Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Jie Shi and Version 1 by Jie Shi.

Green hydrogen, green ammonia, and green methanol are being widely discussed for shipping. Because green methanol and ammonia have higher energy densities and are relatively easier to transport and store on ships, they have become the most promising near-zero-emission marine fuel. In addition, since most of the production pathways for green fuel require green power, the production methods for green power are analyzed in detail.

- green hydrogen

- green ammonia

- green methanol

- green power

1. Introduction

Marine engines mainly use low-quality fuel with high sulfur content, high viscosity, and heavy metals, such as cadmium, vanadium, and lead. The complexity of low-quality fuel components leads to more exhaust pollutants from ships. The substances represented by nitrogen oxides (NOx), sulfur oxides (SOx), particulate matter (PM), and carbon dioxide (CO2) have a great impact on human health, the environment, and the climate [1]. After-treatment technology is often used to purify exhaust gas, such as selective catalytic reduction (SCR) technology or exhaust gas recirculation (EGR) technology to purify NOx [2,3,4,5], exhaust gas cleaning (EGC) technology to purify SOx [6], and carbon capture technology to purify CO2 [7].

From the perspective of energy technology, since fossil fuel are used, internal combustion engines inevitably emit a large amount of CO2. It is difficult to achieve carbon emission reduction development strategies and goals by relying solely on existing energy efficiency improvement methods [10]. The maritime industry is paying increasing attention to the development and application of low-carbon marine fuel. But little attention has been paid to the green fuel pathway from renewable energy to shipping. The main green fuel production processes are based on green power technology. Therefore, analyze green power production technologies with the intent to gain a better understanding of green fuel production technologies.

