- basalt fibers

- shrinkage

- thermal properties

1. Introduction

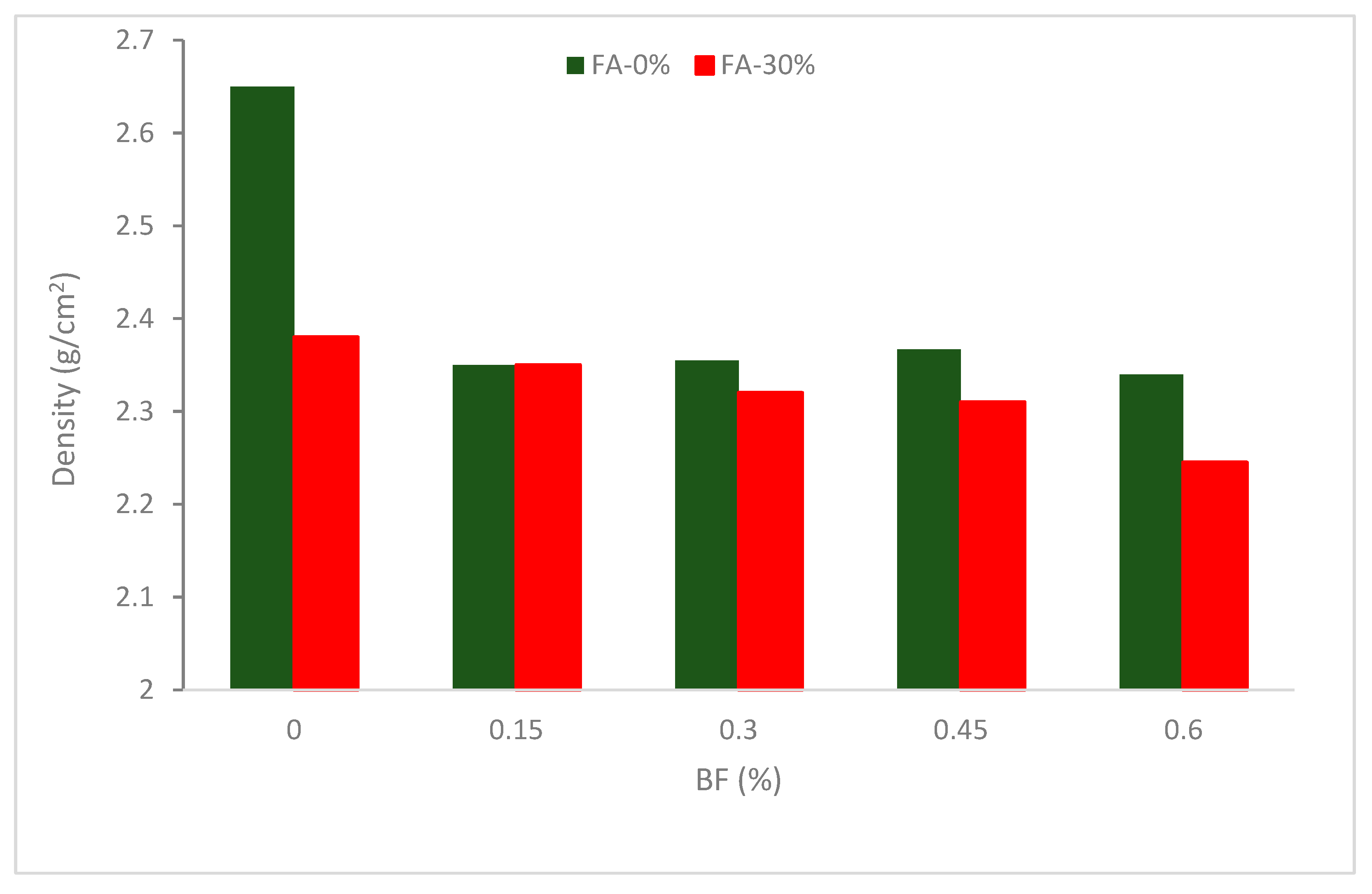

2. Apparent Density

3. Permeability

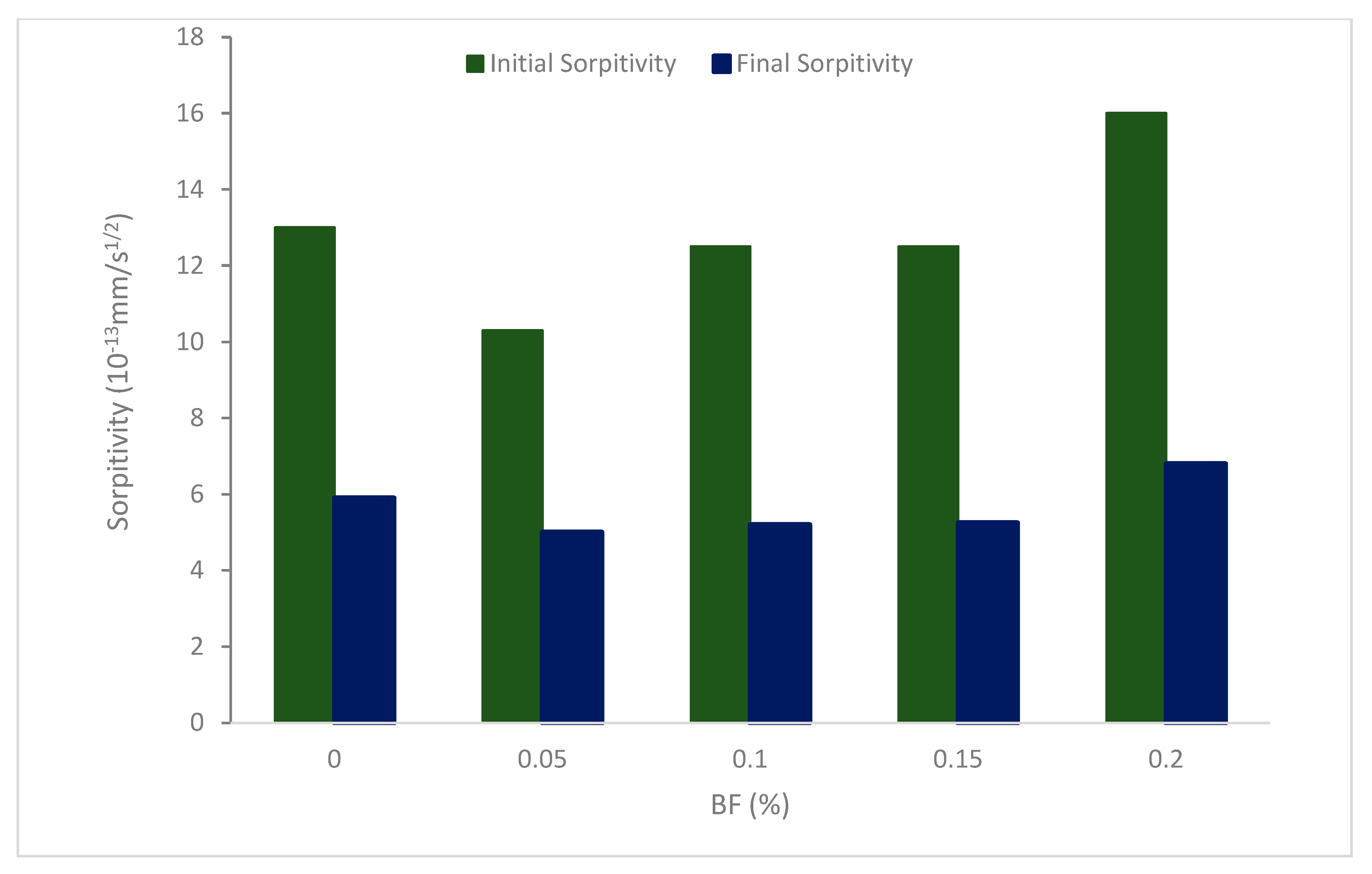

3.1. Sorptivity

3.2. Water Absorption (WA)

Concrete must have both compressive strength and long-term durability. The density of concrete has an impact on its long-lasting qualities. Compact (dense) concrete has more load carrying capacity and has fewer voids and pores. Concrete with fewer voids is less porous to liquid chemicals and water. As a result, this kind of concrete will last longer, and less WA or other harmful chemicals will penetrate.

The statistics on water absorption show that increasing the fiber content somewhat improves the WA as associated to reference SCC. Nevertheless, the water absorption values of all fiber-reinforced SCC were within 2% of one another. Concrete has less water penetration because of a more compact pore structure as a consequence of the GF’s tight bond with cement particles. The endurance of the concrete is increased by the introduction of GF [39]. It was known that the least amount of WA was attained at 2.0% steel fiber [40]. Regular concrete has a lower MOE than fiber concrete. Fibers would improve the tensile strain properties of concrete, reducing the development and spread of early fractures [41]. Therefore, BF addition decreased water absorption penetration due to crack prevention. Furthermore, the substitution of secondary cementitious materials such as silica fume considerably due to combined pozzolanic and micro filling effects.

