Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Gurvinder Singh and Version 2 by Sirius Huang.

There is an urgent need to design nanomaterials sustainably using renewable and natural resources with minimal impact on society. Integrating sustainability with nanotechnology can support the manufacturing of sustainable nanomaterials with optimized performance.

- nanotechnology

- sustainability

- functional nanomaterials

- renewable resources

- green synthesis

- circular economy

- biomedical

- sustainable materials design

1. Introduction

The world population has rapidly increased from 7 billion to 8 billion in the last decade. This has placed tremendous pressure and a socio-economic burden on a better and more affordable healthcare system to protect people from infectious and life-threatening diseases. Additionally, the world is facing grave environmental, climate, and energy challenges. In 2015, the United Nations (UN) established 17 sustainable development goals (SDGs) to address such challenges. These SDGs aim to eradicate poverty, provide better healthcare to various communities, and tackle societal challenges using renewable and sustainable materials. The UN has arguably recognized the role of nanotechnology in achieving 13 out of 17 SDGs by 2030. Nanotechnology has emerged as a game-changing technology for fabricating nanoscale materials. A large surface area to volume and the unique size, shape, and composition-dependent characteristics of nanomaterials make them suitable for various practical applications from biomedical to renewable energy and the environment. In the biomedical field, the scientific revolution of nanotechnology has witnessed the discovery of mRNA vaccines for COVID-19 using lipid nanoparticles [1], the development of wearable medical devices/sensors [2], and wireless bandages stimulating wound healing for people living in both urban and rural regions [3].

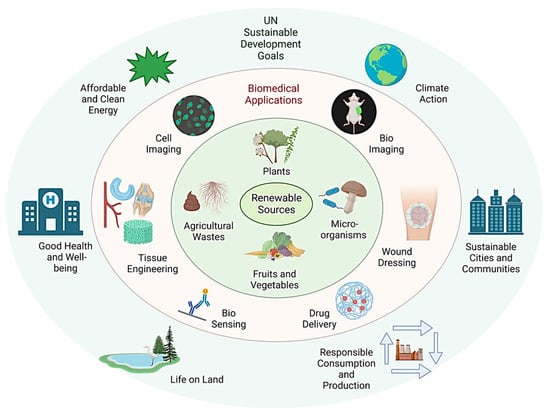

Nanotechnology holds great promise for developing the next generation of medical devices and sensors [4][5][4,5], implants [6], nanovaccines [7], diagnostics [8][9][8,9], and therapeutic technologies (Figure 1) [10][11][10,11]. In the last two decades, intensive research attempts have been made to develop manufacturing strategies involving top-down (lithography and etching) and bottom-up (chemical reduction and sol–gel) for designing functional nanomaterials. These manufacturing methods produce hazardous waste as a by-product, posing an immediate risk to workers and the environment. Furthermore, the mismanagement in the synthesis and handling of nanomaterials can cause severe short-term and long-term consequences to human health and the environment [12]. Though targeted nanomaterials-based chemotherapeutic agents have been developed for treating cancerous diseases [13], the long-term consequences of these nanomaterials on human health, such as inflammation, toxicity, the degradation mechanism of the nanomaterials, alteration in the function of organs and subsequent tumor development, or genetic disorders have not been prioritized in the past decade. Moreover, the issues related to safely manufacturing, nanomaterials’ safe handling, and lack of clinical data have predominantly restricted the translation of nanomaterials-based medicine for clinical applications. Therefore, the choice of raw materials (precursor materials), manufacturing method (cost and scalability), and handling protocols of nanomaterials should be considered when designing safe nanomaterials for biomedical applications. Manufacturing nanomaterials from renewable resources using green synthesis principles can enable the design of safe and sustainable nanomaterials.

Figure 1.

Renewable resources to design sustainable nanomaterials and their biomedical applications for a sustainable future.

2. Design Framework for Sustainable Nanomaterials

Advances in nanotechnological fabrication approaches have accelerated the discovery of new functional nanomaterials in tunable sizes, morphologies, and composition from non-renewable resources [14][15][16][17][18,19,20,21]. Such nanomaterials show superior physical and chemical properties compared to their bulk counterpart, making them beneficial to solve societal problems from health to renewable energy, information technology, and the environment [18][19][20][21][22][22,23,24,25,26]. However, the long-term commercial viability of these nanomaterials is posing a risk due to their reliance on non-renewable resources and highly energy-intensive manufacturing processes. In addition, there is too little attention paid to investigating the impact of non-sustainable materials on human health, climate change, and the environment. To achieve the SDGs set by the UN, intensive research efforts are needed to design sustainable nanomaterials from renewable resources while optimizing the performance, manufacturing process, and production costs of nanomaterials. Integrating sustainable resources with nanotechnology is critical to building a sustainable society in the 21st century. Sustainability encourages the use of natural resources and lower energy manufacturing methods for designing nanomaterials while maintaining the natural resources for current and future generations. Additionally, the sustainable process prevents waste production (zero waste) or harnesses recycled waste for fabricating nanomaterials to ensure minimal waste disposal, leading towards a circular economy for sustainable development.

