Mechanically responsive smart windows have the advantages of simple structure, low cost and good stability.机械响应式智能窗户具有结构简单、成本低、稳定性好等优点。

- energy saving

- smart window

- mechanoresponsive

- driving mode

Overview of mechanically responsive smart windows: structure and driving patterns机械响应智能车窗综述:结构和驾驶模式

CHEN Bo陈波1,, Qi Feng齐峰2 ,, Liu Weiwei刘薇薇1 ,, Liu Yang刘洋2 ,, Yang Lili杨丽丽2,*and Gerdenten和葛登腾3,*

1. Introduction1 中国建筑第三工程局集团有限公司中国建筑先进技术研究院,武汉430075

As2 the energy crisis continues东华大学材料科学与工程学院, 化学纤维与高分子材料改性国家重点实验室, 上海 201620

3 to东华大学功能材料研究所,上海 have201620

* 通信:lits effects, the energy crunch around the world has further intensified. In addition, with the increase in extreme weather caused by global warming, the development of science and technology to slow down global warming is also becoming a trend. Therefore, energy conservation is advocated by all countries. In developed countries, it is reported that building energy use accounts for liyang@dhu.edu.cn(洛杉矶);dengteng@dhu.edu.cn(D.G.)

抽象:全球对全球能源危机和极端天气的认识不断提高

变暖推动智能窗户市场的发展。与传统的电致变色、光致变色或热致变色智能窗相比,机械响应式智能窗具有结构简单、成本低、稳定性好等优点。在这篇综述中,我们总结了机械响应智能窗户的最新发展,重点关注结构和性能。我们概述了类别并讨论了优缺点。特别是,我们还总结了六种非常规的驱动模式来产生机械应变,包括气动、光学、热、电、磁和湿度模式。最后,我们对未来发展前景提出了切实可行的建议。本文旨在为新型机械响应智能窗的设计提供有益的参考,并加速其实际应用。

关键词:节能;智能窗口;机械响应;驾驶模式

1. 简介

随着能源危机的持续影响,全世界的能源紧缩进一步加剧。此外,随着全球变暖引起的极端天气的增加,减缓全球变暖的科学技术的发展也正在成为一种趋势。因此,节能是各国所倡导的。据报道,在发达国家,建筑能源的使用占总能耗的30-40% of total energy consumption [1,2], exceeding the amount of industry or transport. About 47% of energy for building services comes from heating, ventilation and air conditioning systems [3,4]. As the main way of indoor and outdoor heat exchange, energy consumption through windows accounts for a large proportion. In China, 400 million to 600 million square meters of windows are installed every year, more than the United States and European countries combined. Therefore, designing smart windows that can dynamically adjust the light transmittance is considered an effective way to save energy [5-7]. In addition to building energy efficiency, this technology has also generated widespread interest in cars, greenhouses and sunglasses, among others.,2],超过了工业或运输的数量。约47%的建筑服务能源来自供暖、通风和空调系统[3,4]。作为室内外热交换的主要方式,通过窗户的能源消耗占很大比例。在中国,每年安装的窗户面积为4亿至6亿平方米,超过了美国和欧洲国家的总和。因此,设计能够动态调节透光率的智能窗户被认为是一种有效的节能方法[5-7]。除了建筑节能外,这项技术还引起了人们对汽车、温室和太阳镜等的广泛兴趣。

Sunlight radiant heat at visible and near-infrared wavelengths accounts for about 可见光和近红外波长的太阳光辐射热量分别约占总辐射热量的44% and 47% of the total radiated heat, respectively. Under external stimuli, smart windows can reversibly adjust the light reflectivity or transmittance of visible or near-infrared wavelengths [8]. Lambert et al. proposed in the 1980s [9] that smart windows based on electrochromic materials are the most attractive type and the most widely used. It usually presents a sandwich structure with a functional material layer between two transparent electrodes. The optical properties are adjustable due to the properties of re-dox reaction or ion intercalation/separation under an electric field[10]. Thermochromic materials can change color with temperature due to thermal decomposition or geometric conformational changes [11]. When exposed to specific wavelengths of light, photochromic materials change color due to chemical bond homogenization reactions or circumcyclic reactions [12]. Although extensive research has been conducted in electrochromics, thermochromics, and photochromic smart windows, their fabrication and construction are quite complex, requiring external fields to achieve light modulation, limiting the commercialization of these materials. In recent years, mechanically responsive smart windows through simple mechanical strain adjustment have attracted more and more attention. Typically, the surface topography or internal structure of a mechanically responsive material is deformed or reconfigured due to mechanical strain, resulting in a change in light transmittance or color through light scattering or diffraction. Therefore, no external power supply is usually required for control, making mass production cost-effective. In addition, the optical properties of mecharomatic materials can be adjusted even at very small strains (i.e. ~10%). In contrast, electrochromic, photochromic or thermochromic smart windows typically require more time to respond. For example, electrochromic 和47%。在外部刺激下,智能窗户可以可逆地调整可见光或近红外波长的光反射率或透射率[8]。兰伯特等人在1980年代提出[9],基于电致变色材料的智能窗户是最有吸引力的类型,应用最广泛。它通常呈现一种夹层结构,在两个透明电极之间具有功能材料层。由于在电场下重新dox反应或离子嵌入/分离的特性,光学性质可调[10]。由于热分解或几何构象变化,热致变色材料可以随温度改变颜色[11]。当暴露在特定波长的光下时,光致变色材料会因化学键均质反应或周环反应而改变颜色[12]。尽管在电致变色、热致变色和光致变色智能窗方面进行了广泛的研究,但其制造和构造相当复杂,需要外部场来实现光调制,限制了这些材料的商业化。近年来,通过简单的机械应变调整的机械响应智能窗户引起了越来越多的关注。通常,机械响应材料的表面形貌或内部结构由于机械应变而变形或重新配置,导致透光率或颜色通过光散射或衍射发生变化。因此,通常不需要外部电源进行控制,从而实现批量生产的成本效益。此外,即使在非常小的应变(即~10%)下,机械致变色材料的光学特性也能进行调整。相比之下,电致变色、光致变色或热致变色智能窗口通常需要更多时间进行响应。例如,电致变色 WO3The coloring薄膜的着色/bleaching time of the film is 1~6 s. The response time of poly(N-thiopropyl acrylonide) (漂白时间为1~6 s。基于热致变色的聚(N-硫丙基丙烯酰亚胺)(PNIPAm)-based films based on thermochromic is )基薄膜的响应时间为40~120 seconds. Inorganic photochromic films have a wide range of response times, ranging from 0.1 seconds to hundreds of seconds.秒。无机光致变色薄膜的响应时间范围很广,从0.1秒到数百秒不等。

This paper reviews the latest progress of mechanical chromic intelligent temperature channels. Based on the surface本文综述了机械致变色智能温道的最新进展。根据表面/interface mechanism, we discuss strategies for all six types of mechanical chromic smart windows. The most common mode of driving for mechanical strain is mechanical force, i.e. changing surface/interface morphology by stretching, compressing, rotating, etc. Here, we also summarize six unconventional drive modes that generate mechanical strain and discuss their advantages and disadvantages. Finally, it offers future developments for potential applications for mechanically responsive smart windows.界面机制,我们讨论了所有六种类型的机械致变色智能窗户的策略。机械应变最常见的驱动模式是机械力,即通过拉伸、压缩、旋转等改变表面/界面形态。在这里,我们还总结了产生机械应变的六种非常规驱动模式,并讨论了它们的优缺点。最后,为机械响应智能窗户的潜在应用提供了未来发展。

2. The structure of a mechanically responsive smart window机械响应智能窗户的结构

Mechanical机械力驱动的机械应变, strain driven by mechanical force, electricity, humidity, etc., reconfigures the surface topography or changes the interface structure, thereby changing the optical transmittance by modulating the scattering or diffraction of light. Based on the type of surface topography or interface structure that achieves light modulation, we have created six broad classes of mechanically responsive materials: micro/nano arrays, wrinkles, cracks, novel interfaces, tunable interface parameters, and surface-interface synergies. For each category, we focus on the latest developments in mechanism and optically adjustable characteristics.电, 湿度, 等, 重新配置表面形貌或改变界面结构, 从而通过调制光的散射或衍射来改变光学透射率.基于实现光调制的表面形貌或界面结构的类型,我们创建了六大类机械响应材料:微/纳米阵列、皱褶、裂纹、新型界面、可调谐界面参数和表面-界面协同效应。对于每个类别,我们专注于机制和光学可调特性的最新发展。

2.1. Smart window of mechanical response based on micro基于微/nano arrays纳米阵列的机械响应智能窗口

As a new type of smart window material, surface periodic nanoscale or microscale array has attracted much attention because of its special advantages such as flexible light capture, broadband anti-reflection, easy preparation, and high specific surface area. To date, several nanoarrays have been designed and fabricated, such as nanocones 表面周期性纳米级或微尺度阵列作为一种新型智能窗材料,因其具有柔性光捕获性、宽带抗反射、易于制备、比表面积高等特殊优势而备受关注。迄今为止,已经设计和制造了几种纳米阵列,例如纳米锥[13], nanopillars ,纳米柱[14-16], nanopores [17, 18], nanospheres [19]. These structures can change their optical properties by dynamically modulating the surface geometry in response to various external stimuli.,纳米孔[17,18],纳米球[19]。这些结构可以通过动态调制表面几何形状来响应各种外部刺激来改变其光学性能。