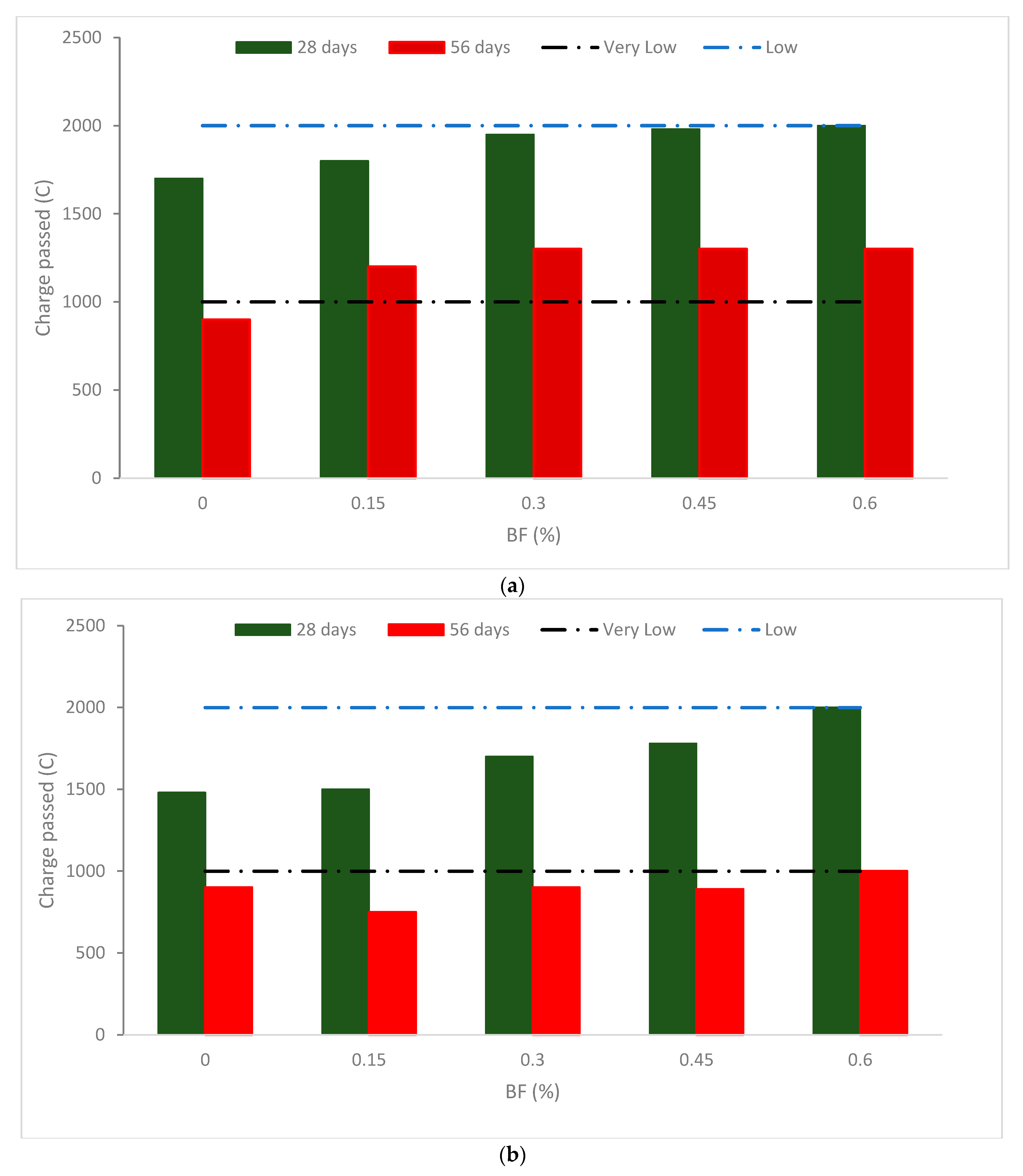

3.3. Rapid Chloride Ions Penetrability

Figure 5 displays the outcomes of the charge after it was run through all combinations that were aged between 28 and 56 days. The outcomes show that adding BF raises the charge of the concrete. For the same series, a greater charge is obtained in the blends with greater BF (0.60 percent). According to a study [34], the inclusion of BFs in cementitious mixtures leads to a reduction in electrical resistivity, making electrical resistivity more apparent as fiber volume increases. Results from the electrical resistivity test have been altered by the percentages and composition of pores and the chemical composition of the pore mixture. Therefore, specimens containing 15% silica fume do not necessarily have higher performance or durability because of their higher specific electrical resistivity.