When designing sustainable nanomaterials for biomedical applications, natural and renewable resources should be used as precursor materials and surfactants. Nature offers a wide range of various renewable and sustainable materials with rapid renewability, such as biomass and biodegradable natural materials (cellulose, chitosan, lignin) [23][24][27,28]. Renewable materials obtained from the photosynthetic process in plants are considered less toxic than synthetic materials. The second most abundant natural material on the planet, known as lignin, is an environmentally friendly material with excellent antioxidant and antimicrobial properties [25][29]. Cellulose, alginate, chitin, and pectin are other natural polysaccharide molecules that can be derived from microbes, animals, and plants [26][30]. Nanomaterials derived from natural polysaccharides offer various advantages, such as low processing cost, biodegradability, non-toxicity, and tunable surface functionalities (hydroxyl, amine, and carboxyl groups). Furthermore, nanomaterials can be designed from biomacromolecules (polypeptides, proteins, or nucleic acids) abundant in nature [26][30]. In addition to natural renewable resources, the waste from chemical industries (e.g., carbon dioxide), agriculture (e.g., rice husk containing ~75–90% organic molecules, such as cellulose and lignin), and the environment (e.g., plastic waste from oceans) can also be considered alternative non-natural renewable resources. This recycled waste from various resources can be used for synthesizing nanomaterials, for example, the use of waste extracted from petrochemicals for fabricating polymeric nanomaterials [27][28][31,32].

In bottom-up approaches, surfactants and reducing agents are commonly used to produce nanomaterials via the reduction of precursor materials and stabilize synthesized nanomaterials in the dispersion medium. Natural renewable resources, such as plants, biopolymers, proteins, sugars, bacteria, algae, and fungi, are a few examples that can act as surfactants and reducing agents [29][30][31][33,34,35]. Among various natural resources, biopolymers are the most common reducing agents used in various chemical reactions involved in the bottom-up manufacturing of nanomaterials. Examples of biopolymers that can act as reducing agents include dextran, chitosan, and cellulose extracted from sugarcane, the exoskeleton of crustaceans, and plants. Vitamin C isolated from fruits and vegetables is also a natural reducing agent that can reduce various metal ions in an aqueous solution. However, vitamin C and other natural biomolecules are more expensive than biopolymers. Therefore, these reducing agents are unsuitable for large-scale manufacturing of nanomaterials. The choice of solvent can also be a concern for synthesizing sustainable nanomaterials. Traditional approaches use toxic organic solvents that offer better control over the size, shape, and chemical composition of nanomaterials. The use of such toxic organic solvents should be prohibited or minimized. Water is the most commonly accessible and low-cost solvent for synthesizing sustainable nanomaterials. Alternatively, supercritical fluid technology has received considerable attention in fabricating nanomaterials with control over size, morphology, and composition with minimal environmental impact. This technology uses supercritical fluids, such as water and carbon dioxide (CO2), instead of toxic organic solvents [32][36]. Exploring the use of such alternative strategies will pave the way for the design of sustainable nanomaterials.

Top-down and bottom-up strategies have been developed to fabricate a variety of nanomaterials [33][34][35][36][37,38,39,40]. However, these energy-intensive approaches use toxic and corrosive precursor and surfactant materials that produce hazardous chemicals or gases. Therefore, the choice of manufacturing process requiring the least energy is essential in fabricating sustainable nanomaterials. The hydrothermal approach is the most popular strategy for synthesizing sustainable nanomaterials [37][41]. In this approach, the aqueous solution of precursor materials is heated to a high temperature using various heat sources, such as microwave energy and focused sunlight [38][39][42,43]. However, these heating mechanisms are not suitable for the large-scale manufacturing of nanomaterials due to insufficient and non-uniform heating of solvents in a large reactor. Recently, cost-effective flow-chemistry-based strategies have been investigated for synthesizing nanomaterials. This method offers better control of heat transfer and reaction mixing time. Another environment-friendly and economically viable approach based on green chemistry has emerged as an alternative strategy to fabricate size- and shape-controlled metallic nanomaterials by using microorganisms (bacteria, fungi, algae, virus) and plant extracts (proteins, polysaccharides, polyphenols) [40][41][44,45]. The advantages and disadvantages of physical, chemical, and green synthesis are discussed in the Table 1. Therefore, it is essential to set design guidelines for developing sustainable nanomaterials that can serve as a viable alternative to conventional methods of nanomaterials fabricated from non-renewable sources. Furthermore, the functional performance of sustainable nanomaterials should be optimized in various aspects, for example, renewable materials type (biopolymer, carbonaceous, or composites), physical characteristics (mechanical, thermal, and conductivity), biocompatibility, materials hazard testing, and environmental impact.

Table 1.

Advantages and disadvantages of physical, chemical, and green synthesis.

| Physical Methods | Chemical Methods | Green Methods |

|---|---|---|

| Advantages | ||

| Production of nanomaterials with control over size and shape | Synthesis of nanomaterials from a range of materials | Sustainable and environmentally friendly methods |

| Fabricating nanomaterials with high purity | Control over size, shape, crystallinity, and surface functionality | Fabrication of biocompatible nanomaterials from non-toxic and renewable resources |

| Scalable | High throughput fabrication of nanomaterials | Less energy intensive method with minimal waste |

| Disadvantages | ||

| Fabrication of nanomaterials from limited materials | Energy intensive | Limited scalability |

| Energy intensive and expensive | Require toxic chemicals and generate hazardous waste as reaction byproduct | Limited control over size, shape, and physical properties |

| Some physical methods (e.g., etching) require toxic gases and chemicals | Require additional steps of modification to improve biocompatibility | Restricted to the fabrication of nanomaterials from few materials |

| Not eco-friendly | Not eco-friendly | Reproducibility |