In the context of the growing human demand for green secondary energy sources, proton-exchange membrane water electrolysis (PEMWE) is necessary to meet the high-efficiency production of high-purity hydrogen required for proton-exchange membrane fuel cells (PEMFCs). The development of stable, efficient, and low-cost oxygen evolution reaction (OER) catalysts is key to promoting the large-scale application of hydrogen production by PEMWE.

- fuel cell

- water electrolysis

- catalyst support interactions

- oxygen evolution

1. Introduction

2. Fundamentals and Current Status of Research on Acidic OER

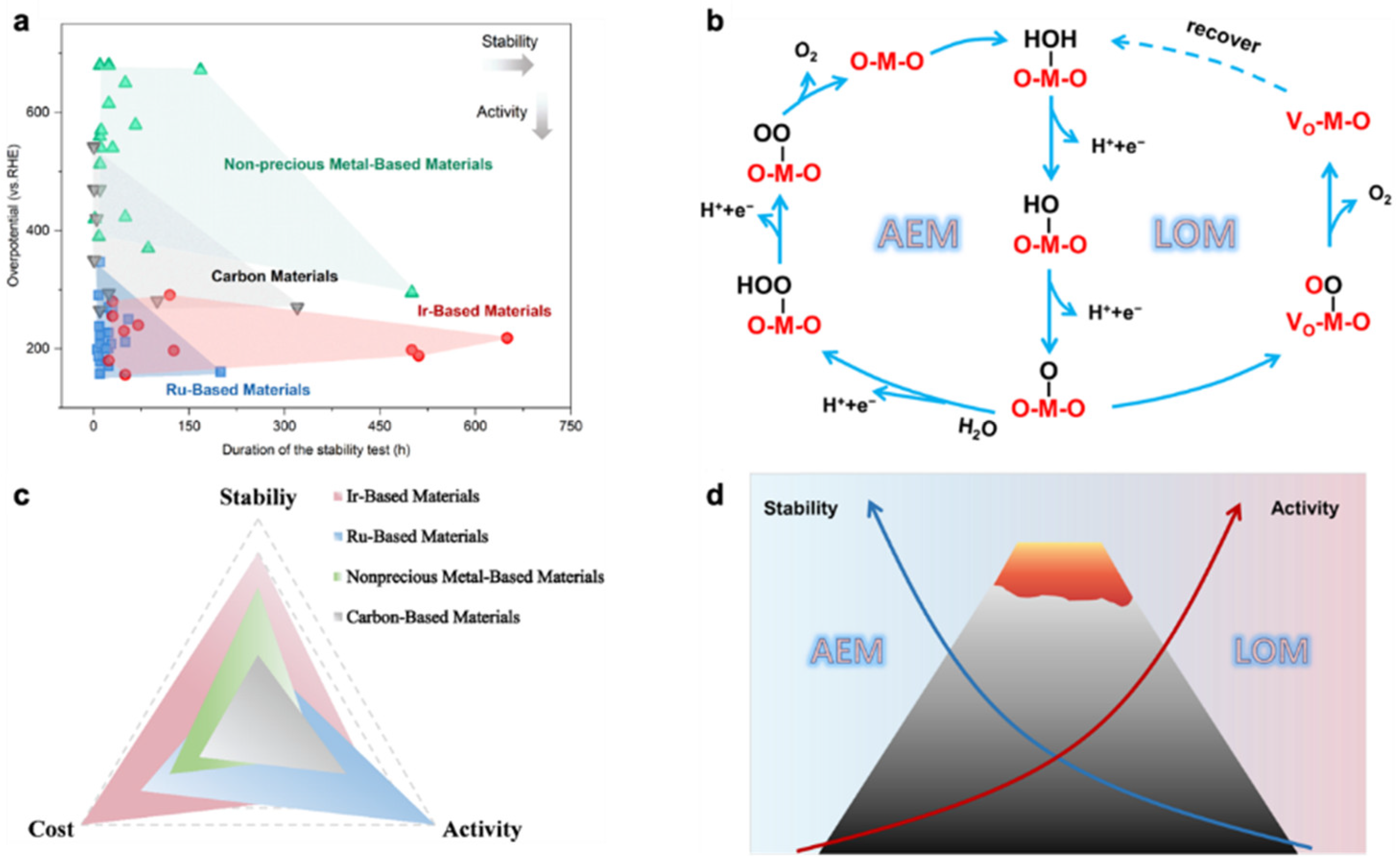

Although the O2 produced by the OER reaction is a by-product of the electrolysis of water for hydrogen production, the reaction kinetics are slower in an acidic environment due to the fact that OER is a four-electron process and requires higher energy to overcome the high potential barrier of the kinetics [14]. As a result, the anode reaction consumes the most energy process in the entire electrolytic water process. In order to reduce the overpotential, large amounts of precious metal are used in the anode catalysts. Ir-based and Ru-based catalysts exhibit impressive catalytic activity for OER reactions in acidic media [15]. It is now generally accepted that the acidic OER process is dominated by two mechanistic routes, the adsorbed evolution mechanism (AEM) and lattice oxygen mechanism (LOM) [16]. As shown in Figure 1b, the OER process through AEM involves four steps and proceeds on a single adsorption site. There is a linear relationship between the adsorption energies of O*, *OH and *OOH [17]. Utilizing isotopic labelling, researchers have investigated the contribution of lattice oxygen to OER. The results show that the acidic OER process is co-dominated by both AEM and LOM. The proportion of LOM is related to the catalyst structure [18][19]. The LOM process typically has a lower activation barrier than the AEM process. However, the LOM process can lead to degradation of the active component of the catalyst, resulting in reduced stability of the OER catalyst [16][20].