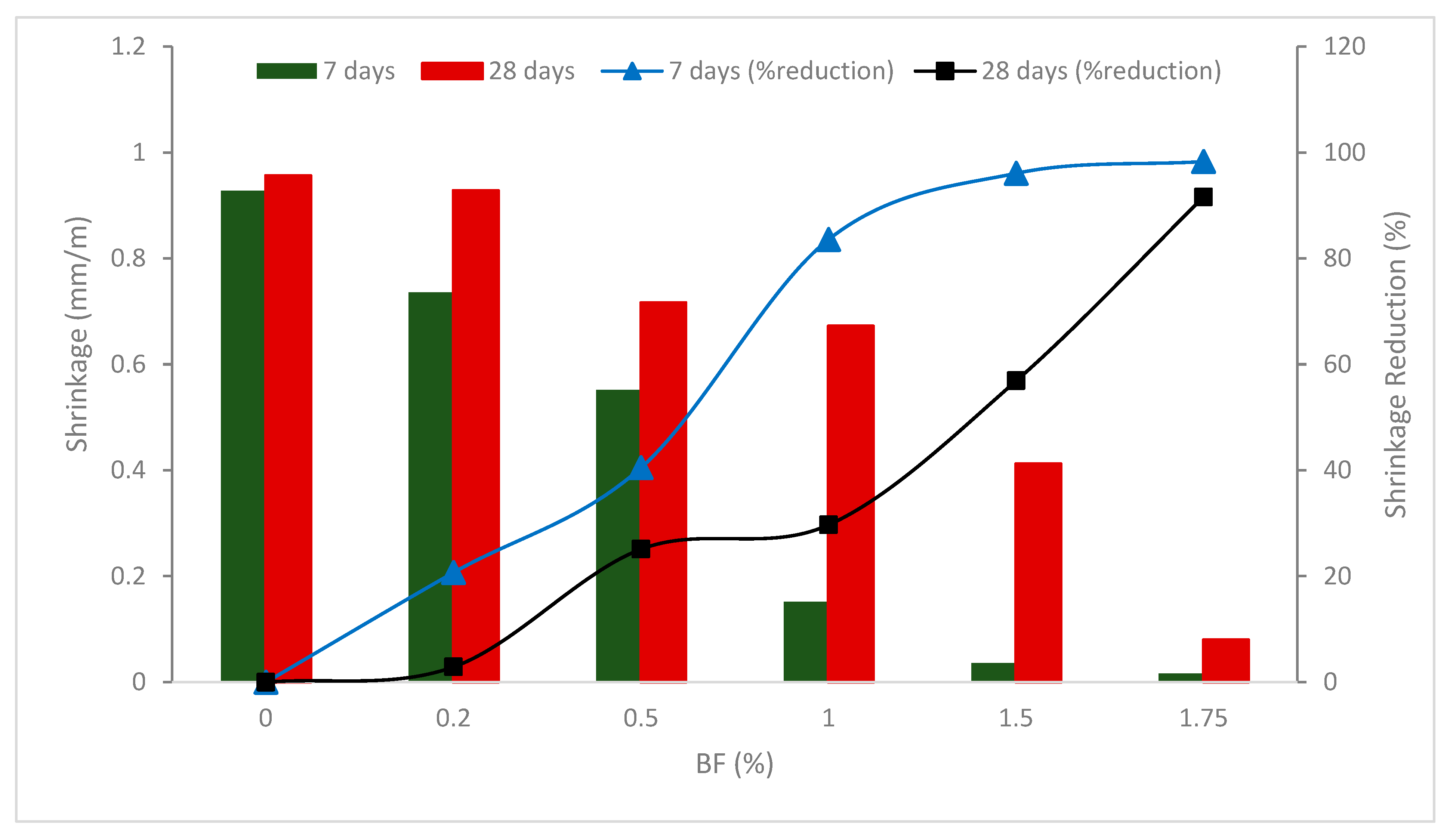

4. Shrinkage

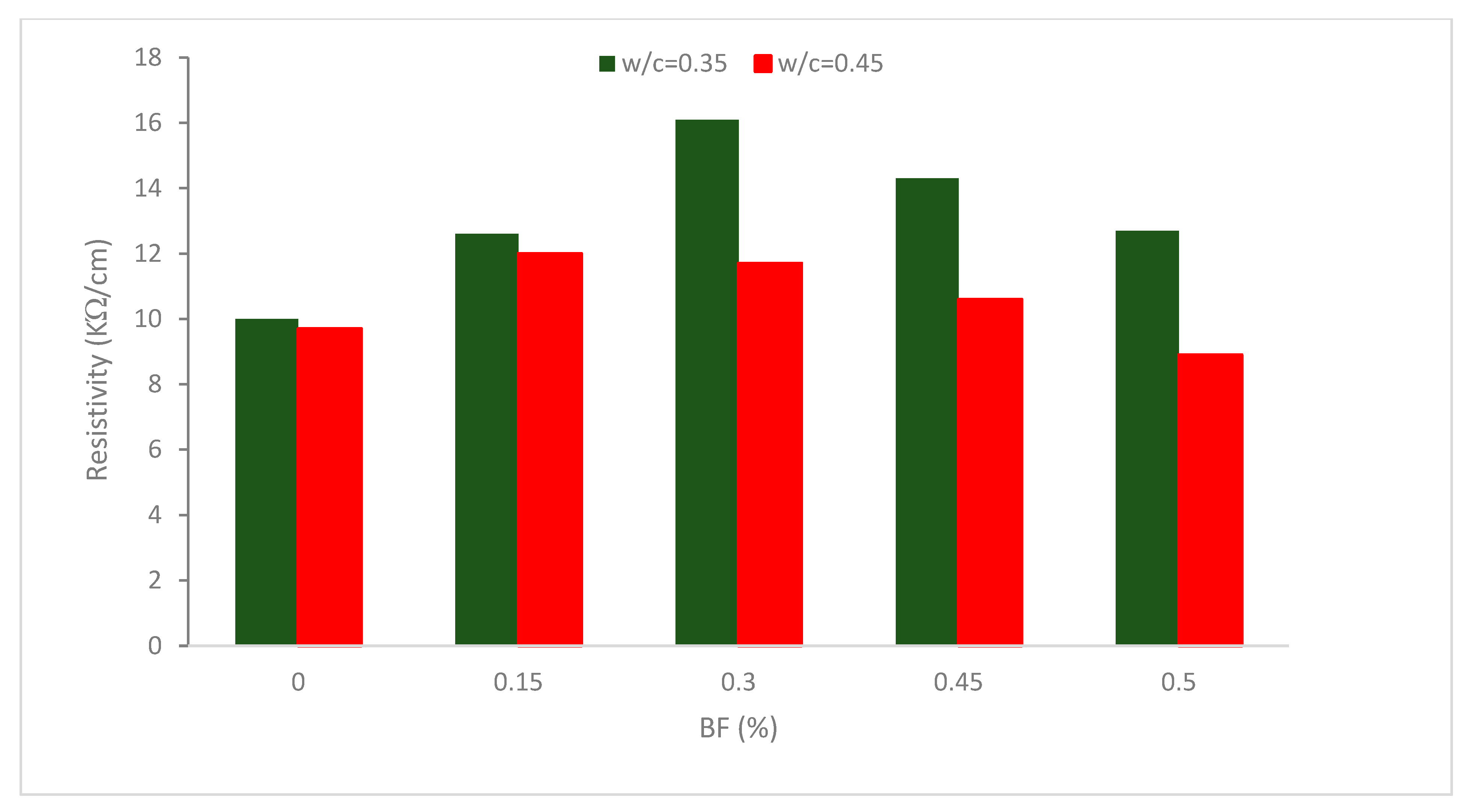

5. Electric Resistivity

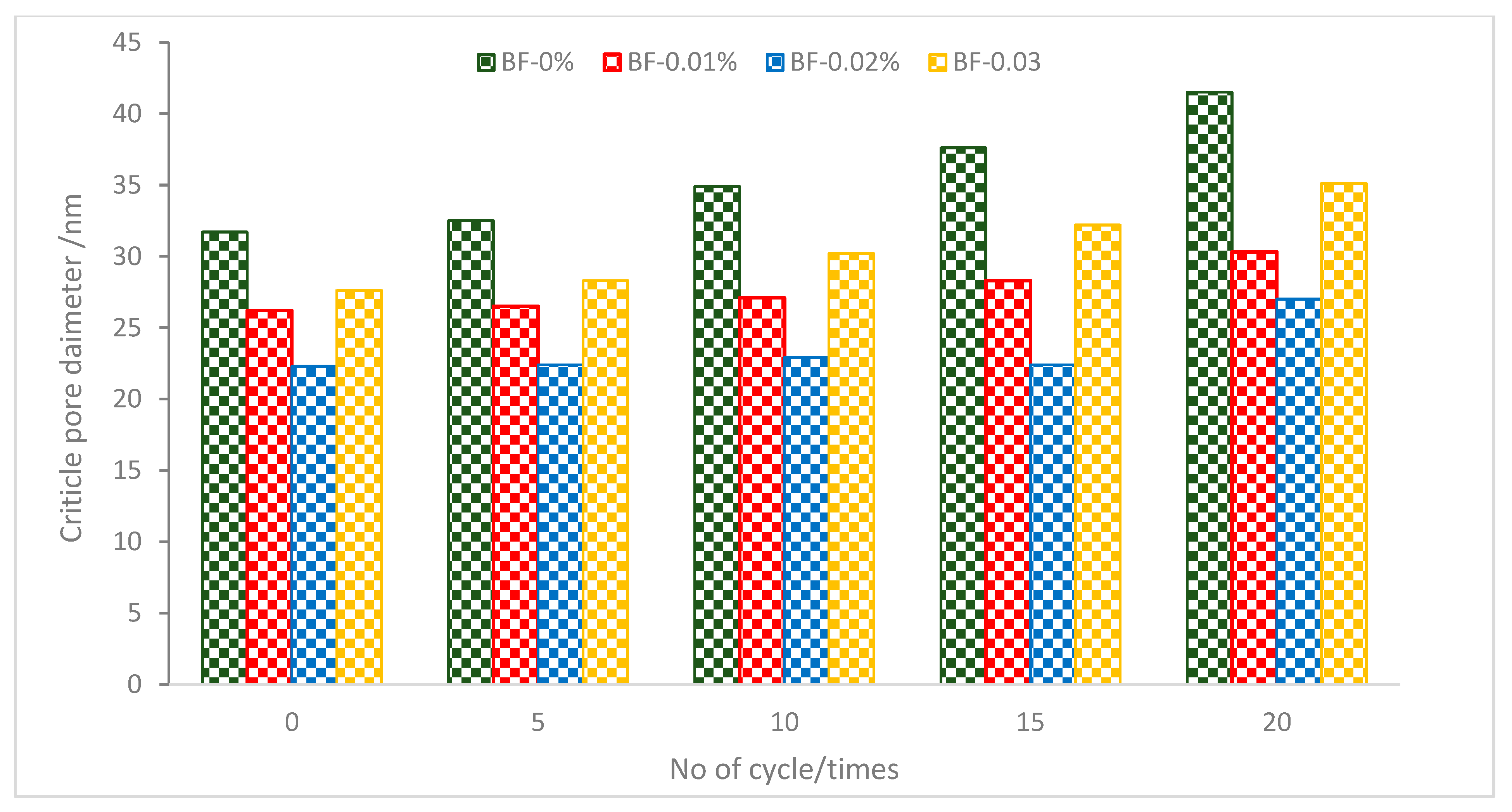

6. Freezing and Thawing

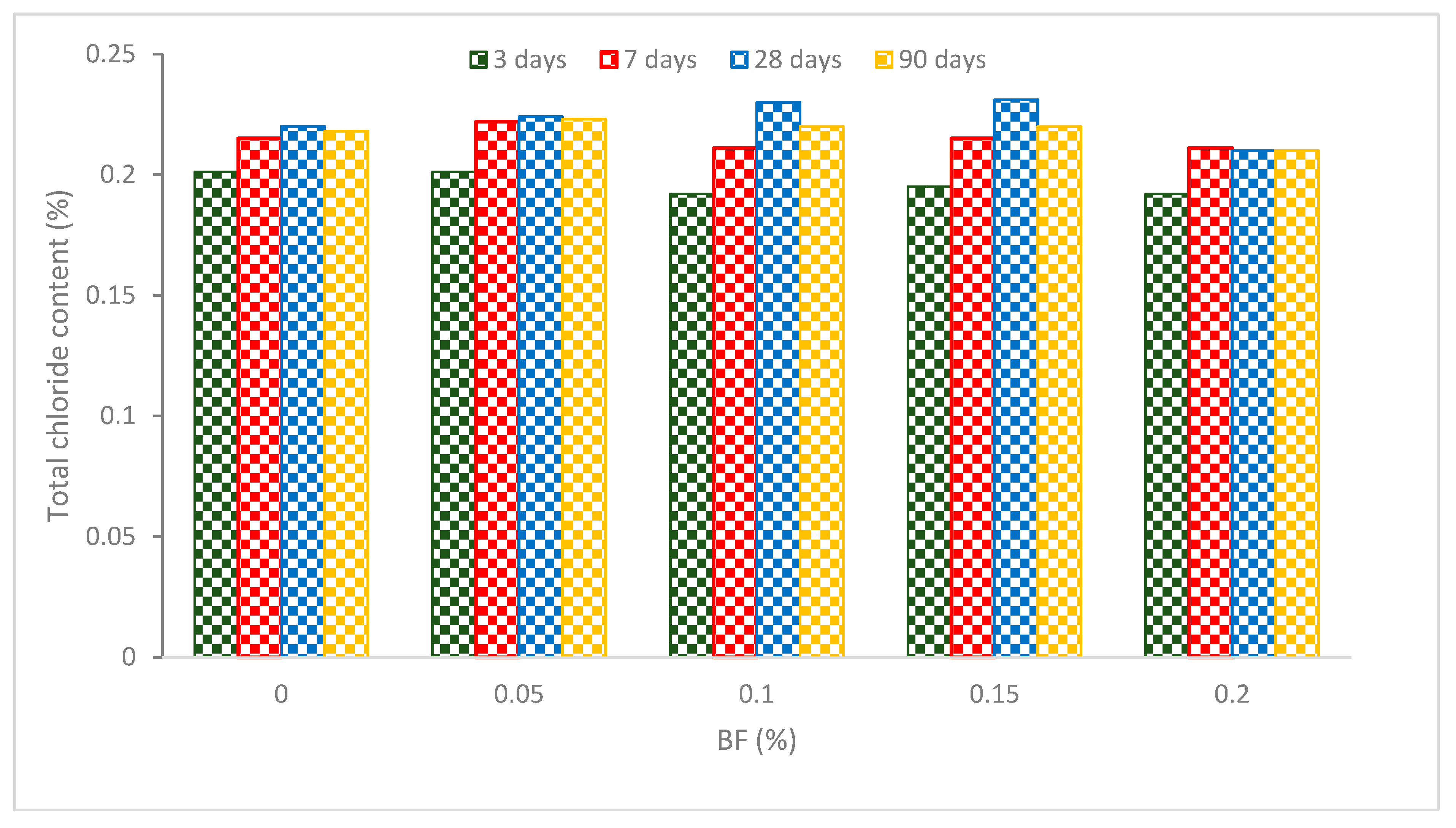

7. Chloride Content

The total chloride concentration of concrete after the addition of BF is shown in Figure 9. The concrete containing 0.05 percent fibers has a greater total chloride ion concentration than normal concrete after curing for more than 3 days. At 14 to 90 days, concrete reinforced with 0.2% BF had a lower total chloride ion level than other specimens. The total chloride ion level decreased by 0.48 to 5.8 percent after 3 days after adding 0.05 and 0.20 percent of BF. The amount of total chloride ions in concrete with 0.05 percent BF rose by 2.7 percent after 90 days. However, by adding 0.1 percent to 0.2 percent of BF, the total chloride ion level was reduced by 0.45 percent to 5 percent.

