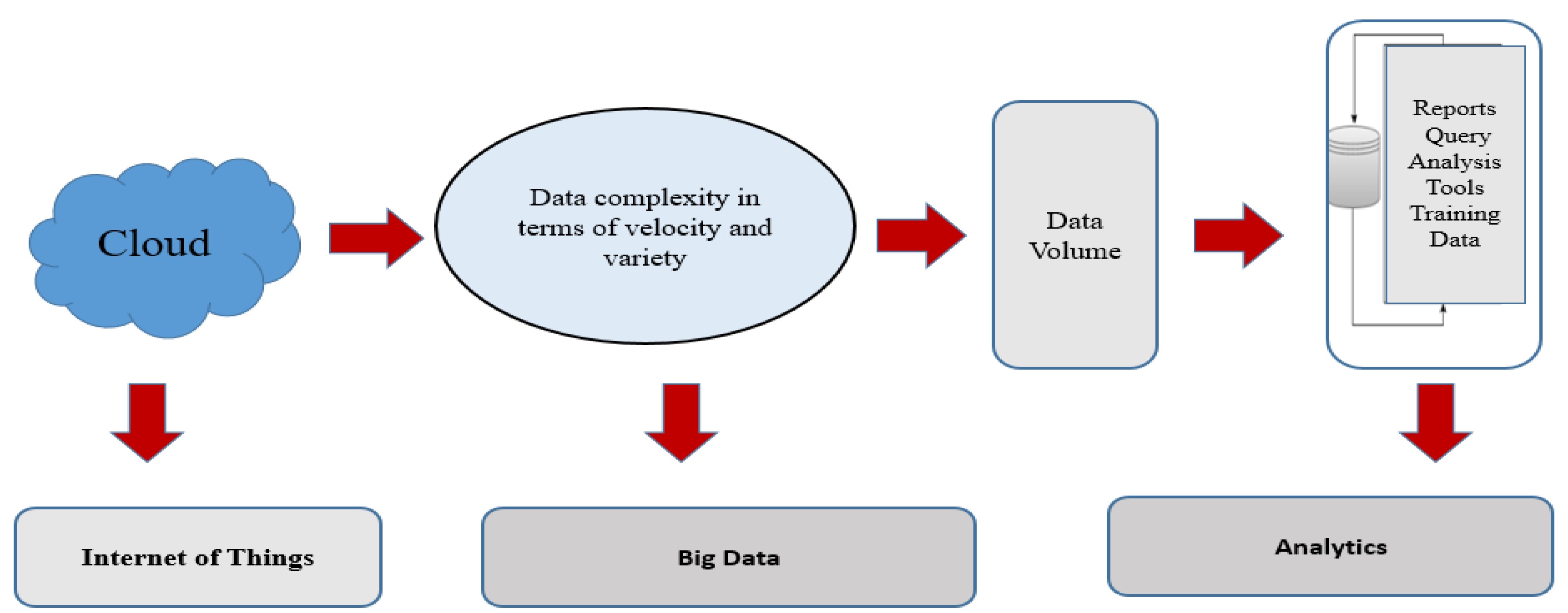

IoT technology through ICT infrastructure and smart devices combines to gather huge amounts of data in real-time, which is commonly known as big data. The big data generated by IoT devices will be stored in the big data storage system and will be used for analysis. The importance of Food Wastage Reduction (FWR) is related to the loss of all the natural resources in the supply chain, including expenditures related to the use of land, water supply, and energy consumption. The application of IoT to FWR systems is also examined where use RFID sensors as a key tool to monitor food waste for each individual in accordance with the proposed model, while describe the application of IoT-based technologies to agricultural supply chain management in developing countries.

