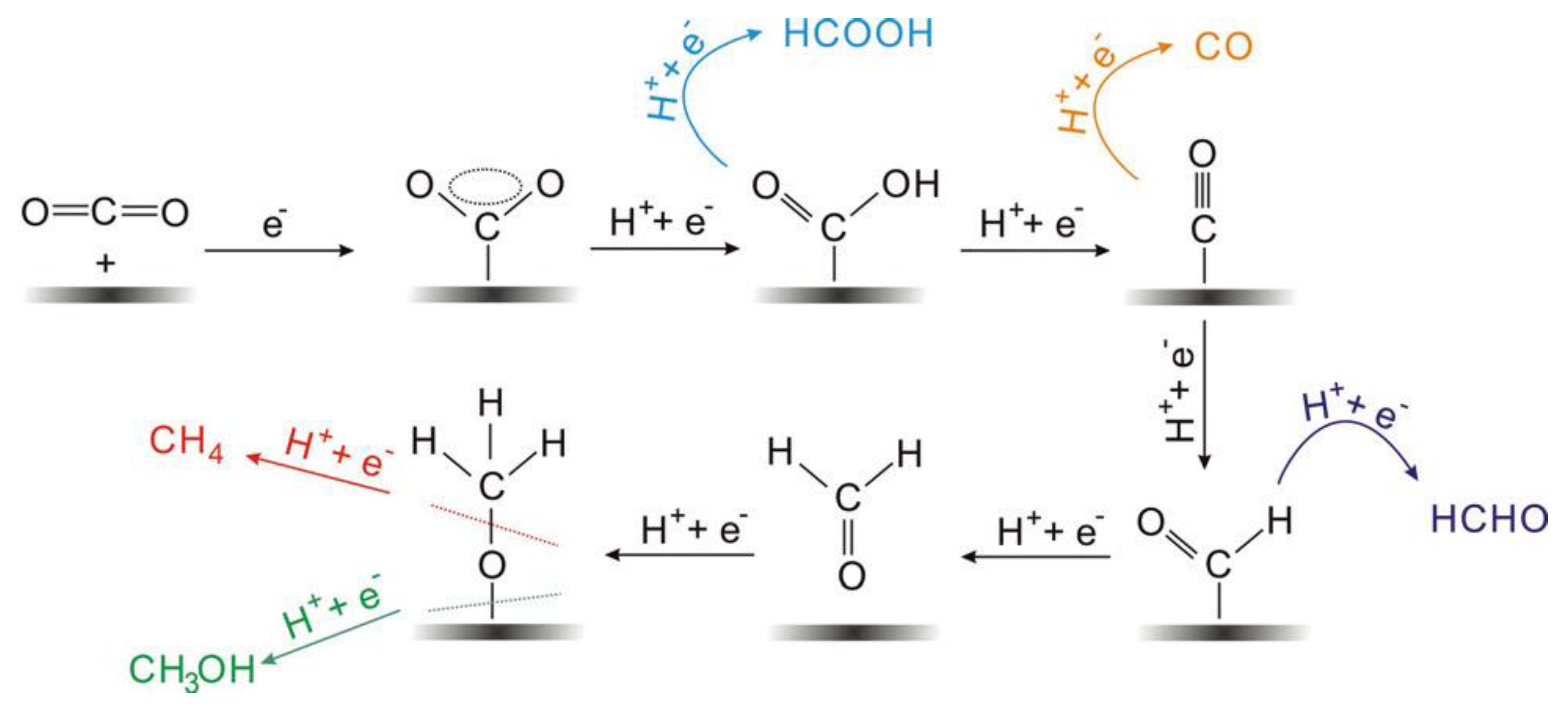

The electrocatalytic reduction of CO2 often occurs at the interface between the electrode and the electrolyte, and the electrolyte is usually an aqueous solution of potassium bicarbonate [19]. As shown in Figure 1, the multiphase catalytic process generally consists of four main steps: (i) The CO2 in the solution diffuses to the surface of the working electrode. (ii) The electrocatalyst adsorbs CO2 from the solution. (iii) Electron transfer or proton migration is used to cleave C-O bonds or form C-H bonds. (iv) The generated products are detached from the electrocatalyst surface and diffused into the electrolyte [60,61][35][36]. The adsorption of CO2 on the electrocatalyst surface is an important step in the whole reaction. During the adsorption process, the C=O bonding is strongly perturbed by the substrate, and the electrons are shared between the CO2 and the catalyst. A number of reaction mechanisms have been proposed for the conversion of CO2. It is widely accepted that the reactive species are the neutral hydrated CO2 molecules, and they will convert into CO2•− in the adsorption process on most of the main-group metal electrodes in aqueous media. Then the absorbed CO2•− reacts with the H2O molecules to form HCO2•. The intermediate would convert into to HCO2− because of its unstable unpaired electron, followed by the desorption of HCO2− species [60][35].

Figure 1. Reaction mechanism of electrochemical CO2 reduction on electrodes in aqueous solutions and the formation paths for the five main C1 products during the reduction process.

