机械响应式智能窗户具有结构简单、成本低、稳定性好等优点。

- energy saving

- smart window

- mechanoresponsive

- driving mode

1. 简介

2. 机械响应智能窗户的结构

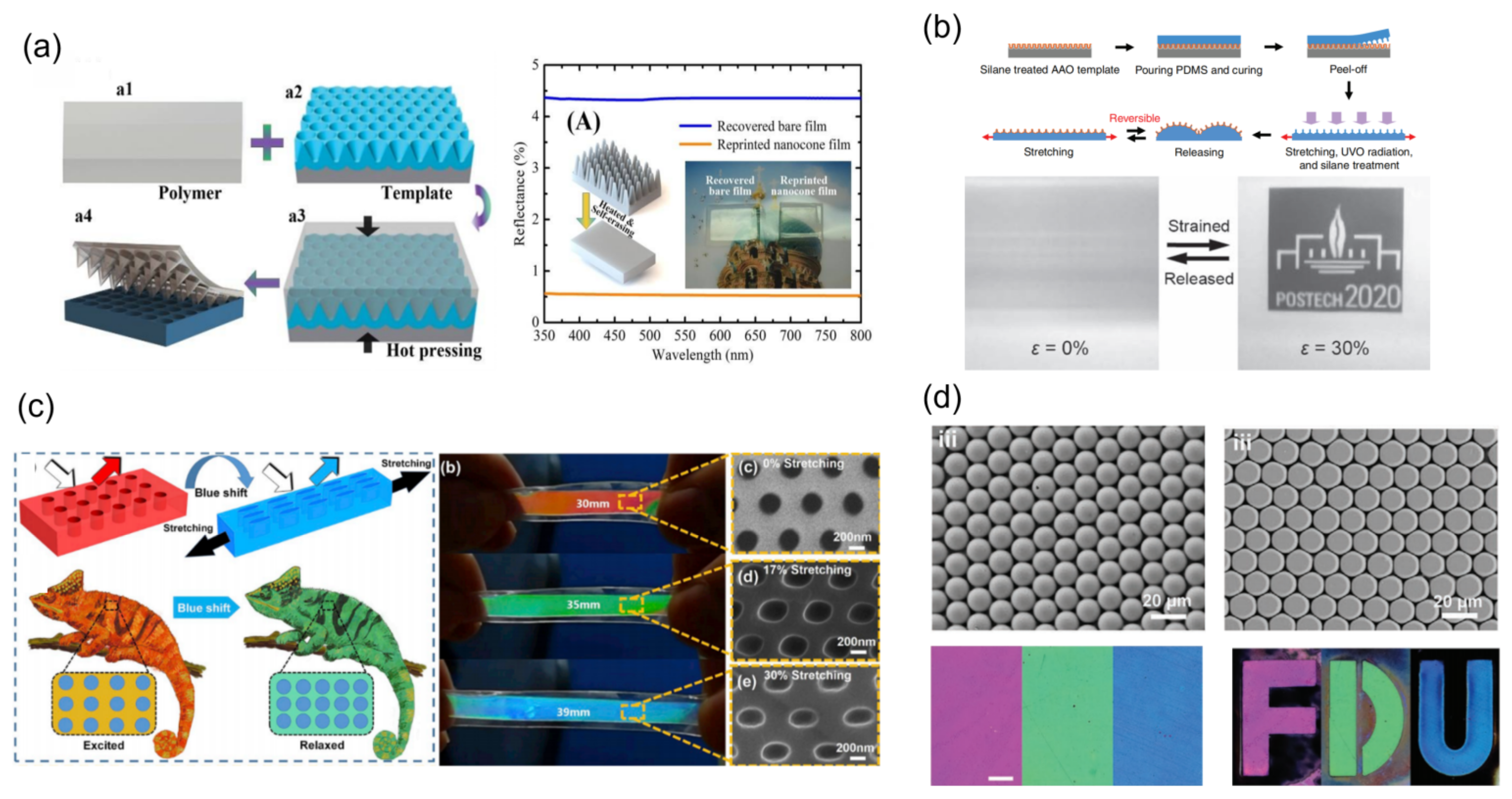

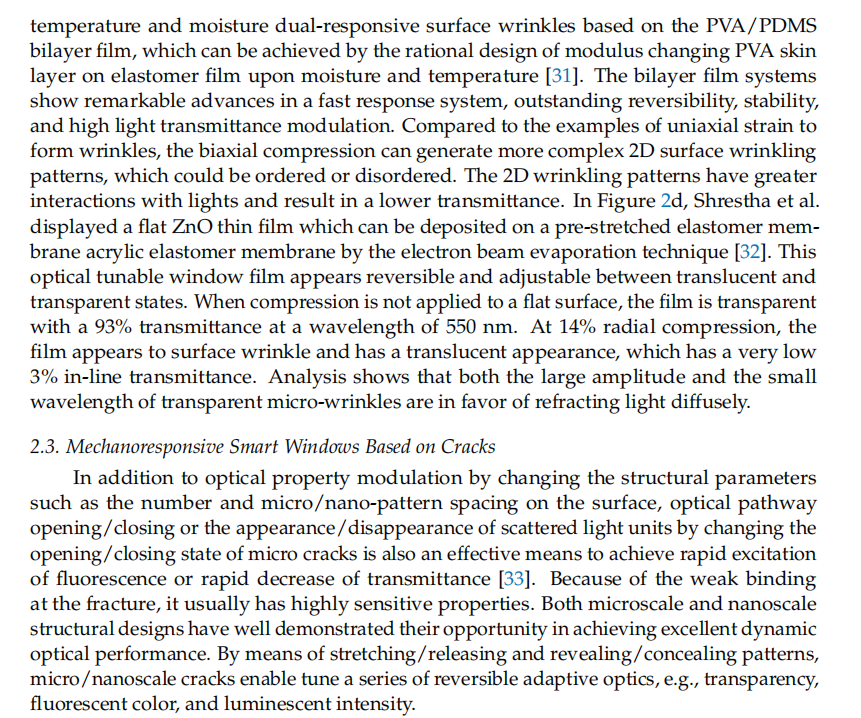

机械力驱动的机械应变, 电, 湿度, 等, 重新配置表面形貌或改变界面结构, 从而通过调制光的散射或衍射来改变光学透射率.基于实现光调制的表面形态或界面结构的类型,研究人员创建了六大类机械响应材料:微/纳米阵列、皱褶、裂纹、新型界面、可调界面参数和表面-界面协同效应。对于每个类别,将重点关注机制和光学可调特性的最新发展。

