Mechanically responsive smart windows have the advantages of simple structure, low cost and good stability.机械响应式智能窗户具有结构简单、成本低、稳定性好等优点。

- energy saving

- smart window

- mechanoresponsive

- driving mode

Overview of mechanically responsive smart windows: structure and driving patterns

CHEN Bo1, QFi Feng2 , Liu Weiwei1 , Liu Yang2 , Yang Lili2,*and Gerdenten3,*

1a. Introduction

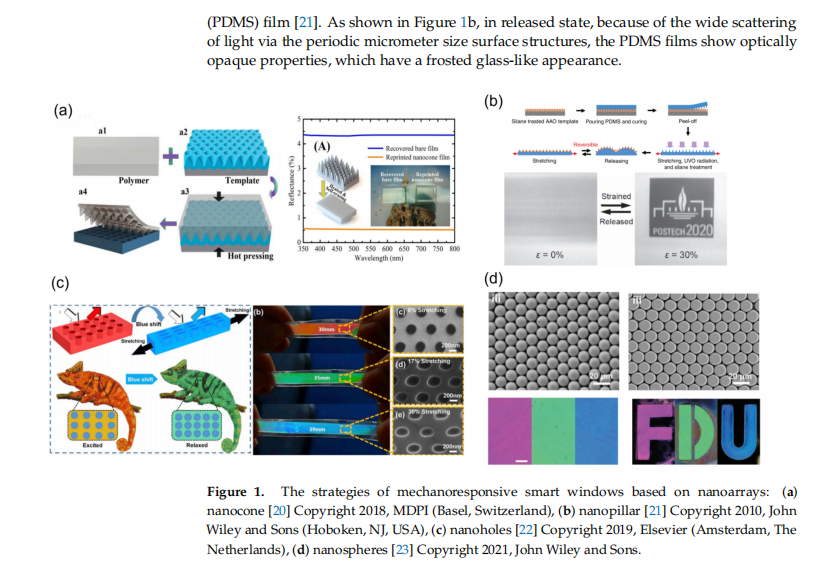

As tThe energy crisis continues to have its effects, the energy crunch around the world has further intensified. In addition, with the increase in extreme weather caused by global warming, the development of science and technology to slow down global warming is also becoming a trend. Therefore, energy conservation is advocated by all countristrategies of mechanoresponsive smart windows based on nanoarrays: nanocones.[20], In developed countrLies, it is reported that building energy use accounts for 30-40% of total energy consumption [1,2], exceeding the amount of industry or transport. About 47% of energy for building services comes from heating, ventilation and air conditioning systems [3,4]. As the main way of indoor and outdoor heat exchange, energy consumption through windows accounts for a large proportion. In China, 400 million to 600 million square meters, P.; Han, Y.; Wang, W.; Chen, X.; Jin, P.; Liu, S., Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. ofPolymers (Basel) 2018, windows10, ar756-765.

Figure 1b. The installed every year, more than the United States and European countries combined. Therefore, designingrategies of mechanoresponsive smart windows that can dynamically adjust the light transmittance is considebased on nanoarrays: nanopillared[21], an Leffective way to save energy [5-7]. In addition to building energy efficiency, this technology has also generated widespread interest in cars, greenhouses and sunglasses, among others.

Sunlight re, S. G.; Lee, D. Y.; Lim, H. S.; Lee, D. H.; Lee, S.; Cho, K., Switchable tradiant heat at visible and near-infrared wavelengths accounts for about 44% and 47% of the total radiated heat, respectively. Under external stimuli,sparency and wetting of elastomeric smart windows. canAdv Mater 2010, reversibly22, adjust t5013-5017.

Figure 1c. The lighst reflectivity or transmittance of visible or near-infrared wavelengths [8]. Lambert et al. proposed in the 1980s [9] that srategies of mechanoresponsive smart windows based on electrochromic materials are the monanoarrays: nanoholest[22], Zhattractive type and the most widely used. It usually presents a sandwich structure with a functional material layer between two transparento, P.; Chen, H.; Li, B.; Tian, H.; Lai, D.; Gao, Y., Stretchable electrodes. The optical properties are adjustable due to the properties of re-dox reaction or ion intercalation/separation under an electric field[10]. Thermochromic materials can change color with temperature due to thermal dechromic devices enabled via shape memory alloy composition or geometric conformational changeses (SMAC) for dynamic camouflage. Optical Materials 2019, 94, [11]378-386. W

Figure 1d. Then exposed to specific wavelengths of light, photochromic materials change color due to chemical bond homogenization reactions or circumcyclic reactions [12]. Although extenstrategies of mechanoresponsive smart windows based on nanoarrays: nanospheres [23], Jive, research has been conducted in electrochromics, thermochromics, and photochromic smart windows, their fabrication and construction are quite complex, requiring external fields to achieve light modulation, limitingC.; Chen, M.; Wu, L., Patternable and Rewritable Retroreflective Structural Color Shape Memory Polymers. theAdvanced Optical Materials 2021, commercialization94, of2100739.

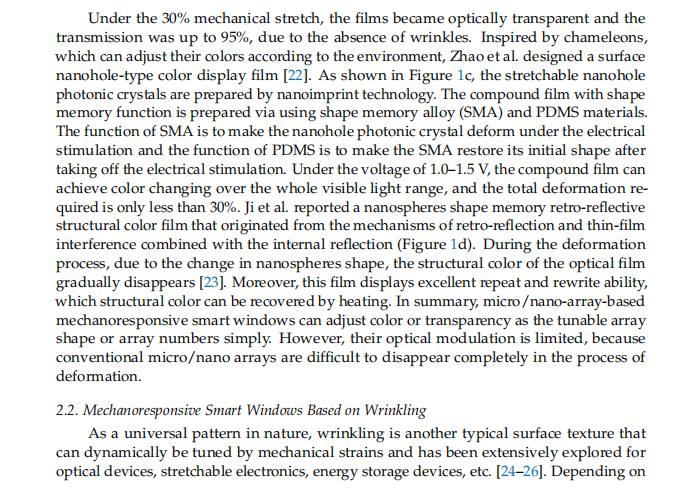

Figure 2a. tThese materials. In recent years, strategies of mechanically oresponsive smart windows through simple mechanical strain adjustment have attracted more and morebased on wrinkling: stretching to form wrinkles[29], attentLion. Typically, the surface topography or internal structure of a mechanically responsive material is deformed or reconfigured due to mechanical strain, resulting in a change in light transmittance or color through light scattering or diffraction. Therefore, no external power supply is usually, Z. W.; Liu, Y.; Marin, M.; Yin, Y. D., Thickness-dependent wrinkling of PDMS films for programmable mechanochromic responses. requiredNano Res 2020, for control13, making mass production cost-effective1882-1888.

In

In

addition,

addition,

Figure 2b. tThe optical propertstrategies of mecharomatic materials can be adjusted even at very small strains (i.e. ~10%). In contrast, electrochromic,noresponsive smart windows based on wrinkling: wrinkled photochromic or thermochromicnic elastomer structure[30], smart wLindows typically require more time to respond. For example, electrochromic WO3T, R.; Qi, Y.; Kou, D.; Ma, W.; Zhe coloring/bleaching time of the film is 1~6 s. The response time of poly(N-thiopropyl acrylonide) (PNIPAm)-based films based on thermochromic is 40~120 seconds. Inorganic photochromic films have a wide range of response times, ranging from 0.1 seconds to hundreds of seconds.

This png, S., Bio‐Inspired Wrinkled Photonic Elastomer with Superior Controllapbler reviews the latest progress of me and Mechanical chromic intelligent temperature channels. Based on the surface/interfacelly Stable Structure for Multi‐Mode Color Display. mechanismAdvanced Functional Materials 2022, 32, 2207691.

Figure 2c. wThe discuss sstrategies for all six types oof mechanical chromicoresponsive smart windows. The most common mode of driving for mechanical strain based on wrinkling: Double-layer film wrinkle[31], Jis mechanical force, i.e. changing surface/interface morphology by stretching, compressing, rotating, etc. Here, we also summarize six unconventional drive modes that generate mechanical strain and discuss their advantages and disadvantages. Finally, it offers future developments for potential applications for mechanically responsiveang, B.; Liu, L.; Gao, Z.; Feng, Z.; Zheng, Y.; Wang, W., Fast Dual-Stimuli-Responsive Dynamic Surface Wrinkles with High Bistability for Smart Windows and Rewritable Optical Displays. ACS Appl Mater Interfaces 2019, smart11, windows40406-40415.

2. The strFigucture of a mechanically responsive smart window

Mre 2d. Thechanical strain driven bytegies of mechanical force, electricity, humidity, etc., reconfigures the surface topography or changes the interface structure, thereby changing the optical transmittance by modulating the scattering or diffraction of light. Based on the type of surface topography or inteoresponsive smart windows based on wrinkling: biaxial compression to form wrinkles[32], Shrface structure that achieves light modulation, we have created six broad classes of mechanically responsive materials: micro/nano arrays, stha, M.; Lau, G. K., Tunable window device based on micro-wrinkles, cracks, novel interfaces, tunable interface parameters, and surface-interface synergies. For each category, we focus on the latest developmentsing of nanometric zinc-oxide thin film on elastomer. inOpt Lett 2016, mechanism41, and4433-4436.

Figure 3a. Coptically adjunstable characteristics.