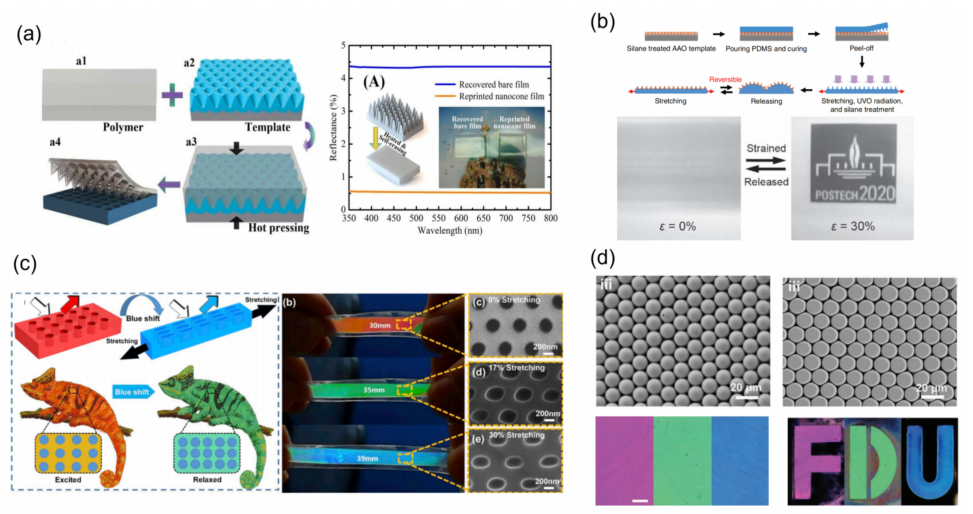

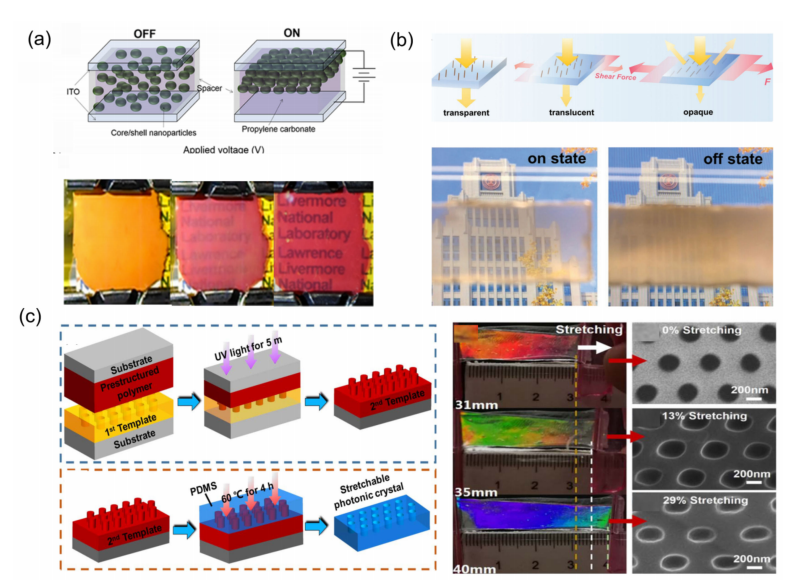

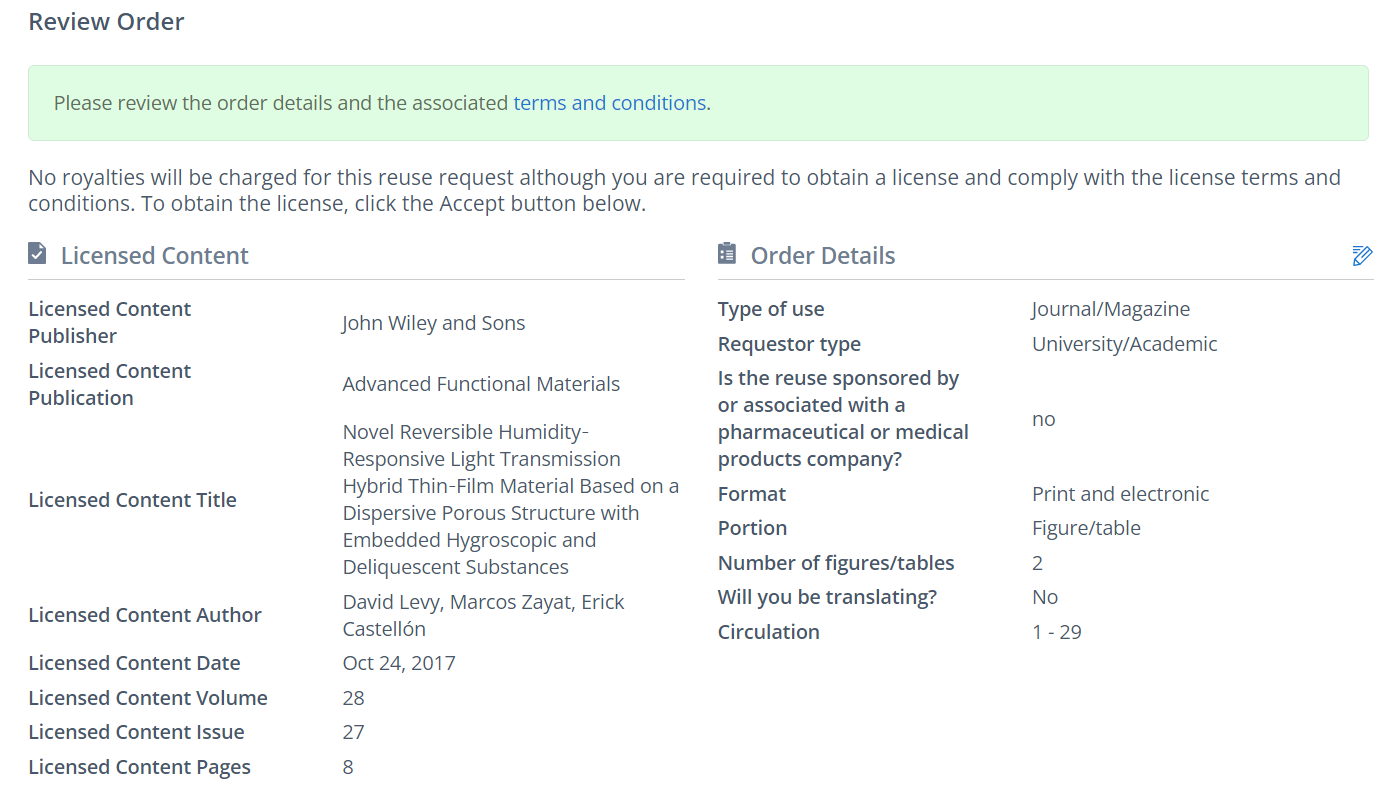

In recent years, 近年来,Li et al. have reported a self-erasing nanocone antireflection coating by a simple surface replication method (Figure 1a) [20]. Nanocone arrays with constant height and cycle can easily form shape memory polymer films of polyvinyl alcohol (PVA) and can be easily erased by thermal stimulation. In its initial state, PVA films with shape memory effects exhibit 0.6% reflectivity in the visible spectrum by adjusting the temperature (等人报道了一种通过简单的表面复制方法自擦除的纳米锥体增透膜(图1a)[20]。具有恒定高度和周期的纳米锥阵列可以很容易地形成聚乙烯醇(PVA)的形状记忆聚合物膜,并且可以通过热刺激方便地擦除。在初始状态下,具有形状记忆效应的PVA薄膜在可见光谱中表现出0.6%的反射率,通过调节温度(>80). orThanks to the shape memory effect of 得益于PVA, the reflectivity of the self-erasing anti-reflective coating in the visible spectral range can be changed. 的形状记忆效应,可以改变自擦抗反射膜在可见光谱范围内的反射率。Lee et al. propose a simple fabrication of a retractable smart window with a surface morphological pattern consisting of a nanopillar array on a crumpled poly(dimethylsiloxane) (PDMS) film [21]. As shown in Figure 1b, in the released state, PDMS films exhibit optically opaque properties with a frosted glass-like appearance due to the extensive scattering of light through periodic micron-sized surface structures.等人提出了一种可伸缩智能窗户的简单制造,其表面形态图案由皱巴巴的聚(二甲基硅氧烷)(PDMS)薄膜上的纳米柱阵列组成[21]。如图1b所示,在释放状态下,由于光通过周期性微米尺寸的表面结构的广泛散射,PDMS薄膜显示出光学不透明特性,具有磨砂玻璃般的外观。

Figure 图1 Str.基于纳米阵列的机械响应智能窗口的策略:(ategies) for Mechanical Response Smart Window Based on Nanoarrays: (a) Nanocones [20] Copyright 2018, MDPI (Basel, Switzerland), (b) Nanopillars纳米锥 [20] 版权所有 2018,MDPI(瑞士巴塞尔),(b) 纳米柱 [21] Copyright 2010, John Wiley & Sons (Hoboken, New Jersey, USA), (c) Nanopores版权所有 2010,约翰·威利父子(美国新泽西州霍博肯),(c) 纳米孔 [22] Copyright 2019, Elsevier (Amsterdam, Netherlands), (d) Nanospheres [23] Copyright 2021, John Wiley & Sons.版权所有 2019,爱思唯尔(荷兰阿姆斯特丹),(d) 纳米球 [23] 版权所有 2021,约翰·威利父子。

At 在30% mechanical stretching, the film becomes optically transparent due to the absence of wrinkles with a transmittance of up to 95%. Inspired by chameleons, which can adjust colors according to the environment, Zhao et al. designed a surface nanoporous color display film [22]. As shown in Figure 1c, stretchable nanohole photonic crystals were prepared using nanoimprinting technology. Shape memory alloy (SMA) and PDMS materials were used to prepare composite membranes with shape memory function. The function of SMA is to deform nanohole photonic crystals under electrical stimulation, and the function of PDMS is to restore SMA to its initial shape after shedding electrical stimulation. At voltages of 的机械拉伸下,由于没有皱纹,薄膜变得光学透明,透射率高达95%。受变色龙的启发,可以根据环境调整颜色,赵等人设计了一种表面纳米孔型彩色显示膜[22]。如图1c所示,可拉伸纳米空穴光子晶体采用纳米压印技术制备。利用形状记忆合金(SMA)和PDMS材料制备具有形状记忆功能的复合膜。SMA的功能是使纳米空穴光子晶体在电刺激下变形,PDMS的功能是使SMA在脱落电刺激后恢复其初始形状。在1.0-1.5 V, the composite film can achieve color change over the entire visible light range, and the total deformation required is only less than 30%. Ji et al. report a nanospheroid shape memory mirror reflective structure colored film that originates from the mechanism of retroreflection and thin film interference binding to internal reflection (Figure 1d). During deformation, the structural color of the optical film gradually disappears due to the change in the shape of the nanospheres [23]. In addition, the film has excellent repeatability and rewrite ability, and its structural color can be restored by heating. In summary, micro/nano array-based mechanical response smart windows can simply adjust color or transparency because the array shape or array number can be adjusted. However, their light modulation is limited because traditional micro/nano arrays are difficult to work with的电压下,复合膜可以在整个可见光范围内实现变色,并且要求的总变形仅小于30%。Ji等人报道了一种纳米球形状记忆镜反射结构彩色薄膜,其起源于逆反射和薄膜干涉结合内反射的机制(图1d)。在变形过程中,由于纳米球形状的变化,光学薄膜的结构颜色逐渐消失[23]。此外,该薄膜具有出色的重复和重写能力,其结构颜色可以通过加热恢复。总之,基于微/纳米阵列的机械响应智能窗口可以简单地调整颜色或透明度,因为可调阵列形状或数组编号。然而,它们的光调制是有限的,因为传统的微/纳米阵列很难在

deformation.