2.1. 基于微/纳米阵列的机械响应智能窗口

2.2. 基于皱纹的机械响应智能窗户

2.3. 基于裂缝的机械响应智能窗户

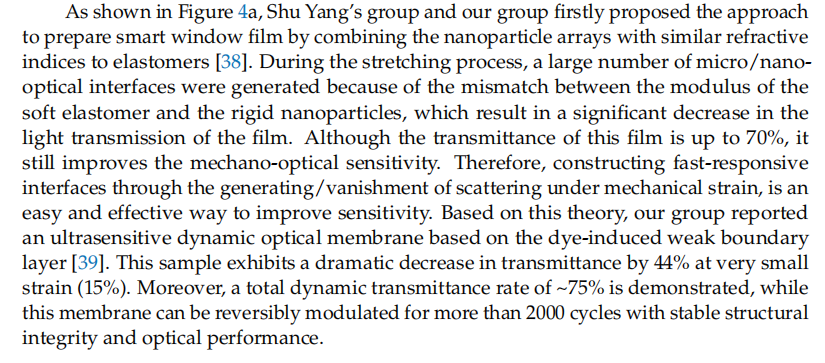

2.4. 新颖界面引入机械响应智能窗口

2.5. 基于可调接口参数的机械响应智能窗口

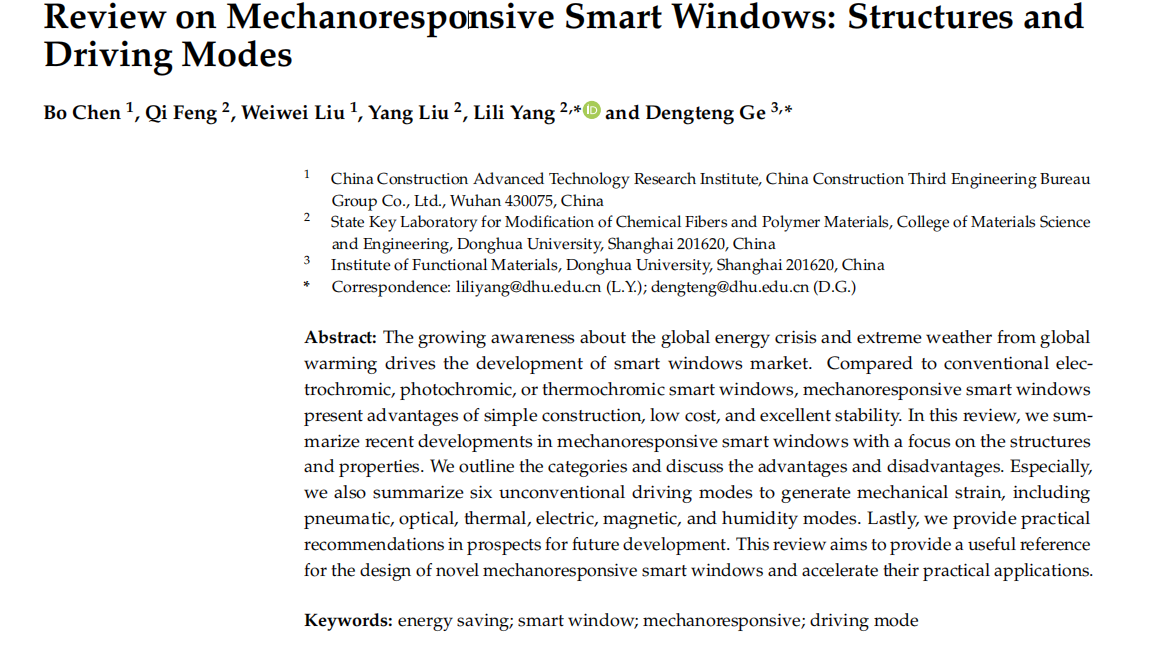

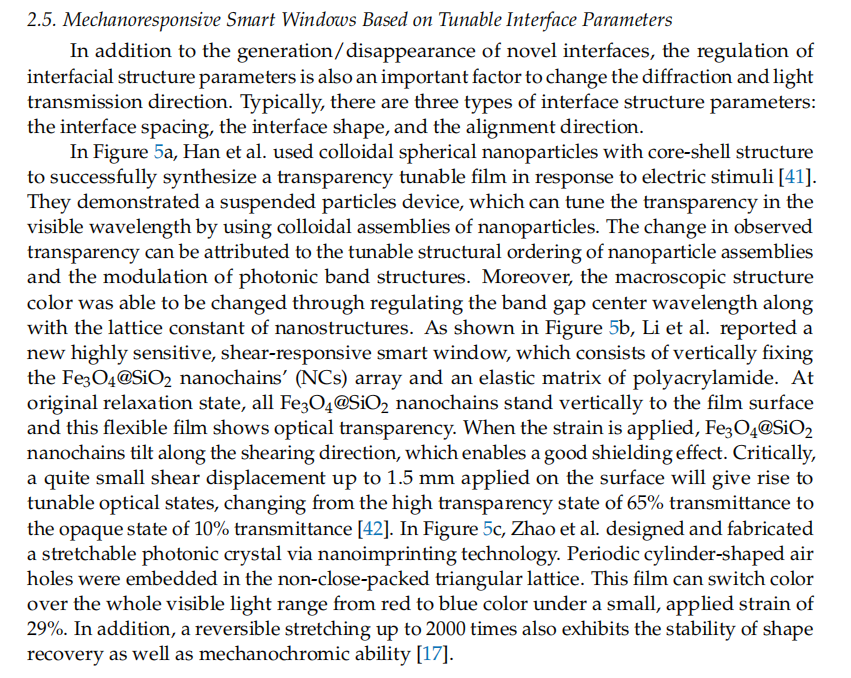

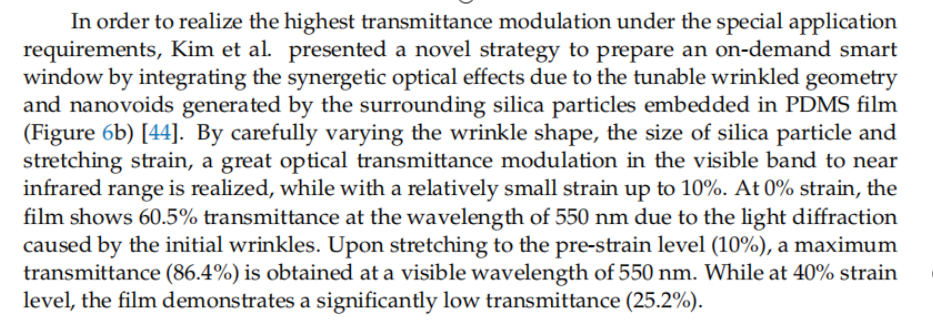

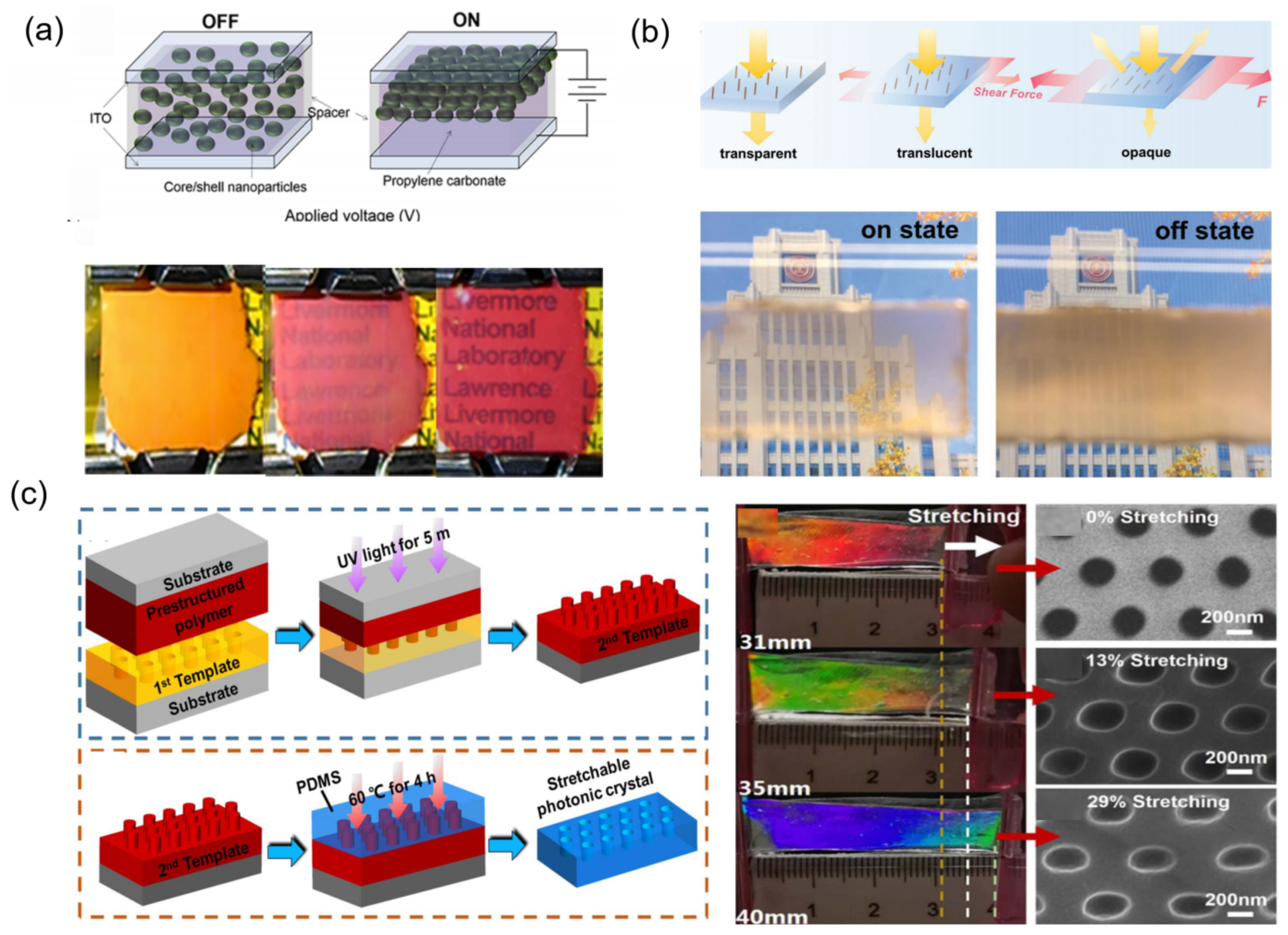

除了新型界面的产生/消失外,界面结构参数的调控也是改变衍射和透光方向的重要因素。通常,界面结构参数有三种类型:界面间距、界面形状和对齐方向。 在图5a中,Han等人使用具有核壳结构的胶体球形纳米颗粒成功地合成了响应电刺激的透明可调薄膜。[41].他们展示了一种悬浮颗粒装置,该装置可以通过使用纳米颗粒的胶体组件来调节可见光波长的透明度。观察到的透明度的变化可归因于纳米颗粒组件的可调结构顺序和光子带结构的调制。此外,通过调节带隙中心波长和纳米结构的晶格常数,可以改变宏观结构的颜色。如图5b所示,Li等人报告了一种新的高灵敏度、剪切响应智能窗口,该窗口包括垂直固定Fe3O4@SiO2纳米链(NCs)阵列和聚丙烯酰胺的弹性基质。在原始弛豫状态下,所有Fe3O4@SiO2纳米链垂直站在薄膜表面,这种柔性薄膜显示出光学透明度。当施加应变时,Fe3O4@SiO2纳米链沿剪切方向倾斜,具有良好的屏蔽效果。至关重要的是,施加在表面上的高达1.5 mm的非常小的剪切位移将产生可调谐的光学状态,从65%透射率的高透明度状态变为透射率10%的不透明状态[42].在图5c中,Zhao等人通过纳米压印技术设计并制造了可拉伸光子晶体。周期性的圆柱形气孔嵌入在非紧密堆积的三角形格子中。这种薄膜可以在29%的小应变下,在整个可见光范围内从红色切换到蓝色。此外,高达2000次的可逆拉伸也表现出形状恢复的稳定性以及机械致变色能力[17].