3. Support-Catalyst Interactions in Acidic OER

3.1. Metal Support Interaction (MSI)

3.1.1. Charge Transfer

Due to the difference in Fermi energy levels between metal NPs and supports, interfacial contact between NPs and supports can induce changes in the electronic structure of both supports and NPs to seek an equilibrium in the electrochemical potential, and such changes are bi-directional in nature [52]. The metallic properties of the NPs give the electrons mobility. However, the mobility is related to the nanosystem because the smaller the NP, the more localized its electronic state is. In some cases, the charge transfer may be accompanied by a change in the oxidation state of the NPs or the metal ions of the supports [53].3.1.2. Interfacial Perimeter

The interfacial region around the NPs forms a unique environment as the NPs, support and reactants make direct contact and synchronously promote the catalytic reaction. As a result, it can significantly enhance the adsorption and reactions of molecules at the perimeter [54]. The close proximity of NPs to different groups or defects (e.g., oxygen vacancies, hydroxyl groups, Lewis acids or Lewis bases) on the surface of the support may also contribute to localized sequential reactions of reactants or products, or the stabilization of transition states [38]. While this phenomenon of MSI can modulate the intensity of oxygenated intermediates adsorption by the catalyst, it accelerates the kinetics of the catalyst’s reaction to the OER process.3.1.3. Nanoparticle Morphology

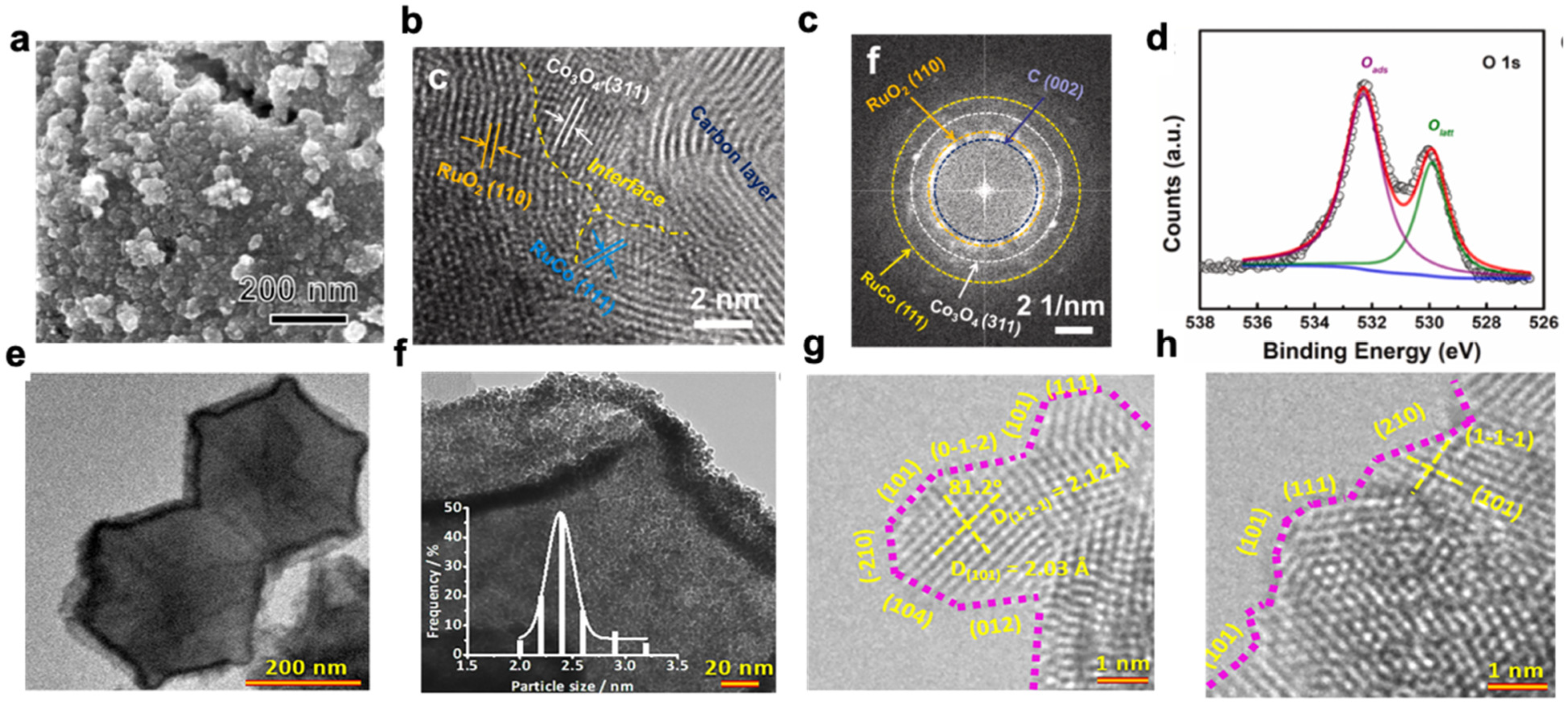

The shape and crystal structure of NPs have a strong influence on their catalytic performance. This is because NPs of different morphologies expose distinct crystalline facets, which can result in either favorable or unfavorable atomic configurations in different reactions. Therefore, the activity and selectivity of catalysts can be effectively modulated by modulating the morphology of NPs at the metal-support interface [55]. Supported iridium- and ruthenium-based NPs are potential OER catalysts for PEMWE, but the inhomogeneous dispersion of these NPs on the support and their inhomogeneous size usually leads to migration and adhesion of the catalyst at high potentials and strong acidity. Ultimately, this leads to a loss of active surface area and catalytic material, resulting in reduced OER performance.3.1.4. Chemical Composition