3. Electrocatalysts

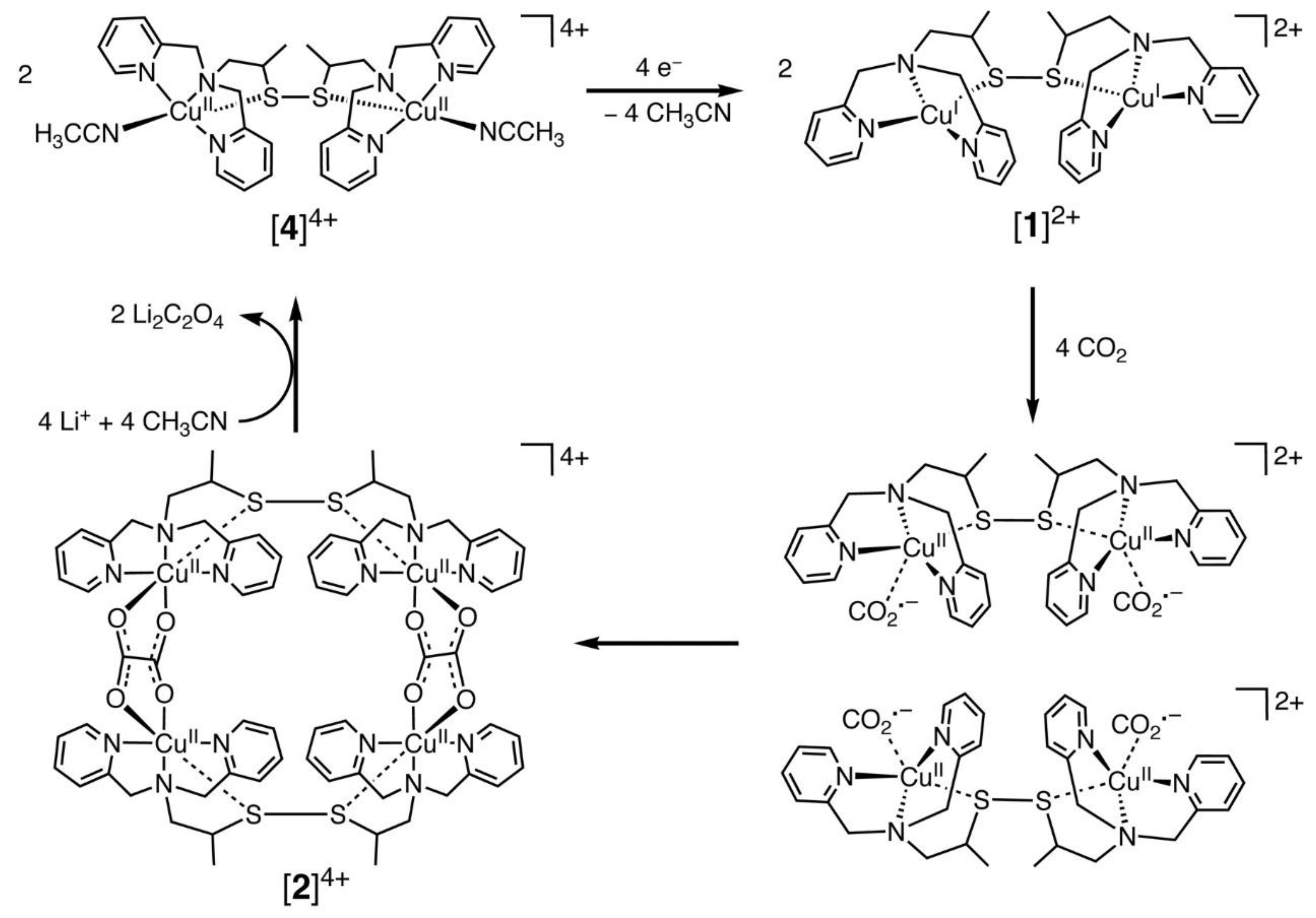

Over the past few decades, researchers have attempted to develop high-performance CO2 electrocatalysts and have carried out extensive work [71,72,73][37][38][39]. The catalysts could reduce the activation energy required for the electroreduction of CO2, thereby minishing the reduction overpotential and current density. Most of the studies have focused on transition-metal-based catalysts, which are mainly Cu, Au, Fe, Ag, Re, Mn, Co, Ni, Pd, Ir, Ru, etc. [17,74,75,76][17][40][41][42]. The main forms of the complexes include transition metal polypyridines, metal porphyrins/phthalocyanines, and various metal phosphine complexes [77,78][43][44]. Among the transition metal complexes, Cu complexes had better activity. Recently, Raja et al. [78][44] designed a dinuclear Cu (I) complex as catalysts for the electroreduction of CO2, and its catalytic cycle is shown in Figure 2 below. They found that the Cu (I) system could be oxidized by CO2, which suggested that the selective bonding of CO2 and Cu (I) ions could provide a low-energy pathway for the formation of CO2•− radical anions. Thus, the Cu (II) tetranuclear oxalate-bridged complex [2]4+ was thermodynamically favorable. Moreover, the bonding of CO2 to the Cu(I) center in the dinuclear copper (I) complex [1]2+ was faster and has a higher selectivity. This was due to the low solubility of lithium oxalate in acetonitrile, and the release of the oxalate double anion from [2]4+ in the presence of LiClO4 could be accomplished instantaneously, and the dinuclear copper (II) complex [4]4+ was produced. Consequently, the electrocatalytic reduction of Cu (II) ions to Cu (I) might be the rate-controlling step in this system. The electrode surface was coated by the lithium oxalate generated during the reaction and then prevented the effective electron transfer.

Figure 2. Proposed electrocatalytic cycle for oxalate formation.

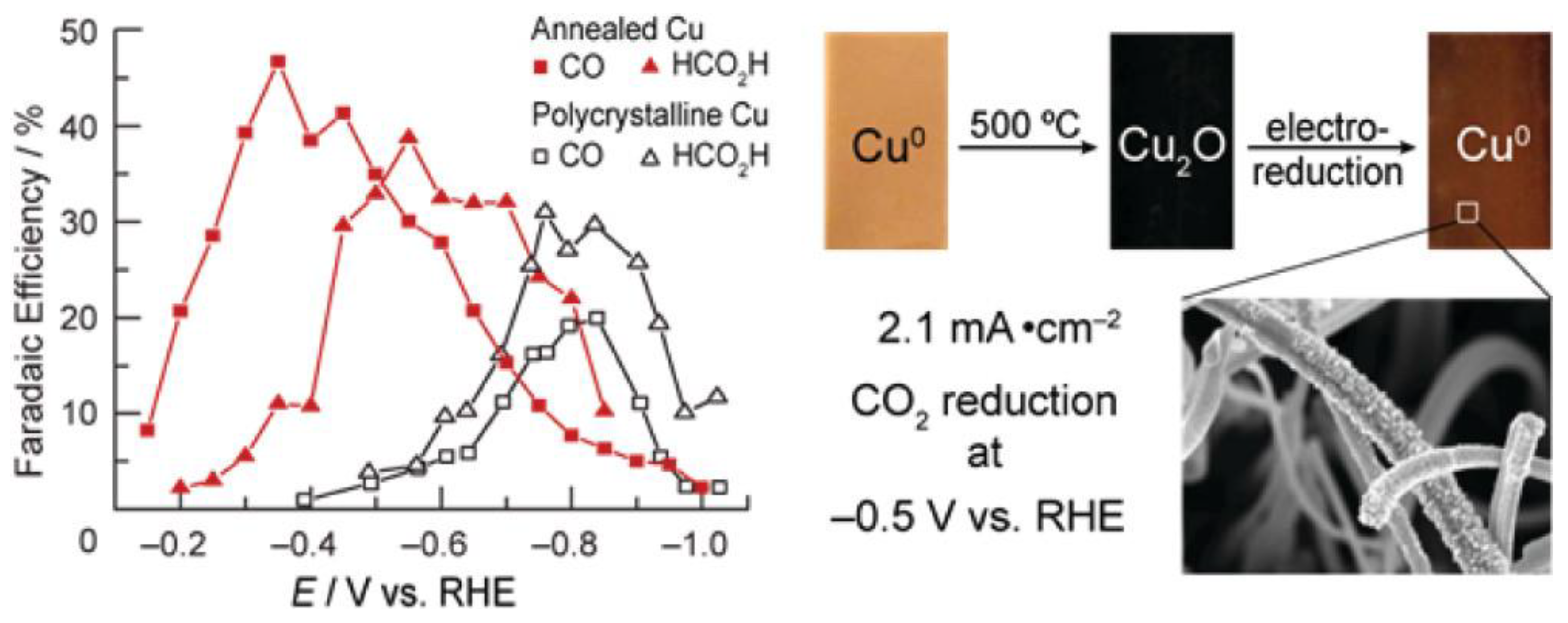

Figure 3. Electrocatalytic performance and the preparation process of Cu electrodes.