2.6. 基于表面-界面协同效应的机械响应智能窗口

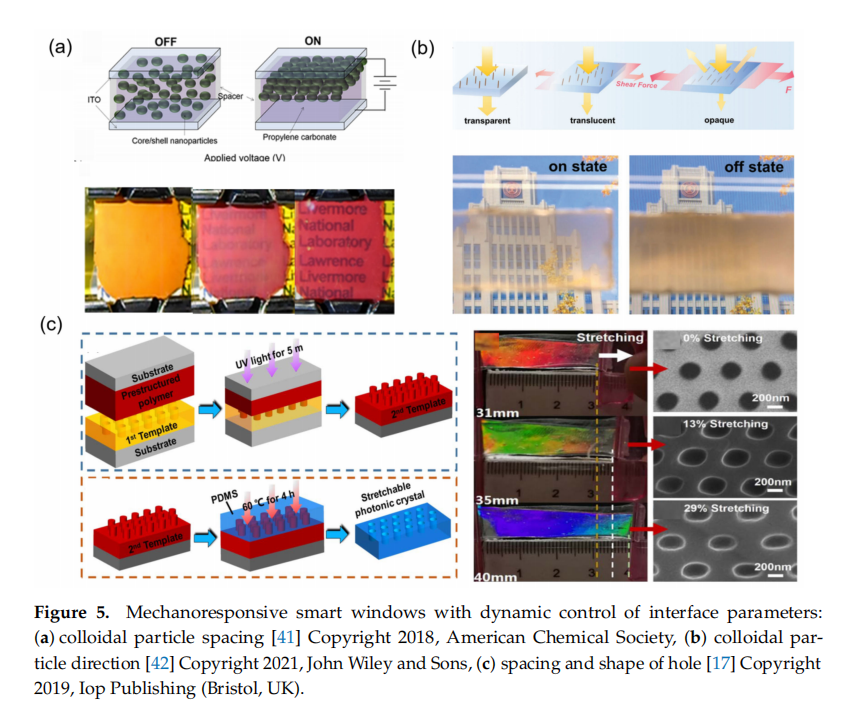

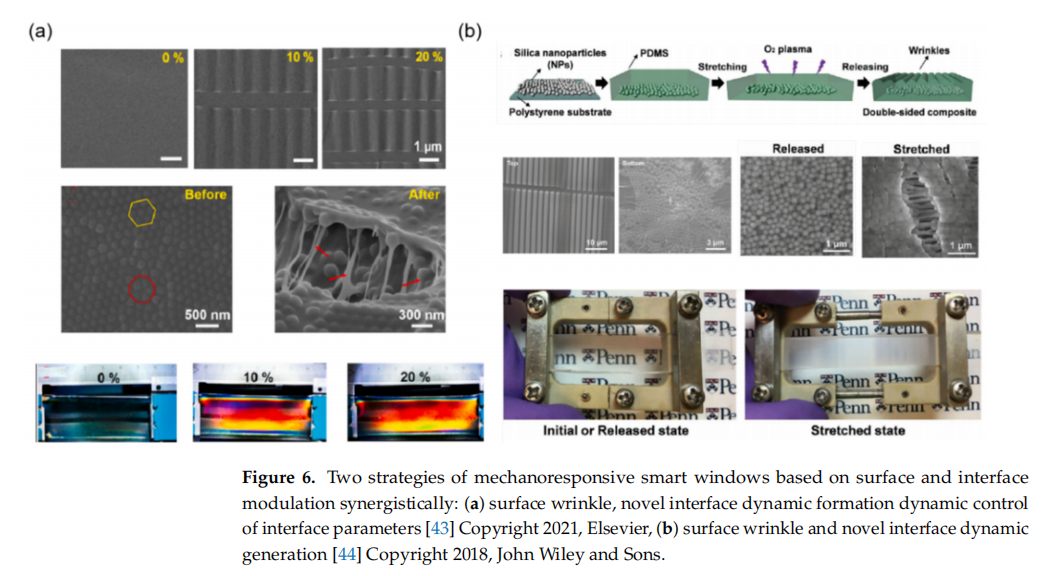

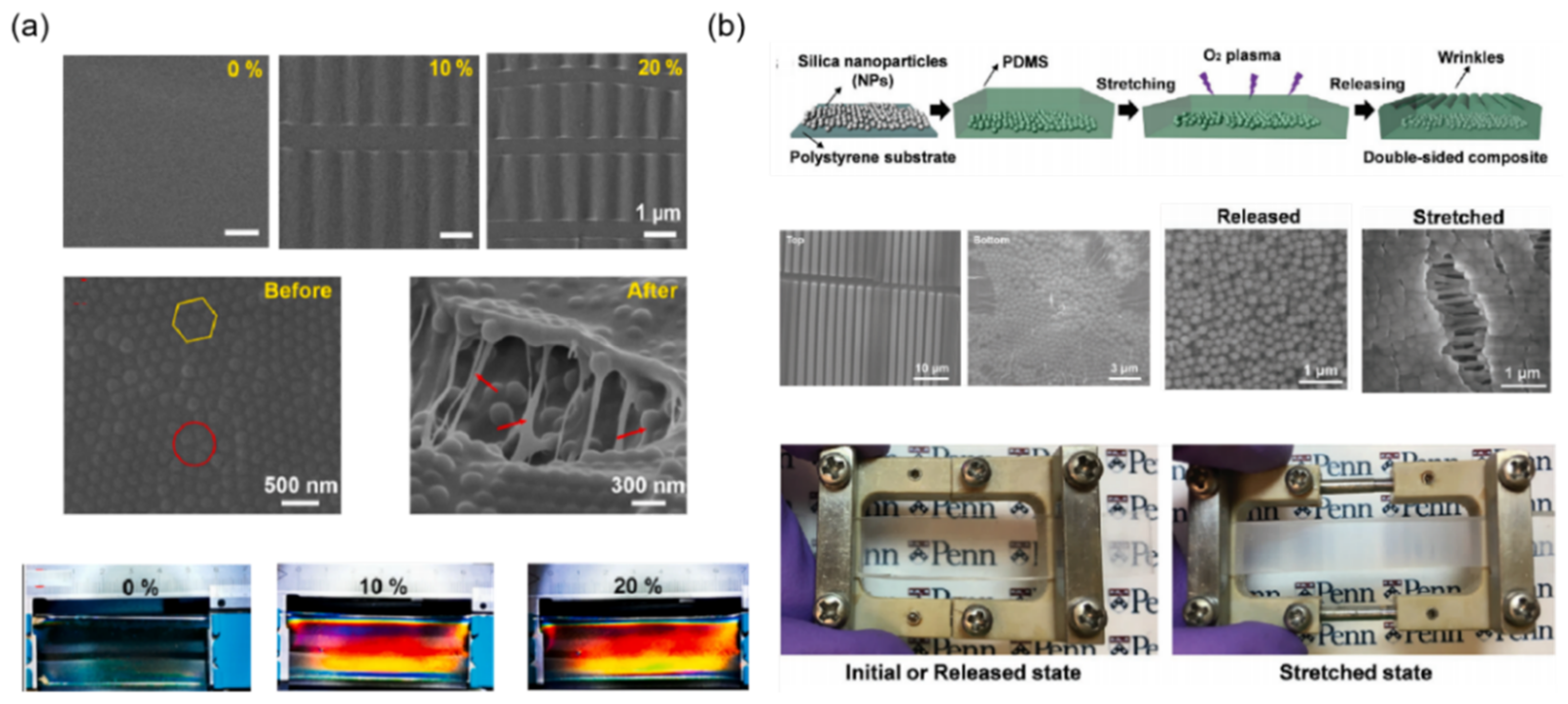

为了增强光调制范围并实现多态,协同表面-界面调制是一种有效的方法。可以同时实现基于多种效果的色彩和透射率调制。因此,表面-界面协同效应在多状态显示和精确调控方面具有独特的优势。 如图6a所示,Qi等人基于双层PDMS薄膜的新设计报道了一种大面积机械着色薄膜,该薄膜通过自下而上的条形涂层包括与角度无关和与角度相关的结构颜色[43].与角度无关的结构颜色归因于聚苯乙烯(PS)纳米阵列的长程无序但短程有序结构。同时,由于表面起皱的拉伸,会产生与角度相关的结构颜色。此外,拉伸引起的PS纳米阵列的裂纹和表面褶皱增强了双层薄膜的散射效果,降低了光的透射率。此外,压力诱导的表面形态重排可以消除起皱行为。因此,可以实现可编程机械变色响应的特性。压力编码的不可见复杂信息可以通过拉伸可逆地显示。

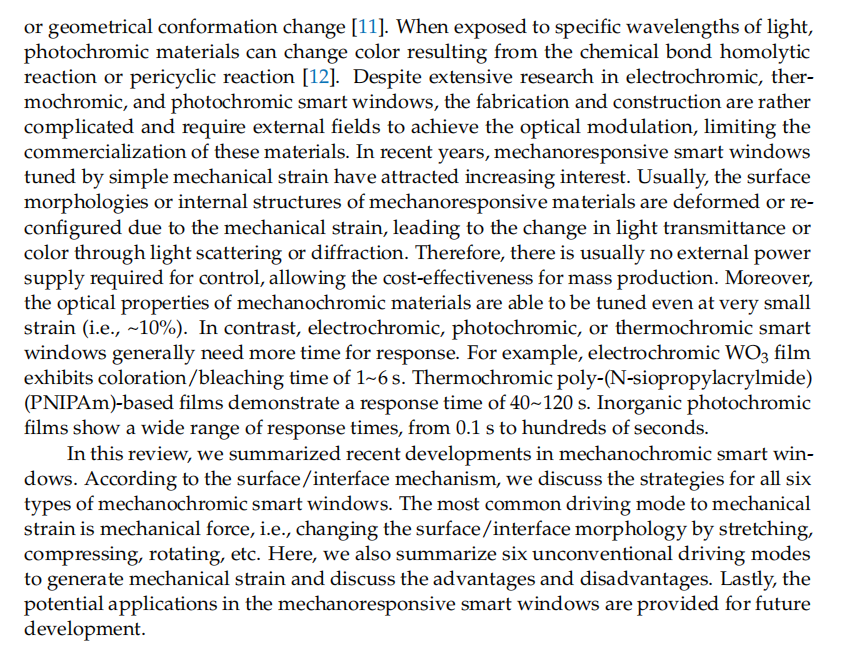

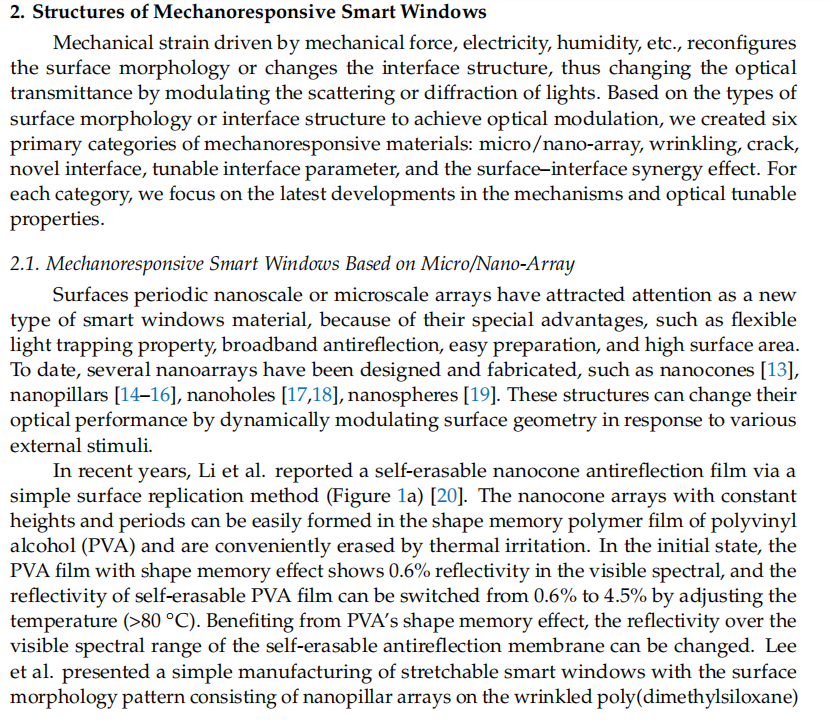

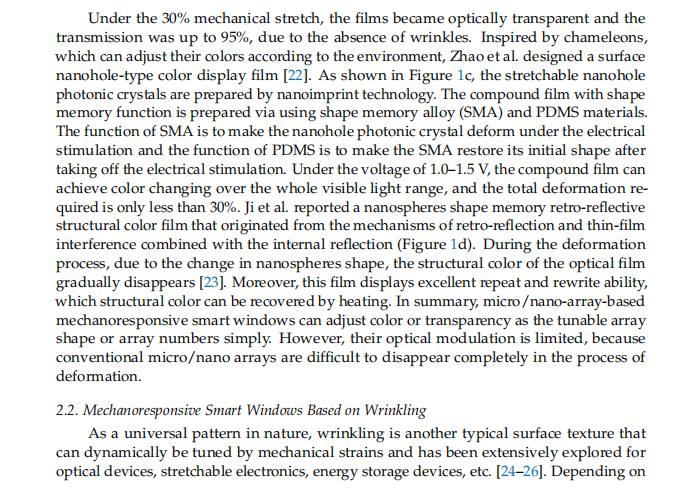

Figure 1a. The strategies of mechanoresponsive smart windows based on nanoarrays: nanocone[20], Li, P.; Han, Y.; Wang, W.; Chen, X.; Jin, P.; Liu, S., Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. Polymers (Basel) 2018, 10, 756-765.