2.2. Mechanoresponsive Smart Windows Based on Wrinkling

As a universal pattern in nature, wrinkling is another typical surface texture that can dynamically be tuned by mechanical strains and has been extensively explored for optical devices, stretchable electronics, energy storage devices, etc. [24–26]. Depending on the incident angles, the wrinkled surface refracts the incident light to different directions and blurs the objects behind the wrinkled thin layer/substrate film. However, when the wrinkles are erased by lateral tensile strains, the light beams can pass through the film with reduced deflection, changing the film from opaque to translucent or to highly transparent [27,28].

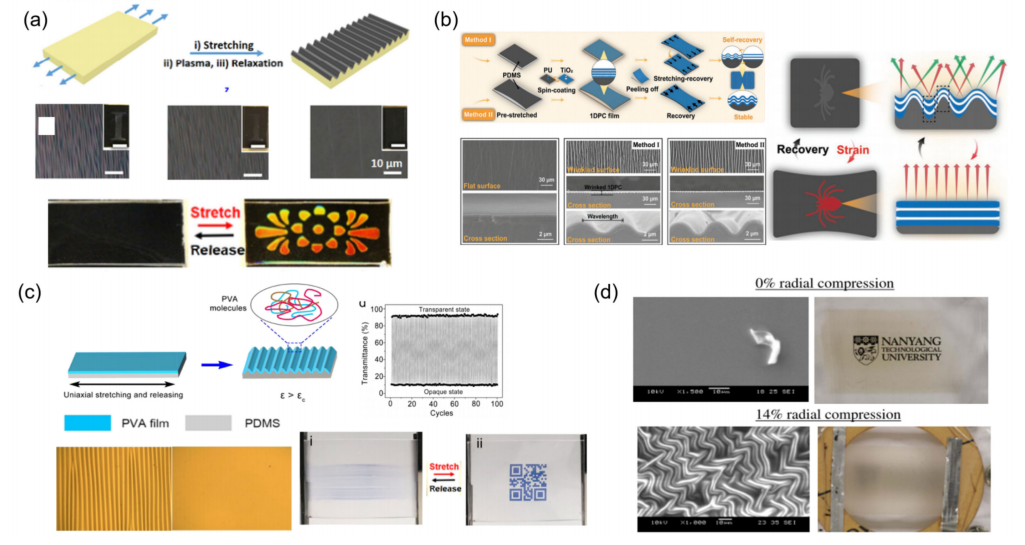

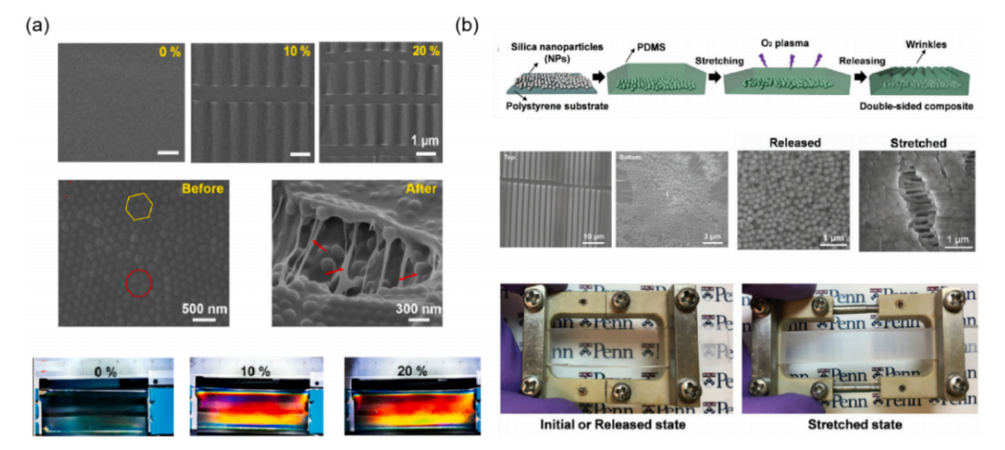

In recent years, researchers have designed a variety of surface wrinkled smart window materials. In Figure 2a, Li et al. reported a notable thickness-dependent wrinkling behavior of PDMS films via using the typical plasma-stretch processes [29]. They have showed brilliant surface structural colors and pre-designed colorimetric responses to mechanical strain on plasma-treated PDMS films by changing the substrate thickness. Because of the high orderliness and considerable small size of the wrinkles, uniform, bright, and angle-dependent structural colors can be obtained on thick PDMS films (>1 mm).

Figure 2. The strategies of mechanoresponsive smart windows based on wrinkling: (a) stretching to form wrinkles [29] Copyright 2020, Springer Nature (Berlin/Heidelberg, Germany), (b) wrinkled pho-tonic elastomer structure [30] Copyright 2022, John Wiley and Sons, (c) double-layer film wrinkle [31] Copyright 2019, American Chemical Society (Washington, DC, USA) (d) biaxial compression to form wrinkles [32] Reprinted with permission Copyright 2016, Optical Society America (Washington, DC, USA).

To eliminate the angle dependence of the structural color, inspired by a kind of bright blue luminescence spider, Lin et al. reported a new wrinkle-based photonic elastomer structure [30]. Through wrinkling stretchable 1D photonic crystals (1D PC), the photonic elastomers film with omnidirectional angle-independent brilliant structural colors are achieved (Figure 2b). They used stretchable polyurethane and nanoscale TiO2 as the raw materials by the method of alternating assembly to fabricate 1D PC as the surface structural color layer, and PDMS as the bottom elastic layer which enables the discoloration response of elastomers to wrinkles with clear boundaries. The wrinkle-based structural color and photonic structure can remain stable after 1000 tensile cycles, and mechanochromic sen-sitivity up to 3.25 nm/%. More importantly, through comprehensively controlling the lattice spacing of photonic films and micro-wrinkle structure, the structural color can realize delayed discoloration and reversible switching performance only by a single strain direction. As shown in Figure 2c, Jing et al. reported an effective strategy to preparing temperature and moisture dual-responsive surface wrinkles based on the PVA/PDMS bilayer film, which can be achieved by the rational design of modulus changing PVA skin layer on elastomer film upon moisture and temperature [31]. The bilayer film systems show remarkable advances in a fast response system, outstanding reversibility, stability, and high light transmittance modulation. Compared to the examples of uniaxial strain to form wrinkles, the biaxial compression can generate more complex 2D surface wrinkling patterns, which could be ordered or disordered. The 2D wrinkling patterns have greater interactions with lights and result in a lower transmittance. In Figure 2d, Shrestha et al. displayed a flat ZnO thin film which can be deposited on a pre-stretched elastomer mem-brane acrylic elastomer membrane by the electron beam evaporation technique [32]. This optical tunable window film appears reversible and adjustable between translucent and transparent states. When compression is not applied to a flat surface, the film is transparent with a 93% transmittance at a wavelength of 550 nm. At 14% radial compression, the film appears to surface wrinkle and has a translucent appearance, which has a very low 3% in-line transmittance. Analysis shows that both the large amplitude and the small wavelength of transparent micro-wrinkles are in favor of refracting light diffusely.

2.3. Mechanoresponsive Smart Windows Based on Cracks

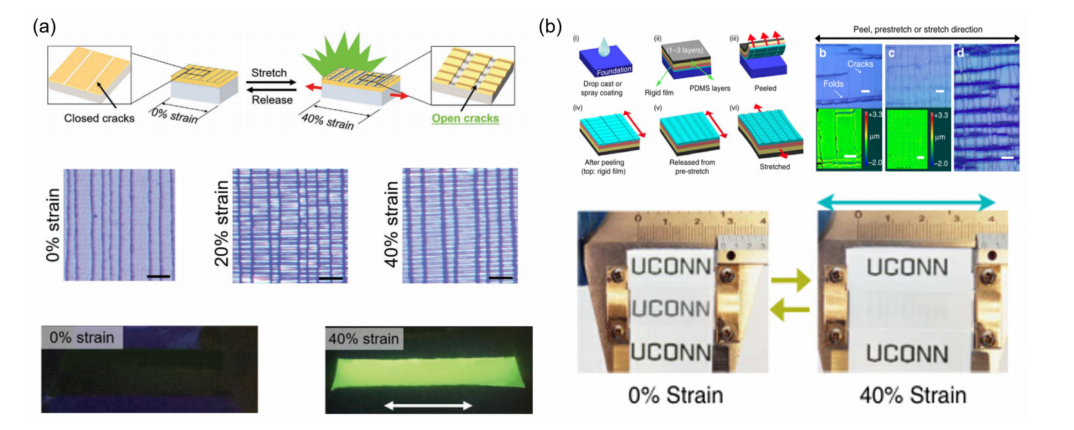

In addition to optical property modulation by changing the structural parameters such as the number and micro/nano-pattern spacing on the surface, optical pathway opening/closing or the appearance/disappearance of scattered light units by changing the opening/closing state of micro cracks is also an effective means to achieve rapid excitation of fluorescence or rapid decrease of transmittance [33]. Because of the weak binding at the fracture, it usually has highly sensitive properties. Both microscale and nanoscale structural designs have well demonstrated their opportunity in achieving excellent dynamic optical performance. By means of stretching/releasing and revealing/concealing patterns, micro/nanoscale cracks enable tune a series of reversible adaptive optics, e.g., transparency, fluorescent color, and luminescent intensity. Mao et al. reported a simple and highly effective method of mechanochromic materials based on a bilayer structure. This structure is composed of a sputter-coated light-shielding metal layer (Au/Pd) on a PDMS bottom substrate containing the fluorescent dye [34], featuring horizontal and/or vertical micro-scale cracks under stretched material (Figure 3a). The width of cracks opening on the metal light-shielding layer under stretching/releasing endows the UV radiation to stimulate the fluorescent dye, which can exhibit luminescent color embed in the PDMS matrix. The crack opening width can be well tuned via applying different degrees of pre-stretching strain in the preparation process, leading to customizable mechanochromic responses. High sensitivity and excellent durability of the devices are also displayed, which can exhibit great mechanochromic properties after 500 cycles of tensile and release. Zeng et al. introduced a thin rigid composite material film, which was prepared by drop-casting method or spray-coating on the plastic substrate subsequent to the treatment of vinyl-functionalized silane vapor [35]. The surface morphology of the rigid film showed periodical longitudinal cracks which are vertical to the peeling direction and the transverse wrinkles perpendicular to the cracks because of the compressive force originating from the Poisson effect. In the released state, this film shows >88% transmittance at 600 nm and the film becomes highly opaque (transmittance < 29%) under 40% strain (Figure 3b).

Figure 3. Construction paths of mechanoresponsive smart windows based on surface crack: (a) surface deposition of metal coating [34] Copyright 2017, John Wiley and Sons, (b) soft substrate/ hard shell [35] Copyright 2017, John Wiley and Sons.