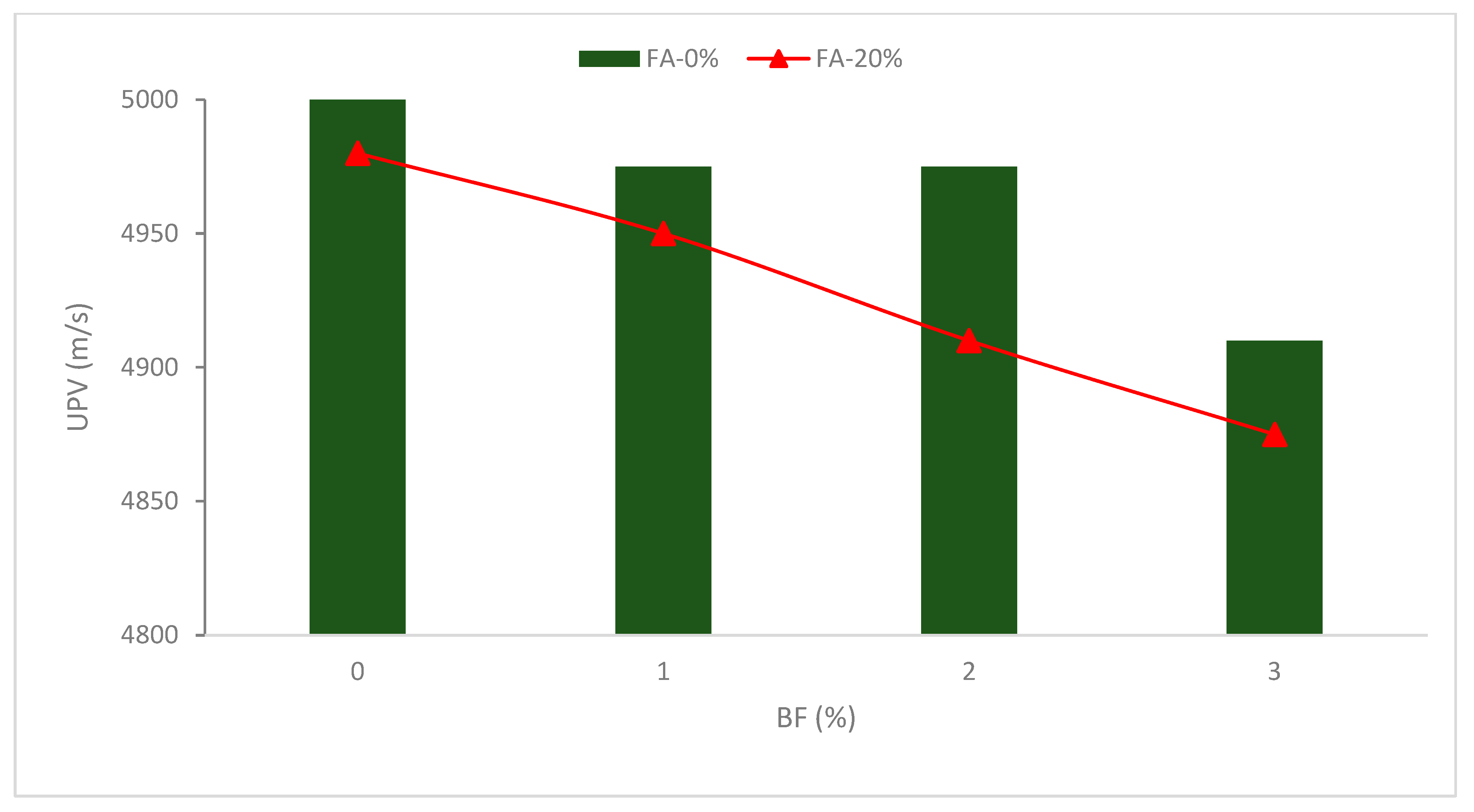

8. Ultra-Sonic Pulse Velocity

Figure 10 demonstrates that when the BF concentration increased, the pulse velocity decreased. The phenomenon may be attributed to several factors. The first is that BF-containing mixes have some capillaries that migrated into the hardened concrete as the hydration process progressed. It has long been known that the most significant influence on the impact of the transmission velocity of ultrasonic pulses comes from the capillaries in the concrete specimen. The fact that void concrete propagates pulses more quickly than solid matter does provide evidence that it slows the predicted velocity by increasing the pulse’s capillary transit [53].

9. Alkali Resistance

References

- Handayani, L.; Aprilia, S.; Abdullah, A.; Rahmawati, C.; Abdullah, M.M.A.B.; Aziz, I.H.; Azimi, E.A. Synthesis of Sodium Silicate from Rice Husk Ash as an Activator to Produce Epoxy-Geopolymer Cement. J. Phys. Conf. Ser. 2021, 1845, 012072.

- Smirnova, O.M.; Menéndez Pidal de Navascués, I.; Mikhailevskii, V.R.; Kolosov, O.I.; Skolota, N.S. Sound-Absorbing Composites with Rubber Crumb from Used Tires. Appl. Sci. 2021, 11, 7347.

- Chevuri, V.R.; Sridhar, S. Usage of Waste Foundry Sand in Concrete. Int. J. Civ. Eng. 2015, 2, 5–10.

- Lee, H.; Hanif, A.; Usman, M.; Sim, J.; Oh, H. Performance Evaluation of Concrete Incorporating Glass Powder and Glass Sludge Wastes as Supplementary Cementing Material. J. Clean. Prod. 2018, 170, 683–693.

- Chavan, S.; Rao, P. Utilization of Waste PET Bottle Fibers in Concrete as an Innovation in Building Materials—. Int. J. Eng. Res. 2016, 5, 304–307.