Solid-state reactions can occur between the metal NPs and the support, resulting in the formation of a new phase. The exchange of species is possible in both directions and is usually designed for redox reactions [55]. The local composition of alloyed metal NPs can be affected by interactions with the support, where the rearrangement of components in alloyed NPs is driven by the interaction of their elements with the support at the interface. This can lead to compositional rearrangements that differ from the initial homogeneous composition, such as sub-nanostructures like core-shells, affecting the synergy between the metal and metal active sites and thus, their catalytic performance (Figure 2) [56].

3.2. Strong Metal-Support Interaction (SMSI)

3.3. Strong Oxide-Support Interaction (SOSI)

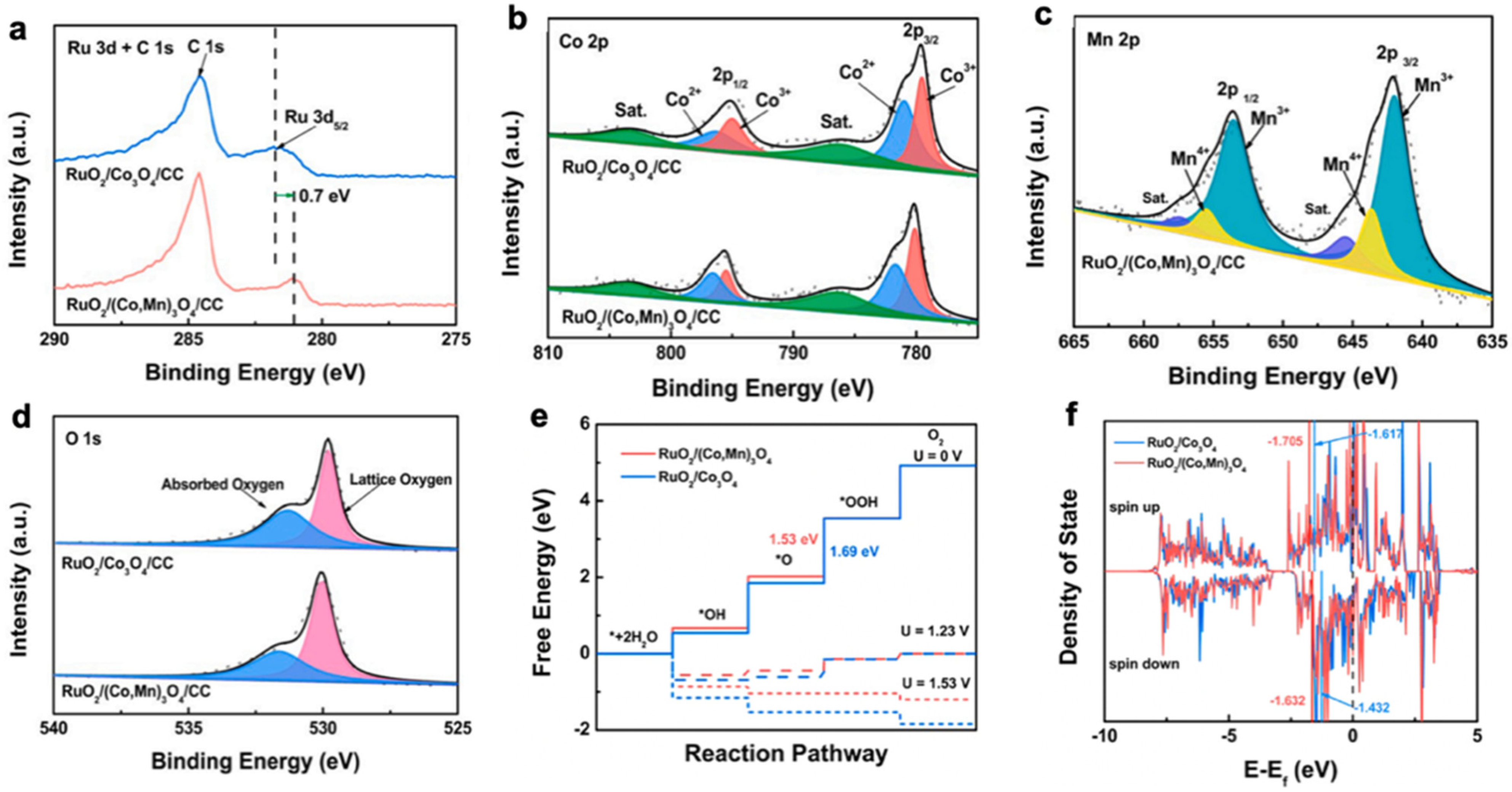

Initially, the SMSI was primarily concerned with strong interactions between metal atoms and supports, but this was gradually extended to strong interactions between metal-containing species and supports [67]. The concept of SOSI was derived to better describe the strong interactions between oxides and supports in order to distinguish them from SMSI. In general, similar to those of SMSI, SOSI has the following effects. (1) SOSI can redistribute electrons at the oxide-support interface and modulate the electronic properties of the catalytic active site. Niu et al. reported the synthesis of a RuO2/(Co, Mn)3O4 nanocomposite. The introduction of manganese in Co3O4 resulted in the redistribution of support electrons. By XPS characterization, the scholars found that RuO2/(Co, Mn)3O4 catalysts appeared as electron-rich Ru species. The adsorption of O on RuO2/(Co, Mn)3O4 was weakened as the electronic properties changed, which resulted in the rate-determining step in the OER process, i.e., the formation of OOH*, being accelerated. This cost-effective catalyst (ultra-low Ru content of 2.51 wt%) requires an overpotential of only 270 mV to achieve a current density of 10 mA cm−2 with a mass activity nearly 69 times better than that of commercial RuO2 (Figure 43) [68].