2.4. Novel Interface-Introduced Mechanoresponsive Smart Windows

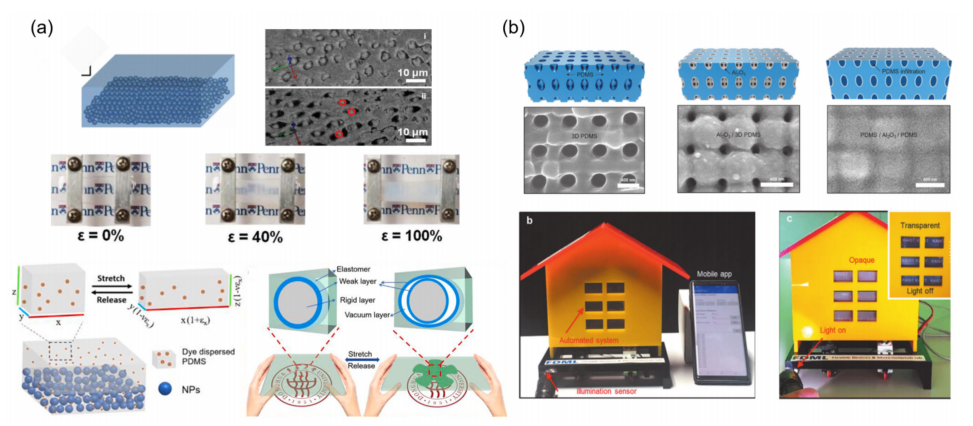

Similar to the surface structure, the interface structure can also dynamically regulate the scattering and interference of light, thus achieving the optical modulation. Moreover, the mechanoresponsive materials based on interface structure regulation can overcome the problem that the surface structure is susceptible to failure by external environment (such as dust, moisture, mechanical load, etc.), and show stronger controllability and stability [36,37]. Based on this, materials that achieve light transmission regulation through dynamic generation/disappearance of novel interfaces have been widely investigated. As shown in Figure 4a, Shu Yang’s group and our group fifirstly proposed the approach to prepare smart window film by combining the nanoparticle arrays with similar refractive indices to elastomers [38]. During the stretching process, a large number of micro/nanooptical interfaces were generated because of the mismatch between the modulus of the soft elastomer and the rigid nanoparticles, which result in a significant decrease in the light transmission of the film. Although the transmittance of this fiilm is up to 70%, it still improves the mechano-optical sensitivity. Therefore, constructing fast-responsive interfaces through the generating/vanishment of scattering under mechanical strain, is an easy and effective way to improve sensitivity. Based on this theory, our group reported an ultrasensitive dynamic optical membrane based on the dye-induced weak boundary layer [39]. This sample exhibits a dramatic decrease in transmittance by 44% at very small strain (15%). Moreover, a total dynamic transmittance rate of ~75% is demonstrated, while this membrane can be reversibly modulated for more than 2000 cycles with stable structural integrity and optical performance.

Figure 4. Methods to novel interface dynamic generation: (a,b) phase separation due to huge elastic modulus difference [38–40] Copyright 2015, John Wiley and Sons, 2021, Elsevier and 2020, John Wiley and Sons.

Cho et al. reported a new type of 3D nanoscale composite film, consisting of an ultrathin Al2O3 nanoshell [40]. Regardless of the stretching direction, a large amount of light-scattering nanogaps form at the interfaces of Al2O3 and the elastomers under stretching (Figure 4b). These result in the dramatic modulation of transmission from a high 90% to a very low 16% at visible wavelengths and does not attenuate after the stretching/releasing of more than 10,000 cycles.

2.5. Mechanoresponsive Smart Windows Based on Tunable Interface Parameters

In addition to the generation/disappearance of novel interfaces, the regulation of interfacial structure parameters is also an important factor to change the diffraction and light transmission direction. Typically, there are three types of interface structure parameters: the interface spacing, the interface shape, and the alignment direction. In Figure 5a, Han et al. used colloidal spherical nanoparticles with core-shell structure to successfully synthesize a transparency tunable film in response to electric stimuli [41]. They demonstrated a suspended particles device, which can tune the transparency in the visible wavelength by using colloidal assemblies of nanoparticles. The change in observed transparency can be attributed to the tunable structural ordering of nanoparticle assemblies and the modulation of photonic band structures. Moreover, the macroscopic structure color was able to be changed through regulating the band gap center wavelength along with the lattice constant of nanostructures. As shown in Figure 5b, Li et al. reported a new highly sensitive, shear-responsive smart window, which consists of vertically fixing the Fe3O4@SiO2 nanochains’ (NCs) array and an elastic matrix of polyacrylamide. At original relaxation state, all Fe3O4@SiO2 nanochains stand vertically to the film surface and this flexible film shows optical transparency. When the strain is applied, Fe3O4@SiO2 nanochains tilt along the shearing direction, which enables a good shielding effect. Critically, a quite small shear displacement up to 1.5 mm applied on the surface will give rise to tunable optical states, changing from the high transparency state of 65% transmittance to the opaque state of 10% transmittance [42]. In Figure 5c, Zhao et al. designed and fabricated a stretchable photonic crystal via nanoimprinting technology. Periodic cylinder-shaped air holes were embedded in the non-close-packed triangular lattice. This film can switch color over the whole visible light range from red to blue color under a small, applied strain of 29%. In addition, a reversible stretching up to 2000 times also exhibits the stability of shape recovery as well as mechanochromic ability [17].

Figure 5. Mechanoresponsive smart windows with dynamic control of interface parameters: (a) colloidal particle spacing [41] Copyright 2018, American Chemical Society, (b) colloidal par-ticle direction [42] Copyright 2021, John Wiley and Sons, (c) spacing and shape of hole [17] Copyright 2019, Iop Publishing (Bristol, UK).

2.6. Mechanoresponsive Smart Windows Based on Surface–Interface Synergy Effect

In order to enhance the optical modulation range and achieve a multi-state, the synergistic surface–interface modulation is an effective approach. It is possible to achieve color and transmittance modulation based on multiple effects at the same time. Therefore, surface–interface synergy effect has unique advantages in multi-state display and precise regulation.

As shown in Figure 6a, a large-area mechanochromic film is reported by Qi et al. based on a novel design of bilayer PDMS film including angle-independent and angledependent structural colors through bottom-up bar coating [43]. The angle-independent structural color is attributed to the long-range disordered but short-range ordered structure of polystyrene (PS) nanoarrays. Meanwhile, angle-dependent structural color is generated due to the stretching of surface wrinkling. Moreover, the cracks and surface wrinkles of PS nanoarrays resulting from the tensile enhance the scattering effect of bilayer film and reduce the transmittance of the light. Furthermore, pressure-induced surface morphology rearrangements can remove the wrinkling behavior. Therefore, the properties of programmable mechanochromic responses can be achieved. The pressure-encoded invisible complex information can be reversibly displayed by stretching.

Figure 6. Two strategies of mechanoresponsive smart windows based on surface and interface modulation synergistically: (a) surface wrinkle, novel interface dynamic formation dynamic control of interface parameters [43] Copyright 2021, Elsevier, (b) surface wrinkle and novel interface dynamic generation [44] Copyright 2018, John Wiley and Sons.

In order to realize the highest transmittance modulation under the special application requirements, Kim et al. presented a novel strategy to prepare an on-demand smart window by integrating the synergetic optical effects due to the tunable wrinkled geometry and nanovoids generated by the surrounding silica particles embedded in PDMS film (Figure 6b) [44]. By carefully varying the wrinkle shape, the size of silica particle and stretching strain, a great optical transmittance modulation in the visible band to near infrared range is realized, while with a relatively small strain up to 10%. At 0% strain, the film shows 60.5% transmittance at the wavelength of 550 nm due to the light diffraction caused by the initial wrinkles. Upon stretching to the pre-strain level (10%), a maximum transmittance (86.4%) is obtained at a visible wavelength of 550 nm. While at 40% strain level, the film demonstrates a significantly low transmittance (25.2%).

Permission to cite literature

图 1a.基于纳米阵列的机械响应智能窗策略:纳米锥[20], 李, P.;韩彦;王文;陈晓;金平;Liu,S.,基于聚乙烯醇(PVA)聚合物形状记忆效应的自擦纳米酮增透膜。聚合物(巴塞尔)2018,10,756-765。

Figure 1b. The strategies of mechanoresponsive smart windows based on nanoarrays: nanopillar[21], Lee, S. G.; Lee, D. Y.; Lim, H. S.; Lee, D. H.; Lee, S.; Cho, K., Switchable transparency and wetting of elastomeric smart windows. Adv Mater 2010, 22, 5013-5017.

Figure 1c. The strategies of mechanoresponsive smart windows based on nanoarrays: nanoholes[22], Zhao, P.; Chen, H.; Li, B.; Tian, H.; Lai, D.; Gao, Y., Stretchable electrochromic devices enabled via shape memory alloy composites (SMAC) for dynamic camouflage. Optical Materials 2019, 94, 378-386.

Figure 1d. The strategies of mechanoresponsive smart windows based on nanoarrays: nanospheres [23], Ji, C.; Chen, M.; Wu, L., Patternable and Rewritable Retroreflective Structural Color Shape Memory Polymers. Advanced Optical Materials 2021, 94, 2100739.

Figure 2a. The strategies of mechanoresponsive smart windows based on wrinkling: stretching to form wrinkles[29], Li, Z. W.; Liu, Y.; Marin, M.; Yin, Y. D., Thickness-dependent wrinkling of PDMS films for programmable mechanochromic responses. Nano Res 2020, 13, 1882-1888.

Figure 2b. The strategies of mechanoresponsive smart windows based on wrinkling: wrinkled photonic elastomer structure[30], Lin, R.; Qi, Y.; Kou, D.; Ma, W.; Zhang, S., Bio‐Inspired Wrinkled Photonic Elastomer with Superior Controllable and Mechanically Stable Structure for Multi‐Mode Color Display. Advanced Functional Materials 2022, 32, 2207691.

Figure 2c. The strategies of mechanoresponsive smart windows based on wrinkling: Double-layer film wrinkle[31], Jiang, B.; Liu, L.; Gao, Z.; Feng, Z.; Zheng, Y.; Wang, W., Fast Dual-Stimuli-Responsive Dynamic Surface Wrinkles with High Bistability for Smart Windows and Rewritable Optical Displays. ACS Appl Mater Interfaces 2019, 11, 40406-40415.

Figure 2d. The strategies of mechanoresponsive smart windows based on wrinkling: biaxial compression to form wrinkles[32], Shrestha, M.; Lau, G. K., Tunable window device based on micro-wrinkling of nanometric zinc-oxide thin film on elastomer. Opt Lett 2016, 41, 4433-4436.