Figure 1b. The strategies of mechanoresponsive smart windows based on nanoarrays: nanopillar[21], Lee, S. G.; Lee, D. Y.; Lim, H. S.; Lee, D. H.; Lee, S.; Cho, K., Switchable transparency and wetting of elastomeric smart windows. Adv Mater 2010, 22, 5013-5017.

Figure 1c. The strategies of mechanoresponsive smart windows based on nanoarrays: nanoholes[22], Zhao, P.; Chen, H.; Li, B.; Tian, H.; Lai, D.; Gao, Y., Stretchable electrochromic devices enabled via shape memory alloy composites (SMAC) for dynamic camouflage. Optical Materials 2019, 94, 378-386.

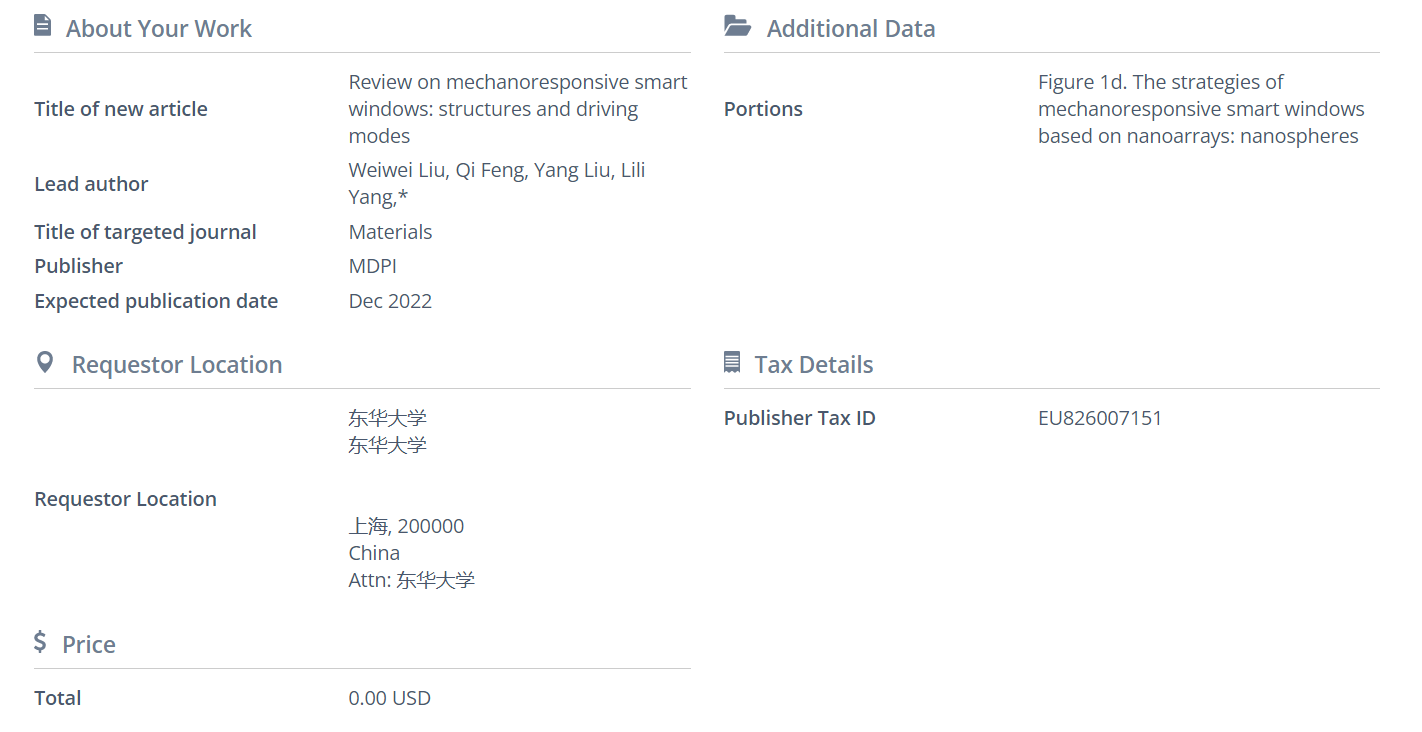

图 1d.基于纳米阵列的机械响应智能窗策略:纳米球 [23], 季春;陈敏;Wu,L.,可图案和可重写的逆反射结构颜色形状记忆聚合物。先进光学材料2021,94, 2100739.