3.4. Electron-Metal-Support Interactions (EMSI)

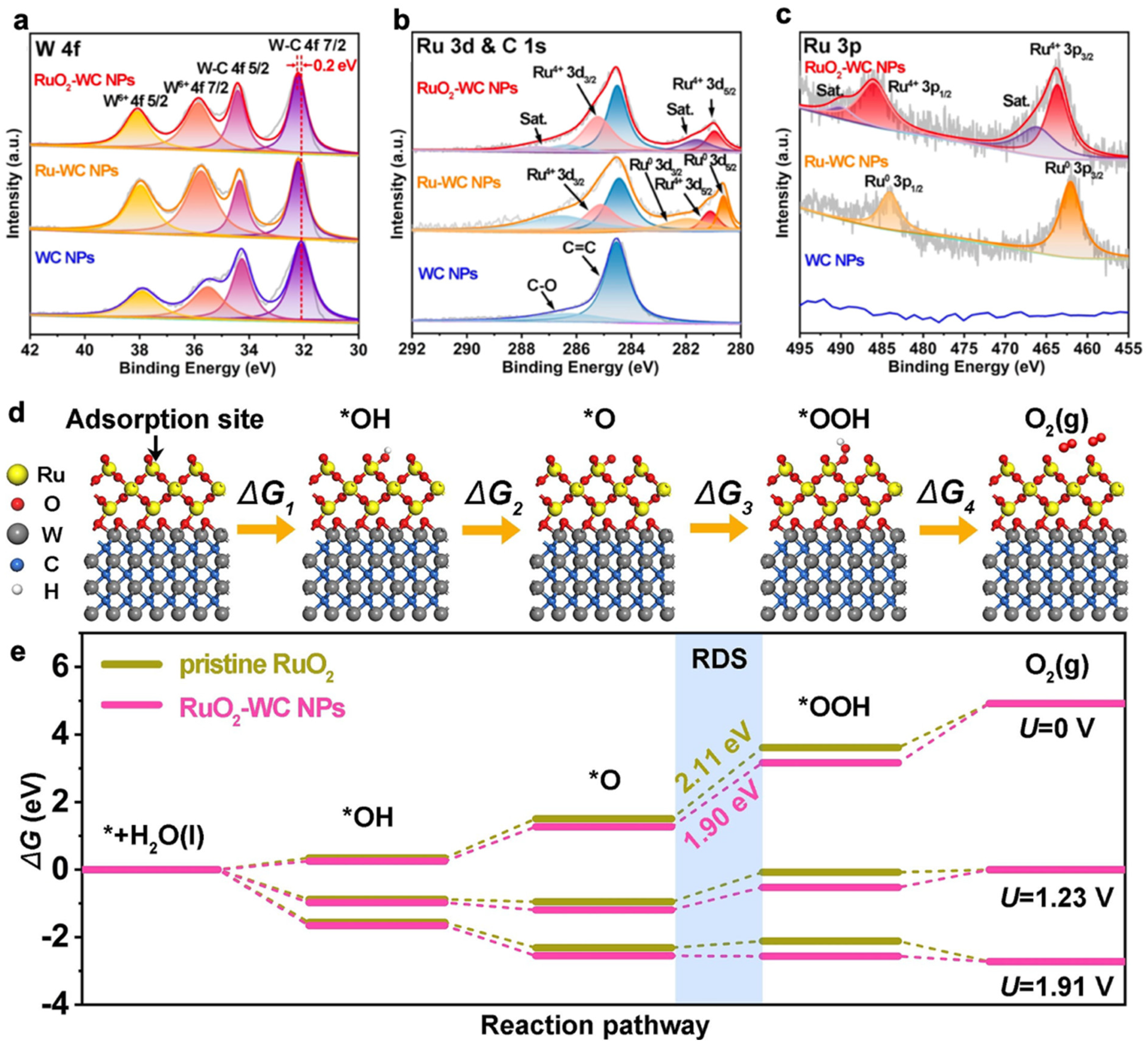

EMSI can lead to changes in the electronic structure of the metal particles and alter the adsorption and activation energies of reactant molecules, resulting in enhanced catalytic properties. In 2012, Campbell et al. first proposed electronic metal-support interactions (EMSI) based on the interaction between platinum and cerium atoms [71]. Specifically, EMSI refers to the charge redistribution phenomenon at the interface between the two, the support and the NPs, in a loaded metal nanoparticle catalyst. This is manifested as a local environmental change in the metal site, causing a change in the d-band (εd) structure of the metal. By designing and modulating EMSI, the εd of the metal can be increased, thereby enhancing the catalytic performance of the catalyst [67][71].