Figure 3a. Construction paths of mechanoresponsive smart windows based on surface crack: surface deposition of metal coating[34], Mao, Z.; Zeng, S.; Shen, K.; Chooi, A. P.; Smith, A. T.; Jones, M. D.; Zhou, Y.; Liu, X.; Sun, L., Dynamic Mechanochromic Optics with Tunable Strain Sensitivity for Strain‐Responsive Digit Display. Advanced Optical Materials 2020, 8, 2001472.

Figure 3b. Construction paths of mechanoresponsive smart windows based on surface crack: soft substrate/ hard shell[35], Li, Z.; Zhai, Y.; Wang, Y.; Wendland, G. M.; Yin, X.; Xiao, J., Harnessing Surface Wrinkling–Cracking Patterns for Tunable Optical Transmittance. Advanced Optical Materials 2017, 5, 1700425.

Figure 4a. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[38], Ge, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D. S.; Yang, S., A robust smart window: reversibly switching from high transparency to angle-independent structural color display. Adv Mater 2015, 27, 2489-95.

Figure 4a. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[39], Liu, Y.; Song, S.; Liu, M.; Hu, Y.; Zhang, L.-w.; Yoon, H.; Yang, L.; Ge, D., Gecko-inspired ultrasensitive multifunctional mechano-optical smart membranes. Chemical Engineering Journal 2022, 429, 132159.

Figure 4b. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[40], Cho, D.; Shim, Y. S.; Jung, J. W.; Nam, S. H.; Min, S.; Lee, S. E.; Ham, Y.; Lee, K.; Park, J.; Shin, J.; Hong, J. W.; Jeon, S., High-Contrast Optical Modulation from Strain-Induced Nanogaps at 3D Heterogeneous Interfaces. Adv Sci (Weinh) 2020, 7, 1903708.

Figure 5a. Mechanoresponsive smart windows with dynamic control of interface parameters: colloidal particle spacing[41], Han, J.; Freyman, M. C.; Feigenbaum, E.; Yong-Jin Han, T., Electro-Optical Device with Tunable Transparency Using Colloidal Core/Shell Nanoparticles. ACS Photonics 2018, 5, 1343-1350.

Figure 5b. Mechanoresponsive smart windows with dynamic control of interface parameters: colloidal particle direction[42], Li, J.; Lu, X.; Zhang, Y.; Ke, X.; Wen, X.; Cheng, F.; Wei, C.; Li, Y.; Yao, K.; Yang, S., Highly Sensitive Mechanoresponsive Smart Windows Driven by Shear Strain. Advanced Functional Materials 2021, 31, 2102350.

Figure 5c. Mechanoresponsive smart windows with dynamic control of interface parameters: spacing and shape of hole[17]. Zhao, P.; Li, B.; Tang, Z.; Gao, Y.; Tian, H.; Chen, H., Stretchable photonic crystals with periodic cylinder shaped air holes for improving mechanochromic performance. Smart Materials and Structures 2019, 28, 075037.

Figure 6a. Two strategies of mechanoresponsive smart windows based on surface and interface modulation synergistically: surface wrinkle, novel interface dynamic formation dynamic control of interface parameters[43], Qi, Y.; Zhou, C.; Zhang, S.; Zhang, Z.; Niu, W.; Wu, S.; Ma, W.; Tang, B., Bar-coating programmable mechanochromic bilayer PDMS film with angle-dependent and angle-independent structural colors. Dyes and Pigments 2021, 189, 109264.

Figure 6b. Two strategies of mechanoresponsive smart windows based on surface and interface modulation synergistically: surface wrinkle and novel interface dynamic generation[44], Kim, H. N.; Ge, D.; Lee, E.; Yang, S., Multistate and On-Demand Smart Windows. Adv Mater 2018, 30, e1803847.

Figure 7a. The strategy of pneumatic drive mode mechanoresponsive smart windows: adjust transparency and color by changing film thickness[45], López Jiménez, F.; Kumar, S.; Reis, P. M., Soft Color Composites with Tunable Optical Transmittance. Advanced Optical Materials 2016, 4, 620-626.

Figure 7b. The strategy of pneumatic drive mode mechanoresponsive smart windows: adjust transparency and color by changing film thickness[46], Kim, S. U.; Lee, Y. J.; Liu, J.; Kim, D. S.; Wang, H.; Yang, S., Broadband and pixelated camouflage in inflating chiral nematic liquid crystalline elastomers. Nat Mater 2022, 21, 41-46.

Figure 7c. The strategy of pneumatic drive mode mechanoresponsive smart windows: pneumatic stretching to adjust transparency[47]; Rotzetter, A. C. C.; Fuhrer, R.; Grass, R. N.; Schumacher, C. M.; Stoessel, P. R.; Stark, W. J., Micro Mirror Polymer Composite Offers Mechanically Switchable Light Transmittance. Advanced Engineering Materials 2014, 16, 878-883.

Figure 7d. The strategy of pneumatic drive mode mechanoresponsive smart windows: pneumatic drive mode mechanochromic hydrogels[48]. Zhu, Q.; Vliet, K.; Holten‐Andersen, N.; Miserez, A., A Double‐Layer Mechanochromic Hydrogel with Multidirectional Force Sensing and Encryption Capability. Advanced Functional Materials 2019, 29, 1808191.

Figure 8a. The approaches for optical-driving mechanoresponsive smart windows: based on the high photothermal conversion efficiency of CNT[49], Li, F.; Hou, H.; Yin, J.; Jiang, X., Near-infrared light–responsive dynamic wrinkle patterns. Science Advances 4, eaar5762.

Figure 8b. The approaches for optical-driving mechanoresponsive smart windows: based on the high photothermal conversion efficiency of CNT[50], Xie, M.; Lin, G.; Ge, D.; Yang, L.; Zhang, L.; Yin, J.; Jiang, X., Pattern Memory Surface (PMS) with Dynamic Wrinkles for Unclonable Anticounterfeiting. ACS Materials Letters 2019, 1, 77-82.

Figure 8c. The approaches for optical-driving mechanoresponsive smart windows: (c) based on metal nanoparticles[51], Cao, D.; Xu, C.; Lu, W.; Qin, C.; Cheng, S., Sunlight-Driven Photo-Thermochromic Smart Windows. Solar RRL 2018, 2, 1700219.

Figure 8d. The approaches for optical-driving mechanoresponsive smart windows: based on inverse opal scaffold structure[52]. Wang, Y.; Zhang, Z.; Chen, H.; Zhang, H.; Zhang, H.; Zhao, Y., Bio-inspired shape-memory structural color hydrogel film. Science Bulletin 2022, 67, 512-519.

Figure 9a. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of surface wrinkles structure[58], Li, D.; Zhou, C.; Meng, Y.; Chen, C.; Yu, C.; Long, Y.; Li, S., Deformable Thermo-Responsive Smart Windows Based on a Shape Memory Polymer for Adaptive Solar Modulations. ACS Appl Mater Interfaces 2021, 13, 61196-61204.

Figure 9b. The strategy of thermal driving mode of mechanoresponsive smart windows: (a) formation of dynamic network structure[59], Zhao, J.; Zhang, L.; Du, X.; Xu, J.; Lin, T.; Li, Y.; Yang, X.; You, J., Panther chameleon-inspired, continuously-regulated, high-saturation structural color of a reflective grating on the nano-patterned surface of a shape memory polymer. Nanoscale Adv 2022, 4, 2942-2949.

Figure 9c. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of nanostripes structure[60], Xu, Z.-Y.; Li, L.; Du, L.; Wang, L.; Shi, L.-Y.; Yang, K.-K.; Wang, Y.-Z., Multiscale shape-memory effects in a dynamic polymer network for synchronous changes in color and shape. Applied Materials Today 2022, 26, 101276.

Figure 9d. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of dynamic network structure[61], Zhang, W.; Wang, H.; Wang, H.; Chan, J. Y. E.; Liu, H.; Zhang, B.; Zhang, Y. F.; Agarwal, K.; Yang, X.; Ranganath, A. S.; Low, H. Y.; Ge, Q.; Yang, J. K. W., Structural multi-colour invisible inks with submicron 4D printing of shape memory polymers. Nat Commun 2021, 12, (1), 112-120.

Figure 10a. The strategy of electric driving mode mechanoresponsive smart windows: controlling movement of nanoparticles via the electrophoresis to modulate transmittance and color[64], Wang, J. L.; Liu, J. W.; Sheng, S. Z.; He, Z.; Gao, J.; Yu, S. H., Manipulating Nanowire Assemblies toward Multicolor Transparent Electrochromic Device. Nano Lett 2021, 21, 9203-9209.

Figure 10b. The strategy of electric driving mode mechanoresponsive smart windows: controlling movement of nanoparticles via the electrophoresis to modulate transmittance and color[65], Liu, S.; Zhang, D.; Peng, H.; Jiang, Y.; Gao, X.; Zhou, G.; Liu, J.-M.; Kempa, K.; Gao, J., High-efficient smart windows enabled by self-forming fractal networks and electrophoresis of core-shell TiO2@SiO2 particles. Energy and Buildings 2021, 232, 110657.

Figure 10c. The strategy of electric driving mode mechanoresponsive smart windows: based on carbon nanotube materials to adjust transmittance[66], Zhang, W.; Weng, M.; Zhou, P.; Chen, L.; Huang, Z.; Zhang, L.; Liu, C.; Fan, S., Transparency-switchable actuator based on aligned carbon nanotube and paraffin-polydimethylsiloxane composite. Carbon 2017, 116, 625-632.

Figure 10d. The strategy of electric driving mode mechanoresponsive smart windows: based on surface wrinkle to modulate transmittance[67], Shrestha, M.; Asundi, A.; Lau, G.-K., Smart Window Based on Electric Unfolding of Microwrinkled TiO2 Nanometric Films. ACS Photonics 2018, 5, 3255-3262.

Figure 11a. The strategy of magnetic driving mode mechanoresponsive smart windows: adjusting the ratio of magnetic nanoparticles to change transmittance[70], Yang, J.; Lee, H.; Heo, S. G.; Kang, S.; Lee, H.; Lee, C. H.; Yoon, H., Squid‐Inspired Smart Window by Movement of Magnetic Nanoparticles in Asymmetric Confinement. Advanced Materials Technologies 2019, 4, 1900140.

Figure 11b. The strategy of magnetic driving mode mechanoresponsive smart windows: forming the magnetic nanopillars array to adjust transmittance[71], Luo, Z.; Evans, B. A.; Chang, C. H., Magnetically Actuated Dynamic Iridescence Inspired by the Neon Tetra. ACS Nano 2019, 13, 4657-4666.