- IoT sensors

- food waste reduction

- big data

- communication technologies

1. IoT and Big Data

1.1. IoT

1.2. Big Data

| Sensor Type | Technology | Application | Reference | Year |

|---|---|---|---|---|

| Proximity Sensor | The position of any nearby object is detected without any physical contact by emitting electromagnetic radiation such as infrared and looking for any variation in the return signal | Multi-application, depending on the type. There are various types such as inductive, capacitive, ultrasonic, photoelectric, and magnetic. Mostly used in applications demanding security and efficiency. Main applications of FWR are cutting number of items, measuring the amount of rotation for positioning of objects, and measuring movement direction. | [23][24][25] | 2019, 2020, 2021 |

| Position and occupancy sensors | Detection of the presence of human or objects in a particular area by sensing the air, temperature, humidity, light, and motion of a nearby object | Security and safety purposes, smart agriculture, smart FWR | [26][27] | 2017 |

| Motion and Velocity sensors |

-

Proximity Sensors: The proximity sensors are intended to detect a nearby object using electromagnetic radiation such as infrared by detecting variations in the return signal. There are various types of these sensors, such as inductive, capacitive, ultrasonic, photoelectric, and magnetic [23]. These sensors are widely used in the food industry and in FWR systems [24].

-

Position Sensors: The position sensor senses the motion of an object in a certain area to detect its presence. It can be used in smart agriculture and in IoT-based FWR systems [26]. There are also motion sensors that can be considered in this category that are designed to sense all kinds of kinetic movements of an object, as described by Ref. [36]. Ndraha et al. [37] apply various types of sensors including position sensors for the improvement of cold chain performance and improper handling.

-

Occupancy Sensors: These sensors are used for the remote monitoring of variables such as temperature, humidity, light, and air [27].

-

Motion or Kinetic Sensors: The sensor detects all kinetic and physical movement in the environment [36] and could be used in a truck to detect possible movement of fruit boxes to provide needed information to estimate the rate of food deterioration in a certain period for better decision-making.

-

Velocity Sensors: The velocity sensors calculate the rate of position variation, which might be linear along a straight line or angular related to device rotation speed at known intervals

-

Real-time analytics (RTA)

-

Off-line analytics (OLA)

2. Food Wastage Reduction (FWR) Based on IOT and Big Data Analytics in Smart Supply-Chains: Sensing and Measurement Layer