Catalyst systems with typical EMSI effects have been identified: metal-doped carbon (M-dN), metal-transition metal compound groups (M-TMCs) and metal-metal substrates [67]. EMSI involves the formation of chemical bonds due to the mixing of metal d-orbitals. On the one hand, this interaction stabilizes the metal NPs; on the other hand, the support effect will greatly influence the catalytic performance of the metal NPs [72][73].The energy balance at the metal-support interface reduces the activation energy of the reaction and thus increases the catalytic activity of the catalyst. The electron flow at the metal-support interface is decisive for the Fermi energy balance of the catalyst [74]. The properties of the support, the loaded metal NPs, defects, and so on can influence the electron transfer process [53]. The net electron transfer across the metal-support interface enhances the chemisorption of the metal NPs to the reactants [75].

References

- Eisenberg, R.; Gray, H.B.; Crabtree, G.W. Addressing the challenge of carbon-free energy. Proc. Natl. Acad. Sci. USA 2020, 117, 12543–12549.

- Dincer, I.; Acar, C. Review and evaluation of hydrogen production methods for better sustainability. Int. J. Hydrogen Energy 2015, 40, 11094–11111.

- Herron, J.A.; Kim, J.; Upadhye, A.A.; Huber, G.W.; Maravelias, C.T. A general framework for the assessment of solar fuel technologies. Energy Environ. Sci. 2015, 8, 126–157.

- Feustel, J. Possibilities and limitations of wind energy utilisation. Int. J. Ambient. Energy 2011, 2, 197–205.

- Fouz, D.M.; Carballo, R.; López, I.; Iglesias, G. Tidal stream energy potential in the Shannon Estuary. Renew. Energy 2022, 185, 61–74.

- Nosratabadi, S.M.; Hemmati, R.; Bornapour, M.; Abdollahpour, M. Economic evaluation and energy/exergy analysis of PV/Wind/PEMFC energy resources employment based on capacity, type of source and government incentive policies: Case study in Iran. Sustain. Energy Technol. Assess. 2021, 43, 100963.

- O’Connell, A.; Kelly, A.L.; Tobin, J.; Ruegg, P.L.; Gleeson, D. The effect of storage conditions on the composition and functional properties of blended bulk tank milk. J. Dairy Sci. 2017, 100, 991–1003.

- Oetjen, H.F.; Schmidt, V.M.; Stimming, U.; Trila, F. Performance Data of a Proton Exchange Membrane Fuel Cell Using H2/CO as Fuel Gas. J. Electrochem. Soc. 1996, 143, 3838.

- Zhao, Y.; Mao, Y.; Zhang, W.; Tang, Y.; Wang, P. Reviews on the effects of contaminations and research methodologies for PEMFC. Int. J. Hydrogen Energy 2020, 45, 23174–23200.

- Balaji, R.; Senthil, N.; Vasudevan, S.; Ravichandran, S.; Mohan, S.; Sozhan, G.; Madhu, S.; Kennedy, J.; Pushpavanam, S.; Pushpavanam, M. Development and performance evaluation of Proton Exchange Membrane (PEM) based hydrogen generator for portable applications. Int. J. Hydrogen Energy 2011, 36, 1399–1403.

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A comprehensive review on PEM water electrolysis. Int. J. Hydrogen Energy 2013, 38, 4901–4934.

- Chen, Y.; Liu, C.; Xu, J.; Xia, C.; Wang, P.; Xia, B.Y.; Yan, Y.; Wang, X. Key Components and Design Strategy for a Proton Exchange Membrane Water Electrolyzer. Small Struct. 2022, 27, 2200130.

- Shiva Kumar, S.; Himabindu, V. Hydrogen production by PEM water electrolysis—A review. Mater. Sci. Energy Technol. 2019, 2, 442–454.

- Fabbri, E.; Schmidt, T.J. Oxygen Evolution Reaction—The Enigma in Water Electrolysis. ACS Catal. 2018, 8, 9765–9774.

- Gao, J.; Tao, H.; Liu, B. Progress of Nonprecious-Metal-Based Electrocatalysts for Oxygen Evolution in Acidic Media. Adv. Mater. 2021, 33, e2003786.

- Song, J.; Wei, C.; Huang, Z.F.; Liu, C.; Zeng, L.; Wang, X.; Xu, Z.J. A review on fundamentals for designing oxygen evolution electrocatalysts. Chem. Soc. Rev. 2020, 49, 2196–2214.

- Ma, Q.; Mu, S. Acidic oxygen evolution reaction: Mechanism, catalyst classification, and enhancement strategies. Interdiscip. Mater. 2023, 2, 53–90.

- Shi, Z.; Wang, Y.; Li, J.; Wang, X.; Wang, Y.; Li, Y.; Xu, W.; Jiang, Z.; Liu, C.; Xing, W.; et al. Confined Ir single sites with triggered lattice oxygen redox: Toward boosted and sustained water oxidation catalysis. Joule 2021, 5, 2164–2176.

- Xu, X.; Pan, Y.; Zhong, Y.; Shi, C.; Guan, D.; Ge, L.; Hu, Z.; Chin, Y.Y.; Lin, H.J.; Chen, C.T.; et al. New Undisputed Evidence and Strategy for Enhanced Lattice-Oxygen Participation of Perovskite Electrocatalyst through Cation Deficiency Manipulation. Adv. Sci. 2022, 9, e2200530.

- Yoo, J.S.; Rong, X.; Liu, Y.; Kolpak, A.M. Role of Lattice Oxygen Participation in Understanding Trends in the Oxygen Evolution Reaction on Perovskites. ACS Catal. 2018, 8, 4628–4636.

- Luo, R.; Qian, Z.; Xing, L.; Du, C.; Yin, G.; Zhao, S.; Du, L. Re-Looking into the Active Moieties of Metal X-ides (X-=Phosph-, Sulf-, Nitr-, and Carb-) Toward Oxygen Evolution Reaction. Adv. Funct. Mater. 2021, 31, 2102918.