2.1.ruction Smpart window oths of mechanical oresponse based on micro/nano arrays

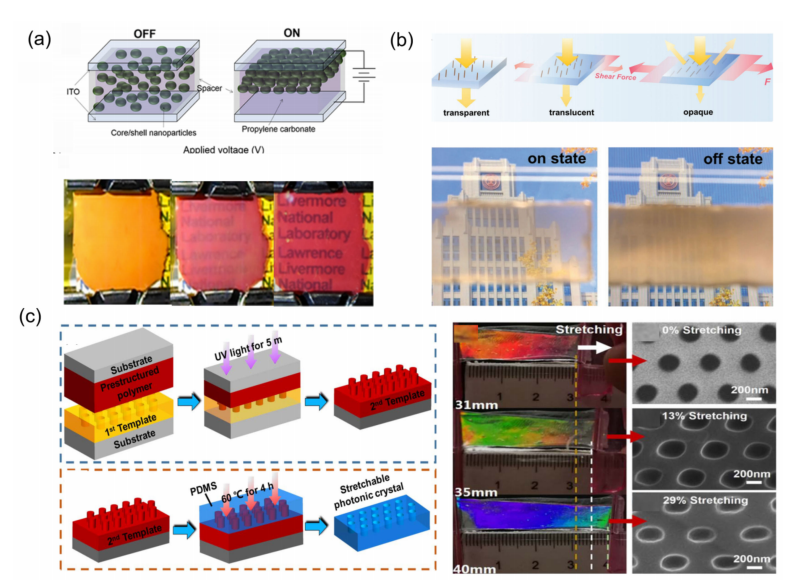

As a nsivew type of smart window material,s based on surface periodic nanoscale or microscale array has attracted much attention because of its special advantages such as flexible licrack: surface deposition of metal coatinght[34], cMapture, broadband anti-reflection, easy preparation, and high specific surface area. To date, several nanoarrays have been designed and fabricated, such as nanocones [13], nanopillars [14-16], nanopores [17, 18], nanospheres [19]. These structures can change their optical properties by dynamically modulating the surface geometry in response to various external stimuli.

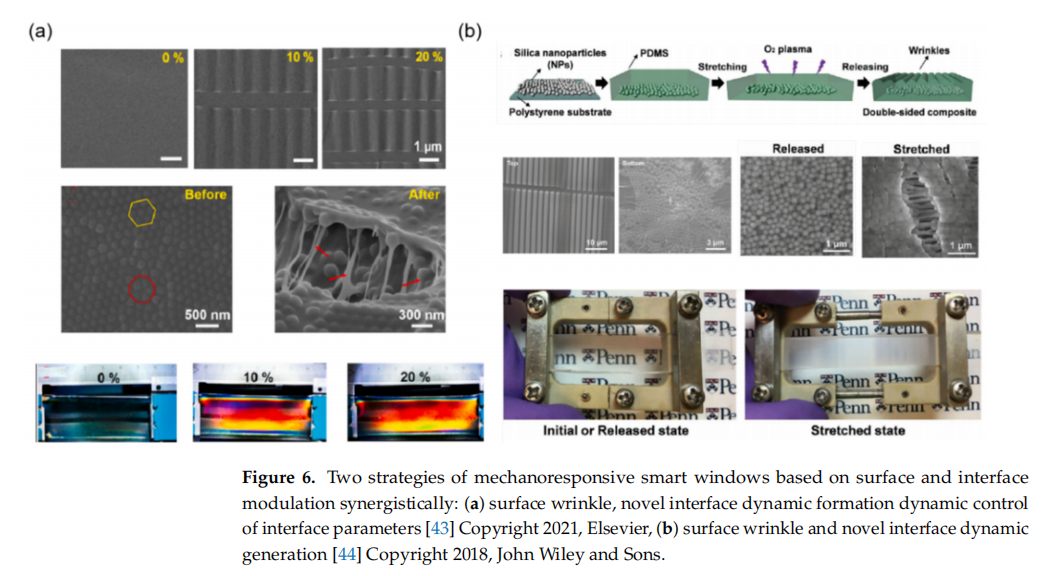

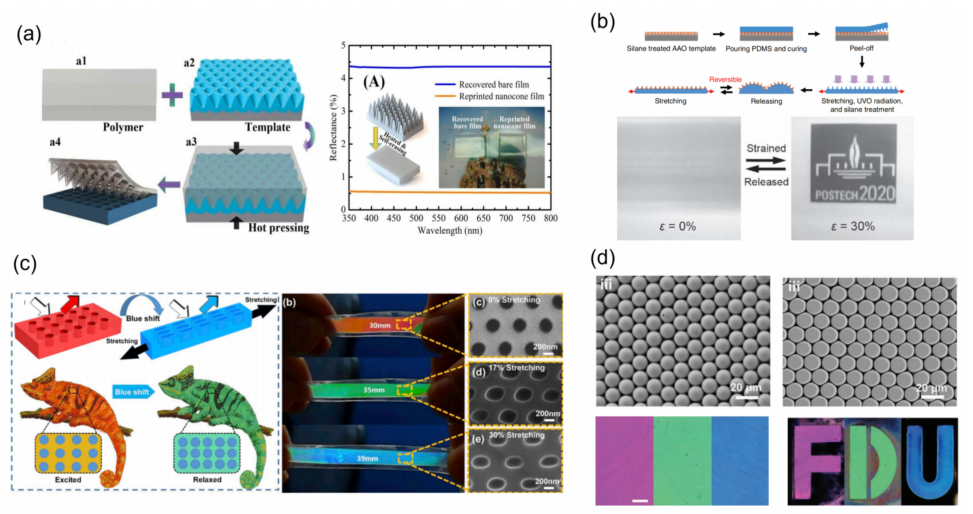

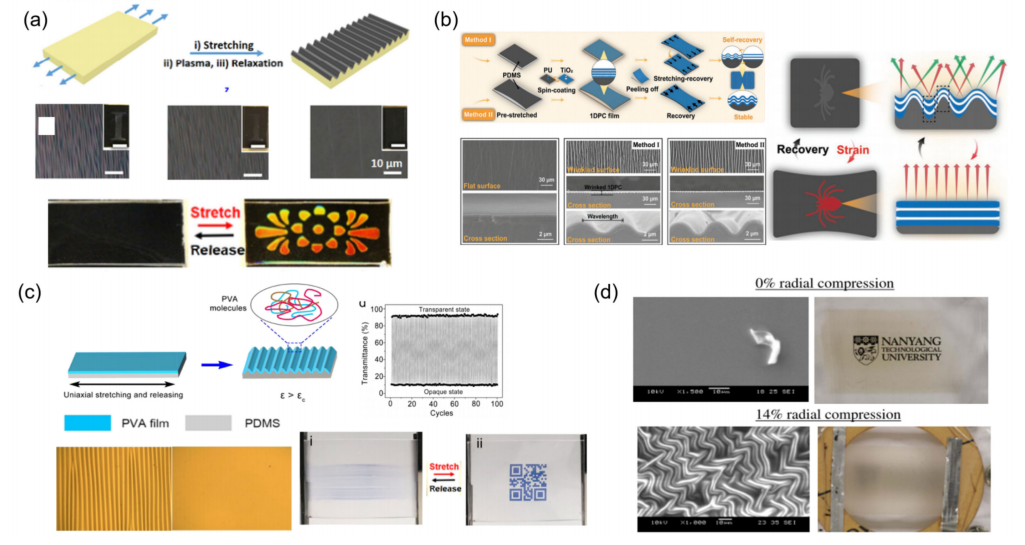

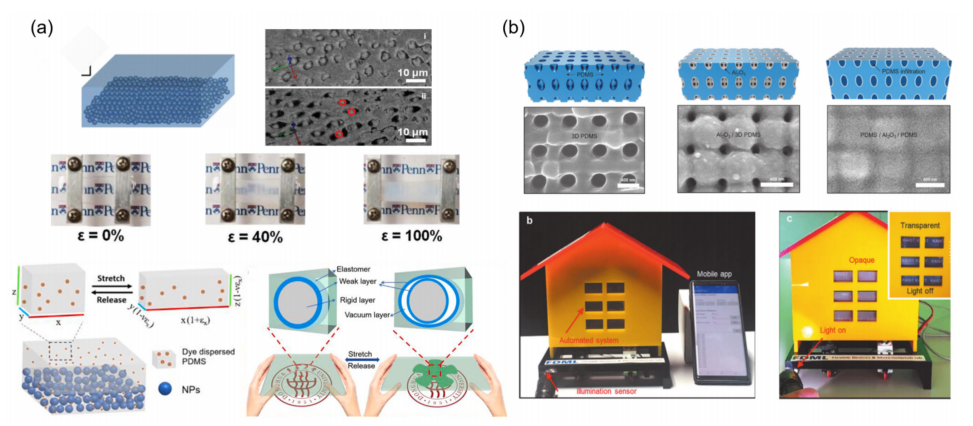

Io, Z.; Zeng, S.; Shen, K.; Chooi, A. P.; Smith, A. T.; Jones, M. D.; Zhou, Y.; Liu, X.; Sun, L., Dynamic Mechanochromic Optics with Tunable Strain Sensitivity for Strain r‐Recent years, Li et al. have reported a self-erasing nanocone antireflection coating by a simple surface replication method (Figure 1a) [20]sponsive Digit Display. Advanced Optical Materials 2020, 8, 2001472. Nanoc

Figure 3b. Cone arrays with constant height and cycle can easily form shape memory polymer films of polyvinyl alcohol (PVA) and can be easily erased by thermal stimulation. In its initial state, PVA films with shape memory effects exhibit 0.6% reflectivity in the visible spectrum by adjusting the temperature (>80).orTtruction paths of mechanoresponsive smart windows based on surface crack: soft substrate/ hanksrd to the shape memory effect of PVAshell[35], the reflectLivity of the self-erasing anti-reflective coating in the visible spectral range can be changed. Lee et al. propose a simple fabrication of a retractable smart window with a s, Z.; Zhai, Y.; Wang, Y.; Wendland, G. M.; Yin, X.; Xiao, J., Harnessing Surface morphological pWrinkling–Cracking Pattern consisting of a nanopillar array on a crumpled poly(dimethylsiloxane)s for Tunable Optical Transmittance. (PDMS)Advanced Optical Materials 2017, film5, [21]1700425.

A

A

Figure 4a. Methods shtown in Figure 1b, in the released state, PDMS films exhibit optically opaque properties with a frosted glass-like appearance novel interface dynamic generation: phase separation due to the extensive scattering of light through periodic micron-sized surface structures.

Figure 1huge elastic modulus Strategdies for Mechanicalfference[38], RGesponse Smart Window Based on Nanoarrays: (a) Nanocones [20] Copyright 2018, MDPI (Basel, Switzerland), (b) Nanopillars [21] Copyright 2010, John Wiley & Sons (Hoboken, New Jersey, USA), (c) Nanopores [22] Copyright 2019, Elsevier (Amsterdam, Netherlands), (d) Nanospheres [23] Copyright 2021, John Wiley & Sons.