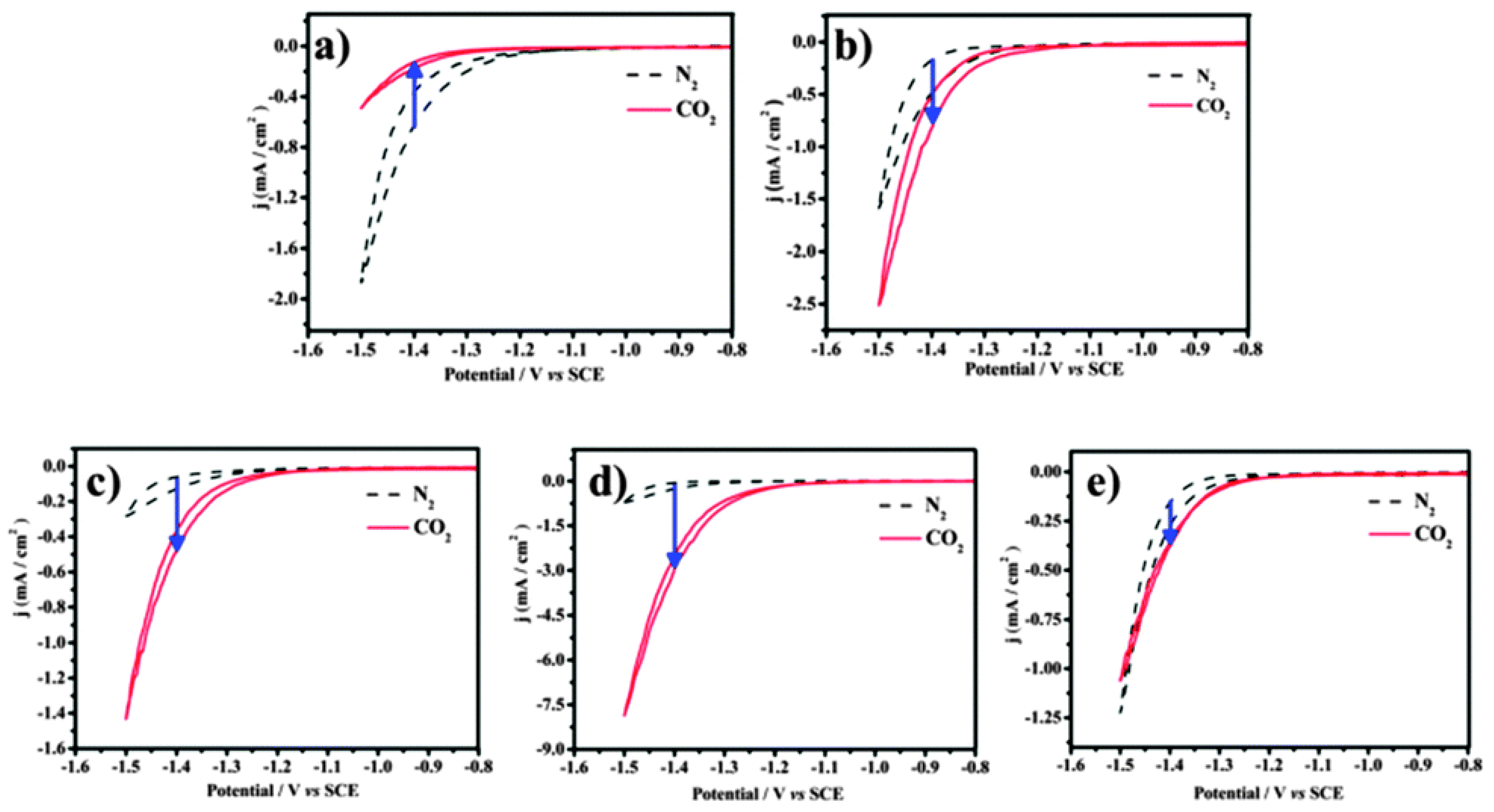

Figure 4. The cyclic voltammograms of catalysts were recorded in N2- and CO2-saturated 0.5 M KHCO3 with a scan rate of 10 mV/s−1 between −0.8 and −1.5 V (vs. SCE). (a) Cu-Pt-1#, (b) Cu-Pt-2#, (c) Cu-Pt-3#, (d) Cu-Pt-4#, and (e) Cu-Pt-5#.

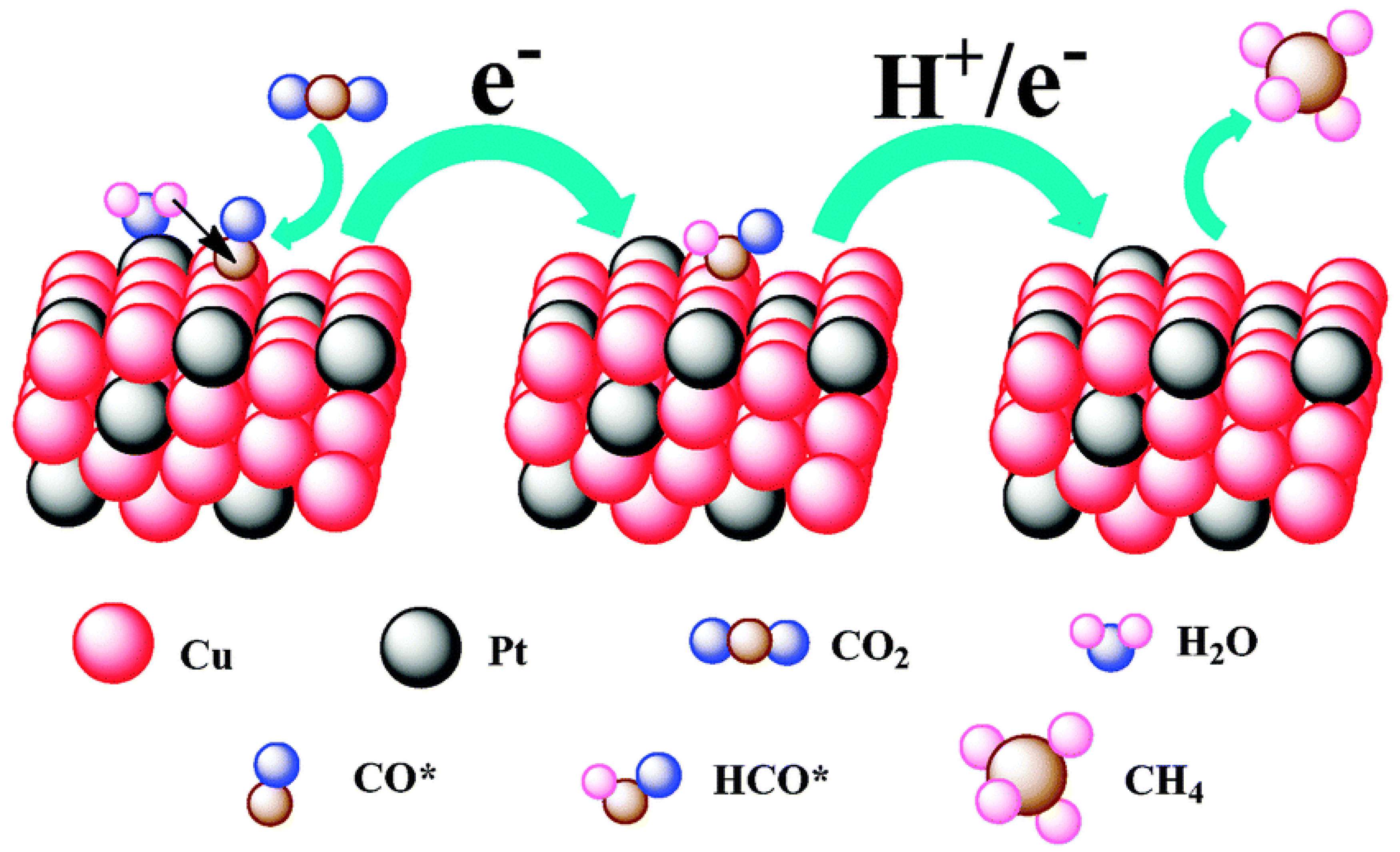

Figure 5. A proposed mechanism illustrating the steps of CO2 electroreduction and CH4 formation occurring at the Cu-Pt 3:1 NC catalyst.

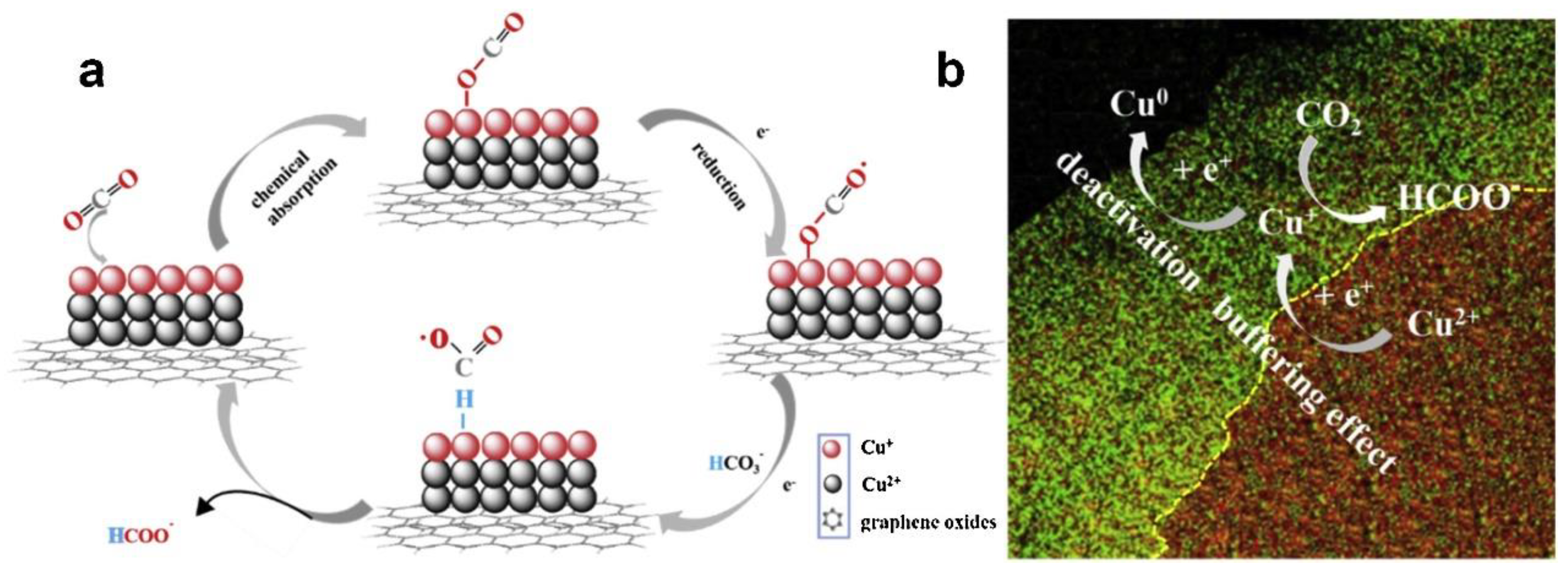

Figure 6. (a) A proposed mechanism illustrating the steps of electrochemical CO2 reduction and the formation of HCOOH occurring at the G-CuxO-2 h electrocatalyst. (b) A proposed “buffering effect” illustrating the origin of the durability of G-CuxO-T electrocatalysts.