Figure 11c. The strategy of magnetic driving mode mechanoresponsive smart windows: forming magnetothermal hydrogel to modulate transmittance[72], Wang, W.; Fan, X.; Li, F.; Qiu, J.; Umair, M. M.; Ren, W.; Ju, B.; Zhang, S.; Tang, B., Magnetochromic Photonic Hydrogel for an Alternating Magnetic Field-Responsive Color Display. Advanced Optical Materials 2018, 6, 1701093.

Figure 12a. The strategy of humidity driving mode mechanoresponsive smart windows: based on thermosensitive hydrogels[73], Wang, M.; Gao, Y.; Cao, C.; Chen, K.; Wen, Y.; Fang, D.; Li, L.; Guo, X., Binary Solvent Colloids of Thermosensitive Poly(N-isopropylacrylamide) Microgel for Smart Windows. Industrial & Engineering Chemistry Research 2014, 53, , 18462-18472.

Figure 12b. The strategy of humidity driving mode mechanoresponsive smart windows: based on the humidity driving mode wrinkles[74] Zeng, S.; Li, R.; Freire, S. G.; Garbellotto, V. M. M.; Huang, E. Y.; Smith, A. T.; Hu, C.; Tait, W. R. T.; Bian, Z.; Zheng, G.; Zhang, D.; Sun, L., Moisture-Responsive Wrinkling Surfaces with Tunable Dynamics. Adv Mater 2017, 29, 1700828.

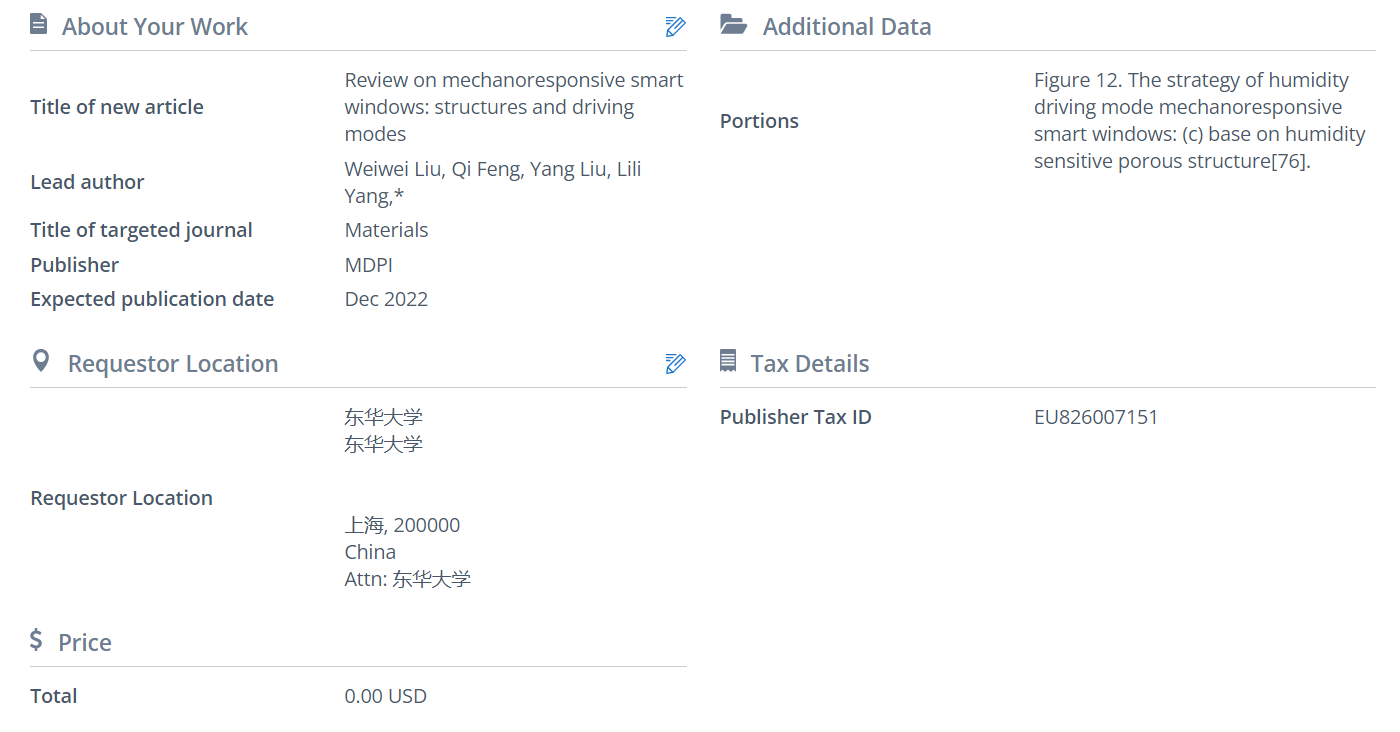

Figure 12c. The strategy of humidity driving mode mechanoresponsive smart windows: base on humidity sensitive porous structure[75],Castellón, E.; Zayat, M.; Levy, D., Novel Reversible Humidity-Responsive Light Transmission Hybrid Thin-Film Material Based on a Dispersive Porous Structure with Embedded Hygroscopic and Deliquescent Substances. Advanced Functional Materials 2018, 28, 1704717.

Figure 1a. The strategies of mechanoresponsive smart windows based on nanoarrays: nanocone[20], Li, P.; Han, Y.; Wang, W.; Chen, X.; Jin, P.; Liu, S., Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. Polymers (Basel) 2018, 10, 756-765.

Figure 1b. The strategies of mechanoresponsive smart windows based on nanoarrays: nanopillar[21], Lee, S. G.; Lee, D. Y.; Lim, H. S.; Lee, D. H.; Lee, S.; Cho, K., Switchable transparency and wetting of elastomeric smart windows. Adv Mater 2010, 22, 5013-5017.

Figure 1c. The strategies of mechanoresponsive smart windows based on nanoarrays: nanoholes[22], Zhao, P.; Chen, H.; Li, B.; Tian, H.; Lai, D.; Gao, Y., Stretchable electrochromic devices enabled via shape memory alloy composites (SMAC) for dynamic camouflage. Optical Materials 2019, 94, 378-386.

Figure 1d. The strategies of mechanoresponsive smart windows based on nanoarrays: nanospheres [23], Ji, C.; Chen, M.; Wu, L., Patternable and Rewritable Retroreflective Structural Color Shape Memory Polymers. Advanced Optical Materials 2021, 94, 2100739.

Figure 2a. The strategies of mechanoresponsive smart windows based on wrinkling: stretching to form wrinkles[29], Li, Z. W.; Liu, Y.; Marin, M.; Yin, Y. D., Thickness-dependent wrinkling of PDMS films for programmable mechanochromic responses. Nano Res 2020, 13, 1882-1888.

Figure 2b. The strategies of mechanoresponsive smart windows based on wrinkling: wrinkled photonic elastomer structure[30], Lin, R.; Qi, Y.; Kou, D.; Ma, W.; Zhang, S., Bio‐Inspired Wrinkled Photonic Elastomer with Superior Controllable and Mechanically Stable Structure for Multi‐Mode Color Display. Advanced Functional Materials 2022, 32, 2207691.

Figure 2c. The strategies of mechanoresponsive smart windows based on wrinkling: Double-layer film wrinkle[31], Jiang, B.; Liu, L.; Gao, Z.; Feng, Z.; Zheng, Y.; Wang, W., Fast Dual-Stimuli-Responsive Dynamic Surface Wrinkles with High Bistability for Smart Windows and Rewritable Optical Displays. ACS Appl Mater Interfaces 2019, 11, 40406-40415.

Figure 2d. The strategies of mechanoresponsive smart windows based on wrinkling: biaxial compression to form wrinkles[32], Shrestha, M.; Lau, G. K., Tunable window device based on micro-wrinkling of nanometric zinc-oxide thin film on elastomer. Opt Lett 2016, 41, 4433-4436.

Figure 3a. Construction paths of mechanoresponsive smart windows based on surface crack: surface deposition of metal coating[34], Mao, Z.; Zeng, S.; Shen, K.; Chooi, A. P.; Smith, A. T.; Jones, M. D.; Zhou, Y.; Liu, X.; Sun, L., Dynamic Mechanochromic Optics with Tunable Strain Sensitivity for Strain‐Responsive Digit Display. Advanced Optical Materials 2020, 8, 2001472.

Figure 3b. Construction paths of mechanoresponsive smart windows based on surface crack: soft substrate/ hard shell[35], Li, Z.; Zhai, Y.; Wang, Y.; Wendland, G. M.; Yin, X.; Xiao, J., Harnessing Surface Wrinkling–Cracking Patterns for Tunable Optical Transmittance. Advanced Optical Materials 2017, 5, 1700425.

Figure 4a. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[38], Ge, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D. S.; Yang, S., A robust smart window: reversibly switching from high transparency to angle-independent structural color display. Adv Mater 2015, 27, 2489-95.

Figure 4a. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[39], Liu, Y.; Song, S.; Liu, M.; Hu, Y.; Zhang, L.-w.; Yoon, H.; Yang, L.; Ge, D., Gecko-inspired ultrasensitive multifunctional mechano-optical smart membranes. Chemical Engineering Journal 2022, 429, 132159.

Figure 4b. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[40], Cho, D.; Shim, Y. S.; Jung, J. W.; Nam, S. H.; Min, S.; Lee, S. E.; Ham, Y.; Lee, K.; Park, J.; Shin, J.; Hong, J. W.; Jeon, S., High-Contrast Optical Modulation from Strain-Induced Nanogaps at 3D Heterogeneous Interfaces. Adv Sci (Weinh) 2020, 7, 1903708.

Figure 5a. Mechanoresponsive smart windows with dynamic control of interface parameters: colloidal particle spacing[41], Han, J.; Freyman, M. C.; Feigenbaum, E.; Yong-Jin Han, T., Electro-Optical Device with Tunable Transparency Using Colloidal Core/Shell Nanoparticles. ACS Photonics 2018, 5, 1343-1350.

Figure 5b. Mechanoresponsive smart windows with dynamic control of interface parameters: colloidal particle direction[42], Li, J.; Lu, X.; Zhang, Y.; Ke, X.; Wen, X.; Cheng, F.; Wei, C.; Li, Y.; Yao, K.; Yang, S., Highly Sensitive Mechanoresponsive Smart Windows Driven by Shear Strain. Advanced Functional Materials 2021, 31, 2102350.

Figure 5c. Mechanoresponsive smart windows with dynamic control of interface parameters: spacing and shape of hole[17]. Zhao, P.; Li, B.; Tang, Z.; Gao, Y.; Tian, H.; Chen, H., Stretchable photonic crystals with periodic cylinder shaped air holes for improving mechanochromic performance. Smart Materials and Structures 2019, 28, 075037.