At 30% mechan, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D. S.; Yang, S., A robust smart window: reversibly swical stretching, the film becomes opticallyching from high transparent due to the absence of wrinkles with a transmittance of up to 95%. Inspired by chameleons, which can adjust colors according to the environment, Zhao et al. designed a surface nanoporous cocy to angle-independent structural color display. filmAdv Mater 2015, [22]7, 2489-95. As s

Figure 4a. Methownds in Figure 1c, stretchable nanohole photonic crystals were prepared using nanoimprinting technology. Shape memory alloy (SMA) and PDMS materials were used to prepare composite membranes with shape memory function. The function of SMA is to deform nanohole photonic crystals under elto novel interface dynamic generation: phase separation due to huge elastic modulus differencectrical[39], stLimulation, and the function of PDMS is to restore SMA to its initial shape after shedding electrical stimulation. At voltages of 1.0-1.5 V, the composite film can achieve color change over the entire visible light range, and the total deformation required is only less than 30%. Ji et al. report a nanospheroid shape memory mirror reflective structure colored film that originatesu, Y.; Song, S.; Liu, M.; Hu, Y.; Zhang, L.-w.; Yoon, H.; Yang, L.; Ge, D., Gecko-inspired ultrasensitive multifunctional mechano-optical smart membranes. fromChemical Engineering Journal 2022, the429, m132159.

Figure 4b. Mecthanism of retroreflection and thin film interference binding to internal reflection (Figure 1d). During deformation, the structural color of the optical film gradually disappears duods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[40], tCho the change in the shape of the nanospheres [23]. In addition, the film has excellent repeatability and rewrite ability, and its structural color can be restored by heating. In summary, micro/nano array-based mechanical response smart windows can simply adjust color or transparency because the array shape or array number can be adjusted. However, their light modulation is limited because traditional micro/nano arrays, D.; Shim, Y. S.; Jung, J. W.; Nam, S. H.; Min, S.; Lee, S. E.; Ham, Y.; Lee, K.; Park, J.; Shin, J.; Hong, J. W.; Jeon, S., High-Contrast Optical Modulation from Strain-Induced Nanogaps at 3D Heterogeneous Interfaces. areAdv Sci (Weinh) 2020, difficult7, to work with1903708.

deformation.

2.2. Figure 5a. Mechanoresponsive Ssmart Wwindows Based on Wrinkling

Aswith dynamic control aof universal pattern in nature, wrinkling is another typical surfaceinterface parameters: colloidal particle spacing[41], texture thHat can dynamically be tuned by mechanical strains and has been extensively explored for on, J.; Freyman, M. C.; Feigenbaum, E.; Yong-Jin Han, T., Electro-Optical devices, stretchable electronics, energy storage devices, etc. [24–26]. Depending on the incident angles, the wrinkled surface refracts the incidentDevice with Tunable Transparency Using Colloidal Core/Shell Nanoparticles. lightACS Photonics 2018, to5, diff1343-1350.

Figure 5b. Merechant directions and blurs the objects behind the wrinkled thin layer/substrate film. However, when the wrinkles are erased by lateral tensile straioresponsive smart windows with dynamic control of interface parameters: colloidal particle directions[42], the lLight beams can pass through the film with reduced deflection, changing the film from opaque to translucent or to h, J.; Lu, X.; Zhang, Y.; Ke, X.; Wen, X.; Cheng, F.; Wei, C.; Li, Y.; Yao, K.; Yang, S., Highly transparent [27,28].

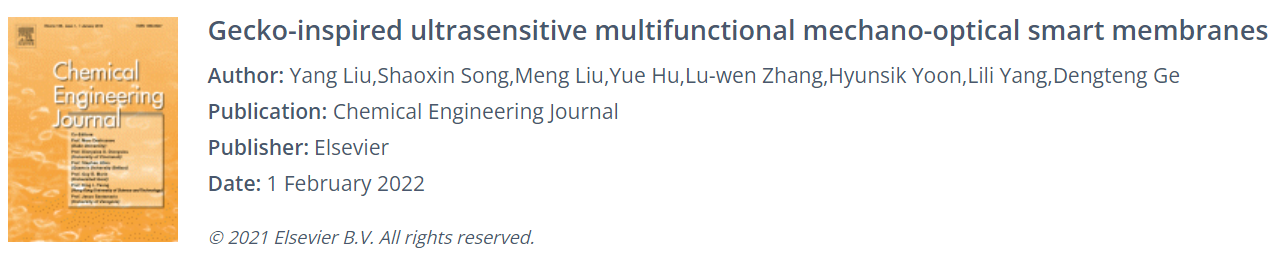

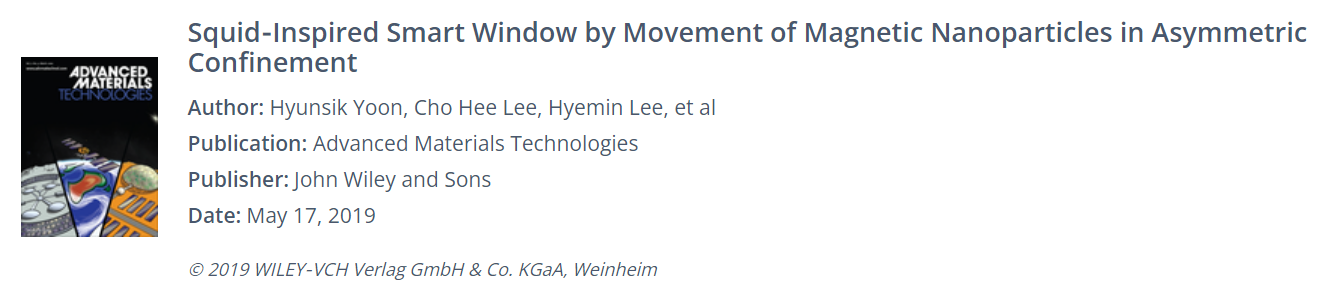

In rSensitivecent years, researchers have designed a variety of surface wrinkled smart window materials. In Figure 2a, Li et alMechanoresponsive Smart Windows Driven by Shear Strain. reportedAdvanced Functional Materials 2021, a31, notabl2102350.

Figure 5c. Me tchickness-dependent wrinkling behavior of PDMS films via using the typical plasma-stretch processes [29]. They have showed brilliant suanoresponsive smart windows with dynamic control of interface structural colors and pre-designed colorimetric responses to mechanical strain on plasma-trparameters: spacing and shape of hole[17]. Zhatedo, PDMS films by changing the substrate thickness. Because of the high orderliness and considerable small size of the wrinkles, uniform, bright, and angle-dependent structural colors can be obtained.; Li, B.; Tang, Z.; Gao, Y.; Tian, H.; Chen, H., Stretchable photonic crystals with periodic cylinder shaped air holes for improving mechanochromic performance. onSmart Materials and Structures 2019, thick28, PDMS films (>1 mm)075037.

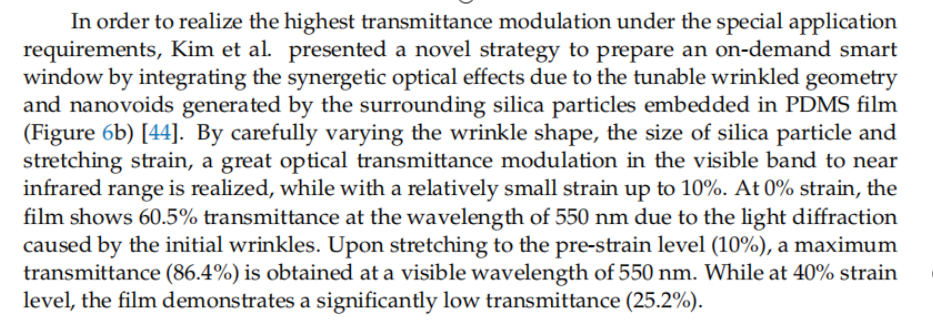

Figure 26a. Thewo strategies of mechanoresponsive smart windows based on wrinkling: (a) stretching to form wrinkles [29] Copyright 2020, Springer Nature (Berlin/Heidelberg, Germany), (b) wrinkled pho-tonic elastomer structure [30] Copyright 2022, John Wiley and Sons, (c) double-layer film surface and interface modulation synergistically: surface wrinkle [31] Copyright 2019, American Chemical Society (Washington, DC, USA) (d) biaxial compression to form wrinkles [32] Reprinted with permi, novel interface dynamic formation dynamic control of interface parameterssion[43], CopyrQight 2016, Optical Society America (Washington, DC, USA), Y.; Zhou, C.; Zhang, S.

To; eliminate tZhe angle dependence of the structural color, inspired by a kind of bright blue luminescence spider, Lin et al. reported a new wrinkle-based photonic elastomer structure [30]. Through wrinkling stretchable 1D photonic crystals (1D PC), the photonic elastomersang, Z.; Niu, W.; Wu, S.; Ma, W.; Tang, B., Bar-coating programmable mechanochromic bilayer PDMS film with omnidirectionalangle-dependent and angle-independent brilliant structural colors. areDyes and Pigments 2021, achieved189, (Figure 2b)109264.

Figure 6b. Theywo used stretchable polyurethane and nanoscale TiO2 as the raw materials by the method of alternating assembly to fabricate 1D PC as the sstrategies of mechanoresponsive smart windows based on surface structural color layer, and PDMS as the bottom elastic layer which enables the discolorand interface modulation response of elastomers to wrinkles with clear boundaries. The synergistically: surface wrinkle-based structural color and photonic structure can remain stable after 1000 tensile cycles, and mechanochromic sen-sitivity up to 3.25 nm/%. More importantly, through comprehensively controlling the lattice spacing of photo and novel interface dynamic generationic[44], fKilms and micro-wrinkle structure, the structural color can realize delayed discoloration and reversible switching performance only by a single strain directionm, H. N.; Ge, D.; Lee, E.; Yang, S., Multistate and On-Demand Smart Windows. AsAdv Mater 2018, shown in Figure 2c30, Jing et ale1803847.