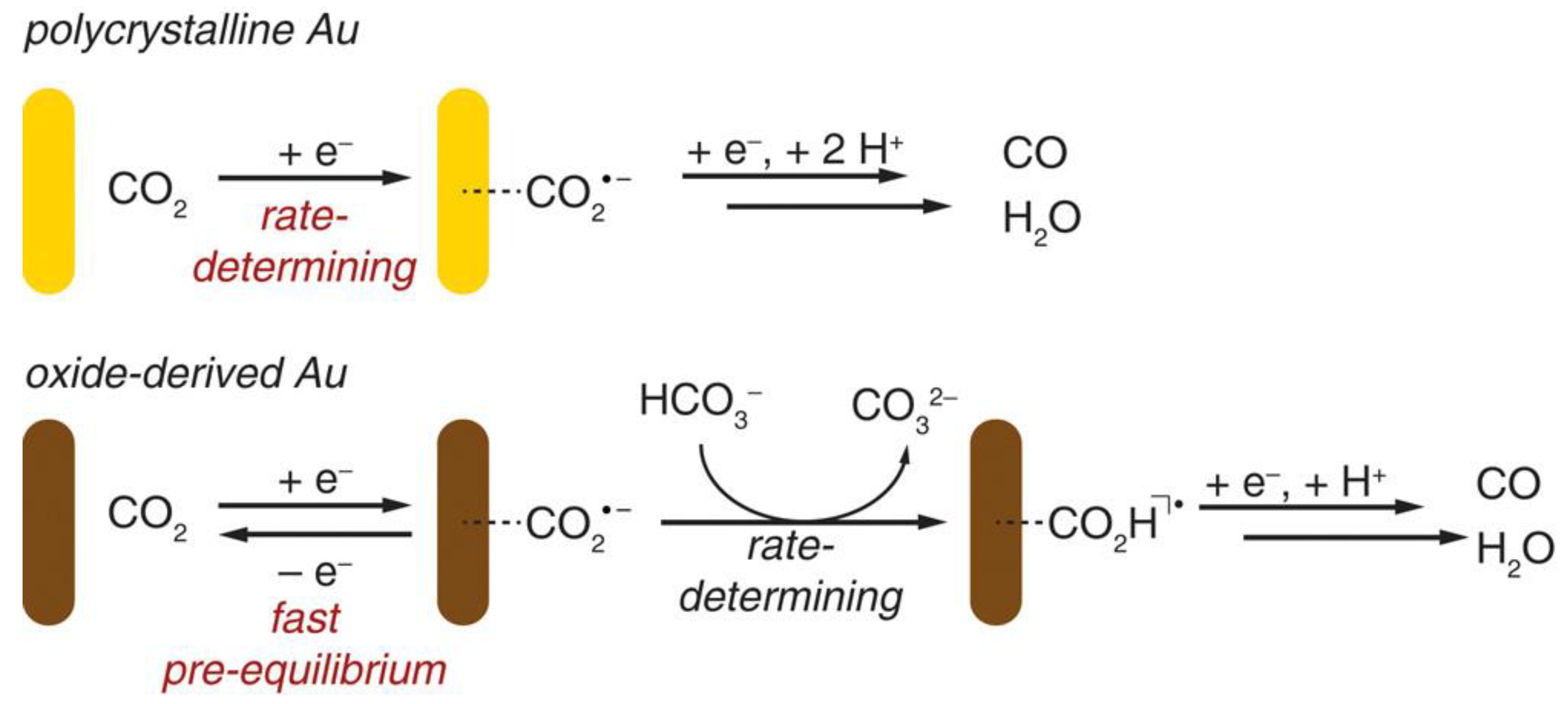

Figure 7. Proposed mechanisms for CO2 reduction to CO on polycrystalline Au and oxide-derived Au.

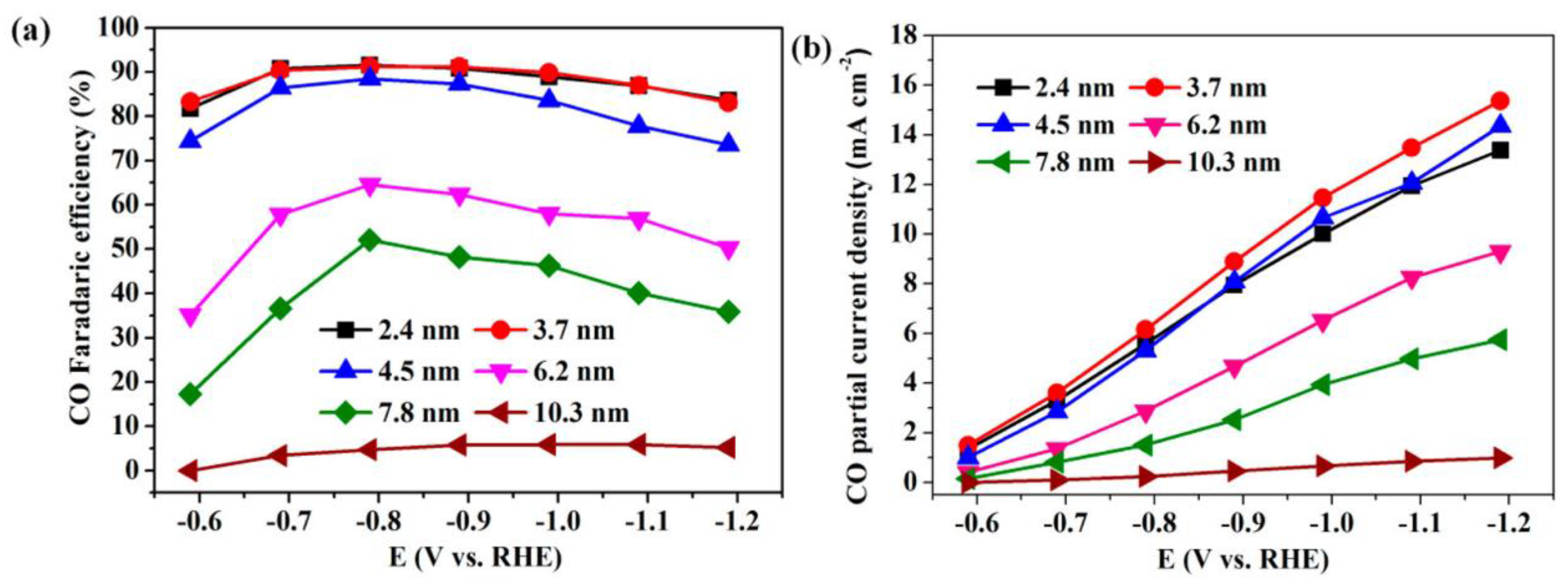

Figure 8. Applied potential dependence of (a) Faradaic efficiencies and (b) current densities for CO production over Pd NPs with different sizes.