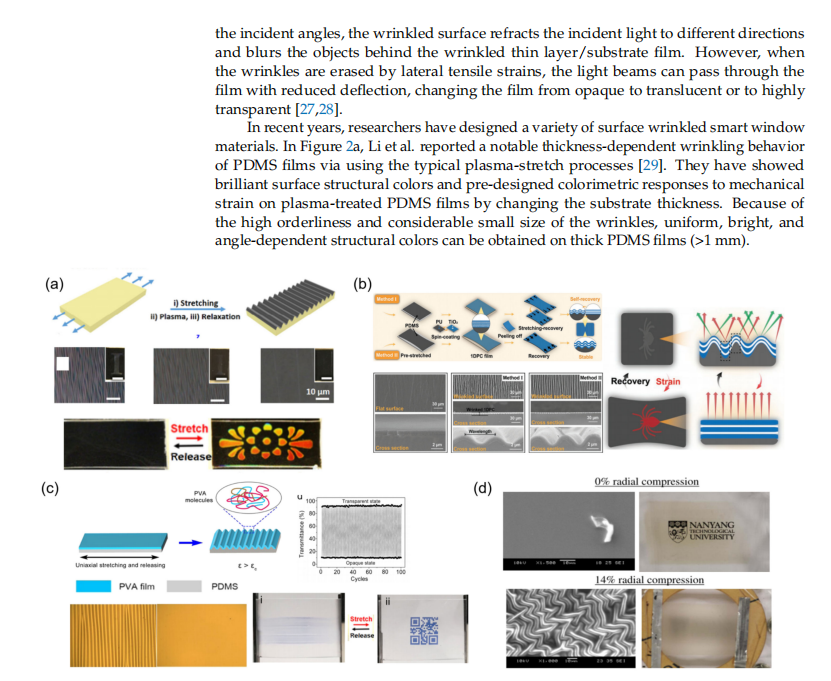

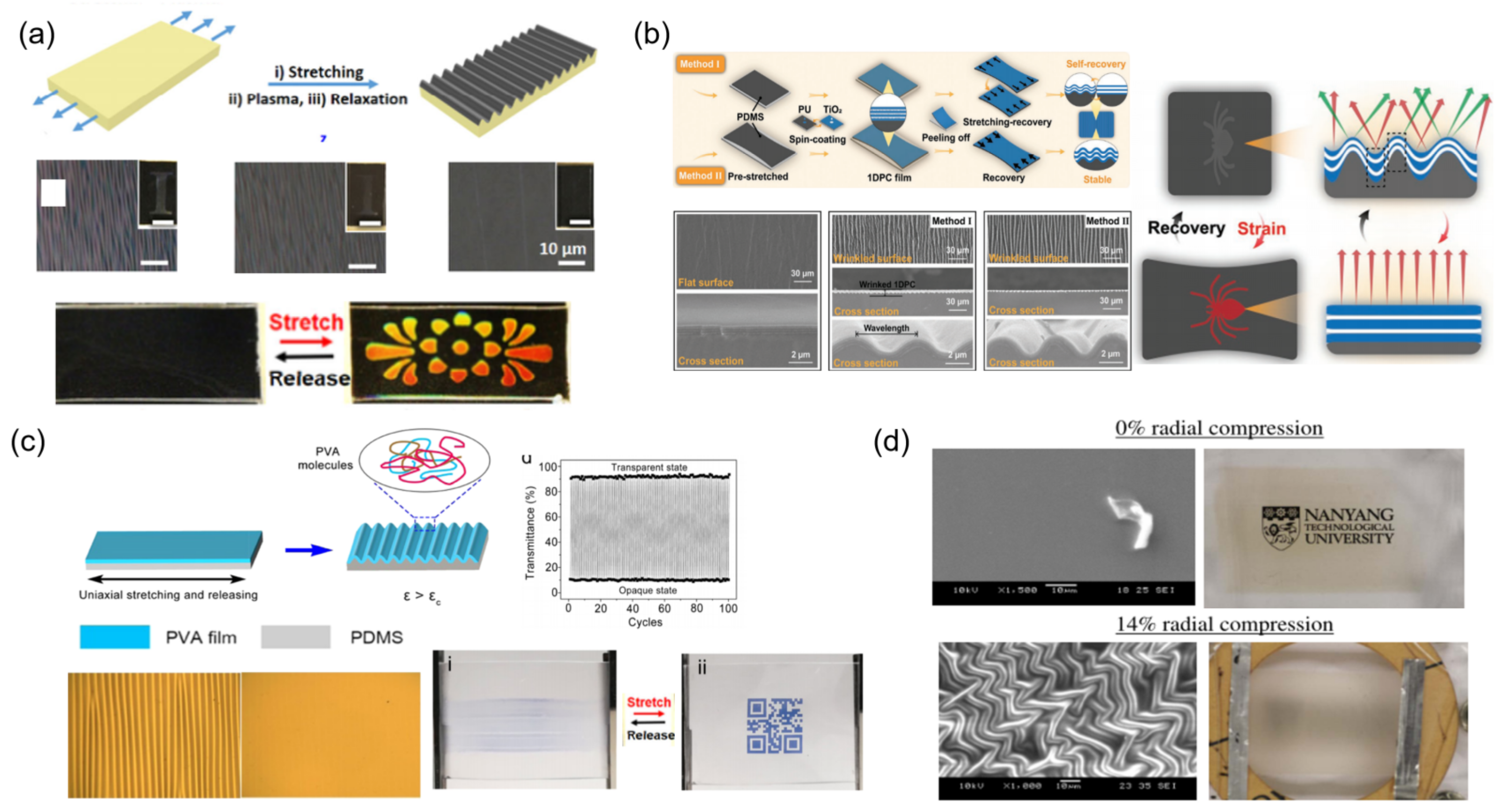

Figure 2a. The strategies of mechanoresponsive smart windows based on wrinkling: stretching to form wrinkles[29], Li, Z. W.; Liu, Y.; Marin, M.; Yin, Y. D., Thickness-dependent wrinkling of PDMS films for programmable mechanochromic responses. Nano Res 2020, 13, 1882-1888.

Figure 2b. The strategies of mechanoresponsive smart windows based on wrinkling: wrinkled photonic elastomer structure[30], Lin, R.; Qi, Y.; Kou, D.; Ma, W.; Zhang, S., Bio‐Inspired Wrinkled Photonic Elastomer with Superior Controllable and Mechanically Stable Structure for Multi‐Mode Color Display. Advanced Functional Materials 2022, 32, 2207691.

Figure 2c. The strategies of mechanoresponsive smart windows based on wrinkling: Double-layer film wrinkle[31], Jiang, B.; Liu, L.; Gao, Z.; Feng, Z.; Zheng, Y.; Wang, W., Fast Dual-Stimuli-Responsive Dynamic Surface Wrinkles with High Bistability for Smart Windows and Rewritable Optical Displays. ACS Appl Mater Interfaces 2019, 11, 40406-40415.

Figure 2d. The strategies of mechanoresponsive smart windows based on wrinkling: biaxial compression to form wrinkles[32], Shrestha, M.; Lau, G. K., Tunable window device based on micro-wrinkling of nanometric zinc-oxide thin film on elastomer. Opt Lett 2016, 41, 4433-4436.