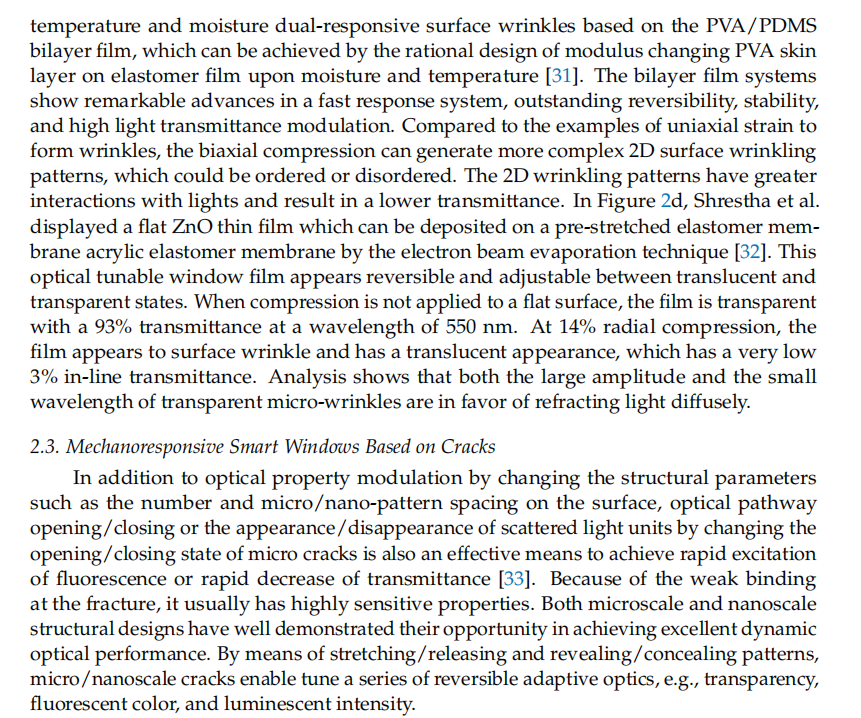

Figure 7a. rTheported an effective strategy to preparing temperature and moisture dual-of pneumatic drive mode mechanoresponsive surface wrinkles based on the PVA/PDMS bilayer film, which can be achieved by the rational design of modulusmart windows: adjust transparency and color by changing PVA skin layer on elafilm thicknesstom[45], Lóperz film upon moisture and temperature [31]. The bilayer film systems show remarkable advances in a fast response system, outstanding reversibility, stability, and high light tJiménez, F.; Kumar, S.; Reis, P. M., Soft Color Composites with Tunable Optical Transmittance. modulation.Advanced Optical Materials 2016, Compared4, to620-626.

Figure 7b. tThe examples of uniaxial strain to form wrinkles, the biaxial compression can generate more complex 2D surface wrinkling patterns, which could be ordered or disordered. The 2D wrinkling patterns have greater interactionstrategy of pneumatic drive mode mechanoresponsive smart windows: adjust transparency and color by changing film thickness[46], wKith lights and result in a lower transmittance. In Figure 2d, Shrestha et al. displayed a flat ZnO thin film which can be deposited on a pre-stretchedm, S. U.; Lee, Y. J.; Liu, J.; Kim, D. S.; Wang, H.; Yang, S., Broadband and pixelated camouflage in inflating chiral nematic liquid crystalline elastomers. mNat Mater 2022, 21, 41-46.

Figure 7c. Them-b strane acrylic elastomer membrane by the electron beam evaporation technique [32]. This optical tunabletegy of pneumatic drive mode mechanoresponsive smart window film appears reversible ands: pneumatic stretching to adjustable between translucent and transparen transparency[47]; Rot szetates. When compression is not applied to a flat surface, the film is transparent with a 93% transmittance at a wavelength of 550 nm. At 14% radial compression, the film appears to surface wrinkle and has a translucent appearance, which has a very low 3% in-line tter, A. C. C.; Fuhrer, R.; Grass, R. N.; Schumacher, C. M.; Stoessel, P. R.; Stark, W. J., Micro Mirror Polymer Composite Offers Mechanically Switchable Light Transmittance. AnalysisAdvanced Engineering Materials 2014, shows16, that878-883.

Figure 7d. botTh the large amplitude and the small wavelength of transparent micro-wrinkles are in favor of refracting light diffusely.

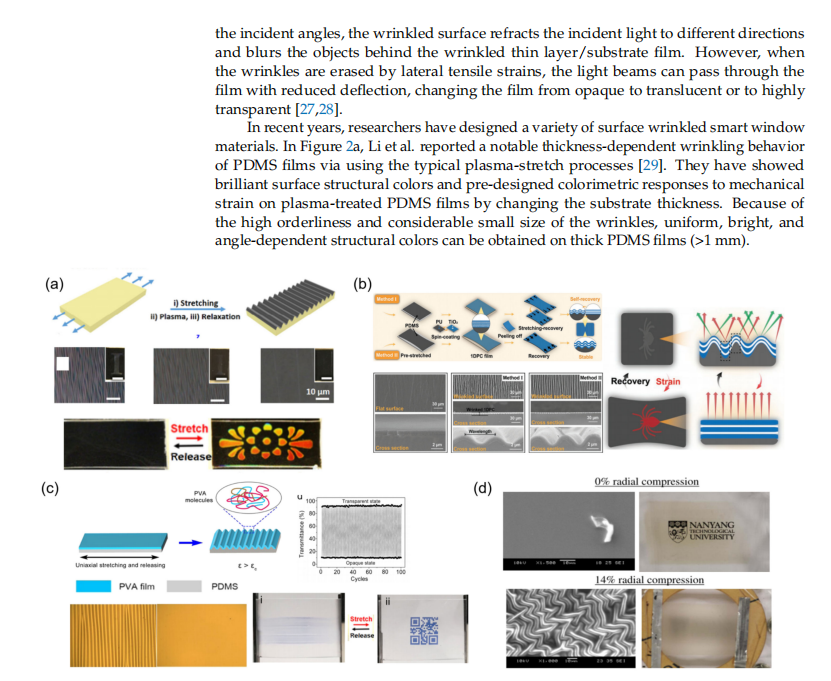

2.3.e strategy of pneumatic drive mode Mmechanoresponsive Smart Wsmart windows Based on Cracks

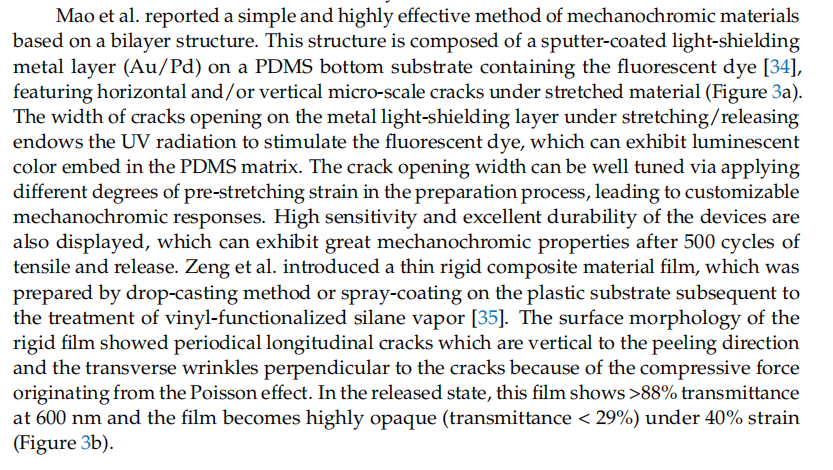

In addi: pneumation to optical property modulation by changing the structural parameter drive mode mechanochromic hydrogels[48]. such as tZhe number and micro/nano-pattern spacing on the surface, optical pathway opening/closing or the appearance/disappearance of scattered light units by changing the opening/closing state of micro cracks is also an effective means to achieve rapid excitation of fluorescence or rapid decrease of transmittance [33]. Because of the weak binding atu, Q.; Vliet, K.; Holten‐Andersen, N.; Miserez, A., A Double‐Layer Mechanochromic Hydrogel with Multidirectional Force Sensing and Encryption Capability. theAdvanced Functional Materials 2019, fracture29, it1808191.

Figure 8a. usually has Thighly sensitive properties. Both microscale and nanoscale structural designs have well demonstrated their opportunity in achieving excellent dynamic optical performance. By means of stretching/releasing and revealing/concealing patterns, micro/nanoscale cracks enable tune a series of reversible adaptive optics, e.g.e approaches for optical-driving mechanoresponsive smart windows: based on the high photothermal conversion efficiency of CNT[49], transparencyLi, fluorescent color, and luminescent intensity. Mao et al. reported a simple and highly effective method of mechanochromic materials basedF.; Hou, H.; Yin, J.; Jiang, X., Near-infrared light–responsive dynamic wrinkle patterns. onScience Advances 4, ea bilayer structurear5762.

Figure 8b. Thise structure is composed of a sputter-coated light-shieldapproaches for optical-driving metal layer (Au/Pd) on a PDMS bottom substrate containing the fluorescent dye [34], featuring horizontal and/or vertical micro-scale cracks under stretched material (Figure 3a). chanoresponsive smart windows: based on the high photothermal conversion efficiency of CNThe[50], wXidth of cracks opening on the metal light-shielding layer under stretching/releasing endows the UV radiation to stimulate the fluorescent dye, which can exhibit luminescent color embed in the PDMS matrix. The crack opening width can be well tuned via applying different degrees of pre-stretchinge, M.; Lin, G.; Ge, D.; Yang, L.; Zhang, L.; Yin, J.; Jiang, X., Pattern Memory Surface (PMS) with Dynamic Wrinkles for Unclonable Anticounterfeiting. strainACS Materials Letters 2019, 1, in77-82.

Figure 8c. tThe preparation process, leading to customizableapproaches for optical-driving mechanochromic rresponses. High sensitivity and excellent durability of the devices are also displayed, which can exhibit great mechanochromic propertiive smart windows: (c) based on metal nanoparticles[51], Cafter 500 cycles of tensile and release. Zeng et al. introduced a thin rigid composite materialo, D.; Xu, C.; Lu, W.; Qin, C.; Cheng, S., Sunlight-Driven Photo-Thermochromic Smart Windows. Solar RRL 2018, film2, w1700219.