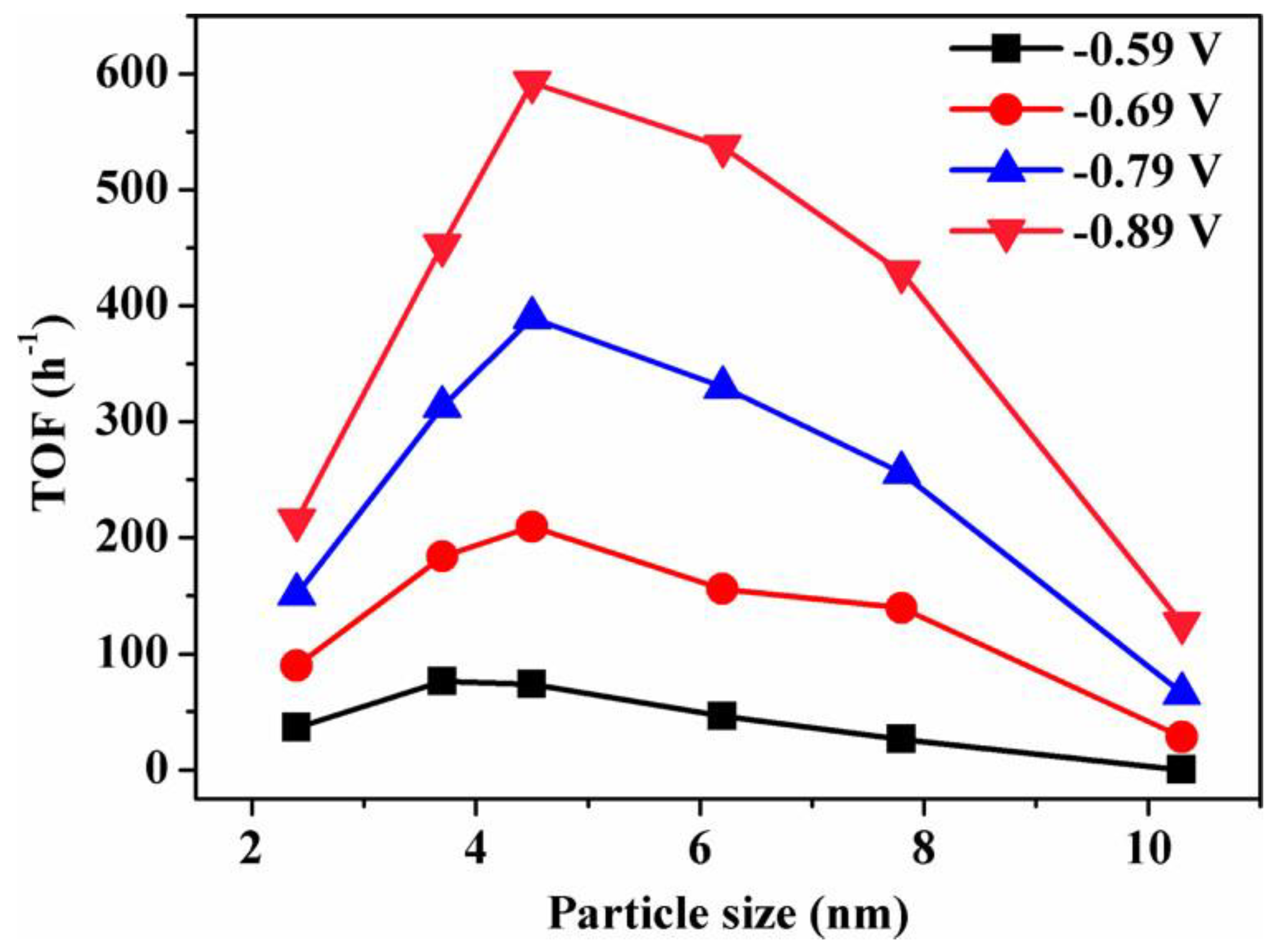

Figure 9. Size dependence of TOF for CO production on Pd NPs at various potentials.

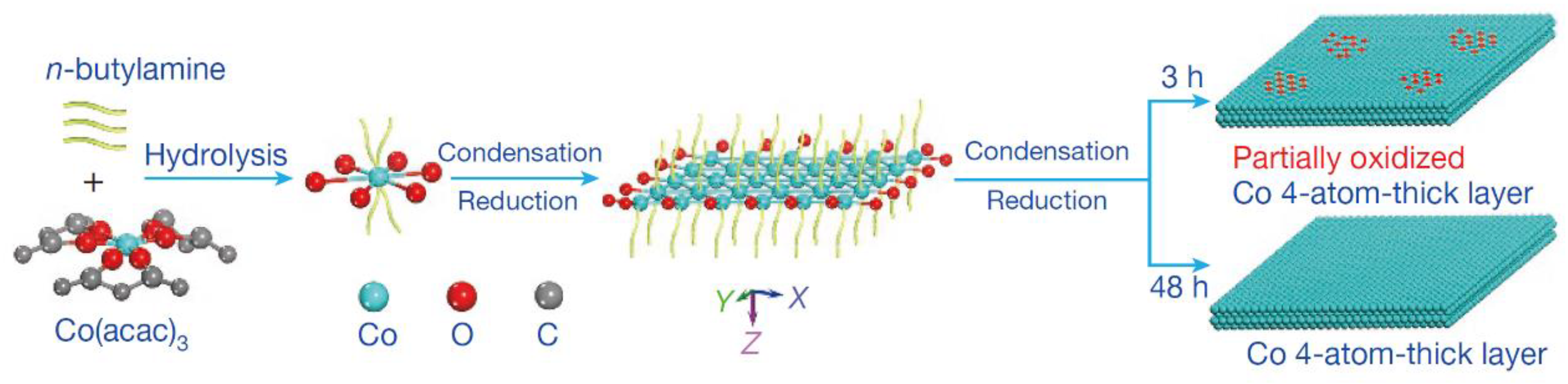

Figure 10. Schematic formation process of the partially oxidized and pure-Co 4-atomic-layer, respectively.

Figure 11. Correlation between turnover frequency and overpotential for the series of CO2-to-CO electroreduction catalysts. The star indicates TOF and η values from preparative-scale experiments of Fe0TDHPP.