- Han, H.; Kim, I.; Park, S. Cobalt-based oxygen evolution catalyst as active and stable as iridium in acidic media. Electrochim. Acta 2020, 344, 136160.

- Wen, Y.; Chen, P.; Wang, L.; Li, S.; Wang, Z.; Abed, J.; Mao, X.; Min, Y.; Dinh, C.T.; Luna, P.; et al. Highly Active Ru Sites by Suppressing Lattice Oxygen Participation in Acidic Water Oxidation. J. Am. Chem. Soc. 2021, 143, 6482–6490.

- Liu, Z.; Liu, Y.; He, H.; Shao, H.; Zhang, Y.; Li, J.; Cai, W. Valence regulation of Ru/Mo2C heterojunction for efficient acidic overall water splitting. Electrochim. Acta 2023, 443, 141920.

- Yao, Q.; Huang, B.; Xu, Y.; Li, L.; Shao, Q.; Huang, X. A chemical etching strategy to improve and stabilize RuO2-based nanoassemblies for acidic oxygen evolution. Nano Energy 2021, 84, 105909.

- Guo, H.; Fang, Z.; Li, H.; Fernandez, D.; Henkelman, G.; Humphrey, S.M.; Yu, G. Rational Design of Rhodium-Iridium Alloy Nanoparticles as Highly Active Catalysts for Acidic Oxygen Evolution. ACS Nano 2019, 13, 13225–13234.

- Li, H.; Liu, H.; Qin, Q.; Liu, X. BaLaIr double mixed metal oxides as competitive catalysts for oxygen evolution electrocatalysis in acidic media. Inorg. Chem. Front. 2022, 9, 702–708.

- Ying, Y.; Godinez Salomon, J.F.; Lartundo-Rojas, L.; Moreno, A.; Meyer, R.; Damin, C.A.; Rhodes, C.P. Hydrous cobalt-iridium oxide two-dimensional nanoframes: Insights into activity and stability of bimetallic acidic oxygen evolution electrocatalysts. Nanoscale Adv. 2021, 3, 1976–1996.

- Sharma, L.; Katiyar, N.K.; Parui, A.; Das, R.; Kumar, R.; Tiwary, C.S.; Singh, A.K.; Halder, A.; Biswas, K. Low-cost high entropy alloy (HEA) for high-efficiency oxygen evolution reaction (OER). Nano Res. 2021, 15, 4799–4806.

- Zhao, J.-W.; Shi, Z.-X.; Li, C.-F.; Ren, Q.; Li, G.-R. Regulation of Perovskite Surface Stability on the Electrocatalysis of Oxygen Evolution Reaction. ACS Mater. Lett. 2021, 3, 721–737.

- Liu, W.; Kawano, K.; Kamiko, M.; Kato, Y.; Okazaki, Y.; Yamada, I.; Yagi, S. Effects of A-site Cations in Quadruple Perovskite Ruthenates on Oxygen Evolution Catalysis in Acidic Aqueous Solutions. Small 2022, 18, e2202439.

- Liang, X.; Shi, L.; Liu, Y.; Chen, H.; Si, R.; Yan, W.; Zhang, Q.; Li, G.D.; Yang, L.; Zou, X. Activating Inert, Nonprecious Perovskites with Iridium Dopants for Efficient Oxygen Evolution Reaction under Acidic Conditions. Angew. Chem. Int. Ed. Engl. 2019, 58, 7631–7635.

- Chen, H.; Shi, L.; Sun, K.; Zhang, K.; Liu, Q.; Ge, J.; Liang, X.; Tian, B.; Huang, Y.; Shi, Z.; et al. Protonated Iridate Nanosheets with a Highly Active and Stable Layered Perovskite Framework for Acidic Oxygen Evolution. ACS Catal. 2022, 12, 8658–8666.

- Zhang, T.; Zhang, B.; Peng, Q.; Zhou, J.; Sun, Z. Mo2B2 MBene-supported single-atom catalysts as bifunctional HER/OER and OER/ORR electrocatalysts. J. Mater. Chem. A 2021, 9, 433–441.

- Cao, L.; Luo, Q.; Chen, J.; Wang, L.; Lin, Y.; Wang, H.; Liu, X.; Shen, X.; Zhang, W.; Liu, W.; et al. Dynamic oxygen adsorption on single-atomic Ruthenium catalyst with high performance for acidic oxygen evolution reaction. Nat. Commun. 2019, 10, 4849.

- Yin, J.; Jin, J.; Lu, M.; Huang, B.; Zhang, H.; Peng, Y.; Xi, P.; Yan, C.H. Iridium Single Atoms Coupling with Oxygen Vacancies Boosts Oxygen Evolution Reaction in Acid Media. J. Am. Chem. Soc. 2020, 142, 18378–18386.

- Gao, Z.; Lai, Y.; Gong, L.; Zhang, L.; Xi, S.; Sun, J.; Zhang, L.; Luo, F. Robust Th-MOF-Supported Semirigid Single-Metal-Site Catalyst for an Efficient Acidic Oxygen Evolution Reaction. ACS Catal. 2022, 12, 9101–9113.

- Li, S.; Gao, Y.; Li, N.; Ge, L.; Bu, X.; Feng, P. Transition metal-based bimetallic MOFs and MOF-derived catalysts for electrochemical oxygen evolution reaction. Energy Environ. Sci. 2021, 14, 1897–1927.

