You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Rabiga Musaparovna Kudaibergenova and Version 2 by Sirius Huang.

One of the most pressing environmental problems worldwide is sewage sludge (SS) management. Every year, wastewater volume increases and thus, the amount of SS produced increases as well. The disposal of SS in landfills, as practiced in many countries, is not a sustainable solution. Instead, SS, rich in organic matter and other nutrients, can be used as an alternative soil additive or fertilizer. The properties of these materials depend on their chemical composition and the method of treatment. Experience from a number of countries, such as the US and Europe, has shown that SS can be transformed from a waste into a valuable resource, provided that the final product fulfils the relevant regulatory standards.

- sewage sludge

- anaerobic digestion

- composting

- fertilizer

- agriculture

1. Introduction

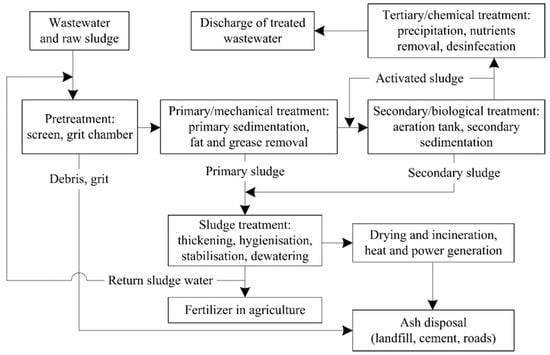

Wastewater is produced in huge amounts in big cities and is typically treated in wastewater treatment plants (WWTPs) employing biological reactors generating waste sewage sludge (SS). The principal sources of SS at municipal WWTPs are the primary sedimentation basin and the secondary clarifiers. Additional sludge may also come from chemical precipitation, screening, grinding, and filtration [1][2]. The amount of SS is constantly growing, and it currently constitutes a serious environmental problem. Unfortunately, the uncontrolled disposal of SS on land has been, and remains, the main method of solving this problem in many countries of the world. Another common practice is its disposal in landfills, many of which have reached their capacity and also do not meet the engineering standards. Waste management is directly or indirectly regulated by international conventions, national laws, and codes, as well as other regulatory and technical documentation. Each country has its own SS management system, regulated by domestic legislation, and international conventions regulate the transboundary movement of waste (e.g., the Basel Convention) [2][3][3,4]. Some conventions, i.e., the Stockholm Convention on persistent organic pollutants [4][5], provide detailed recommendations on the management of certain types of waste, but unfortunately, these conventions do not contain clear recommendations on the management of SS.

2. Sewage Sludge Production and Management

SS includes solids generated at facilities for the mechanical, biological, and physicochemical treatment of municipal and industrial wastewater and water intended for human consumption (i.e., surface and groundwater) [1][2]. The biological treatment of wastewater is one of the largest industries in the world, producing millions of tons of SS annually. Biological treatment is the most effective way to treat municipal and some types of industrial wastewater rich in organic load, although is known that certain types of organics either escape the treatment or are poorly degraded, for instance, antibiotics, drugs, pesticides, etc. [5][12]. The main portion of the organic load is turned into SS [6][13]. It is known that SS is an organogenic substrate containing biogenic elements (nitrogen, phosphorus, potassium, and their compounds) in concentrations comparable to those of traditional organic fertilizers. Therefore, much attention has always been paid to the rational use of the biological potential of SS. The composition of silt deposits is 40% organic matter and up to 60% mineral component, in terms of dry weight [7][14]. Moreover, the humic acids and proteins content is high [8][15]. SS contains trace elements, such as heavy metals, which, inadequate concentrations, are vital for plant development, but in high concentrations, can cause sludge toxicity [9][16]. Depending on the region’s population density and industrial activity, the amount of heavy metals in SS can vary significantly and frequently exceed the maximum allowable concentrations [10][11][17,18].

The uncontrolled disposal of untreated SS in the environment, practiced in the past and still in use in many parts of the world, is a serious threat to the environment. Other common practices, such as disposal in landfills and incineration, are environmentally unsound and can be costly [12][19]. Therefore, alternative options for sludge management have been studied, such as in the production of building materials, biofuels, carbon, and electricity, as well as in agriculture. Efficient use of secondary resources, including SS, benefit many countries, both economically and environmentally. Waste disposal at open landfills is an irrational solution from both an environmental and an economic perspective, and it also contradicts legislative changes. There is a growing incentive to develop cost-effective reuse and recycling options by converting SS and bottom ash into new marketable materials [13][9]. The main methods of disposal of SS currently used in the EU are waste disposal, tillage, and incineration, which are used to treat almost 90% of the generated SS, as shown in Figure 1 [14][20]. Depending on the regional socio-economic, and geo-ecological characteristics of the countries, from 10 to 90% of the accumulated SS is used in agricultural production, with an average of 30–40% in the Western Europe, and at least 60% in the US.

Although in developed countries, such as in Europe, the technologies and legislation regarding pollution have long been developed, this is not the case for SS. However, the sustainable management of SS is of great importance as Europe moves towards a CE in line with the European Green Deal [15][21] and the goal of zero pollution.

The experience of SS disposal in Germany, the USA, France, Finland, and several other countries indicates that if there is an effective sludge treatment technology and control over its use, most of the SS (up to 60%) can be used as a fertilizer in agriculture, in urban landscaping, as well as for inland reclamation, reforestation, and other works. The transformation of SS into a new substance or product that meets quality protocols, along with a new level of processing, will provide an opportunity to obtain scarce critical raw materials from secondary raw materials, leading to the successful management of SS waste. Ongoing research and development in the field of SS waste management shows that SS recycling can be used to produce valuable organic substances and plant nutrients that can be used as fertilizers [16][17][18][23,24,25] or additives to improve soil quality and to increase the fertility and productivity of agricultural land.