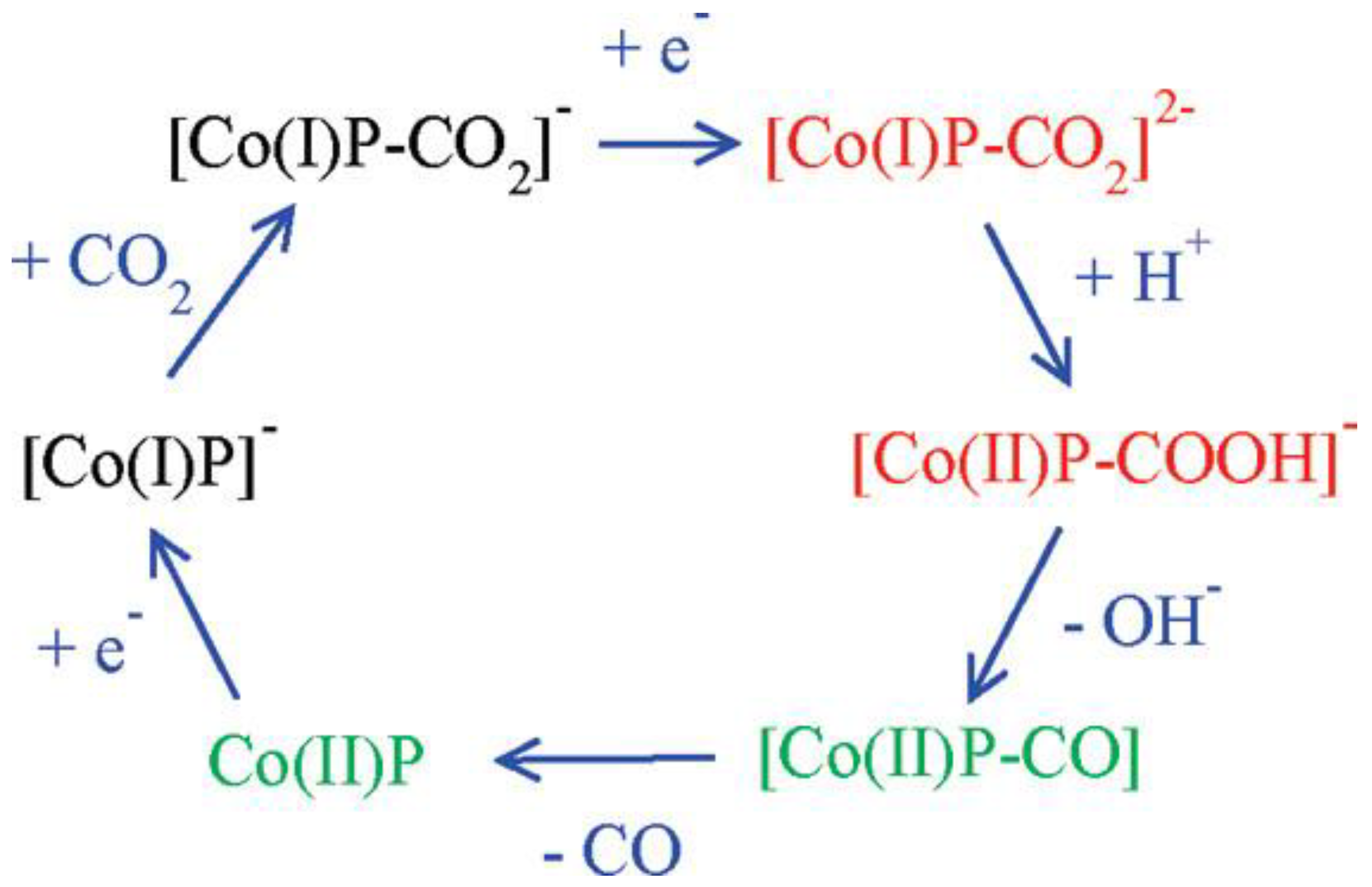

Figure 12. Mechanism of CO2 reduction with electron addition deduced from hybrid DFT plus dielectric continuum redox potential calculations. Red denotes key intermediates; green species should undergo fast reactions.

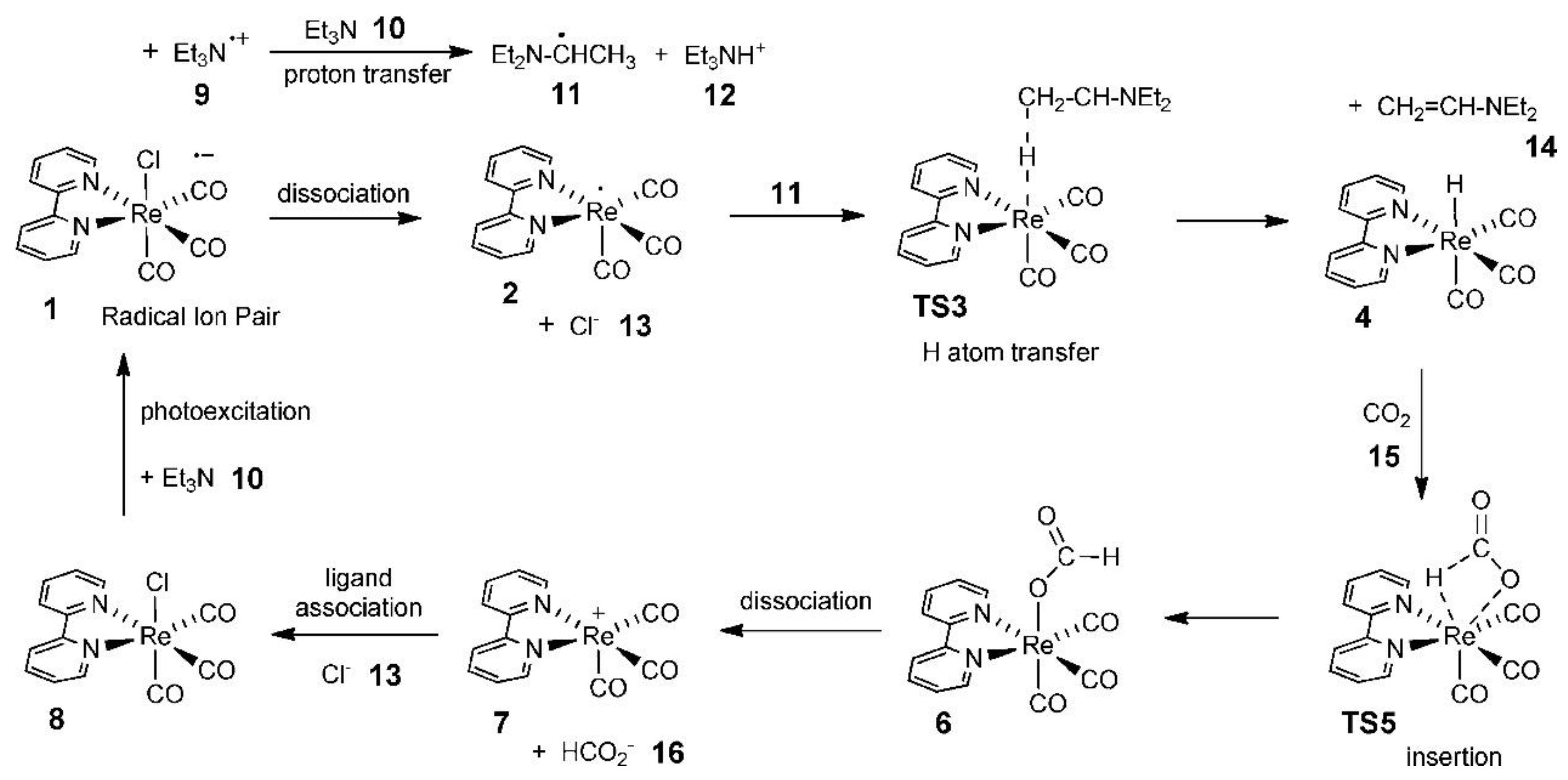

Figure 13. Computed photocatalytic cycle for CO2 reduction on a Re catalyst.

References

- Li, C.; Hu, H.; Yang, M.F.; Pei, Z.Y.; Zhou, Q.; Ren, X.; Liu, B.; Liu, D.; Zeng, X.; Zhang, G.; et al. Characteristics of the lunar samples returned by the Chang’E-5 mission. Natl. Sci. Rev. 2022, 9, nwab188.

- McClean, J.B.; Hoffman, J.A.; Hecht, M.H.; Aboobaker, A.M.; Araghi, K.R.; Elangovan, S.; Graves, C.R.; Hartvigsen, J.J.; Hinterman, E.D.; Liu, A.M. Pre-landing plans for mars oxygen in-situ resource utilization experiment (MOXIE) science operations. Acta Astronaut. 2022, 192, 301–313.

- Schlüter, L.; Cowley, A. Review of techniques for In-Situ oxygen extraction on the moon. Planet. Space Sci. 2020, 181, 104753.

- Kaschubek, D.; Killian, M.; Grill, L. System analysis of a Moon base at the south pole: Considering landing sites, ECLSS and ISRU. Acta Astronaut. 2021, 186, 33–49.

- Starr, S.O.; Muscatello, A.C. Mars in situ resource utilization: A review. Planet. Space Sci. 2020, 182, 104824.

- Chen, H.; du Jonchay, T.S.; Hou, L.; Ho, K. Integrated in-situ resource utilization system design and logistics for Mars exploration. Acta Astronaut. 2020, 170, 80–92.

- Liu, S.; Hu, B.; Zhao, J.; Jiang, W.; Feng, D.; Zhang, C.; Yao, W. Enhanced electrocatalytic CO2 reduction of bismuth nanosheets with introducing surface bismuth subcarbonate. Coatings 2022, 12, 233.

- Zhang, W.; Hu, Y.; Ma, L.; Zhu, G.; Zhao, P.; Xue, X.; Chen, R.; Yang, S.; Ma, J.; Liu, J. Liquid-phase exfoliated ultrathin Bi nanosheets: Uncovering the origins of enhanced electrocatalytic CO2 reduction on two-dimensional metal nanostructure. Nano Energy 2018, 53, 808–816.

- Feng, D.; Jiang, W.; Zhang, C.; Li, L.; Hu, B.; Song, J.; Yao, W. A Membrane Reactor with Microchannels for Carbon Dioxide Reduction in Extraterrestrial Space. Catalysts 2022, 12, 3.

