You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Please note this is a comparison between Version 1 by Yeek Chia Ho and Version 2 by Sirius Huang.

Plant-based natural coagulants (PBNCs) have been shown to be a promising alternative to the conventional coagulants used in water treatment. PBNCs’ advantages include excellent biodegradability, biocompatibility, sustainable production, low cost, and high availability. Problems associated with using PBNC have hindered the progression of their practical applications and commercialisation. However, several modification methods have been employed to enhance the performance of various plant polysaccharides to overcome these disadvantages.

- coagulation

- characterisation

- modification

- optimisation

- water and wastewater treatment

1. Introduction

In water treatment, the coagulation and flocculation process, in which suspended and colloidal particles agglomerate to form flocs heavy enough to quickly settle to the bottom of the clarifier, is essential. This process produces a supernatant, free from visible particles and ready for filtration [1][6]. However, there is more to drinking water coagulation and flocculation processes than floc formation and settling time [2][7]. The use of chemical coagulants has been shown to leave trace amounts of chemicals in water filtrate, which has been associated with neurodegenerative diseases due to long-term ingestion of these traces of chemicals. This negates the essence of water treatment; hence, an alternative to using these chemicals is necessary [3][4][8,9].

Due to the health and environmental problems caused by these chemical coagulants, the search for alternative coagulants that are non-toxic and environmentally friendly has been and is still a popular topic for researchers in the water industry. These potential alternatives, referred to as natural coagulants, are broadly classified into plant-based and non-plant-based natural coagulants. Plant-based options are more investigated because of their availability and biological formations.

2. Plant-Based Natural Coagulants (PBNCs)

The conventional coagulants used in water treatment are chemical-based coagulants (CBCs). The most common CBCs are alum salts and ferrous salts, and the significant advantages of their usage are their suitability and low cost [1][6]. There is no doubt these CBCs have high efficiency in treating water; however, their resulting health and environmental problems are the reason why an alternative to their use is necessary. Plant-based natural coagulants (PBNCs) have been shown to be a promising alternative. The active agents, mainly extracted as polysaccharides, have demonstrated remarkable performance as natural coagulants in water and wastewater treatment [5][6][7][10,11,12]. Plant-based natural coagulants’ advantages include excellent biodegradability, biocompatibility, sustainable production, low cost, and high availability [3][8][9][10][11][12][13][14][15][8,13,14,15,16,17,18,19,20].

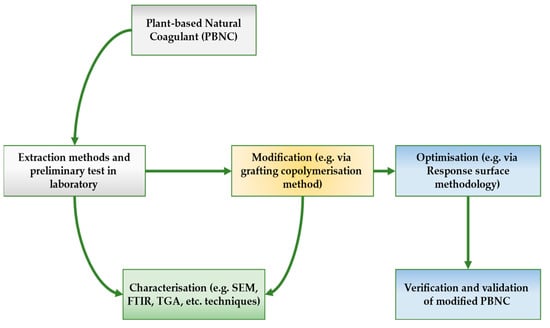

Plant-based natural coagulants are naturally occurring macromolecules of carbohydrates extracted from plant fruits, leaves, seeds, peels, etc. [16][17][21,22]. They contain some physicochemical properties proposed to be responsible for the flocculation process in water treatment. Among these properties are various functional groups, including carboxyl, hydroxyl, and phenolic [16][18][21,23]. However, there are disadvantages associated with these plant polysaccharides, including thermo-sensitivity, pH sensitivity, sensitivity to severe conditions, the possibility of microbial contamination, and loss of viscosity during storage [8][19][20][21][13,24,25,26]). Furthermore, some plant-based natural coagulants are anionic, making them more suitable as coagulant aids in water treatment [22][23][27,28]. These and other problems associated with using PBNC have hindered the progression of their practical applications and commercialisation. However, several modification methods have been employed to enhance the performance of various plant polysaccharides to overcome these disadvantages [5][24][10,29]. Figure 1 presents a flow chart showing stages for investigating PBNCs’ potentiality as natural coagulants.

Figure 1. Stages for investigating the potentiality of natural coagulants. The first horizontal arrow from the extraction chart is the characterisation of material before modification, and the second horizontal arrow from the modification chart is the characterisation after modification.