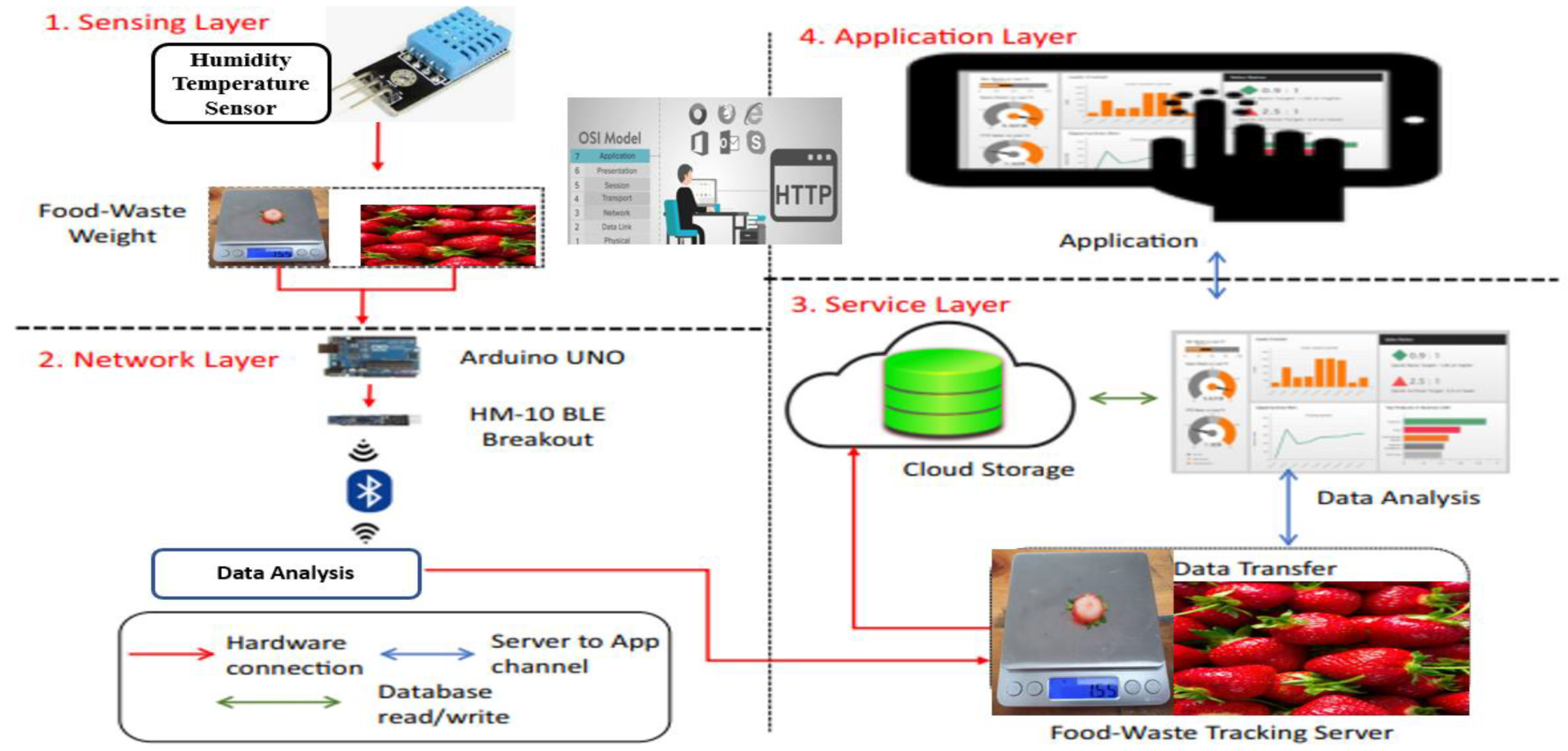

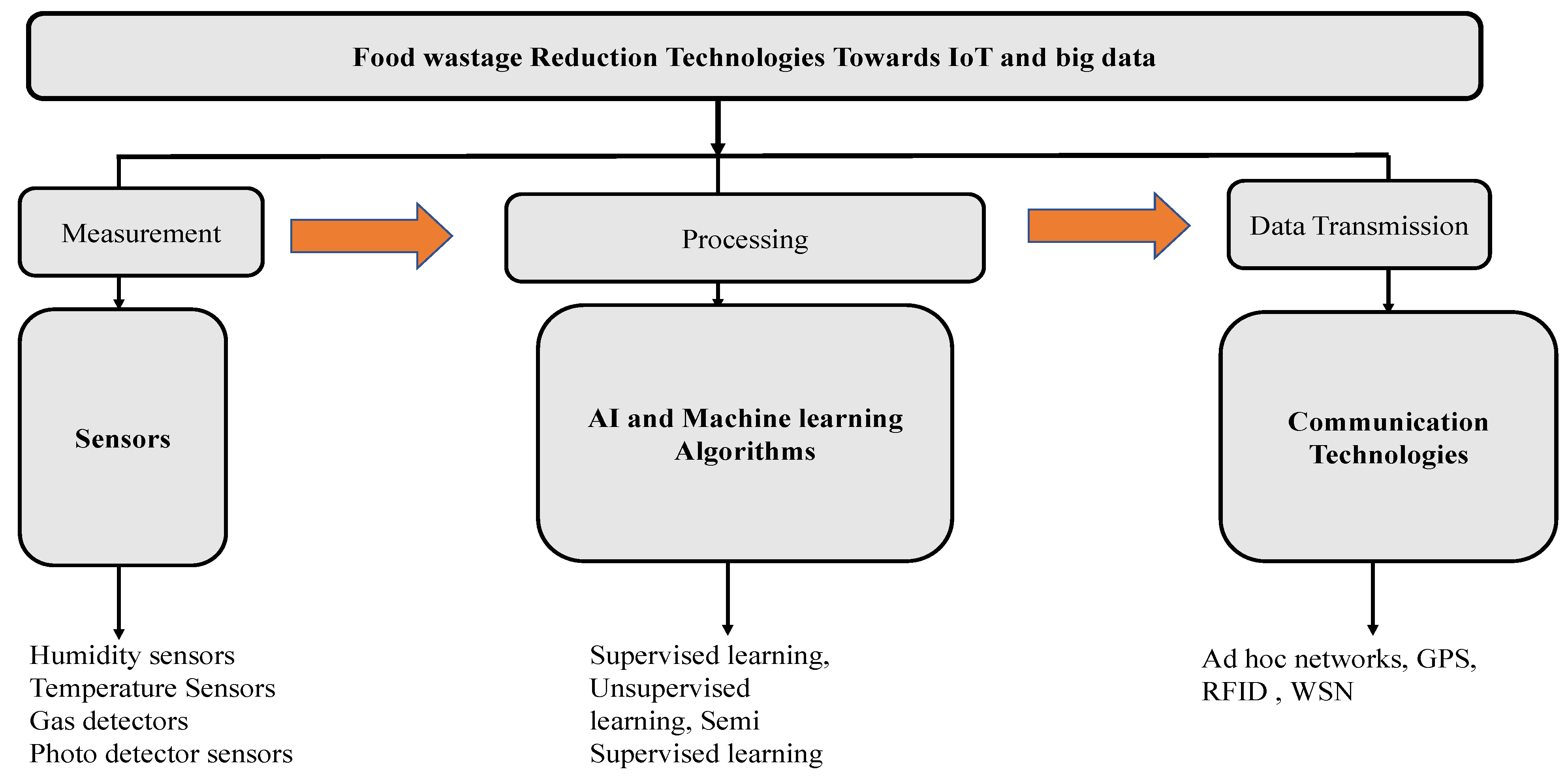

In the work by Anagnostopoulos et al. [22], a visual tree for waste management is developed. It can be further developed to reduce food waste. Figure 3 illustrates how to classify the technologies that reduce food wastage. Anagnostopoulos et al. [22] review the literature related IoT-based technologies for reducing food waste in different layers of sensing and measurement, processing, and data transmission. As illustrated in| Motion sensors detect all kinds of physical movements in the environment and the velocity sensors calculates the rate of change in position measurement at known intervals in linear or angular manner | ||||

| Smart city applications for intelligent vehicle monitoring, for example, acceleration detection of the boxes of food in the trucks for food protection during transmission | ||||

| [ | 28 | ] | [29] | 2015, 2016 |

| Temperature sensors | Measurement of heat energy | FWR and smart farm | [30][31] | 2016, 2018 |

| Pressure sensor | Measurement the amount of force and convert it to signal | Smart FWR, smart refrigerator | [32] | 2018 |

| Chemical sensors | Conversion of a chemical or physical property of a specific analyte into a measurable signal that its magnitude is normally proportional to the concertation of the analyte. | FWR and smart agriculture | [33] | 2020 |

| Optical sensors | Light intensity measurement | Food industry, FWR For instance, assessment of wine grape phenolic maturity based on berry fluorescence |

[34][35] | 2021, 2008 |

- [

- ]