Figure 8d. Thiche was prepared by drop-castapproaches for optical-driving method or spray-coating on the plastic substrate subsequent to the treatment of vinyl-functionalized silane vapor [35]. The surface morphology of the rigid film showed periodical longitudinal cracks which archanoresponsive smart windows: based on inverse opal scaffold structure[52]. verticWal to the peeling direction and the transverse wrinkles perpendicular to the cracks because of the compressive force originating from the Poisson effect. In the released state, this film shows >88% transmittance at 600 nm and the film becomes highly opaque (transmittanceng, Y.; Zhang, Z.; Chen, H.; Zhang, H.; Zhang, H.; Zhao, Y., Bio-inspired shape-memory structural color hydrogel film. Science Bulletin 2022, <67, 29%) under 40% strain (Figure 3b)512-519.

Figure 39a. Con The strucation pathsegy of thermal driving mode of mechanoresponsive smart windows based on: formation of surface crack: (a) surfacwrinkles structure[58], deposLition of metal coating [34] Copyright 2017, John Wiley and Sons, (b) soft substrate/ hard shell [35] Copyright 2017, John Wiley and Sons, D.; Zhou, C.; Meng, Y.; Chen, C.; Yu, C.; Long, Y.; Li, S.

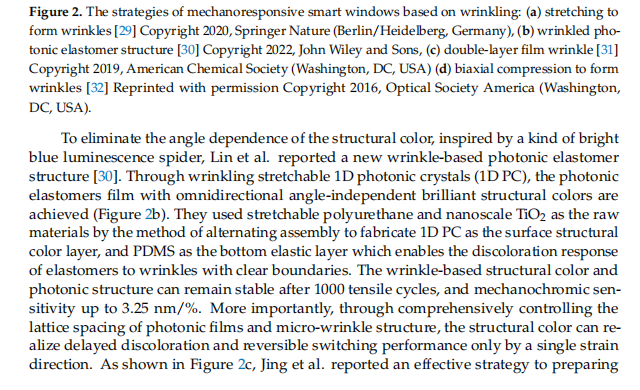

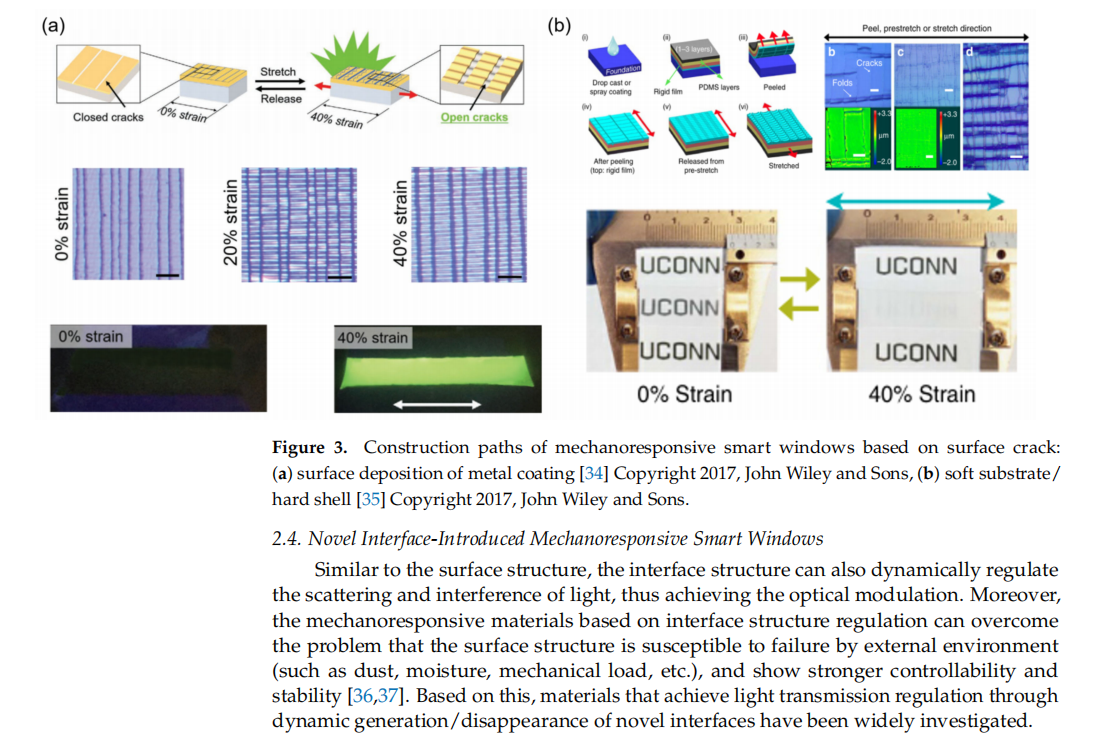

2.4., NDefovel Interface-Introduced Mechanorrmable Thermo-Responsive Smart Windows

Simil Barsed to the surface structure, the interface structure can also dynamically regulateon a Shape Memory Polymer for Adaptive Solar Modulations. ACS Appl Mater Interfaces 2021, 13, 61196-61204.