- Singh, K.; Guillen Campos, J.d.J.; Dinic, F.; Hao, Z.; Yuan, T.; Voznyy, O. Manganese MOF Enables Efficient Oxygen Evolution in Acid. ACS Mater. Lett. 2020, 2, 798–800.

- Li, Z.; Zou, J.; Liang, T.; Song, X.; Li, Z.; Wen, J.; Peng, M.; Zeng, X.; Huang, H.; Wu, H. MOF-derived ultrasmall 2 heterostructures as bifunctional and pH-universal electrocatalysts for 0.79 V asymmetric amphoteric overall water splitting. Chem. Eng. J. 2023, 460, 141672.

- Patel, K.B.; Parmar, B.; Ravi, K.; Patidar, R.; Chaudhari, J.C.; Srivastava, D.N.; Bhadu, G.R. Metal-organic framework derived core-shell nanoparticles as high performance bifunctional electrocatalysts for HER and OER. Appl. Surf. Sci. 2023, 616, 156499.

- Li, S.; Lei, X.; Hu, H.; Fu, L.; Peng, R.; Huang, H.; Wang, J. Flaky cobalt phosphide-modified manganese iron oxide as a highly efficient OER catalyst. New J. Chem. 2021, 45, 11797–11802.

- Li, A.; Sun, Y.; Yao, T.; Han, H. Earth-Abundant Transition-Metal-Based Electrocatalysts for Water Electrolysis to Produce Renewable Hydrogen. Chemistry 2018, 24, 18334–18355.

- Lin, Y.; Zhang, M.; Zhao, L.; Wang, L.; Cao, D.; Gong, Y. Ru doped bimetallic phosphide derived from 2D metal organic framework as active and robust electrocatalyst for water splitting. Appl. Surf. Sci. 2021, 536, 147952.

- Zhou, Y.-N.; Yu, N.; Lv, Q.-X.; Liu, B.; Dong, B.; Chai, Y.-M. Surface evolution of Zn doped-RuO2 under different etching methods towards acidic oxygen evolution. J. Mater. Chem. A 2022, 10, 16193–16203.

- Zhang, H.; Wu, B.; Su, J.; Zhao, K.; Chen, L. MOF-Derived Zinc-Doped Ruthenium Oxide Hollow Nanorods as Highly Active and Stable Electrocatalysts for Oxygen Evolution in Acidic Media. ChemNanoMat 2021, 7, 117–121.

- Park, Y.J.; Lee, J.; Park, Y.S.; Yang, J.; Jang, M.J.; Jeong, J.; Choe, S.; Lee, J.W.; Kwon, J.D.; Choi, S.M. Electrodeposition of High-Surface-Area IrO2 Films on Ti Felt as an Efficient Catalyst for the Oxygen Evolution Reaction. Front. Chem. 2020, 8, 593272.

- Gou, W.; Zhang, M.; Zou, Y.; Zhou, X.; Qu, Y. Iridium-Chromium Oxide Nanowires as Highly Performed OER Catalysts in Acidic Media. ChemCatChem 2019, 11, 6008–6014.

- Liu, H.; Wang, Z.; Li, M.; Zhao, X.; Duan, X.; Wang, S.; Tan, G.; Kuang, Y.; Sun, X. Rare-earth-regulated Ru-O interaction within the pyrochlore ruthenate for electrocatalytic oxygen evolution in acidic media. Sci. China Mater. 2021, 64, 1653–1661.

- Gao, L.; Zhong, X.; Chen, J.; Zhang, Y.; Liu, J.; Zhang, B. Optimizing the electronic structure of Fe-doped Co3O4 supported Ru catalyst via metal-support interaction boosting oxygen evolution reaction and hydrogen evolution reaction. Chin. Chem. Lett. 2022, 108085.

- Karim, W.; Spreafico, C.; Kleibert, A.; Gobrecht, J.; VandeVondele, J.; Ekinci, Y.; van Bokhoven, J.A. Catalyst support effects on hydrogen spillover. Nature 2017, 541, 68–71.

- Wurster, B.; Grumelli, D.; Hotger, D.; Gutzler, R.; Kern, K. Driving the Oxygen Evolution Reaction by Nonlinear Cooperativity in Bimetallic Coordination Catalysts. J. Am. Chem. Soc. 2016, 138, 3623–3626.

- Pacchioni, G. Electronic interactions and charge transfers of metal atoms and clusters on oxide surfaces. Phys. Chem. Chem. Phys. 2013, 15, 1737–1757.

- Zhang, B.; Qin, Y. Interface Tailoring of Heterogeneous Catalysts by Atomic Layer Deposition. ACS Catal. 2018, 8, 10064–10081.

- Van Deelen, T.W.; Hernández Mejía, C.; de Jong, K.P. Control of metal-support interactions in heterogeneous catalysts to enhance activity and selectivity. Nat. Catal. 2019, 2, 955–970.

- Tauster, S.J.; Fung, S.C.; Garten, R.L. Group 8 noble metals supported on TiO2. J. Am. Chem. Soc. 1978, 100, 100–175.

- Xu, J.; Li, J.; Lian, Z.; Araujo, A.; Li, Y.; Wei, B.; Yu, Z.; Bondarchuk, O.; Amorim, I.; Tileli, V.; et al. Atomic-Step Enriched Ruthenium–Iridium Nanocrystals Anchored Homogeneously on MOF-Derived Support for Efficient and Stable Oxygen Evolution in Acidic and Neutral Media. ACS Catal. 2021, 11, 3402–3413.