- . These sensors can be used in crates to determine the variation of food position during food transfer. This will enable to monitor the parameters that can affect food quality and make the appropriate decisions.

-

Temperature sensors: Temperature sensors are widely used for the monitoring of environmental conditions of the surroundings [30]. This type of sensor is also widely used in FWR systems and more, especially for smart agriculture to enable farmers to increase their overall yield and product quality by getting real-time data on their land [31].

-

Pressure Sensors: Pressure sensors sense the amount of force and convert it into signals. Sensors of this type can be used to measure the amount of pressure in boxes of food and send the data to the server for decision-making to avoid food waste caused by excessive pressure in boxes during transport. The sensor triggers a notification to the user as soon as the applied pressure is below a certain value that affects the quality of the food [32][38].

-

Chemical Sensors: These types of sensors sense any chemical reaction and can be used for reducing food wastage in smart agriculture [33].

References

- Marjani, M.; Nasaruddin, F.; Gani, A.; Karim, A.; Hashem, I.A.T.; Siddiqa, A.; Yaqoob, I. Big iot data analytics: Architecture, opportunities, and open research challenges. IEEE Access 2017, 5, 5247–5261.

- Al Nuaimi, E.; Al Neyadi, H.; Mohamed, N.; Al Jaroodi, J. Applications of big data to smart cities. J. Internet Serv. Appl. 2015, 6, 1–15.

- Jagtap, S.; Rahimifard, S. The digitisation of food manufacturing to reduce waste–case study of a ready meal factory. Waste Manag. 2019, 87, 387–397.