Figure 6a. Two strategies of mechanoresponsive smart windows based on surface and interface modulation synergistically: surface wrinkle, novel interface dynamic formation dynamic control of interface parameters[43], Qi, Y.; Zhou, C.; Zhang, S.; Zhang, Z.; Niu, W.; Wu, S.; Ma, W.; Tang, B., Bar-coating programmable mechanochromic bilayer PDMS film with angle-dependent and angle-independent structural colors. Dyes and Pigments 2021, 189, 109264.

Figure 6b. Two strategies of mechanoresponsive smart windows based on surface and interface modulation synergistically: surface wrinkle and novel interface dynamic generation[44], Kim, H. N.; Ge, D.; Lee, E.; Yang, S., Multistate and On-Demand Smart Windows. Adv Mater 2018, 30, e1803847.

Figure 7a. The strategy of pneumatic drive mode mechanoresponsive smart windows: adjust transparency and color by changing film thickness[45], López Jiménez, F.; Kumar, S.; Reis, P. M., Soft Color Composites with Tunable Optical Transmittance. Advanced Optical Materials 2016, 4, 620-626.

Figure 7b. The strategy of pneumatic drive mode mechanoresponsive smart windows: adjust transparency and color by changing film thickness[46], Kim, S. U.; Lee, Y. J.; Liu, J.; Kim, D. S.; Wang, H.; Yang, S., Broadband and pixelated camouflage in inflating chiral nematic liquid crystalline elastomers. Nat Mater 2022, 21, 41-46.

Figure 7c. The strategy of pneumatic drive mode mechanoresponsive smart windows: pneumatic stretching to adjust transparency[47]; Rotzetter, A. C. C.; Fuhrer, R.; Grass, R. N.; Schumacher, C. M.; Stoessel, P. R.; Stark, W. J., Micro Mirror Polymer Composite Offers Mechanically Switchable Light Transmittance. Advanced Engineering Materials 2014, 16, 878-883.

Figure 7d. The strategy of pneumatic drive mode mechanoresponsive smart windows: pneumatic drive mode mechanochromic hydrogels[48]. Zhu, Q.; Vliet, K.; Holten‐Andersen, N.; Miserez, A., A Double‐Layer Mechanochromic Hydrogel with Multidirectional Force Sensing and Encryption Capability. Advanced Functional Materials 2019, 29, 1808191.

Figure 8a. The approaches for optical-driving mechanoresponsive smart windows: based on the high photothermal conversion efficiency of CNT[49], Li, F.; Hou, H.; Yin, J.; Jiang, X., Near-infrared light–responsive dynamic wrinkle patterns. Science Advances 4, eaar5762.

Figure 8b. The approaches for optical-driving mechanoresponsive smart windows: based on the high photothermal conversion efficiency of CNT[50], Xie, M.; Lin, G.; Ge, D.; Yang, L.; Zhang, L.; Yin, J.; Jiang, X., Pattern Memory Surface (PMS) with Dynamic Wrinkles for Unclonable Anticounterfeiting. ACS Materials Letters 2019, 1, 77-82.

Figure 8c. The approaches for optical-driving mechanoresponsive smart windows: (c) based on metal nanoparticles[51], Cao, D.; Xu, C.; Lu, W.; Qin, C.; Cheng, S., Sunlight-Driven Photo-Thermochromic Smart Windows. Solar RRL 2018, 2, 1700219.

Figure 8d. The approaches for optical-driving mechanoresponsive smart windows: based on inverse opal scaffold structure[52]. Wang, Y.; Zhang, Z.; Chen, H.; Zhang, H.; Zhang, H.; Zhao, Y., Bio-inspired shape-memory structural color hydrogel film. Science Bulletin 2022, 67, 512-519.

Figure 9a. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of surface wrinkles structure[58], Li, D.; Zhou, C.; Meng, Y.; Chen, C.; Yu, C.; Long, Y.; Li, S., Deformable Thermo-Responsive Smart Windows Based on a Shape Memory Polymer for Adaptive Solar Modulations. ACS Appl Mater Interfaces 2021, 13, 61196-61204.

Figure 9b. The strategy of thermal driving mode of mechanoresponsive smart windows: (a) formation of dynamic network structure[59], Zhao, J.; Zhang, L.; Du, X.; Xu, J.; Lin, T.; Li, Y.; Yang, X.; You, J., Panther chameleon-inspired, continuously-regulated, high-saturation structural color of a reflective grating on the nano-patterned surface of a shape memory polymer. Nanoscale Adv 2022, 4, 2942-2949.

Figure 9c. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of nanostripes structure[60], Xu, Z.-Y.; Li, L.; Du, L.; Wang, L.; Shi, L.-Y.; Yang, K.-K.; Wang, Y.-Z., Multiscale shape-memory effects in a dynamic polymer network for synchronous changes in color and shape. Applied Materials Today 2022, 26, 101276.

Figure 9d. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of dynamic network structure[61], Zhang, W.; Wang, H.; Wang, H.; Chan, J. Y. E.; Liu, H.; Zhang, B.; Zhang, Y. F.; Agarwal, K.; Yang, X.; Ranganath, A. S.; Low, H. Y.; Ge, Q.; Yang, J. K. W., Structural multi-colour invisible inks with submicron 4D printing of shape memory polymers. Nat Commun 2021, 12, (1), 112-120.

Figure 10a. The strategy of electric driving mode mechanoresponsive smart windows: controlling movement of nanoparticles via the electrophoresis to modulate transmittance and color[64], Wang, J. L.; Liu, J. W.; Sheng, S. Z.; He, Z.; Gao, J.; Yu, S. H., Manipulating Nanowire Assemblies toward Multicolor Transparent Electrochromic Device. Nano Lett 2021, 21, 9203-9209.

Figure 10b. The strategy of electric driving mode mechanoresponsive smart windows: controlling movement of nanoparticles via the electrophoresis to modulate transmittance and color[65], Liu, S.; Zhang, D.; Peng, H.; Jiang, Y.; Gao, X.; Zhou, G.; Liu, J.-M.; Kempa, K.; Gao, J., High-efficient smart windows enabled by self-forming fractal networks and electrophoresis of core-shell TiO2@SiO2 particles. Energy and Buildings 2021, 232, 110657.

Figure 10c. The strategy of electric driving mode mechanoresponsive smart windows: based on carbon nanotube materials to adjust transmittance[66], Zhang, W.; Weng, M.; Zhou, P.; Chen, L.; Huang, Z.; Zhang, L.; Liu, C.; Fan, S., Transparency-switchable actuator based on aligned carbon nanotube and paraffin-polydimethylsiloxane composite. Carbon 2017, 116, 625-632.

Figure 10d. The strategy of electric driving mode mechanoresponsive smart windows: based on surface wrinkle to modulate transmittance[67], Shrestha, M.; Asundi, A.; Lau, G.-K., Smart Window Based on Electric Unfolding of Microwrinkled TiO2 Nanometric Films. ACS Photonics 2018, 5, 3255-3262.

Figure 11a. The strategy of magnetic driving mode mechanoresponsive smart windows: adjusting the ratio of magnetic nanoparticles to change transmittance[70], Yang, J.; Lee, H.; Heo, S. G.; Kang, S.; Lee, H.; Lee, C. H.; Yoon, H., Squid‐Inspired Smart Window by Movement of Magnetic Nanoparticles in Asymmetric Confinement. Advanced Materials Technologies 2019, 4, 1900140.

Figure 11b. The strategy of magnetic driving mode mechanoresponsive smart windows: forming the magnetic nanopillars array to adjust transmittance[71], Luo, Z.; Evans, B. A.; Chang, C. H., Magnetically Actuated Dynamic Iridescence Inspired by the Neon Tetra. ACS Nano 2019, 13, 4657-4666.

Figure 11c. The strategy of magnetic driving mode mechanoresponsive smart windows: forming magnetothermal hydrogel to modulate transmittance[72], Wang, W.; Fan, X.; Li, F.; Qiu, J.; Umair, M. M.; Ren, W.; Ju, B.; Zhang, S.; Tang, B., Magnetochromic Photonic Hydrogel for an Alternating Magnetic Field-Responsive Color Display. Advanced Optical Materials 2018, 6, 1701093.

Figure 12a. The strategy of humidity driving mode mechanoresponsive smart windows: based on thermosensitive hydrogels[73], Wang, M.; Gao, Y.; Cao, C.; Chen, K.; Wen, Y.; Fang, D.; Li, L.; Guo, X., Binary Solvent Colloids of Thermosensitive Poly(N-isopropylacrylamide) Microgel for Smart Windows. Industrial & Engineering Chemistry Research 2014, 53, , 18462-18472.

Figure 12b. The strategy of humidity driving mode mechanoresponsive smart windows: based on the humidity driving mode wrinkles[74] Zeng, S.; Li, R.; Freire, S. G.; Garbellotto, V. M. M.; Huang, E. Y.; Smith, A. T.; Hu, C.; Tait, W. R. T.; Bian, Z.; Zheng, G.; Zhang, D.; Sun, L., Moisture-Responsive Wrinkling Surfaces with Tunable Dynamics. Adv Mater 2017, 29, 1700828.

Figure 12c. The strategy of humidity driving mode mechanoresponsive smart windows: base on humidity sensitive porous structure[75],Castellón, E.; Zayat, M.; Levy, D., Novel Reversible Humidity-Responsive Light Transmission Hybrid Thin-Film Material Based on a Dispersive Porous Structure with Embedded Hygroscopic and Deliquescent Substances. Advanced Functional Materials 2018, 28, 1704717.

References

- Searchinger, T.D.; Beringer, T.; Holtsmark, B.; Kammen, D.M.; Lambin, E.F.; Lucht, W.; Raven, P.; van Ypersele, J.-P. Europe’s renewable energy directive poised to harm global forests. Nat. Commun. 2018, 9, 3741.

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398.

- Shin, M.; Baltazar, J.-C.; Haberl, J.S.; Frazier, E.; Lynn, B. Evaluation of the energy performance of a net zero energy building in a hot and humid climate. Energy Build. 2019, 204, 109531.

- Ma, Z.Y.; Guan, B.W.; Liu, X.H.; Zhang, T. Performance analysis and improvement of air filtration and ventilation process in semiconductor clean air-conditioning system. Energy Build. 2020, 228, 110489.

- Dussault, J.-M.; Gosselin, L.; Galstian, T. Integration of smart windows into building design for reduction of yearly overall energy consumption and peak loads. Sol. Energy 2012, 86, 3405–3416.