- Ahmad, J.; Majdi, A.; Deifalla, A.F.; Isleem, H.F.; Rahmawati, C. Concrete Made with Partially Substitutions of Copper Slag (CPS): State of the Art Review. Materials 2022, 15, 5196.

- Rahmawati, C.; Aprilia, S.; Saidi, T.; Aulia, T.B. Current Development of Geopolymer Cement with Nanosilica and Cellulose Nanocrystals. J. Phys. Conf. Ser. 2021, 1783, 012056.

- Smirnova, O. Compatibility of Shungisite Microfillers with Polycarboxylate Admixtures in Cement Compositions. ARPN J. Eng. Appl. Sci. 2019, 14, 600–610.

- Mahmoud, A.A.; Elkatatny, S. Improving Class G Cement Carbonation Resistance for Applications of Geologic Carbon Sequestration Using Synthetic Polypropylene Fiber. J. Nat. Gas Sci. Eng. 2020, 76, 103184.

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-Based Fiber-Reinforced Materials and Structural Applications in Civil Engineering. Compos. Struct. 2019, 214, 246–263.

- Hasan, K.M.F.; Horváth, P.G.; Alpár, T. Lignocellulosic Fiber Cement Compatibility: A State of the Art Review. J. Nat. Fibers 2021, 19, 5409–5434.

- Ahmad, J.; Aslam, F.; Martinez-Garcia, R.; Ouni, M.H.E.; Khedher, K.M. Performance of Sustainable Self-Compacting Fiber Reinforced Concrete with Substitution of Marble Waste (MW) and Coconut Fibers (CFs). Sci. Rep. 2021, 11, 23184.

- Said, A.; Elsayed, M.; Abd El-Azim, A.; Althoey, F.; Tayeh, B.A. Using Ultra-High Performance Fiber Reinforced Concrete In Improvement Shear Strength of Reinforced Concrete Beams. Case Stud. Constr. Mater. 2022, 16, e01009.

- Ahmad, J.; Majdi, A.; Al-Fakih, A.; Deifalla, A.F.; Althoey, F.; El Ouni, M.H.; El-Shorbagy, M.A. Mechanical and Durability Performance of Coconut Fiber Reinforced Concrete: A State-of-the-Art Review. Materials 2022, 15, 3601.

- Sekar, A.; Kandasamy, G. Study on Durability Properties of Coconut Shell Concrete with Coconut Fiber. Buildings 2019, 9, 107.

- Cosgun, T. An Experimental Study of RC Beams with Varying Concrete Strength Classes Externally Strengthened with CFRP Composites. J. Eng. Fiber. Fabr. 2016, 11, 155892501601100300.

- Hossain, M.A.; Rahman, M.M.; Morshed, A.Z.; Haque, S.K.M. Investigation of the effect of nylon fiber in concrete rehabilitation. In Proceedings of the 1st International Conference on Civil Engineering for Sustainable Development, Khulna, Bangladesh, 2–3 March 2012.

- Alomayri, T. Mechanical and Fracture Behaviour of Micro Steel Fibre-Reinforced Fly Ash-Based Geopolymer Paste Containing Nano CaCO3. J. Taibah Univ. Sci. 2021, 15, 391–406.

- Ibrahim, K.I.M. The Combined Influence of Polypropylene Fibers and Silica Fume on Concrete Strength. Int. J. Eng. Res. Technol. (IJERT) 2017, 6, 106–112.

- Gu, M.; Ahmad, W.; Alaboud, T.M.; Zia, A.; Akmal, U.; Awad, Y.A.; Alabduljabbar, H. Scientometric Analysis and Research Mapping Knowledge of Coconut Fibers in Concrete. Materials 2022, 15, 5639.

- Suresh, A.; Jayakumar, L.; Devaraju, A. Investigation of Mechanical and Wear Characteristic of Banana/Jute Fiber Composite. Mater. Today Proc. 2021, 39, 324–330.

- Ibrahim, K. Mechanical Properties of Glass Fiber Reinforced Concrete (GFRC). IOSR J. Mech. Civ. Eng 2016, 13, 47–50.

- Singh, A.P. Strength and Permeability Characteristics of Steel Fibre Reinforced Concrete. Int. J. Civil. Archit. Sci. Eng. 2013, 7, 211–216.

- Afroughsabet, V.; Ozbakkaloglu, T. Mechanical and Durability Properties of High-Strength Concrete Containing Steel and Polypropylene Fibers. Constr. Build. Mater. 2015, 94, 73–82.

- Ahmad, J.; González-Lezcano, R.A.; Majdi, A.; Ben Kahla, N.; Deifalla, A.F.; El-Shorbagy, M.A. Glass Fibers Reinforced Concrete: Overview on Mechanical, Durability and Microstructure Analysis. Materials 2022, 15, 5111.

- Feduik, R. Reducing Permeability of Fiber Concrete Using Composite Binders. Spec. Top. Rev. Porous Media 2018, 9, 79–89.

- Olivito, R.S.; Zuccarello, F.A. An Experimental Study on the Tensile Strength of Steel Fiber Reinforced Concrete. Compos. Part B Eng. 2010, 41, 246–255.

- Czigany, T.; Pölöskei, K.; Karger-Kocsis, J. Fracture and Failure Behavior of Basalt Fiber Mat-Reinforced Vinylester/Epoxy Hybrid Resins as a Function of Resin Composition and Fiber Surface Treatment. J. Mater. Sci. 2005, 40, 5609–5618.

- Kim, Y.-H.; Park, J.-M.; Yoon, S.-W.; Lee, J.-W.; Jung, M.-K.; Murakami, R.-I. The Effect of Moisture Absorption and Gel-Coating Process on the Mechanical Properties of the Basalt Fiber Reinforced Composite. Int. J. Ocean Syst. Eng. 2011, 1, 148–154.

- Sim, J.; Park, C. Characteristics of Basalt Fiber as a Strengthening Material for Concrete Structures. Compos. Part B Eng. 2005, 36, 504–512.