2. Electrochemical Energy and Carbon Cycle

2.1. Carbon Capture and Carbon Cycling

Undisturbed, carbon moves between each reservoir in an exchange known as the carbon cycle, which maintains relatively stable carbon concentrations in the atmosphere, on land, in plants, and in oceans. This balance helps to keep the Earth’s temperature relatively stable [24]. However, today, due to the continuous intensive use of fossil fuel, land-use change, and other human activities, the concentration of CO2 in the atmosphere is rising at an unprecedented rate; the carbon cycle is disrupted, and a large amount of CO2 enters the atmosphere, causing the Earth’s temperature to rise [25]. In general, there are two ways to remove CO2. One is to attempt to accelerate the absorption of atmospheric CO2 by enhancing natural sinks, such as afforestation to increase carbon storage in biomass [26]. Another way is to reduce CO2 through artificial methods, such as carbon capture technology [27,28], which is currently popular. As a result, it is increasingly necessary to remove the CO2 emitted by humans to achieve net-zero CO2 emission. Carbon capture technologies include carbon capture and storage (CCS) and carbon capture and utilization (CCU). The captured CO2 can be stored in geological formations as well as in the oceans. In addition to storage, CO2 can be used directly in different industrial sectors, including the food, beverage, and pharmaceutical industries. It can also be converted into high-demand products such as urea, methanol, and biofuels. Although both CCS and CCU technologies seek to mitigate climate change, they can only be seen as temporary solutions, as they merely delay CO2 emissions rather than permanently eliminate them [29]. Compared to CCS, CCU may play a small role in mitigating climate change. However, CCU may offer a very cost-effective option for CO2 abatement, and even generate profits in some cases. One option that could be deployed on a large scale is the conversion of CO2 into fuel. However, this would require significant progress in catalysis and process design. In addition, this route will not store CO2 for a long time but will provide carbon-neutral fuel under the best conditions [30]. CO2 utilization focuses on the reduction of CO2 emissions, which is the end problem of today’s industry. Artz et al. [31] provided a detailed review of the methods and processes of CO2 conversion, which sought to identify opportunities, through the development of new feedstocks, to avoid the use of fossil resources in the transition to a more sustainable future of production. Furthermore, the current rate of CO2 emissions and the variable nature of point sources suggest that capture at the point of emission alone is not sufficient to mitigate the increasing greenhouse effect of CO2. Large-scale deployment of technologies involving the direct capture of CO2 from the atmosphere is essential [32]. Electrochemical CO2 capture technology is interesting due to its flexibility and its ability to address dispersed emissions (e.g., atmospheric). Although electrochemical CO2 capture technology is costly compared to amine-based capture, it could be particularly interesting if cheaper renewable electricity and materials (e.g., electrodes and membranes) become widely available. In addition, electrochemical methods can convert captured CO2 into value-added chemicals and fuel, thus preparing the way for a fully electrified circular carbon economy [33]. Galimova et al. [34] analyzed the global demand for CO2 as a feedstock for fuel and chemical production during the global energy transition to 100% renewable energy. The CO2 capture and utilization potential of key industrial point sources, including cement plants, pulp and paper mills, and waste incinerators, were assessed. According to the study’s estimates, the demand for carbon dioxide will increase from 0.6 million tons in 2030 to 6.1 billion tons in 2050. Key industrial point sources are likely to supply 2.1 billion tons of CO2 to meet most demand in the 2030s. By 2050, however, direct air capture is expected to meet most of the demand, producing 3.8 billion tons of CO2 a year. The application of carbon capture on board ships could be a transitional solution to reducing CO2 emissions from the maritime industry in the short term, providing the time necessary to fully develop and implement zero-emission technologies. There are three main types of carbon capture technologies available: pre-combustion carbon capture, post-combustion carbon capture, and O2 fuel combustion capture. Post-combustion carbon capture, which captures CO2 from the exhaust of the ship, has gained widespread interest. This process is suitable for ships sailing on conventional carbon-containing fuel and is expected to mature and be commercialized earlier than alternative fuel because it is based on proven technology and does not require as much research and development as alternative fuel. Luo et al. [35] explored how a solvent-based carbon capture process could be applied to capture CO2 from a typical cargo ship’s energy system, with a capture cost of EUR 77.50/tonne CO2 at a carbon capture rate of 73%. Feenstra et al. [36] evaluated a 3000 kW LNG carrier-based carbon capture. The cost of using 30 wt % aqueous monoethanolamine was EUR 120/tonne CO2, and the cost of using aqueous piperazine was EUR 98/tonne CO2, both of which had 90% capture efficiency. The implementation of amine-based carbon capture systems on board ships was evaluated by Stec et al. [37], with total CO2 recovery rates ranging from 31.4% to 56.5%. Long et al. [38] developed an efficient sea-based CO2 capture, CO2 compression, and liquefaction technology for a 3000 kW diesel engine, with a CO2 removal rate of 94.7%. Ros et al. [39] discussed advances in marine carbon capture technology for LNG ships, based on the results of the DerisCO2 project. Oh et al. [40] presented a membrane carbon capture and liquefaction system for LNG ships with much smaller dimensions compared to conventional amine-based processes. Carbon capture technology on board ships shows great potential for carbon reduction; however, the cost is one of the barriers to the development of carbon capture on board. As emissions regulations become more stringent, conventional ships need to install not only after-treatment units to remove pollutants such as NOx and SOx, but also carbon capture units to remove CO2, which inevitably takes up valuable space on board, and the physical operating conditions on board are becoming a barrier to the application of carbon capture [41].2.2. Renewable Energy and Green Power

Renewable energy sources are naturally replenished and never depleted on Earth; they include bioenergy, hydropower, geothermal, solar, wind, and ocean (tidal and wave) energy [42]. To harness wind energy on modern ships, a range of wind-assisted ship propulsion (WASP) products have been developed and tested [43]: rotors, towing kites, suction wings, rigid sails/wing sails, soft sails, wind turbines, and hull sails. Wang et al. [44] proposed an integrated collaborative decision-making approach to optimizing the energy consumption of sail-assisted ship, which can make full use of wind energy while keeping the hybrid system operating at optimal conditions under various operating conditions and can reduce energy consumption and CO2 emissions by approximately 8.9% during a single voyage. However, the high-cost investment in research into WASP and the uncertainty about reducing fuel consumption have limited WASP in the maritime industry. Ships harness solar energy by using photovoltaic installations: sunlight is converted into electricity by photovoltaic systems installed on board; this electricity is temporarily stored in batteries and then used for propulsion or to supply electrical equipment. Solar energy on ships is very promising, but the question remains as to how to install more PV panels in the limited area on the ship’s deck to increase the installed capacity of the PV system. Even in areas with sufficient solar radiation, it is not feasible to connect the PV system directly to the ship’s main grid due to the low conversion efficiency of the PV panels [45]. Waves can damage coastal structures and affect the stability of a ship, increasing the resistance of a ship underway and even leading to capsizing. If used properly, wave energy can be converted into propulsion for the ship, reducing the interference of waves with the ship’s stability, but this requires devices capable of extracting wave energy [46]. However, in general, if wave energy is used while the ship is sailing, the wave energy device needs to be in direct contact with the water surface, which undoubtedly increases the contact area between the ship and the water surface, causing additional resistance to the ship’s navigation. This may also affect the stability of the ship due to the weight of the device. Wind and solar energy are undoubtedly the most promising renewable energy sources for ships. However, they are hardly used as the main power source for ships and are generally used as auxiliary power sources to reduce CO2 emissions. For the above reasons, alternative ways of applying renewable energy to ships are needed. Green fuel produced from renewable energy can be used as the main power for ships, so this paper is concerned with methods of producing green fuel for ships from renewable energy. The main green fuel production processes are based on green power technology. Green power [47] refers to electricity supplied from more readily renewable energy sources than traditional electrical power sources. The following subsection, therefore, analyzes green power production technologies with the intent to gain a better understanding of green fuel production technologies, as discussed in Section 3.2.2.1. Hydropower