- Mak, T.M.; Xiong, X.; Tsang, D.C.; Iris, K.; Poon, C.S. Sustainable food waste management towards circular bioeconomy: Policy review, limitations and opportunities. Bioresour. Technol. 2020, 297, 122497.

- Kambatla, K.; Kollias, G.; Kumar, V.; Grama, A. Trends in big data analytics. J. Parallel Distrib. Comput. 2014, 74, 2561–2573.

- Gantz, J.; Reinsel, D. The Digital Universe in 2020: Big Data, Bigger Digital Shadows, and Biggest Growth in the Far East; IDC iView; IDC Analyze the Future: Framingham, MA, USA, 2012; pp. 1–16.

- Gani, D.; Siddiqa, D.; Shamshirband, S.; Hanum, F. A survey on indexing techniques for big data: Taxonomy and performance evaluation. Knowl. Inf. Syst. 2016, 46, 241–284.

- Paul, A.; Chen, B.-W.; Bharanitharan, K.; Wang, J.-F. Video search and indexing with reinforcement agent for interactive multimedia services. ACM Trans. Embed. Comput. Syst. 2013, 12, 1–16.

- Mital, R.; Coughlin, J.; Canaday, M. Using big data technologies and analytics to predict sensor anomalies. In Proceedings of the Advanced Maui Optical and Space Surveillance Technologies Conference, Maui, HI, USA, 15–18 September 2015; p. 84.

- Hashem, I.A.T.; Yaqoob, I.; Anuar, N.B.; Mokhtar, S.; Gani, A.; Khan, S.U. The rise of big data on cloud computing: Review and open research issues. Inf. Syst. 2015, 47, 98–115.

- Singh, D.; Reddy, C.K. A survey on platforms for big data analytics. J. Big Data 2015, 2, 1–20.

- Siddiqa, A.; Hashem, I.A.T.; Yaqoob, I.; Marjani, M.; Shamshirband, S.; Gani, A.; Nasaruddin, F. A survey of big data management: Taxonomy and state-of-the-art. J. Netw. Comput. Appl. 2016, 71, 151–166.

- Pfaffl, M.W. A new mathematical model for relative quantification in real-time rt-pcr. Nucleic Acids Res. 2001, 29, e45.

- Mohamed, N.; Al-Jaroodi, J. Real-time big data analytics: Applications and challenges. In Proceedings of the 2014 International Conference on High Performance Computing & Simulation (HPCS), Bologna, Italy, 21–25 July 2014; pp. 305–310.

- Novak, A.; Bennett, D.; Kliestik, T. Product decision-making information systems, real-time sensor networks, and artificial intelligence driven big data analytics in sustainable industry 4.0. Econ. Manag. Financ. Mark. 2021, 16, 62–72.

- Chen, C.P.; Zhang, C.-Y. Data-intensive applications, challenges, techniques and technologies: A survey on big data. Inf. Sci. 2014, 275, 314–347.

- Zahid, H.; Mahmood, T.; Morshed, A.; Sellis, T. Big data analytics in telecommunications: Literature review and architecture recommendations. IEEE/CAA J. Autom. Sin. 2019, 7, 18–38.

- Rossi, J.; Bianchini, A.; Guarnieri, P. Circular economy model enhanced by intelligent assets from industry 4.0: The proposition of an innovative tool to analyze case studies. Sustainability 2020, 12, 7147.

- Bifet, A.; Holmes, G.; Pfahringer, B.; Kranen, P.; Kremer, H.; Jansen, T.; Seidl, T. Moa: Massive online analysis, a framework for stream classification and clustering. In Proceedings of the First Workshop on Applications of Pattern Analysis, Windsor, UK, 1–3 September 2010; pp. 44–50.

- Nguyen, T.; Li, Z.; Spiegler, V.; Ieromonachou, P.; Lin, Y. Big data analytics in supply chain management: A state-of-the-art literature review. Comput. Oper. Res. 2018, 98, 254–264.

- Arora, Y.; Goyal, D. Big data: A review of analytics methods & techniques. In Proceedings of the 2nd International Conference on Contemporary Computing and Informatics (IC3I), Greater Noida, India, 14–17 December 2016; pp. 225–230.