In the Regulation on the European Waste list (waste code 19 08 05), municipal sludge from WWTP is assessed as safe. However, an exception is described in the article of the Waste Framework Directive 2008/98/EC [19][26], stating that the sludge is safe only: if the competent authority of an EU Member State considers that the relevant evidence is sufficient to assign the code ANH to this type of waste. Once recovered, the SS must be processed to ensure economical and safe transport and disposal. Depending on the type of plant, primary and secondary sludges are treated separately or together. Co-treatment options include thickening, stabilizing, dewatering, and drying the sludge. Additional and well-established methods for controlling SS include lime treatment, anaerobic digestion (AD), and composting with other organic matter. The final disposal stage is the distribution of sludge over the soil surface, incineration, and disposal. In Europe, there are technologies for extracting phosphorus and, in rare cases, nitrogen. Removal of waste for agricultural purposes usually takes place in the area adjacent to the plant to minimize transport costs.

Sulfate-reducing bacteria can use H2 to form sulfides in the presence of sulfate [28][35], even at extremely low H2 concentrations (0.02 ppm). The following equation describes the biochemical reaction:

Hydrogenotrophic methanogens can use H2 and CO2 to form CH4 [29][36]. For example, a biochemical reaction is described as the following equation:

Other H2 consumption pathways are also observed in the production of propionic, valeric, and caproic acids, and the detailed reactions can be described as follows [30][37]:

AD also contributes to a “short carbon cycle” by removing carbon from the atmosphere. Carbon from organic residues for biogas production continues to be reused in the digestate, returning it to the soil [31][38]. Biogas and biomethane production as renewable fuel sources is justified in terms of reducing greenhouse gas emissions (CO2 and CH4) in agriculture and animal husbandry, as well as for improving the climate by 2050 [32][33][34][39,40,41]. Europe is the largest producer of biogas and biomethane globally [34][41]. Globally, more than 1000 M tons of biomethane could be produced by 2040, with average costs reduced by 15% compared to prices in 2018. Thus, digestate as a biofertilizer will increase shortly, contributing to agriculture and lessening the demand for the carbon-intensive production of mineral fertilizers.

3. Treatment and Disposal Strategies for Sewage Sludge

The SS treatment methods are stabilization (composting, aerobic digestion, treatment with lime, etc.) and dewatering (air drying, vacuum filtering, centrifuging, etc.) [1][2]. The main objective of SS treatment is to produce biosolids that are safe for agricultural use (i.e., reduction or elimination of pathogens and reduction of fermentability of the final biosolids).3.1. Anaerobic Digestion

AD is the most important SS treatment method. The SS is thickened, digested, and dewatered before it is used for other applications. A useful product of AD is the biogas, consisting of 60–70% CH4, 30–40% CO2 and small quantities of H2, N2, H2S and H2O, which is used for energy production. AD consists of a series of chemical reactions that lead to the decomposition of organic materials in the absence of oxygen [1][2]. Co-digestion is the simultaneous digestion of a homogenous mixture of two or more substrates. In the case of sludge digesters, this is a very common practice, with the addition of organic waste from the food industry or households as a co-substrate. Although AD has been known for over a century, it has only been studied in depth for various commercial applications in the last three decades [20][27]. The use of AD for organic fertilizers is challenging due to the long duration of microbial reactions, usually 20–40 days. Each stage of decomposition involves a different consortium of microorganisms, belonging to both bacterial and Archean domains, with varying needs for growth. The physicochemical characteristics of the co-substrates added to the AD bioreactors at the treatment plant significantly influence the co-fermentation and the quality of the digestate. The co-digestion process increases biogas production, as there is a higher degree of volatile solids decomposition [21][28], resulting in an 82% increase in CH4 yield, and a 29.5% removal of volatile solids compared to the treatment of SS alone. Digestate obtained after AD requires additional treatment before disposal. The solid fraction obtained after digestion consists of partially decomposed organic matter and a high content of NH4+-N and minerals [22][29]. Regardless of the type of food waste, NH4+-N levels in 2540–7200 mg/kg of dry matter and humidity of 70–96% have been reported in different countries [22][29]. The content of 60–70% NH3 generates emissions and phytotoxic effect on plants [23][30]. Therefore, further stabilization through the composting process is required to improve the properties of food SS into a beneficial soil change in an environmentally sustainable manner. Ting and Lee [24][31] reported H2 and CH4 production from SS using a strain of clostridium. In this work, the authors investigated the formation of H2 and CH4 during the AD of pre-treated SS (acidified, alkalized, and frozen/thawed). Yang and Wang [25][32] provided a critical review of AD sludge handling. H2 production during sludge fermentation was observed. The primary consumers of H2 are homoacetogenic bacteria, sulfate-reducing bacteria, and hydrogenotrophic methanogens. Homoacetogenic bacteria are strictly anaerobic and can catalyze acetate formation from H2 and CO2, such as Clostridium thermoaceticum and Clostridium aceticum [26][27][33,34]. A biochemical reaction can be described by the following equation:2 HCO

3−

+ H

+

+ 4 H

2

→ CH

3

COO

−

+ 4 H

2O

O

SO

42−

+ 4 H

2

+ H

+

→ HS

−

+ 4 H

2O

O

HCO

3−

+ 4 H

2

+ H

+

→ CH

4

+ 3 H

2O

O

C

6

H

12

O

6

+ 2 H

2

→ 2 CH

3

CH

2

COOH + 2 H

2O

O

C

6

H

12

O

6

+ 4 CO

2

+ 14 H

2

→ 2 CH

3

(CH

2

)

3

COOH + 10 H

2O

O

C

6

H

12

O

6

+ 4 H

2

→ CH

3

(CH

2

)

4

COOH + 4 H

2O

O