- Cestellos-Blanco, S.; Friedline, S.; Sander, K.B.; Abel, A.J.; Kim, J.M.; Clark, D.S.; Arkin, A.P.; Yang, P. Production of PHB from CO2-derived acetate with minimal processing assessed for space biomanufacturing. Front. Microbiol. 2021, 12, 700010.

- Su, Y.; Cestellos-Blanco, S.; Kim, J.M.; Shen, Y.-X.; Kong, Q.; Lu, D.; Liu, C.; Zhang, H.; Cao, Y.; Yang, P. Close-packed nanowire-bacteria hybrids for efficient solar-driven CO2 fixation. Joule 2020, 4, 800–811.

- Hecht, M.; Hoffman, J.; Rapp, D.; McClean, J.; SooHoo, J.; Schaefer, R.; Aboobaker, A.; Mellstrom, J.; Hartvigsen, J.; Meyen, F. Mars oxygen ISRU experiment (MOXIE). Space Sci. Rev. 2021, 217, 1–76.

- Calvinho, K.U.; Laursen, A.B.; Yap, K.M.; Goetjen, T.A.; Hwang, S.; Murali, N.; Mejia-Sosa, B.; Lubarski, A.; Teeluck, K.M.; Hall, E.S. Selective CO2 reduction to C3 and C4 oxyhydrocarbons on nickel phosphides at overpotentials as low as 10 mV. Energy Environ. Sci. 2018, 11, 2550–2559.

- da Silva Freitas, W.; D’Epifanio, A.; Mecheri, B. Electrocatalytic CO2 reduction on nanostructured metal-based materials: Challenges and constraints for a sustainable pathway to decarbonization. J. CO2 Util. 2021, 50, 101579.

- Casebolt, R.; Levine, K.; Suntivich, J.; Hanrath, T. Pulse check: Potential opportunities in pulsed electrochemical CO2 reduction. Joule 2021, 5, 1987–2026.

- Chen, J.; Wang, T.; Li, Z.; Yang, B.; Zhang, Q.; Lei, L.; Feng, P.; Hou, Y. Recent progress and perspective of electrochemical CO2 reduction towards C2-C5 products over non-precious metal heterogeneous electrocatalysts. Nano Res. 2021, 14, 3188–3207.

- Chen, Q.; Tsiakaras, P.; Shen, P. Electrochemical Reduction of Carbon Dioxide: Recent Advances on Au-Based Nanocatalysts. Catalysts 2022, 12, 1348.

- Chen, C.; Zhang, Z.; Li, G.; Li, L.; Lin, Z. Recent advances on nanomaterials for electrocatalytic CO2 conversion. Energy Fuels 2021, 35, 7485–7510.

- Tran, K.; Ulissi, Z.W. Active learning across intermetallics to guide discovery of electrocatalysts for CO2 reduction and H2 evolution. Nat. Catal. 2018, 1, 696–703.

- Xie, L.; Liang, J.; Priest, C.; Wang, T.; Ding, D.; Wu, G.; Li, Q. Engineering the atomic arrangement of bimetallic catalysts for electrochemical CO2 reduction. Chem. Commun. 2021, 57, 1839–1854.

- Giusi, D.; Miceli, M.; Genovese, C.; Centi, G.; Perathoner, S.; Ampelli, C. In situ electrochemical characterization of CuxO-based gas-diffusion electrodes (GDEs) for CO2 electrocatalytic reduction in presence and absence of liquid electrolyte and relationship with C2+ products formation. Appl. Catal. B Environ. 2022, 318, 121845.

- Yang, K.; Yang, Z.; Zhang, C.; Gu, Y.; Wei, J.; Li, Z.; Ma, C.; Yang, X.; Song, K.; Li, Y. Recent advances in CdS-based photocatalysts for CO2 photocatalytic conversion. Chem. Eng. J. 2021, 418, 129344.

- Yang, K.D.; Lee, C.W.; Jin, K.; Im, S.W.; Nam, K.T. Current status and bioinspired perspective of electrochemical conversion of CO2 to a long-chain hydrocarbon. J. Phys. Chem. Lett. 2017, 8, 538–545.

- Khan, I. Strategies for Improved Electrochemical CO2 Reduction to Value-Added Products by Highly Anticipated Copper-Based Nanoarchitectures. Chem. Rec. 2022, 22, e202100219.

- Fan, Q.; Zhang, M.; Jia, M.; Liu, S.; Qiu, J.; Sun, Z. Electrochemical CO2 reduction to C2+ species: Heterogeneous electrocatalysts, reaction pathways, and optimization strategies. Mater. Today Energy 2018, 10, 280–301.

- Zhang, B.; Wang, L.; Li, D.; Li, Z.; Bu, R.; Lu, Y. Tandem strategy for electrochemical CO2 reduction reaction. Chem Catal. 2022, 2, 3395–3429.

- Zhang, J.; Sewell, C.D.; Huang, H.; Lin, Z. Closing the anthropogenic chemical carbon cycle toward a sustainable future via CO2 valorization. Adv. Energy Mater. 2021, 11, 2102767.

- Sun, M.; Wong, H.H.; Wu, T.; Dougherty, A.W.; Huang, B. Entanglement of spatial and energy segmentation for C1 pathways in CO2 reduction on carbon skeleton supported atomic catalysts. Adv. Energy Mater. 2022, 12, 2103781.

- Rehman, A.; Nazir, G.; Rhee, K.Y.; Park, S.-J. Electrocatalytic and photocatalytic sustainable conversion of carbon dioxide to value-added chemicals: State-of-the-art progress, challenges, and future directions. J. Environ. Chem. Eng. 2022, 10, 108219.

- Li, R.; Xiang, K.; Liu, Z.; Peng, Z.; Zou, Y.; Wang, S. Recent Advances in Upgrading of Low-Cost Oxidants to Value-Added Products by Electrocatalytic Reduction Reaction. Adv. Funct. Mater. 2022, 32, 2208212.

- He, C.; Duan, D.; Low, J.; Bai, Y.; Jiang, Y.; Wang, X.; Chen, S.; Long, R.; Song, L.; Xiong, Y. Cu2−xS derived copper nanoparticles: A platform for unraveling the role of surface reconstruction in efficient electrocatalytic CO2-to-C2H4 conversion. Nano Res. 2021, 1–5.

- Wijaya, D.T.; Lee, C.W. Metal-Organic framework catalysts: A versatile platform for bioinspired electrochemical conversion of carbon dioxide. Chem. Eng. J. 2022, 446, 137311.

- Franco, F.; Rettenmaier, C.; Jeon, H.S.; Cuenya, B.R. Transition metal-based catalysts for the electrochemical CO2 reduction: From atoms and molecules to nanostructured materials. Chem. Soc. Rev. 2020, 49, 6884–6946.

- Zhang, J.; Zeng, G.; Chen, L.; Lai, W.; Yuan, Y.; Lu, Y.; Ma, C.; Zhang, W.; Huang, H. Tuning the reaction path of CO2 electroreduction reaction on indium single-atom catalyst: Insights into the active sites. Nano Res. 2022, 15, 4014–4022.

- Zhang, L.; Zhao, Z.J.; Gong, J. Nanostructured materials for heterogeneous electrocatalytic CO2 reduction and their related reaction mechanisms. Angew. Chem. Int. Ed. 2017, 56, 11326–11353.

- Zhu, D.D.; Liu, J.L.; Qiao, S.Z. Recent advances in inorganic heterogeneous electrocatalysts for reduction of carbon dioxide. Adv. Mater. 2016, 28, 3423–3452.

- Yoo, C.J.; Dong, W.J.; Park, J.Y.; Lim, J.W.; Kim, S.; Choi, K.S.; Odongo Ngome, F.O.; Choi, S.-Y.; Lee, J.-L. Compositional and geometrical effects of bimetallic Cu–Sn catalysts on selective electrochemical CO2 reduction to CO. ACS Appl. Energy Mater. 2020, 3, 4466–4473.

- Matavos-Aramyan, S.; Soukhakian, S.; Jazebizadeh, M.H.; Moussavi, M.; Hojjati, M.R. On engineering strategies for photoselective CO2 reduction–A thorough review. Appl. Mater. Today 2020, 18, 100499.