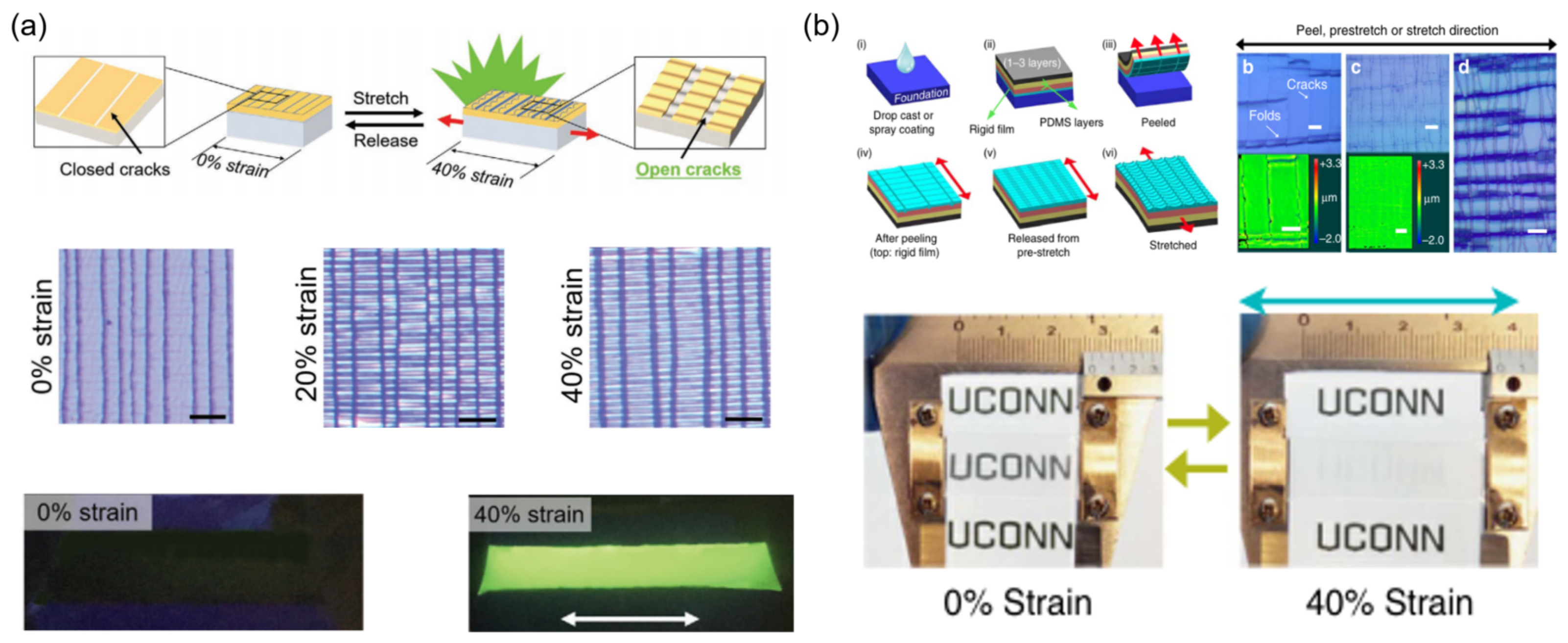

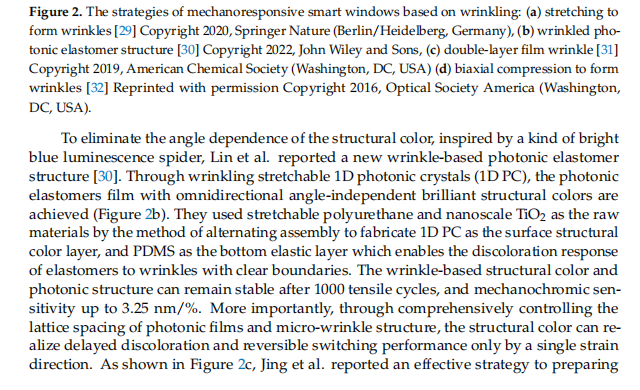

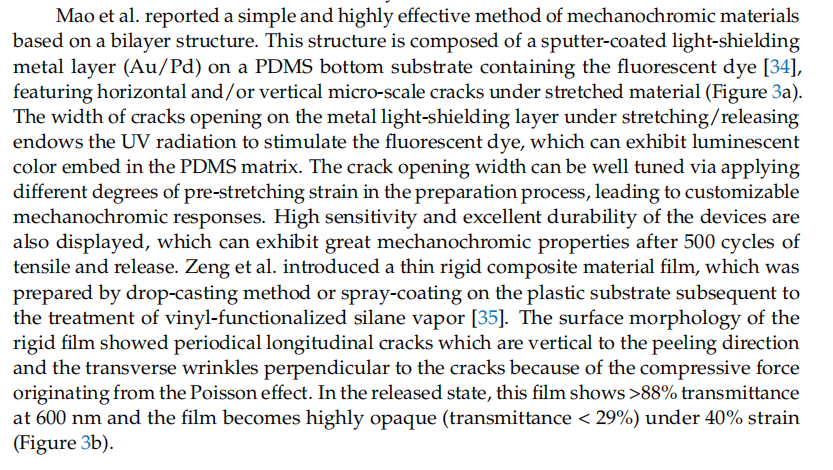

Figure 3a. Construction paths of mechanoresponsive smart windows based on surface crack: surface deposition of metal coating[34], Mao, Z.; Zeng, S.; Shen, K.; Chooi, A. P.; Smith, A. T.; Jones, M. D.; Zhou, Y.; Liu, X.; Sun, L., Dynamic Mechanochromic Optics with Tunable Strain Sensitivity for Strain‐Responsive Digit Display. Advanced Optical Materials 2020, 8, 2001472.

Figure 3b. Construction paths of mechanoresponsive smart windows based on surface crack: soft substrate/ hard shell[35], Li, Z.; Zhai, Y.; Wang, Y.; Wendland, G. M.; Yin, X.; Xiao, J., Harnessing Surface Wrinkling–Cracking Patterns for Tunable Optical Transmittance. Advanced Optical Materials 2017, 5, 1700425.