- Liu, X.; Liu, M.H.; Luo, Y.C.; Mou, C.Y.; Lin, S.D.; Cheng, H.; Chen, J.M.; Lee, J.F.; Lin, T.S. Strong metal-support interactions between gold nanoparticles and ZnO nanorods in CO oxidation. J. Am. Chem. Soc. 2012, 134, 10251–10258.

- Matsubu, J.C.; Zhang, S.; DeRita, L.; Marinkovic, N.S.; Chen, J.G.; Graham, G.W.; Pan, X.; Christopher, P. Adsorbate-mediated strong metal-support interactions in oxide-supported Rh catalysts. Nat. Chem. 2017, 9, 120–127.

- Dong, J.; Fu, Q.; Li, H.; Xiao, J.; Yang, B.; Zhang, B.; Bai, Y.; Song, T.; Zhang, R.; Gao, L.; et al. Reaction-Induced Strong Metal-Support Interactions between Metals and Inert Boron Nitride Nanosheets. J. Am. Chem. Soc. 2020, 142, 17167–17174.

- Xu, W.; Huang, H.; Wu, X.; Yuan, Y.; Liu, Y.; Wang, Z.; Zhang, D.; Qin, Y.; Lai, J.; Wang, L. Mn-doped Ru/RuO2 with strong metal-support interaction for efficient water splitting in acidic media. Compos. Part B Eng. 2022, 242, 110013.

- Tang, H.; Su, Y.; Zhang, B.; Lee, A.F.; Isaacs, M.A.; Wilson, K.; Li, L.; Ren, Y.; Huang, J.; Haruta, M.; et al. Classical strong metal–support interactions between gold nanoparticles and titanium dioxide. Sci. Adv. 2017, 3, e1700231.

- Burch, R.; Flambard, A.R. Strong Metal-Support Interactions in Nickel/Titania Catalysts: The Importance of Interfacial Phenomena. J. Catal. 1982, 78, 389–405.

- Jin, L.; Liu, B.; Louis, M.E.; Li, G.; He, J. Highly Crystalline Mesoporous Titania Loaded with Monodispersed Gold Nanoparticles: Controllable Metal-Support Interaction in Porous Materials. ACS Appl. Mater. Interfaces 2020, 12, 9617–9627.

- Wu, J.; Liu, M.; Chatterjee, K.; Hackenberg, K.P.; Shen, J.; Zou, X.; Yan, Y.; Gu, J.; Yang, Y.; Lou, J.; et al. Exfoliated 2D Transition Metal Disulfides for Enhanced Electrocatalysis of Oxygen Evolution Reaction in Acidic Medium. Adv. Mater. Interfaces 2016, 3, 1500669.

- Chakrapani, V.; Thangala, J.; Sunkara, M.K. WO3 and W2N nanowire arrays for photoelectrochemical hydrogen production. Int. J. Hydrogen Energy 2009, 34, 9050–9059.

- Yang, J.; Li, W.; Wang, D.; Li, Y. Electronic Metal–Support Interaction of Single-Atom Catalysts and Applications in Electrocatalysis. Adv. Mater. 2020, 32, 2003300.

- Niu, S.; Kong, X.-P.; Li, S.; Zhang, Y.; Wu, J.; Zhao, W.; Xu, P. Low Ru loading RuO2/(Co,Mn)3O4 nanocomposite with modulated electronic structure for efficient oxygen evolution reaction in acid. Appl. Catal. B Environ. 2021, 297, 120442.

- Zheng, X.; Qin, M.; Ma, S.; Chen, Y.; Ning, H.; Yang, R.; Mao, S.; Wang, Y. Strong Oxide-Support Interaction over IrO2/V2 O5 for Efficient pH-Universal Water Splitting. Adv. Sci. 2022, 9, e2104636.

- Sun, S.C.; Jiang, H.; Chen, Z.Y.; Chen, Q.; Ma, M.Y.; Zhen, L.; Song, B.; Xu, C.Y. Bifunctional WC-Supported RuO2 Nanoparticles for Robust Water Splitting in Acidic Media. Angew. Chem. Int. Ed. 2022, 61, e202202519.

- Campbell, C.T. Catalyst-support interactions: Electronic perturbations. Nat. Chem. 2012, 4, 597–598.

- Shi, Y.; Wang, J.; Wang, C.; Zhai, T.T.; Bao, W.J.; Xu, J.J.; Xia, X.H.; Chen, H.Y. Hot electron of Au nanorods activates the electrocatalysis of hydrogen evolution on MoS2 nanosheets. J. Am. Chem. Soc. 2015, 137, 7365–7370.

- Lykhach, Y.; Kozlov, S.M.; Skala, T.; Tovt, A.; Stetsovych, V.; Tsud, N.; Dvorak, F.; Johanek, V.; Neitzel, A.; Myslivecek, J.; et al. Counting electrons on supported nanoparticles. Nat. Mater. 2016, 15, 284–288.

- Losurdo, M.; Yi, C.; Suvorova, A.; Rubanov, S.; Kim, T.H.; Giangregorio, M.M.; Jiao, W.; Bergmair, I.; Bruno, G.; Brown, A.S. Demonstrating the Capability of the High-Performance Plasmonic Gallium–Graphene Couple. ACS Nano 2014, 8, 3031–3034.

- Chen, G.; Xu, C.; Huang, X.; Ye, J.; Gu, L.; Li, G.; Tang, Z.; Wu, B.; Yang, H.; Zhao, Z.; et al. Interfacial electronic effects control the reaction selectivity of platinum catalysts. Nat. Mater. 2016, 15, 564–569.