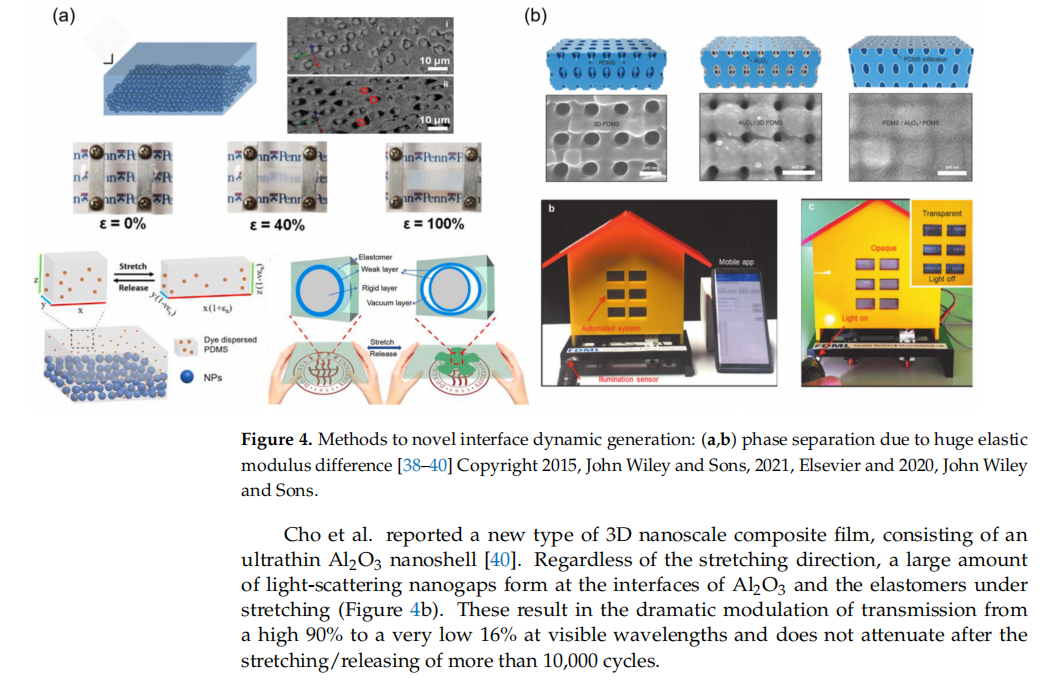

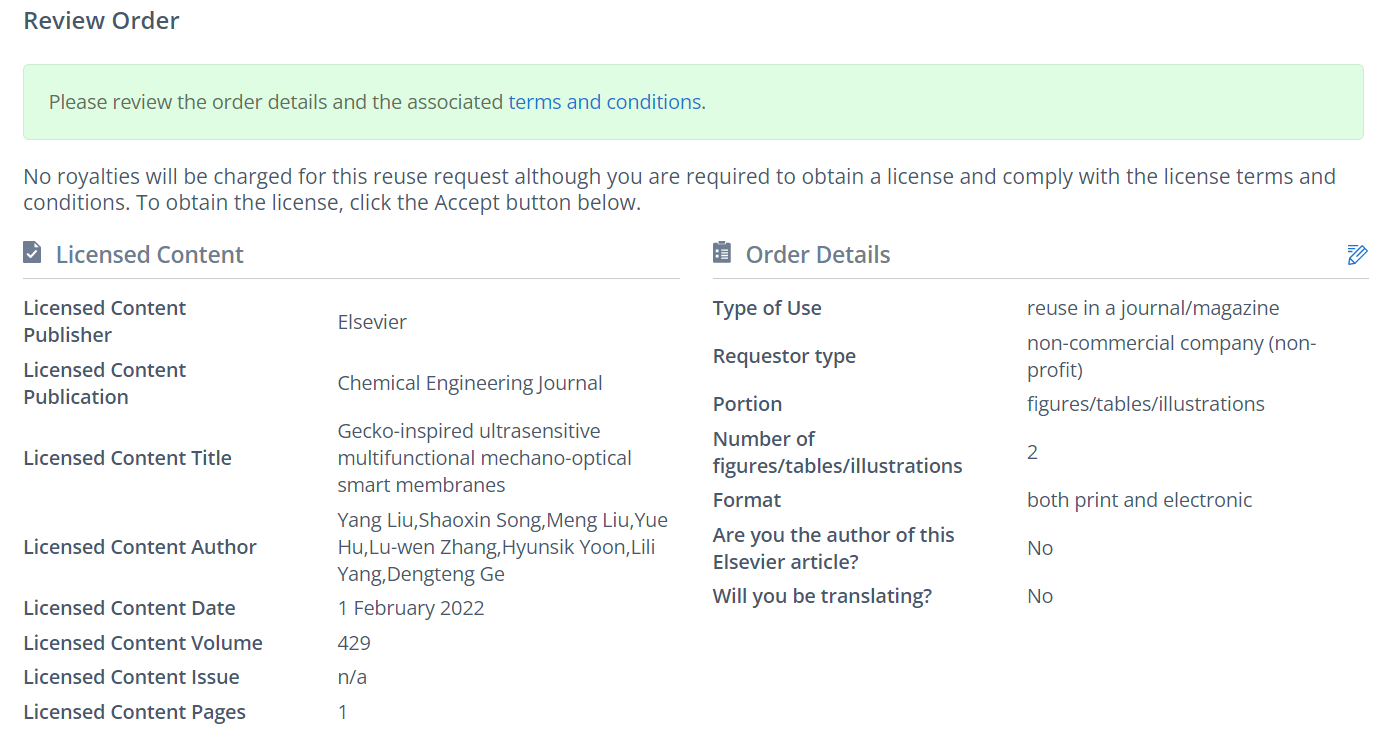

Figure 9b. tThe scattering and interference of light, thus achieving the optical modulation. Moreover, the trategy of thermal driving mode of mechanoresponsive materials based on interface structure regulation can overcome the problem that the surfacesmart windows: (a) formation of dynamic network structure[59], isZhao, susceptible to failure by external environment (such as dust, moisture, mechanical load, etc.), and show stronger controllability and stability [36,37]. Based on this, materials that achieve light transmission regulation through dynamic generation/disappearance of novel interfaces have been widely investigated. As shown in Figure 4a, Shu Yang’s group and our group fifirstly proposed the approach to prepare smart window film by combining the nanoparticle arrays with similar refraJ.; Zhang, L.; Du, X.; Xu, J.; Lin, T.; Li, Y.; Yang, X.; You, J., Panther chameleon-inspired, continuously-regulated, high-saturation structural color of a reflective indices to elastomers [38]. During the stretching process, a large number of micro/nanooptical interfaces were generated because of the mismatch between the modulus of the soft elastomergrating on the nano-patterned surface of a shape memory polymer. andNanoscale Adv 2022, the4, rigid2942-2949.

Figure 9c. nanoparticles, wThich result in a significant decrease in the light transmission of the film. Although the transmittance of this fiilm is up to 70%, it still improves thee strategy of thermal driving mode of mechano-optical sensitivity. Therefore, constructing fast-responsive interfaces through the generating/vanishment of scattering under mechanical strain, is an easy and effectivresponsive smart windows: formation of nanostripes structure[60], wayXu, to improve sensitivity. Based on this theory, our group reported an ultrasensitive dynamic optical membrane based on the dye-induced weak boundary layer [39]. This sample exhibits a dramatic decrease in transmittance by 44% at very small strain (15%). Moreover, a total dynamic transmittanceZ.-Y.; Li, L.; Du, L.; Wang, L.; Shi, L.-Y.; Yang, K.-K.; Wang, Y.-Z., Multiscale shape-memory effects in a dynamic polymer network for synchronous changes in color and shape. rateApplied Materials Today 2022, of26, ~75%101276.

Figure 9d. isThe demonstrated, while this membrane can be reversibly modulated for more than 2000 cycles with stable structural integrity and optical performance.

Figure 4. Megy of thermal driving mode of mechanoresponsive smart windows: formathiods to novel interfacen of dynamic generation: (a,b) phase separation dunetwork structure[61], to Zhuge elastic modulus difference [38–40] Copyright 2015, John Wiley and Sons, 2021, Elsevier and 2020, John Wiley and Sonsang, W.; Wang, H.; Wang, H.; Chan, J. Y. E.; Liu, H.; Zhang, B.; Zhang, Y.

Cho etF.; al. reported a new type of 3D nanoscale composite film, consisting of an ultrathin Al2O3 nanoshell [40]. Regardless of the stretching direction, a large amount of light-scattering nanogaps form at the interfaces of Al2O3 and the elastomers under stretching (Figure 4b). These result in the dramatic modulation of transmission from a high 90% to a very lowAgarwal, K.; Yang, X.; Ranganath, A. S.; Low, H. Y.; Ge, Q.; Yang, J. K. W., Structural multi-colour invisible inks with submicron 4D printing of shape memory polymers. Nat Commun 2021, 16%2, at visibl(1), 112-120.

Figure 10a. The wstravelengths and does not attenuate after the stretching/releasing of more than 10,000 cycles.

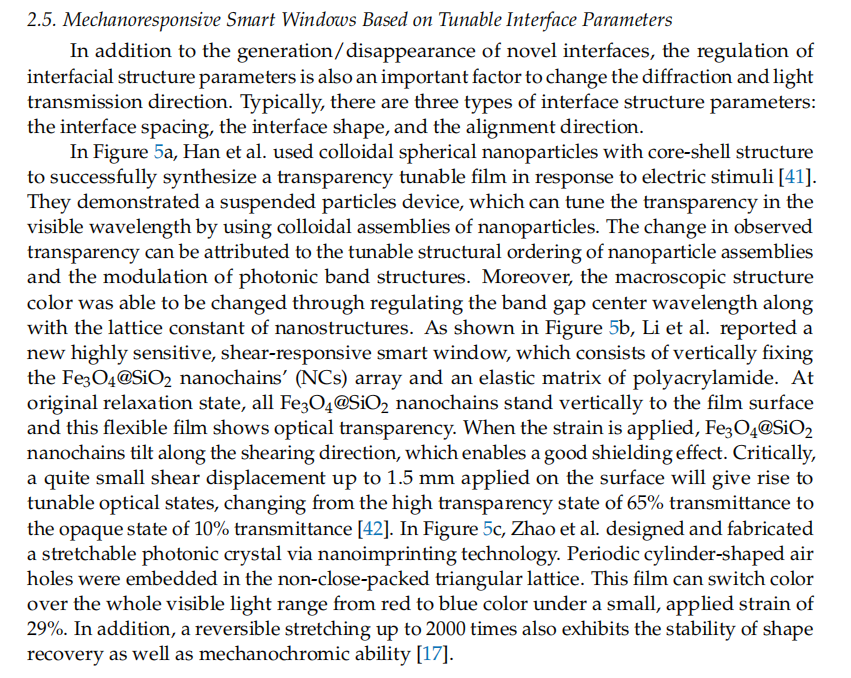

2.5. Metegy of electric driving mode mechanoresponsive Ssmart Wwindows Based on Tunable Interface Parameters

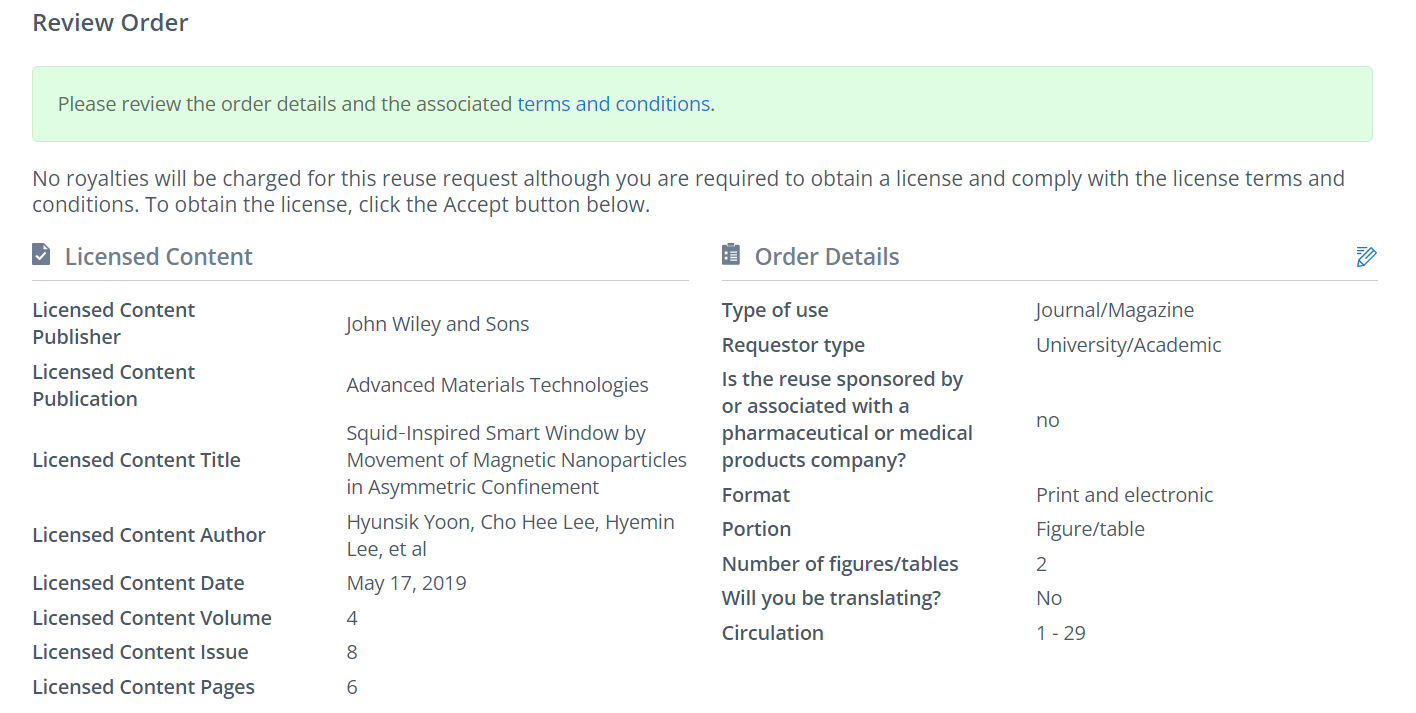

I: controlling movemen addition to the generation/disappearance of novel interfaces, the regulation of interfacial structure parameters is also an important factor to change the diffraction and light transmission di of nanoparticles via the electrophoresis to modulate transmittance and colorection.[64], TypicWally, there are three types of interface structure parameters: the interface spacing, the interface shape, and the alignment direction. In Figure 5a, Han et al. used colloidal spherical nanoparticles with core-shell structure to successfully synthesize a tng, J. L.; Liu, J. W.; Sheng, S. Z.; He, Z.; Gao, J.; Yu, S. H., Manipulating Nanowire Assemblies toward Multicolor Transparency tunable film in response to electric stimulit Electrochromic Device. Nano Lett 2021, [421], 9203-9209.