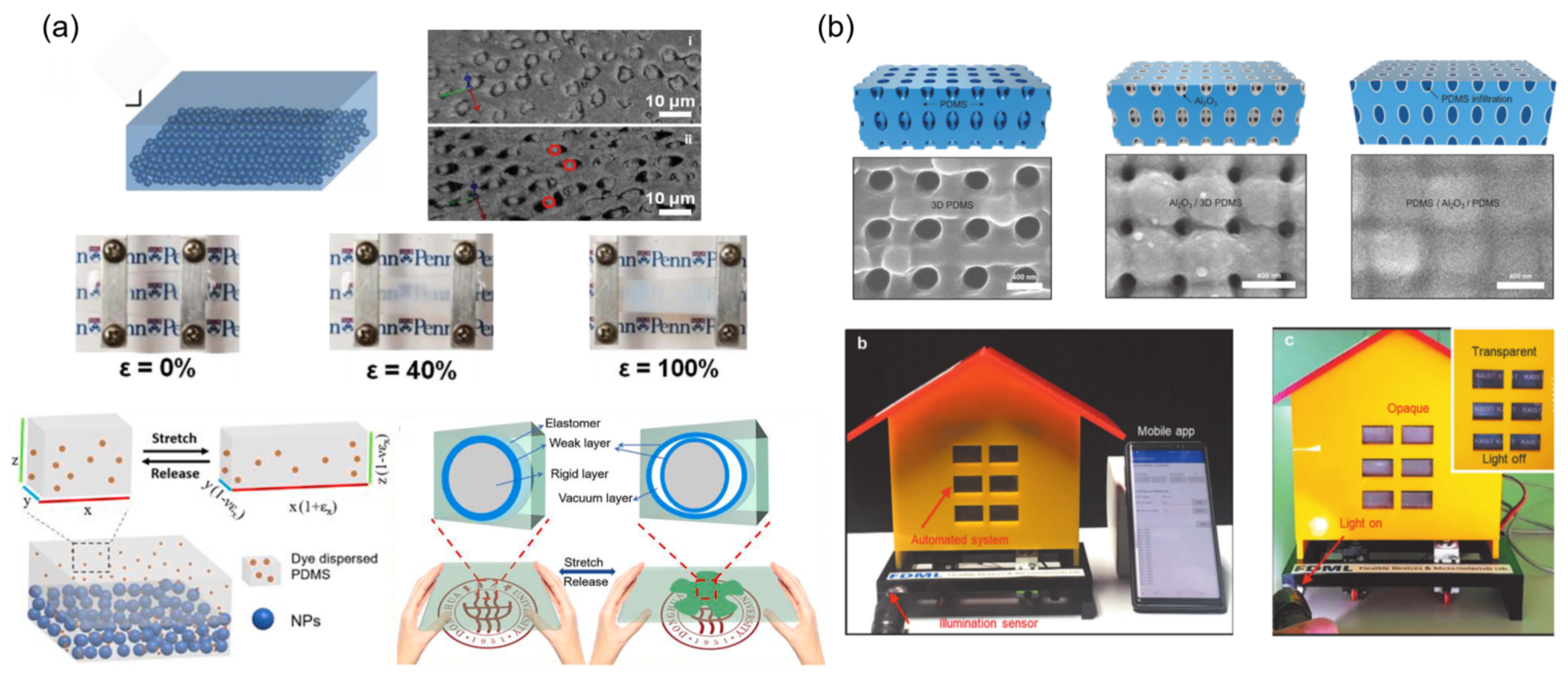

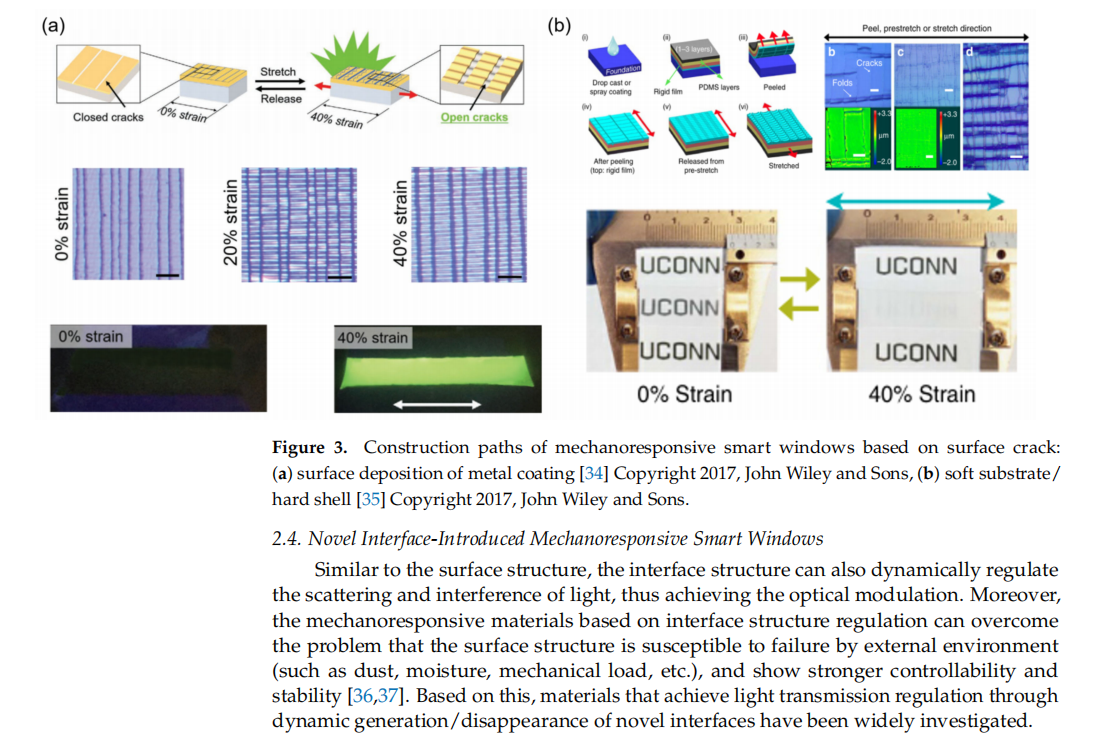

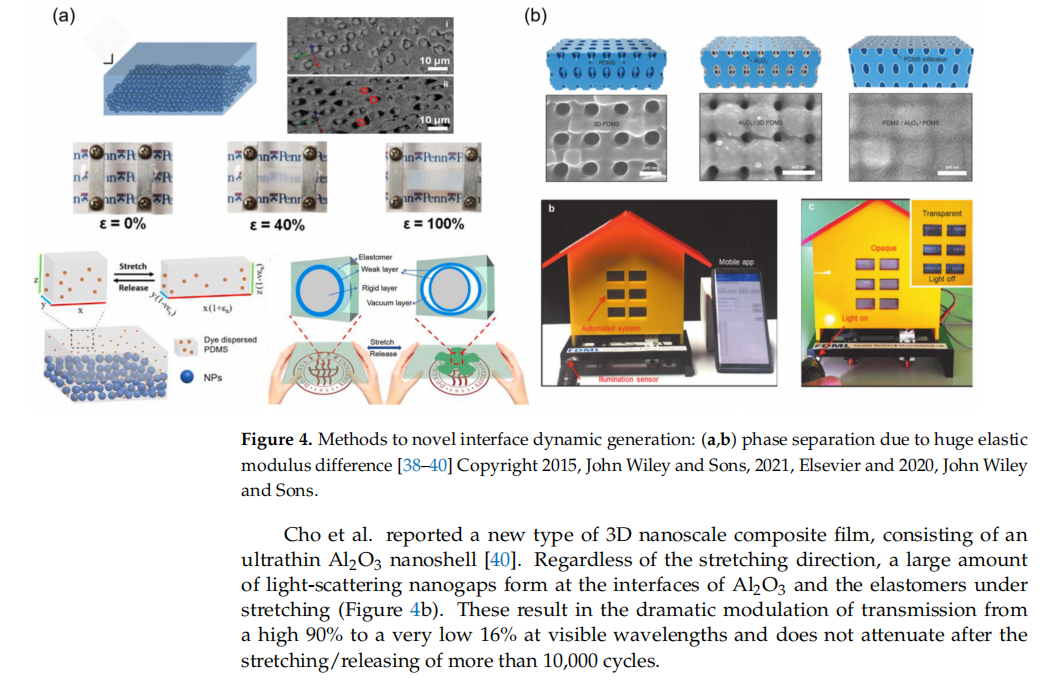

Figure 4a. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[38], Ge, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D. S.; Yang, S., A robust smart window: reversibly switching from high transparency to angle-independent structural color display. Adv Mater 2015, 27, 2489-95.

Figure 4a. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[39], Liu, Y.; Song, S.; Liu, M.; Hu, Y.; Zhang, L.-w.; Yoon, H.; Yang, L.; Ge, D., Gecko-inspired ultrasensitive multifunctional mechano-optical smart membranes. Chemical Engineering Journal 2022, 429, 132159.

Figure 4b. Methods to novel interface dynamic generation: phase separation due to huge elastic modulus difference[40], Cho, D.; Shim, Y. S.; Jung, J. W.; Nam, S. H.; Min, S.; Lee, S. E.; Ham, Y.; Lee, K.; Park, J.; Shin, J.; Hong, J. W.; Jeon, S., High-Contrast Optical Modulation from Strain-Induced Nanogaps at 3D Heterogeneous Interfaces. Adv Sci (Weinh) 2020, 7, 1903708.

Figure 5a. Mechanoresponsive smart windows with dynamic control of interface parameters: colloidal particle spacing[41], Han, J.; Freyman, M. C.; Feigenbaum, E.; Yong-Jin Han, T., Electro-Optical Device with Tunable Transparency Using Colloidal Core/Shell Nanoparticles. ACS Photonics 2018, 5, 1343-1350.

Figure 5b. Mechanoresponsive smart windows with dynamic control of interface parameters: colloidal particle direction[42], Li, J.; Lu, X.; Zhang, Y.; Ke, X.; Wen, X.; Cheng, F.; Wei, C.; Li, Y.; Yao, K.; Yang, S., Highly Sensitive Mechanoresponsive Smart Windows Driven by Shear Strain. Advanced Functional Materials 2021, 31, 2102350.

Figure 5c. Mechanoresponsive smart windows with dynamic control of interface parameters: spacing and shape of hole[17]. Zhao, P.; Li, B.; Tang, Z.; Gao, Y.; Tian, H.; Chen, H., Stretchable photonic crystals with periodic cylinder shaped air holes for improving mechanochromic performance. Smart Materials and Structures 2019, 28, 075037.

Figure 6a. Two strategies of mechanoresponsive smart windows based on surface and interface modulation synergistically: surface wrinkle, novel interface dynamic formation dynamic control of interface parameters[43], Qi, Y.; Zhou, C.; Zhang, S.; Zhang, Z.; Niu, W.; Wu, S.; Ma, W.; Tang, B., Bar-coating programmable mechanochromic bilayer PDMS film with angle-dependent and angle-independent structural colors. Dyes and Pigments 2021, 189, 109264.

Figure 6b. Two strategies of mechanoresponsive smart windows based on surface and interface modulation synergistically: surface wrinkle and novel interface dynamic generation[44], Kim, H. N.; Ge, D.; Lee, E.; Yang, S., Multistate and On-Demand Smart Windows. Adv Mater 2018, 30, e1803847.