- Wang, F. Artificial photosynthetic systems for CO2 reduction: Progress on higher efficiency with cobalt complexes as catalysts. ChemSusChem 2017, 10, 4393–4402.

- Govindan, B.; Madhu, R.; Abu Haija, M.; Kusmartsev, F.V.; Banat, F. Pd-Decorated 2D MXene (2D Ti3C2Tix) as a High-Performance Electrocatalyst for Reduction of Carbon Dioxide into Fuels toward Climate Change Mitigation. Catalysts 2022, 12, 1180.

- Mostafa, M.M.M.; Bajafar, W.; Gu, L.; Narasimharao, K.; Abdel Salam, M.; Alshehri, A.; Khdary, N.H.; Al-Faifi, S.; Chowdhury, A.D. Electrochemical Characteristics of Nanosized Cu, Ni, and Zn Cobaltite Spinel Materials. Catalysts 2022, 12, 893.

- Li, X.; Chang, S.; Wang, Y.; Zhang, L. Silver-Carbonaceous Microsphere Precursor-Derived Nano-Coral Ag Catalyst for Electrochemical Carbon Dioxide Reduction. Catalysts 2022, 12, 479.

- Costentin, C.; Drouet, S.; Robert, M.; Savéant, J.-M. A local proton source enhances CO2 electroreduction to CO by a molecular Fe catalyst. Science 2012, 338, 90–94.

- Angamuthu, R.; Byers, P.; Lutz, M.; Spek, A.L.; Bouwman, E. Electrocatalytic CO2 conversion to oxalate by a copper complex. Science 2010, 327, 313–315.

- Zhang, Y.; Dong, L.-Z.; Li, S.; Huang, X.; Chang, J.-N.; Wang, J.-H.; Zhou, J.; Li, S.-L.; Lan, Y.-Q. Coordination environment dependent selectivity of single-site-Cu enriched crystalline porous catalysts in CO2 reduction to CH4. Nat. Commun. 2021, 12, 6390.

- Peterson, A.A.; Abild-Pedersen, F.; Studt, F.; Rossmeisl, J.; Nørskov, J.K. How copper catalyzes the electroreduction of carbon dioxide into hydrocarbon fuels. Energy Environ. Sci. 2010, 3, 1311–1315.

- Li, C.W.; Kanan, M.W. CO2 reduction at low overpotential on Cu electrodes resulting from the reduction of thick Cu2O films. J. Am. Chem. Soc. 2012, 134, 7231–7234.

- Guo, X.; Zhang, Y.; Deng, C.; Li, X.; Xue, Y.; Yan, Y.-M.; Sun, K. Composition dependent activity of Cu–Pt nanocrystals for electrochemical reduction of CO2. Chem. Commun. 2015, 51, 1345–1348.

- Ni, W.; Li, C.; Zang, X.; Xu, M.; Huo, S.; Liu, M.; Yang, Z.; Yan, Y.-M. Efficient electrocatalytic reduction of CO2 on CuxO decorated graphene oxides: An insight into the role of multivalent Cu in selectivity and durability. Appl. Catal. B Environ. 2019, 259, 118044.

- Chen, Y.; Li, C.W.; Kanan, M.W. Aqueous CO2 reduction at very low overpotential on oxide-derived Au nanoparticles. J. Am. Chem. Soc. 2012, 134, 19969–19972.

- Gao, D.; Zhou, H.; Wang, J.; Miao, S.; Yang, F.; Wang, G.; Wang, J.; Bao, X. Size-dependent electrocatalytic reduction of CO2 over Pd nanoparticles. J. Am. Chem. Soc. 2015, 137, 4288–4291.

- Li, S.; Dong, X.; Chen, W.; Song, Y.; Li, G.; Wei, W.; Sun, Y. Efficient CO2 Electroreduction over Silver Hollow Fiber Electrode. Catalysts 2022, 12, 453.

- Chen, X.; Wang, H.; Wang, Y.; Bai, Q.; Gao, Y.; Zhang, Z. Synthesis and electrocatalytic performance of multi-component nanoporous PtRuCuW alloy for direct methanol fuel cells. Catalysts 2015, 5, 1003–1015.

- Zhang, Y.-H.; Liu, M.-M.; Chen, J.-L.; Fang, S.-M.; Zhou, P.-P. Recent advances in Cu2O-based composites for photocatalysis: A review. Dalton Trans. 2021, 50, 4091–4111.

- Niu, Z.-Z.; Gao, F.-Y.; Zhang, X.-L.; Yang, P.-P.; Liu, R.; Chi, L.-P.; Wu, Z.-Z.; Qin, S.; Yu, X.; Gao, M.-R. Hierarchical copper with inherent hydrophobicity mitigates electrode flooding for high-rate CO2 electroreduction to multicarbon products. J. Am. Chem. Soc. 2021, 143, 8011–8021.

- Halder, A.; Curtiss, L.A.; Fortunelli, A.; Vajda, S. Perspective: Size selected clusters for catalysis and electrochemistry. J. Chem. Phys. 2018, 148, 110901.

- Cao, T.; Lin, R.; Liu, S.; Cheong, W.-C.M.; Li, Z.; Wu, K.; Zhu, Y.; Wang, X.; Zhang, J.; Li, Q. Atomically dispersed Ni anchored on polymer-derived mesh-like N-doped carbon nanofibers as an efficient CO2 electrocatalytic reduction catalyst. Nano Res. 2022, 15, 3959–3963.

- Azhari, N.J.; Nurdini, N.; Mardiana, S.; Ilmi, T.; Fajar, A.T.; Makertihartha, I.; Kadja, G.T. Zeolite-based catalyst for direct conversion of CO2 to C2+ hydrocarbon: A review. J. CO2 Util. 2022, 59, 101969.

- Choukroun, D.; Daems, N.; Kenis, T.; Van Everbroeck, T.; Hereijgers, J.; Altantzis, T.; Bals, S.; Cool, P.; Breugelmans, T. Bifunctional nickel–nitrogen-doped-carbon-supported copper electrocatalyst for CO2 reduction. J. Phys. Chem. C 2020, 124, 1369–1381.

- Cho, J.H.; Lee, C.; Hong, S.H.; Jang, H.Y.; Back, S.; Seo, M.g.; Lee, M.; Min, H.K.; Choi, Y.; Jang, Y.J. Transition Metal Ion Doping on ZIF-8 for Enhanced the Electrochemical CO2 Reduction Reaction. Adv. Mater. 2022, 2208224.

- Zha, B.; Li, C.; Li, J. Efficient electrochemical reduction of CO2 into formate and acetate in polyoxometalate catholyte with indium catalyst. J. Catal. 2020, 382, 69–76.

- Gao, S.; Lin, Y.; Jiao, X.; Sun, Y.; Luo, Q.; Zhang, W.; Li, D.; Yang, J.; Xie, Y. Partially oxidized atomic cobalt layers for carbon dioxide electroreduction to liquid fuel. Nature 2016, 529, 68–71.

- Bhugun, I.; Lexa, D.; Saveant, J.-M. Ultraefficient selective homogeneous catalysis of the electrochemical reduction of carbon dioxide by an iron (0) porphyrin associated with a weak Broensted acid cocatalyst. J. Am. Chem. Soc. 1994, 116, 5015–5016.

- Leung, K.; Nielsen, I.M.; Sai, N.; Medforth, C.; Shelnutt, J.A. Cobalt− porphyrin catalyzed electrochemical reduction of carbon dioxide in water. 2. mechanism from first principles. J. Phys. Chem. A 2010, 114, 10174–10184.

- Tornow, C.E.; Thorson, M.R.; Ma, S.; Gewirth, A.A.; Kenis, P.J. Nitrogen-based catalysts for the electrochemical reduction of CO2 to CO. J. Am. Chem. Soc. 2012, 134, 19520–19523.

- Agarwal, J.; Johnson, R.P.; Li, G. Reduction of CO2 on a tricarbonyl rhenium (I) complex: Modeling a catalytic cycle. J. Phys. Chem. A 2011, 115, 2877–2881.

More