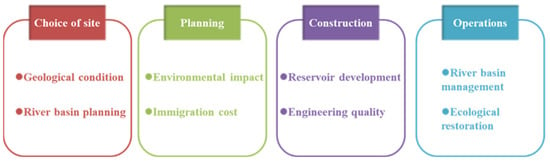

Hydropower [48] is a renewable energy source where power is derived from the energy of water moving from higher to lower elevations. It is a proven, mature, predictable, and price-competitive technology. Hydropower has among the best conversion efficiencies of all known energy sources (about 90% efficiency). Hydropower projects are usually classified into four major types: run of river, storage (reservoir)-based, pumped storage, and instream technologies (hydrokinetic). Kougias et al. [49] reviewed recent research and development activities in the field of hydropower technology, including the following topics: (1) techniques supporting the wide-range operation of hydraulic turbines; (2) instabilities in Francis turbines of pumped hydro energy storage stations; (3) the digitalization of hydropower operation; (4) hydro generators with current-controlled rotors; (5) variable speed hydropower generation; (6) innovative concepts in hydroelectric energy storage; (7) novel technologies in small-scale hydropower; and (8) fish-friendly hydropower technologies. With rapid economic development and the global need to reduce carbon emissions, hydropower is playing a greater role than ever before as an important source of clean energy. For examples, hydropower plays an important role in stabilizing Poland’s power generation system [50] and is the best option for meeting Southeast Asia’s energy needs [51]. However, the environmental impact of hydropower is controversial. Developed countries have stopped building dams because the best sites for them have been developed and because environmental and social issues make the costs unacceptable. Today, more dams are being removed than are being built in North America and Europe. The hydropower industry began building dams in developing countries and, since the 1970s, has begun building larger hydropower dams in the Mekong, Amazon, and Congo river basins. The same problems are being repeated [52]: destruction of river ecology, deforestation, loss of aquatic and terrestrial biodiversity, release of large amounts of greenhouse gases, displacement of thousands of people, change of livelihoods, and impact on nearby food systems, water quality, and agriculture. The widespread perception that a small run-of-river hydropower plant is a renewable energy source with little or no environmental impact has led to a global spread [53]. However, it may alter natural flow regimes and damage river ecosystems. Pata et al. [54] investigated the relationship between hydropower energy consumption, ecological footprint, and economic growth in the top six hydropower-consuming countries (China, Canada, Brazil, the US, Norway, and India, as of 2016). In terms of policies’ impact, policies to encourage the use of hydropower energy can be implemented in China and Brazil, which saw the fastest growth in hydropower energy consumption over a 52-year period (1965–2016). From an economic perspective, the efficient use of hydropower and the increase of investment in hydropower energy in China and Brazil were appropriate policies to support economic growth. Concerning the relationship between the environmental and ecological footprints, the environment should be taken into account when implementing economic policies in the USA and Norway. In Canada and India, the causal relationship between the environmental footprint and the ecological footprint showed that environmental issues affected the ecological footprint. Environmental pollution in these countries could provide direction for economic policy. From an environmental perspective, hydropower energy consumption had not been used effectively to reduce the ecological footprint. A better understanding of environmental issues, ecological issues, and the continued development of new technologies and a sound planning system, as shown in Figure 1, is therefore essential for future hydropower development.

Figure 1. Planning system of hydropower [55].