3. Modification of Plant-Based Natural Coagulants Using Grafting Copolymerisation Method

Plant-based materials and their recent progression are fascinating areas of applied polymer science that is gaining recognition [25][26][30,31]. Their emergence towards replacing synthetic materials is becoming research niche. Researchers mainly focus on the total replacement of synthetic materials with natural materials, or modifications to reduce the content of the synthetic materials or even modification using two raw materials. Modifying the properties of a polymer to meet its required specifications for application is essential [27][28][29][30][32,33,34,35]. There are several ways of modifying polymer properties, including blending, curing, and grafting. Grafting is a method where covalent bonding of a substance onto a polymer chain occurs. In simple terms, the effective way is to mixing two or more different types of polymers to form a copolymer with enhanced characteristics [24][27][29,32]. Grafting-from, grafting-to, and grafting-through are controlled copolymerisation processes in preparing well-defined copolymers. In grafting-from, growth of the copolymer chain occurs in situ from an initiator that has been previously hooked to a monomer’s surface. Grafting-to or grafting-on, which arose from the development of “click” chemistry, involve the individual synthetisation of two or more different monomers, and then connecting them, where the end functionalised polymer reacts with reactive sites on the monomer’s surface. For grafting-through, polymerisable groups are hooked onto the surface of monomers [5][31][32][33][34][10,36,37,38,39].

Natural plant polysaccharides are mostly unsuitable because of their poor stability and substantial swelling in the natural environment. Their modification through graft copolymerisation to enhance their characteristics is necessary to make them attractive natural materials and increase their resilience and suitability in the biological environment [19][21][24][24,26,29]. Graft copolymerisation research is a priority of polymeric research because it enhances modify biopolymers’ characteristics to obtain an upgraded natural material with enhanced properties [5][19][20][24][35][10,24,25,29,40]. Furthermore, it is important to understand the difference between copolymers. Copolymers are classified into block copolymers, random copolymers, alternate copolymers, and graft copolymers. In brief, a block copolymer consists of a combination of two or more segments of different polymers linearly joined from end-to-end. A random copolymer is when a monomer is attached randomly to the polymerised polymer, and an alternate copolymer has its monomer present in an ordered manner. A graft copolymer involves the mixing of a natural polymer and a synthetic polymer. In this case, the natural polymer is mostly the backbone of the grafted polymer, with the synthetic monomer as the side chains attached to the new polymer product at multiple sites [5][10].

Recently, natural plant polysaccharide modifications through graft copolymerisation procedures concerning different approaches have been studied. Several vinyl monomers, such as acrylamide (AM), methacrylamide (MA), methyl methacrylate (MMA), N-acrylonitrile, tert-butyl acrylamide, N-poly vinylpyrrolidone (NPVP), and 2-methacryloyloxyethyl trimethyl ammonium chloride (DMC), have been grafted to many plant-derived polysaccharides to optimise the potential properties [24][36][29,41]. The structural features of plant polysaccharides, the type and characteristics of the grafting monomers, grafting efficiency, and grafting ratio, are all factors that determine the characteristics and features of the grafted copolymer. Plant polysaccharides-g-copolymers have been used in several fields and industries, including civil engineering, biomaterials, agriculture, wastewater treatment, food, cosmetics, and pharmaceutical industries [18][24][32][37][38][23,29,37,42,43].