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A Review on Basalt Fibre and Its Composites. Compos. Part B Eng. 2015, 74, 74–94.

- Di Ludovico, M.; Prota, A.; Manfredi, G. Structural Upgrade Using Basalt Fibers for Concrete Confinement. J. Compos. Constr. 2010, 14, 541–552.

- Guo, Y.; Hu, X.; Lv, J. Experimental Study on the Resistance of Basalt Fibre-Reinforced Concrete to Chloride Penetration. Constr. Build. Mater. 2019, 223, 142–155.

- Sadrmomtazi, A.; Tahmouresi, B.; Saradar, A. Effects of Silica Fume on Mechanical Strength and Microstructure of Basalt Fiber Reinforced Cementitious Composites (BFRCC). Constr. Build. Mater. 2018, 162, 321–333.

- Tadepalli, P.R.; Mo, Y.L.; Hsu, T.T.C. Mechanical Properties of Steel Fibre Concrete. Mag. Concr. Res. 2013, 65, 462–474.

- Zhang, L.F.; Wang, D.F. Effect of Basalt Fiber Content on Sulfate Resistance and Impermeability of Concrete. Bull. Chin. Ceram. Soc. 2018, 37, 1946–1950.

- Martys, N.S.; Ferraris, C.F. Capillary Transport in Mortars and Concrete. Cem. Concr. Res. 1997, 27, 747–760.

- Niu, D.; Su, L.; Luo, Y.; Huang, D.; Luo, D. Experimental Study on Mechanical Properties and Durability of Basalt Fiber Reinforced Coral Aggregate Concrete. Constr. Build. Mater. 2020, 237, 117628.

- Sivakumar, V.R.; Kavitha, O.R.; Arulraj, G.P.; Srisanthi, V.G. An Experimental Study on Combined Effects of Glass Fiber and Metakaolin on the Rheological, Mechanical, and Durability Properties of Self-Compacting Concrete. Appl. Clay Sci. 2017, 147, 123–127.

- Ahmad, J.; Manan, A.; Ali, A.; Khan, M.W.; Asim, M.; Zaid, O. A Study on Mechanical and Durability Aspects of Concrete Modified with Steel Fibers (SFs). Civ. Eng. Archit. 2020, 8, 814–823.

- Huang, G.; Xie, X. Experimental Study on the Effect of Nano-SiO2 to Durability in Hydraulic Concrete. Yellow River 2011, 33, 138–140.

- Martinelli, E.; Caggiano, A.; Xargay, H. An Experimental Study on the Post-Cracking Behaviour of Hybrid Industrial/Recycled Steel Fibre-Reinforced Concrete. Constr. Build. Mater. 2015, 94, 290–298.

- Lam, N.N.; Van Hung, L. Mechanical and Shrinkage Behavior of Basalt Fiber Reinforced Ultra-High-Performance Concrete. GEOMATE J. 2021, 20, 28–35.

- Lan, Y.; Zheng, B.; Shi, T.; Ma, C.; Liu, Y.; Zhao, Z. Crack Resistance Properties of Carbon Nanotube-Modified Concrete. Mag. Concr. Res. 2022, 74, 1165–1175.

- Alrshoudi, F.; Mohammadhosseini, H.; Tahir, M.M.; Alyousef, R.; Alghamdi, H.; Alharbi, Y.; Alsaif, A. Drying Shrinkage and Creep Properties of Prepacked Aggregate Concrete Reinforced with Waste Polypropylene Fibers. J. Build. Eng. 2020, 32, 101522.

- Figueiras, H.; Nunes, S.; Coutinho, J.S.; Andrade, C. Linking Fresh and Durability Properties of Paste to SCC Mortar. Cem. Concr. Compos. 2014, 45, 209–226.

- Fiala, L.; Toman, J.; Vodička, J.; Ráček, V. Experimental Study on Electrical Properties of Steel-Fibre Reinforced Concrete. Procedia Eng. 2016, 151, 241–248.

- Elshazli, M.T.; Ramirez, K.; Ibrahim, A.; Badran, M. Mechanical, Durability and Corrosion Properties of Basalt Fiber Concrete. Fibers 2022, 10, 10.

- Xu, J.; Wu, Z.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Influence of Dry-Wet Cycles on the Strength Behavior of Basalt-Fiber Reinforced Loess. Eng. Geol. 2022, 302, 106645.

- Wu, Z.; Xu, J.; Chen, H.; Shao, L.; Zhou, X.; Wang, S. Shear Strength and Mesoscopic Characteristics of Basalt Fiber–Reinforced Loess after Dry–Wet Cycles. J. Mater. Civ. Eng. 2022, 34, 4022083.

- Powers, T.C. Void Space as a Basis for Producing Air-Entrained Concrete. J. Proc. 1954, 50, 741–760.

- Tiberti, G.; Minelli, F.; Plizzari, G.A.; Vecchio, F.J. Influence of Concrete Strength on Crack Development in SFRC Members. Cem. Concr. Compos. 2014, 45, 176–185.

- Shafiq, N.; Fadhilnuruddin, M.; Elshekh, A.E.A.; Fathi, A. Correlation between Compressive Strength and Ultrasonic Pulse Velocity of High Strength Concrete Incorporating Chopped Basalt Fibre. In Proceedings of the AIP Conference Proceedings; AIP Publishing LLC: Woodbury, NY, USA, 2015; Volume 1669, p. 20010.

- Ramachandran, B.E.; Velpari, V.; Balasubramanian, N. Chemical Durability Studies on Basalt Fibres. J. Mater. Sci. 1981, 16, 3393–3397.

- Mingchao, W.; Zuoguang, Z.; Yubin, L.; Min, L.; Zhijie, S. Chemical Durability and Mechanical Properties of Alkali-Proof Basalt Fiber and Its Reinforced Epoxy Composites. J. Reinf. Plast. Compos. 2008, 27, 393–407.