- Wang, M.; Xing, X.; Perepichka, I.F.; Shi, Y.H.; Zhou, D.Y.; Wu, P.H.; Meng, H. Electrochromic Smart Windows Can Achieve an Absolute Private State through Thermochromically Engineered Electrolyte. Adv. Energy Mater. 2019, 9, 1900433.

- Ke, Y.J.; Chen, J.W.; Lin, C.J.; Wang, S.C.; Zhou, Y.; Yin, J.; Lee, P.S.; Long, Y. Smart Windows: Electro-, Thermo-, Mechano-, Photochromics, and Beyond. Adv. Energy Mater. 2019, 9, 1902066.

- Zhou, Y.; Fan, F.; Liu, Y.P.; Zhao, S.S.; Xu, Q.; Wang, S.C.; Luo, D.; Long, Y. Unconventional smart windows: Materials, structures and designs. Nano Energy 2021, 90, 106613.

- Svensson, J.S.E.M.; Granqvist, C.G. Electrochromic Coatings for Smart Windows. Sol. Energy Mater. 1985, 12, 391–402.

- Tällberg, R.; Jelle, B.P.; Loonen, R.; Gao, T.; Hamdy, M. Comparison of the energy saving potential of adaptive and controllable smart windows: A state-of-the-art review and simulation studies of thermochromic, photochromic and electrochromic technologies. Sol. Energy Mater. Sol. Cells 2019, 200, 109828.

- Wang, X.J.; Narayan, S. Thermochromic Materials for Smart Windows: A State-of-Art Review. Front. Energy Res. 2021, 9, 837–841.

- Chun, S.Y.; Park, S.; Lee, S.I.; Nguyen, H.D.; Lee, K.-K.; Hong, S.; Han, C.-H.; Cho, M.; Choi, H.-K.; Kwak, K. Operando Raman and UV-Vis spectroscopic investigation of the coloring and bleaching mechanism of self-powered photochromic devices for smart windows. Nano Energy 2021, 82, 105721.

- Liu, S.; Tso, C.Y.; Lee, H.H.; Zhang, Y.; Yu, K.M.; Chao, C.Y.H. Bio-inspired TiO2 nano-cone antireflection layer for the optical performance improvement of VO2 thermochromic smart windows. Sci. Rep. 2020, 10, 11376.

- Quan, Y.-J.; Kim, Y.-G.; Kim, M.-S.; Min, S.-H.; Ahn, S.-H. Stretchable Biaxial and Shear Strain Sensors Using Diffractive Structural Colors. ACS Nano 2020, 14, 5392–5399.

- Lee, E.; Zhang, M.; Cho, Y.; Cui, Y.; Van der Spiegel, J.; Engheta, N.; Yang, S. Tilted Pillars on Wrinkled Elastomers as a Reversibly Tunable Optical Window. Adv. Mater. 2014, 26, 4127–4133.

- Fan, Z.; Razavi, H.; Do, J.W.; Moriwaki, A.; Ergen, O.; Chueh, Y.L.; Leu, P.W.; Ho, J.C.; Takahashi, T.; Reichertz, L.A. Three-dimensional nanopillar-array photovltaics on low-cost and flexible substrates. Nat. Mater. 2009, 8, 648–653.

- Zhao, P.; Li, B.; Tang, Z.; Gao, Y.; Tian, H.; Chen, H. Stretchable photonic crystals with periodic cylinder shaped air holes for improving mechanochromic performance. Smart Mater. Struct. 2019, 28, 075037.

- Li, J.; Shim, J.; Deng, J.; Overvelde, J.T.B.; Zhu, X.; Bertoldi, K.; Yang, S. Switching periodic membranes via pattern transformation and shape memory effect. Soft Matter. 2012, 8, 10322–10328.

- Wang, K.; Li, C.; Li, Z.; Li, H.; Li, A.; Li, K.; Lai, X.; Liao, Q.; Xie, F.; Li, M.; et al. A facile fabrication strategy for anisotropic photonic crystals using deformable spherical nanoparticles. Nanoscale 2019, 11, 14147–14154.

- Li, P.; Han, Y.; Wang, W.; Chen, X.; Jin, P.; Liu, S. Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. Polymers 2018, 10, 756.

- Lee, S.G.; Lee, D.Y.; Lim, H.S.; Lee, D.H.; Lee, S.; Cho, K. Switchable transparency and wetting of elastomeric smart windows. Adv. Mater. 2010, 22, 5013–5017.

- Zhao, P.; Chen, H.; Li, B.; Tian, H.; Lai, D.; Gao, Y. Stretchable electrochromic devices enabled via shape memory alloy composites (SMAC) for dynamic camouflage. Opt. Mater. 2019, 94, 378–386.

- Ji, C.; Chen, M.; Wu, L. Patternable and Rewritable Retroreflective Structural Color Shape Memory Polymers. Adv. Opt. Mater. 2021, 9, 2100739.

- Thomas, A.V.; Andow, B.C.; Suresh, S.; Eksik, O.; Yin, J.; Dyson, A.H.; Koratkar, N. Controlled Crumpling of Graphene Oxide Films for Tunable Optical Transmittance. Adv. Mater. 2015, 27, 3256–3265.

- Zang, J.; Ryu, S.; Pugno, N.; Wang, Q.; Tu, Q.; Buehler, M.J.; Zhao, X. Multifunctionality and control of the crumpling and unfolding of large-area graphene. Nat. Mater. 2013, 12, 321–325.

- Ke, Y.; Zhang, Q.; Wang, T.; Wang, S.; Li, N.; Lin, G.; Liu, X.; Dai, Z.; Yan, J.; Yin, J.; et al. Cephalopod-inspired versatile design based on plasmonic VO2 nanoparticle for energy-efficient mechano-thermochromic windows. Nano Energy 2020, 73, 104785.

- Lin, G.; Chandrasekaran, P.; Lv, C.; Zhang, Q.; Tang, Y.; Han, L.; Yin, J. Self-similar Hierarchical Wrinkles as a Potential Multifunctional Smart Window with Simultaneously Tunable Transparency, Structural Color, and Droplet Transport. ACS Appl. Mater. Interfaces 2017, 9, 26510–26517.

- Cao, C.; Chan, H.F.; Zang, J.; Leong, K.W.; Zhao, X. Harnessing localized ridges for high-aspect-ratio hierarchical patterns with dynamic tunability and multifunctionality. Adv. Mater. 2014, 26, 1763–1770.

- Li, Z.W.; Liu, Y.; Marin, M.; Yin, Y.D. Thickness-dependent wrinkling of PDMS films for programmable mechanochromic responses. Nano Res. 2020, 13, 1882–1888.

- Lin, R.; Qi, Y.; Kou, D.; Ma, W.; Zhang, S. Bio-Inspired Wrinkled Photonic Elastomer with Superior Controllable and Mechanically Stable Structure for Multi-Mode Color Display. Adv. Funct. Mater. 2022, 32, 2207691.

- Jiang, B.; Liu, L.; Gao, Z.; Feng, Z.; Zheng, Y.; Wang, W. Fast Dual-Stimuli-Responsive Dynamic Surface Wrinkles with High Bistability for Smart Windows and Rewritable Optical Displays. ACS Appl. Mater. Interfaces 2019, 11, 40406–40415.

- Shrestha, M.; Lau, G.-K. Tunable window device based on micro-wrinkling of nanometric zinc-oxide thin film on elastomer. Opt. Lett. 2016, 41, 4433–4436.

- Zeng, S.; Zhang, D.; Huang, W.; Wang, Z.; Freire, S.G.; Yu, X.; Smith, A.T.; Huang, E.Y.; Nguon, H.; Sun, L. Bio-inspired sensitive and reversible mechanochromisms via strain-dependent cracks and folds. Nat. Commun. 2016, 7, 11802.

- Mao, Z.; Zeng, S.; Shen, K.; Chooi, A.P.; Smith, A.T.; Jones, M.D.; Zhou, Y.; Liu, X.; Sun, L. Dynamic Mechanochromic Optics with Tunable Strain Sensitivity for Strain-Responsive Digit Display. Adv. Opt. Mater. 2020, 8, 2001472.

- Li, Z.; Zhai, Y.; Wang, Y.; Wendland, G.M.; Yin, X.; Xiao, J. Harnessing Surface Wrinkling–Cracking Patterns for Tunable Optical Transmittance. Adv. Opt. Mater. 2017, 5, 1700425.

- Jiang, Y.; Zeng, S.; Yao, Y.; Xu, S.; Dong, Q.; Chen, P.; Wang, Z.; Zhang, M.; Zhu, M.; Xu, G.; et al. Dynamic Optics with Transparency and Color Changes under Ambient Conditions. Polymers 2019, 11, 103.

- Zhao, H.; Sun, Q.; Zhou, J.; Deng, X.; Cui, J. Switchable Cavitation in Silicone Coatings for Energy-Saving Cooling and Heating. Adv. Mater. 2020, 32, e2000870.

- Ge, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D.S.; Yang, S. A Robust Smart Window: Reversibly Switching from High Transparency to Angle-Independent Structural Color Display. Adv. Mater. 2015, 27, 2489–2495.

- Liu, Y.; Song, S.; Liu, M.; Hu, Y.; Zhang, L.-W.; Yoon, H.; Yang, L.; Ge, D. Gecko-inspired ultrasensitive multifunctional mechano-optical smart membranes. Chem. Eng. J. 2021, 429, 132159.

- Cho, D.; Shim, Y.S.; Jung, J.W.; Nam, S.H.; Min, S.; Lee, S.E.; Ham, Y.; Lee, K.; Park, J.; Shin, J.; et al. High-Contrast Optical Modulation from Strain-Induced Nanogaps at 3D Heterogeneous Interfaces. Adv. Sci. 2020, 7, 1903708.

- Han, J.; Freyman, M.C.; Feigenbaum, E.; Han, T.Y.-J. Electro-Optical Device with Tunable Transparency Using Colloidal Core/Shell Nanoparticles. ACS Photonics 2018, 5, 1343–1350.

- Li, J.; Lu, X.; Zhang, Y.; Ke, X.; Wen, X.; Cheng, F.; Wei, C.; Li, Y.; Yao, K.; Yang, S. Highly Sensitive Mechanoresponsive Smart Windows Driven by Shear Strain. Adv. Funct. Mater. 2021, 31, 2102350.

- Qi, Y.; Zhou, C.; Zhang, S.; Zhang, Z.; Niu, W.; Wu, S.; Ma, W.; Tang, B. Bar-coating programmable mechanochromic bilayer PDMS film with angle-dependent and angle-independent structural colors. Dyes Pigments 2021, 189, 109264.

- Kim, H.N.; Ge, D.; Lee, E.; Yang, S. Multistate and On-Demand Smart Windows. Adv. Mater. 2018, 30, e1803847.