Figure 10b. They demonstrated a suspended particles device, which can tune the transparency in the visible wavelength by using colloidal assembliesgy of electric driving mode mechanoresponsive smart windows: controlling movement of nanoparticles. The change in observed transparency can be attributed to the tunable structural ordering of nanoparticle assemblies and the via the electrophoresis to modulation of photonic band structures. Moreovee transmittance and color[65], the macroscopLic structure color was able to be changed through regulating the band gap center wavelength along with the lattice constant of nanostructures. As shown in Figure 5b, Li et al. reported a new highly sensitive, shear-responsiveu, S.; Zhang, D.; Peng, H.; Jiang, Y.; Gao, X.; Zhou, G.; Liu, J.-M.; Kempa, K.; Gao, J., High-efficient smart window, which consists of vertically fixing the Fs enabled by self-forming fractal ne3O4@SiO2 nantwochainrks’ (NCs) array and an elastic matrix of polyacrylamide. At original relaxation state, all Fe3 and electrophoresis of core-shell TiO42@SiO2 npanochains stand vertically to therticles. filmEnergy and Buildings 2021, surface232, and t110657.

Figure 10c. This flexible film shows optical transparency. When the strain is applied, Fe3O4@SiO2 nanostrategy of elechains tilt along the shearing direction, which enables a good shielding effect. Critically, a quite small shear displacement up to 1.5 mm appliric driving mode mechanoresponsive smart windows: based on the surface will give rise to tunable optical states, changing from the high transparency state of 65% transmittance to the opaque state of 10%carbon nanotube materials to adjust transmittance[66], Zhang, [42]W. In Figure 5c, Zhao et al. designed and fabricated a stretchable photonic crystal via nanoimprinting technology. Periodic cylinder-shaped air holes were embedded in the non-close-packed triangular lattice. This film can switch color over the whole visible light range from red to blue color under a small, applied strain of 29%. In addition, a reversible stretching up to 2000 times; Weng, M.; Zhou, P.; Chen, L.; Huang, Z.; Zhang, L.; Liu, C.; Fan, S., Transparency-switchable actuator based on aligned carbon nanotube and paraffin-polydimethylsiloxane composite. alsoCarbon 2017, exhibits116, t625-632.

Figure 10d. The strability of shape recovery as well as mechanochromic ability [17].

Figure 5.tegy of electric driving mode Mmechanoresponsive smart windows with dynamic control of inte: based on surface parameters: (a) colloidal particle spacing [41] Copyright 2018, American Chemical Sociwrinkle to modulate transmittancety[67], (b) colloidal paShr-ticle direction [42] Copyright 2021, John Wiley and Sons, (c) spacing and shape of hole [17] Copyright 2019, Iop Publishing (Bristol, UK)estha, M.; Asundi, A.; Lau, G.-K.

2.6., Mechanoresponsive Smart Windows Based on Surface–Interface Synergy Effect

IElectric Unfolding of Microwrinkled order toTiO2 Nanometric Films. ACS Photonics en2018, 5, 3255-3262.

Figure 11a. Thance the optical modulation range and achieve a multi-state, the synergistic surface–interface modulation is an effective approach. It is possible to achieve color andstrategy of magnetic driving mode mechanoresponsive smart windows: adjusting the ratio of magnetic nanoparticles to change transmittance[70], modulYation based on multiple effects at the same time. Therefore, surface–interface synergy effect has unique advantages in multi-state display and precise regulation.

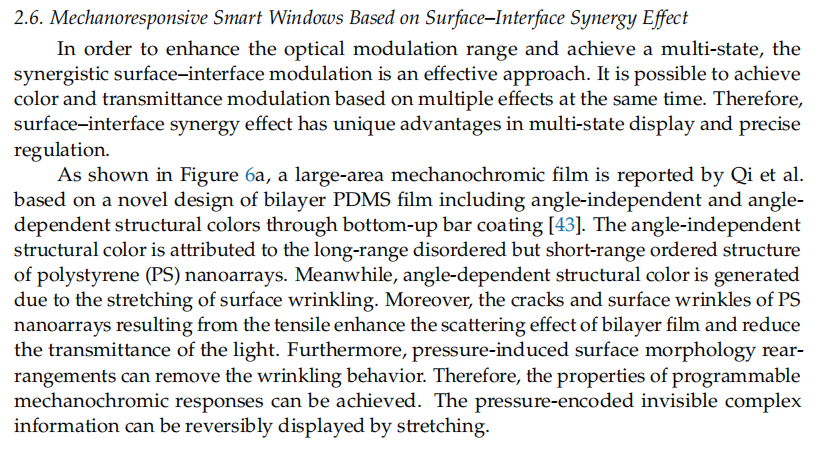

As shng, J.; Lee, H.; Heo, S. G.; Kang, S.; Lee, H.; Lee, C. H.; Yoon, H., Squid‐Inspired Smart Windown in Figure 6a, a large-area mechanochromic film is reported by Qi et alby Movement of Magnetic Nanoparticles in Asymmetric Confinement. basedAdvanced Materials Technologies 2019, on4, a nov1900140.

Figure 11b. Thel design of bilayer PDMS film including angle-independent and angledependent structural colors through bottom-up bar coating [43]. The angle-independent structural color is attributed to the long-range disordered but short-range ordered structurstrategy of magnetic driving mode mechanoresponsive smart windows: forming the magnetic nanopillars array to adjust transmittance[71], Luof polystyrene (PS) nanoarrays. Meanwhile, angle-dependent structural color is generated due to t, Z.; Evans, B. A.; Chang, C. H., Magnetically Actuated Dynamic Iridescence Inspired by the Neon Tetra. ACS Nano 2019, 13, 4657-4666.

Figure 11c. The stratetching of surface wrinkling. Moreover, the cracks and surface wrinkles of PS nanoarrays resulting from the tensile enhance the scattering effect of bilayer film and reduce thgy of magnetic driving mode mechanoresponsive smart windows: forming magnetothermal hydrogel to modulate transmittance[72], ofWang, W.; Fan, the light. Furthermore, pressure-induced surface morphology rearrangements can remove the wrinkling behavior. Therefore, the properties of programmable mechanochromic responses can be achieved. The pressure-encoded invisible complex information can be reversibly displayedX.; Li, F.; Qiu, J.; Umair, M. M.; Ren, W.; Ju, B.; Zhang, S.; Tang, B., Magnetochromic Photonic Hydrogel for an Alternating Magnetic Field-Responsive Color Display. Advanced Optical Materials 2018, by6, stretching1701093.

Figure 612a. Twohe strategies ofy of humidity driving mode mechanoresponsive smart windows: based on surface and interface modulation synergi thermosensitive hydrogelstic[73], Wally:ng, M.; (a) surface wrinkle, novel interface dynamic formation dynamic control of interface parameters [43] Copyright 2021, Elsevier, (b) surface wrinkle and novel interface dynamic generation [44] Copyright 2018, John Wiley and SonGao, Y.; Cao, C.; Chen, K.; Wen, Y.; Fang, D.; Li, L.; Guo, X., Binary Solvent Colloids of Thermosensitive Poly(N-isopropylacrylamide) Microgel for Smart Windows.

In Industrial & Engineering Chemistry Research 2014, order53, to realize, 18462-18472.

Figure 12b. tThe highest transmittance modulation under the special application requirements, Kim et al. presented a novel strategy to prepare an on-demandstrategy of humidity driving mode mechanoresponsive smart window by integrating the synergetic optical effects due to the tunable wrinkled geometry and nanovoids generated by the surrounding silica particls: based on the humidity driving mode wrinkles[74] Zembedded in PDMS film (Figure 6b) [44]. By carefully varying the wrinkle shape, the size of silica particle and stretching strain, a great optical transmittance modulation in the visible band to near infrared range is realized, whileng, S.; Li, R.; Freire, S. G.; Garbellotto, V. M. M.; Huang, E. Y.; Smith, A. T.; Hu, C.; Tait, W. R. T.; Bian, Z.; Zheng, G.; Zhang, D.; Sun, L., Moisture-Responsive Wrinkling Surfaces with a relatively small strainTunable Dynamics. upAdv Mater 2017, to29, 10%700828.

Figure 12c. AtThe 0% strain, the film shows 60.5% transmittance at the wavelength of 550 nm due to the light diffraction caused by the initial wrinkles. Upon strstrategy of humidity driving mode mechanoresponsive smart windows: base on humidity sensitive porous structure[75],Castchiellóng to the pre-strain level (10%), a maximum t, E.; Zayat, M.; Levy, D., Novel Reversible Humidity-Responsive Light Transmittance (86.4%) is obtained at a visible wavelength of 550 nm. While at 40% strain level, the film demonstrates a significantly low transmittancession Hybrid Thin-Film Material Based on a Dispersive Porous Structure with Embedded Hygroscopic and Deliquescent Substances. (Advanced Functional Materials 2018, 258, 1704717.2%).

References

- Searchinger, T.D.; Beringer, T.; Holtsmark, B.; Kammen, D.M.; Lambin, E.F.; Lucht, W.; Raven, P.; van Ypersele, J.-P. Europe’s renewable energy directive poised to harm global forests. Nat. Commun. 2018, 9, 3741.

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398.

- Shin, M.; Baltazar, J.-C.; Haberl, J.S.; Frazier, E.; Lynn, B. Evaluation of the energy performance of a net zero energy building in a hot and humid climate. Energy Build. 2019, 204, 109531.

- Ma, Z.Y.; Guan, B.W.; Liu, X.H.; Zhang, T. Performance analysis and improvement of air filtration and ventilation process in semiconductor clean air-conditioning system. Energy Build. 2020, 228, 110489.

- Dussault, J.-M.; Gosselin, L.; Galstian, T. Integration of smart windows into building design for reduction of yearly overall energy consumption and peak loads. Sol. Energy 2012, 86, 3405–3416.

- Wang, M.; Xing, X.; Perepichka, I.F.; Shi, Y.H.; Zhou, D.Y.; Wu, P.H.; Meng, H. Electrochromic Smart Windows Can Achieve an Absolute Private State through Thermochromically Engineered Electrolyte. Adv. Energy Mater. 2019, 9, 1900433.

- Ke, Y.J.; Chen, J.W.; Lin, C.J.; Wang, S.C.; Zhou, Y.; Yin, J.; Lee, P.S.; Long, Y. Smart Windows: Electro-, Thermo-, Mechano-, Photochromics, and Beyond. Adv. Energy Mater. 2019, 9, 1902066.