- Anagnostopoulos, T.; Zaslavsky, A.; Kolomvatsos, K.; Medvedev, A.; Amiria, P.; Morley, J.; Hadjieftymiades, S. Challenges and opportunities of waste management in IoT-enabled smart cities: A survey. IEEE Trans. Sustain. Comput. 2017, 2, 275–289.

- Sehrawat, D.; Gill, N.S. Smart sensors: Analysis of different types of IoT sensors. In Proceedings of the 3rd International Conference on Trends in Electronics and Informatics (ICOEI), Tirunelveli, India, 23–25 April 2019; pp. 523–528.

- Gull, S.; Bajwa, I.S.; Anwar, W.; Rashid, R. Smart enose food waste management system. J. Sens. 2021, 2021, 9931228.

- ROBU.IN. Types of Proximity Sensors. Available online: https://robu.in/types-ofproximity-sensor/ (accessed on 1 February 2020).

- Mekala., M.S.; Viswanathan, P. A novel technology for smart agriculture based on IoT with cloud computing. In Proceedings of the 2017 International Conference on I-SMAC (IoT in Social, Mobile, Analytics, and Cloud) (I-SMAC), Palladam, India, 10–11 February 2017; pp. 75–82.

- Nesa, N.; Banerjee, I. Iot-based sensor data fusion for occupancy sensing using dempster–shafer evidence theory for smart buildings. IEEE Internet Things J. 2017, 4, 1563–1570.

- Strohbach, M.; Ziekow, H.; Gazis, V.; Akiva, N. Towards a big data analytics framework for IoT and smart city applications. In Modeling and Processing for Next-Generation Big-Data Technologies; Springer: Cham, Switzerland, 2015; pp. 257–282.

- Pendor, R.B.; Tasgaonkar, P.P. An IoT framework for intelligent vehicle monitoring system. In Proceedings of the International Conference on Communication and Signal Processing (ICCSP), Melmaruvathur, India, 6–8 April 2016; pp. 1694–1696.

- Zafar, S.; Miraj, G.; Baloch, R.; Murtaza, D.; Arshad, K. An IoT based real-time environmental monitoring system using arduino and cloud service. Eng. Technol. Appl. Sci. Res. 2018, 8, 3238–3242.

- Nayyar, A.; Puri, V. Smart farming: IoT based smart sensors agriculture stick for live temperature and moisture monitoring using Arduino, cloud computing & solar technology. In Proceedings of the International Conference on Communication and Computing Systems (ICCCS-2016), Gurgaon, India, 9–11 September 2016; p. 9781315364094-121.

- Nasir, H.; Aziz, W.B.; Ali, F.; Kadir, K.; Khan, S. The implementation of IoT based smart refrigerator system. In Proceedings of the 2nd International Conference on Smart Sensors and Application (ICSSA), Kuching, Malaysia, 24–26 July 2018; pp. 48–52.

- Ratnaparkhi, S.; Khan, S.; Arya, C.; Khapre, S.; Singh, P.; Diwakar, M.; Shankar, A. Smart agriculture sensors in iot: A review. Mater. Today Proc. 2020, withdrawn article in press.

- Machado, C.C.S.; da Silveira Petruci, J.F.; Silva, S.G. A iot optical sensor for photometric determination of oxalate in infusions. Microchem. J. 2021, 168, 106466.

- Cerovic, Z.; Moise, N.; Agati, G.; Latouche, G.; Ghozlen, N.B.; Meyer, S. New portable optical sensors for the assessment of winegrape phenolic maturity based on berry fluorescence. J. Food Compos. Anal. 2008, 21, 650–654.

- Ansari, A.N.; Sedky, M.; Sharma, N.; Tyagi, A. An Internet of things approach for motion detection using Raspberry Pi. In Proceedings of the 2015 International Conference on Intelligent Computing and Internet of Things, Harbin, China, 17–18 January 2015; pp. 131–134.

- Ndraha, N.; Vlajic, J.; Chang, C.C.; Hsiao, H.I. Challenges with food waste management in the food cold chains. In Food Industry Wastes; Elsevier: Amsterdam, The Netherlands, 2020; pp. 467–483.

- Prapulla, S.; Shobha, G.; Thanuja, T. Smart refrigerator using internet of things. J. Multidiscip. Eng. Sci. Technol. 2015, 2, 1795–1801.