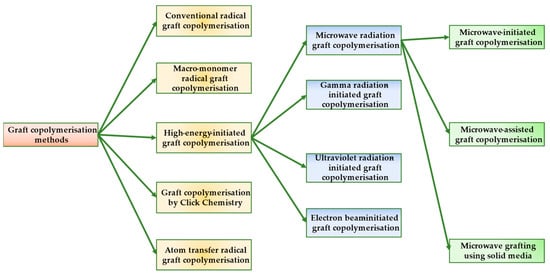

Among the methods of graft copolymerisation is conventional radical grafting copolymerisation, where, generally, hydroxyl (- OH) groups of polymers are involved. This occurs through radical polymerisation reaction under the influence of redox and thermal initiators [19][24][24,29]. Some examples of different polysaccharide-grafted copolymers synthesised by different redox initiators, as outlined by Nayak, et al. [24][29], include guar gum (GG) with an initiation system of H2O2, and cerium ammonium nitrate (CAN) to produce new polysaccharide copolymers GG-g-PMMA and GG-g-PAN, respectively; gum acacia (GA) with an initiation system of potassium persulfate, and CAN to produce GA-g-PAM and GA-g-PMMA, respectively; tamarind kernel polysaccharide (TKP) with CAN to produce TKP-g-PAM, etc. Another graft copolymerisation method is macromonomer radical grafting copolymerisation. Polymers of lower reactivity are chemically modified to form monomer-like structures as grafted copolymers. In most free radical grafting reactions, vinyl-functionalised polymers are considered macromonomers since these involve several active vinyl groups. Hence, synthesising many macromonomers is the main issue influencing the grafting reaction and grafted copolymer product quality, as shown in Nayak, et al. [24][29]. In addition to the high cost of conventional grafting copolymerisation, this method has difficulties treating solid samples, and undesirable chemicals are often produced because of the system’s dependence on different chemical initiators. The production of these chemicals may affect the safety application of grafted copolymers in many areas of application. These issues led to the emergence of high-energy initiated grafting copolymerisation. The simplicity of high-energy initiated grafting copolymerisation and its advantages concerning its grafting capabilities in soluble and non-soluble samples make it a preferred method for grafting different polysaccharides [5][24][37][10,29,42].

High-energy-initiated grafting copolymerisation is subdivided into four methods as outlined by Setia [5][10] and Nayak et al. [24][29]: microwave-assisted, gamma radiation-initiated, ultraviolet radiation-initiated, and electron beam-initiated grafting copolymerisation methods. Grafting by radiation has several advantages over the conventional grafting method. The radiation-induced method is regarded as the most convenient method of grafting copolymers. It is easily controlled due to the small number and length of copolymers. It does not change the molecular weight of the copolymer, and chains attached to the backbone can be achieved at different depths as the penetrating power of the radiation is regulated [39][40][41][44,45,46]. Other graft copolymerisation methods include click chemistry and atom transfer radical grafting copolymerisation. A flowchart outlining grafting copolymerisation methods is shown in Figure 2.

Figure 2. Different methods of grafting copolymerisation with a focus on high-energy initiated methods, within which microwave-assisted grafting has shown to be the most preferred.

4. Challenges and Future Perspectives of Plant-Based Natural Coagulants for Water and Wastewater Treatment

The use of plant-based natural coagulants (PBNCs) dates back to 2000 BC when plant materials were applied to clarifying drinking water [1][42][6,115]. Karnena and Saritha [43][116], in their brief timeline of PBNCs, outlined several historical applications for drinking water by rural dwellers, travellers, and even royalties. Similarly, today, PBNCs have been reported in some rural communities of Sudan, Tanzania, Mexico, and Peru [42][43][44][115,116,117]. Although the successful use of PBNCs was evident then, the quantity of water generally treated was small, and storage was only possible for a short period, as outlined by Ogden et al. [45][118]. An extended storage period is impossible due to the material’s instability. Moreover, Alazaiza et al. [46][119] reported that during the coagulation process, rapid mixing could lead to the breakage of cells of coagulant materials, thus increasing the organic matter load, which may react with the disinfectant in the disinfection stage, thus producing by-products [47][120].

Another major challenge for PBNCs is the use of edible plants as coagulants. The challenge between meeting food demand and finding an alternative to chemical coagulants will undoubtedly hinder the progression of PBNCs to practical application. Furthermore, the current extraction methods of PBNCs are complex and sometimes uncertain. Even though some research milestones have been achieved yearly through bench-scale coagulation experiments, a large-scale practical application has not been proven. The lack of PBNC practicality and commercialisation is mainly due to several disadvantages associated with PBNCs, as mentioned in previous sections.

Choy et al. [48][121] and Saleem and Bachmann [42][115] have noted that financial capabilities, framework directives, market awareness, and research development are among the challenges faced by PBNC progression. Until the known disadvantages of PBNCs are overcome, extensive application and commercialisation of PBNC will remain a future possibility.

Finding alternatives to chemical coagulants is necessary, and PBNCs are promising. They are suitable and environmentally friendly alternatives. The following are necessary for PBNCs to be successfully and realistically applied commercially: (1) Raw material sources must be abundant and easily accessible. (2) Competition in meeting food demand needs to be eliminated by focusing research on non-edible plants that are generally nontoxic, easily cultivated, and available free of charge. It should be noted, however, that some non-edible plants are used for medicine. Therefore, the high use of such plants in water treatment could affect their supply to the medical sector. Hence, their availability needs to be enhanced [46][119]. (3) Modification in PBNCs should be encouraged, and modification parameters should be optimised to achieve highly efficient products that meet commercialisation requirements as natural coagulants.