- Zhou, Y.; Fan, F.; Liu, Y.P.; Zhao, S.S.; Xu, Q.; Wang, S.C.; Luo, D.; Long, Y. Unconventional smart windows: Materials, structures and designs. Nano Energy 2021, 90, 106613.

- Svensson, J.S.E.M.; Granqvist, C.G. Electrochromic Coatings for Smart Windows. Sol. Energy Mater. 1985, 12, 391–402.

- Tällberg, R.; Jelle, B.P.; Loonen, R.; Gao, T.; Hamdy, M. Comparison of the energy saving potential of adaptive and controllable smart windows: A state-of-the-art review and simulation studies of thermochromic, photochromic and electrochromic technologies. Sol. Energy Mater. Sol. Cells 2019, 200, 109828.

- Wang, X.J.; Narayan, S. Thermochromic Materials for Smart Windows: A State-of-Art Review. Front. Energy Res. 2021, 9, 837–841.

- Chun, S.Y.; Park, S.; Lee, S.I.; Nguyen, H.D.; Lee, K.-K.; Hong, S.; Han, C.-H.; Cho, M.; Choi, H.-K.; Kwak, K. Operando Raman and UV-Vis spectroscopic investigation of the coloring and bleaching mechanism of self-powered photochromic devices for smart windows. Nano Energy 2021, 82, 105721.

- Liu, S.; Tso, C.Y.; Lee, H.H.; Zhang, Y.; Yu, K.M.; Chao, C.Y.H. Bio-inspired TiO2 nano-cone antireflection layer for the optical performance improvement of VO2 thermochromic smart windows. Sci. Rep. 2020, 10, 11376.

- Quan, Y.-J.; Kim, Y.-G.; Kim, M.-S.; Min, S.-H.; Ahn, S.-H. Stretchable Biaxial and Shear Strain Sensors Using Diffractive Structural Colors. ACS Nano 2020, 14, 5392–5399.

- Lee, E.; Zhang, M.; Cho, Y.; Cui, Y.; Van der Spiegel, J.; Engheta, N.; Yang, S. Tilted Pillars on Wrinkled Elastomers as a Reversibly Tunable Optical Window. Adv. Mater. 2014, 26, 4127–4133.

- Fan, Z.; Razavi, H.; Do, J.W.; Moriwaki, A.; Ergen, O.; Chueh, Y.L.; Leu, P.W.; Ho, J.C.; Takahashi, T.; Reichertz, L.A. Three-dimensional nanopillar-array photovltaics on low-cost and flexible substrates. Nat. Mater. 2009, 8, 648–653.

- Zhao, P.; Li, B.; Tang, Z.; Gao, Y.; Tian, H.; Chen, H. Stretchable photonic crystals with periodic cylinder shaped air holes for improving mechanochromic performance. Smart Mater. Struct. 2019, 28, 075037.

- Li, J.; Shim, J.; Deng, J.; Overvelde, J.T.B.; Zhu, X.; Bertoldi, K.; Yang, S. Switching periodic membranes via pattern transformation and shape memory effect. Soft Matter. 2012, 8, 10322–10328.

- Wang, K.; Li, C.; Li, Z.; Li, H.; Li, A.; Li, K.; Lai, X.; Liao, Q.; Xie, F.; Li, M.; et al. A facile fabrication strategy for anisotropic photonic crystals using deformable spherical nanoparticles. Nanoscale 2019, 11, 14147–14154.

- Li, P.; Han, Y.; Wang, W.; Chen, X.; Jin, P.; Liu, S. Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. Polymers 2018, 10, 756.

- Lee, S.G.; Lee, D.Y.; Lim, H.S.; Lee, D.H.; Lee, S.; Cho, K. Switchable transparency and wetting of elastomeric smart windows. Adv. Mater. 2010, 22, 5013–5017.

- Zhao, P.; Chen, H.; Li, B.; Tian, H.; Lai, D.; Gao, Y. Stretchable electrochromic devices enabled via shape memory alloy composites (SMAC) for dynamic camouflage. Opt. Mater. 2019, 94, 378–386.

- Ji, C.; Chen, M.; Wu, L. Patternable and Rewritable Retroreflective Structural Color Shape Memory Polymers. Adv. Opt. Mater. 2021, 9, 2100739.

- Thomas, A.V.; Andow, B.C.; Suresh, S.; Eksik, O.; Yin, J.; Dyson, A.H.; Koratkar, N. Controlled Crumpling of Graphene Oxide Films for Tunable Optical Transmittance. Adv. Mater. 2015, 27, 3256–3265.

- Zang, J.; Ryu, S.; Pugno, N.; Wang, Q.; Tu, Q.; Buehler, M.J.; Zhao, X. Multifunctionality and control of the crumpling and unfolding of large-area graphene. Nat. Mater. 2013, 12, 321–325.

- Ke, Y.; Zhang, Q.; Wang, T.; Wang, S.; Li, N.; Lin, G.; Liu, X.; Dai, Z.; Yan, J.; Yin, J.; et al. Cephalopod-inspired versatile design based on plasmonic VO2 nanoparticle for energy-efficient mechano-thermochromic windows. Nano Energy 2020, 73, 104785.

- Lin, G.; Chandrasekaran, P.; Lv, C.; Zhang, Q.; Tang, Y.; Han, L.; Yin, J. Self-similar Hierarchical Wrinkles as a Potential Multifunctional Smart Window with Simultaneously Tunable Transparency, Structural Color, and Droplet Transport. ACS Appl. Mater. Interfaces 2017, 9, 26510–26517.

- Cao, C.; Chan, H.F.; Zang, J.; Leong, K.W.; Zhao, X. Harnessing localized ridges for high-aspect-ratio hierarchical patterns with dynamic tunability and multifunctionality. Adv. Mater. 2014, 26, 1763–1770.

- Li, Z.W.; Liu, Y.; Marin, M.; Yin, Y.D. Thickness-dependent wrinkling of PDMS films for programmable mechanochromic responses. Nano Res. 2020, 13, 1882–1888.

- Lin, R.; Qi, Y.; Kou, D.; Ma, W.; Zhang, S. Bio-Inspired Wrinkled Photonic Elastomer with Superior Controllable and Mechanically Stable Structure for Multi-Mode Color Display. Adv. Funct. Mater. 2022, 32, 2207691.

- Jiang, B.; Liu, L.; Gao, Z.; Feng, Z.; Zheng, Y.; Wang, W. Fast Dual-Stimuli-Responsive Dynamic Surface Wrinkles with High Bistability for Smart Windows and Rewritable Optical Displays. ACS Appl. Mater. Interfaces 2019, 11, 40406–40415.

- Shrestha, M.; Lau, G.-K. Tunable window device based on micro-wrinkling of nanometric zinc-oxide thin film on elastomer. Opt. Lett. 2016, 41, 4433–4436.

- Zeng, S.; Zhang, D.; Huang, W.; Wang, Z.; Freire, S.G.; Yu, X.; Smith, A.T.; Huang, E.Y.; Nguon, H.; Sun, L. Bio-inspired sensitive and reversible mechanochromisms via strain-dependent cracks and folds. Nat. Commun. 2016, 7, 11802.

- Mao, Z.; Zeng, S.; Shen, K.; Chooi, A.P.; Smith, A.T.; Jones, M.D.; Zhou, Y.; Liu, X.; Sun, L. Dynamic Mechanochromic Optics with Tunable Strain Sensitivity for Strain-Responsive Digit Display. Adv. Opt. Mater. 2020, 8, 2001472.

- Li, Z.; Zhai, Y.; Wang, Y.; Wendland, G.M.; Yin, X.; Xiao, J. Harnessing Surface Wrinkling–Cracking Patterns for Tunable Optical Transmittance. Adv. Opt. Mater. 2017, 5, 1700425.

- Jiang, Y.; Zeng, S.; Yao, Y.; Xu, S.; Dong, Q.; Chen, P.; Wang, Z.; Zhang, M.; Zhu, M.; Xu, G.; et al. Dynamic Optics with Transparency and Color Changes under Ambient Conditions. Polymers 2019, 11, 103.

- Zhao, H.; Sun, Q.; Zhou, J.; Deng, X.; Cui, J. Switchable Cavitation in Silicone Coatings for Energy-Saving Cooling and Heating. Adv. Mater. 2020, 32, e2000870.

- Ge, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D.S.; Yang, S. A Robust Smart Window: Reversibly Switching from High Transparency to Angle-Independent Structural Color Display. Adv. Mater. 2015, 27, 2489–2495.

- Liu, Y.; Song, S.; Liu, M.; Hu, Y.; Zhang, L.-W.; Yoon, H.; Yang, L.; Ge, D. Gecko-inspired ultrasensitive multifunctional mechano-optical smart membranes. Chem. Eng. J. 2021, 429, 132159.

- Cho, D.; Shim, Y.S.; Jung, J.W.; Nam, S.H.; Min, S.; Lee, S.E.; Ham, Y.; Lee, K.; Park, J.; Shin, J.; et al. High-Contrast Optical Modulation from Strain-Induced Nanogaps at 3D Heterogeneous Interfaces. Adv. Sci. 2020, 7, 1903708.

- Han, J.; Freyman, M.C.; Feigenbaum, E.; Han, T.Y.-J. Electro-Optical Device with Tunable Transparency Using Colloidal Core/Shell Nanoparticles. ACS Photonics 2018, 5, 1343–1350.

- Li, J.; Lu, X.; Zhang, Y.; Ke, X.; Wen, X.; Cheng, F.; Wei, C.; Li, Y.; Yao, K.; Yang, S. Highly Sensitive Mechanoresponsive Smart Windows Driven by Shear Strain. Adv. Funct. Mater. 2021, 31, 2102350.

- Qi, Y.; Zhou, C.; Zhang, S.; Zhang, Z.; Niu, W.; Wu, S.; Ma, W.; Tang, B. Bar-coating programmable mechanochromic bilayer PDMS film with angle-dependent and angle-independent structural colors. Dyes Pigments 2021, 189, 109264.

- Kim, H.N.; Ge, D.; Lee, E.; Yang, S. Multistate and On-Demand Smart Windows. Adv. Mater. 2018, 30, e1803847.