Figure 7a. The strategy of pneumatic drive mode mechanoresponsive smart windows: adjust transparency and color by changing film thickness[45], López Jiménez, F.; Kumar, S.; Reis, P. M., Soft Color Composites with Tunable Optical Transmittance. Advanced Optical Materials 2016, 4, 620-626.

Figure 7b. The strategy of pneumatic drive mode mechanoresponsive smart windows: adjust transparency and color by changing film thickness[46], Kim, S. U.; Lee, Y. J.; Liu, J.; Kim, D. S.; Wang, H.; Yang, S., Broadband and pixelated camouflage in inflating chiral nematic liquid crystalline elastomers. Nat Mater 2022, 21, 41-46.

Figure 7c. The strategy of pneumatic drive mode mechanoresponsive smart windows: pneumatic stretching to adjust transparency[47]; Rotzetter, A. C. C.; Fuhrer, R.; Grass, R. N.; Schumacher, C. M.; Stoessel, P. R.; Stark, W. J., Micro Mirror Polymer Composite Offers Mechanically Switchable Light Transmittance. Advanced Engineering Materials 2014, 16, 878-883.

Figure 7d. The strategy of pneumatic drive mode mechanoresponsive smart windows: pneumatic drive mode mechanochromic hydrogels[48]. Zhu, Q.; Vliet, K.; Holten‐Andersen, N.; Miserez, A., A Double‐Layer Mechanochromic Hydrogel with Multidirectional Force Sensing and Encryption Capability. Advanced Functional Materials 2019, 29, 1808191.

Figure 8a. The approaches for optical-driving mechanoresponsive smart windows: based on the high photothermal conversion efficiency of CNT[49], Li, F.; Hou, H.; Yin, J.; Jiang, X., Near-infrared light–responsive dynamic wrinkle patterns. Science Advances 4, eaar5762.

Figure 8b. The approaches for optical-driving mechanoresponsive smart windows: based on the high photothermal conversion efficiency of CNT[50], Xie, M.; Lin, G.; Ge, D.; Yang, L.; Zhang, L.; Yin, J.; Jiang, X., Pattern Memory Surface (PMS) with Dynamic Wrinkles for Unclonable Anticounterfeiting. ACS Materials Letters 2019, 1, 77-82.

Figure 8c. The approaches for optical-driving mechanoresponsive smart windows: (c) based on metal nanoparticles[51], Cao, D.; Xu, C.; Lu, W.; Qin, C.; Cheng, S., Sunlight-Driven Photo-Thermochromic Smart Windows. Solar RRL 2018, 2, 1700219.

Figure 8d. The approaches for optical-driving mechanoresponsive smart windows: based on inverse opal scaffold structure[52]. Wang, Y.; Zhang, Z.; Chen, H.; Zhang, H.; Zhang, H.; Zhao, Y., Bio-inspired shape-memory structural color hydrogel film. Science Bulletin 2022, 67, 512-519.

Figure 9a. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of surface wrinkles structure[58], Li, D.; Zhou, C.; Meng, Y.; Chen, C.; Yu, C.; Long, Y.; Li, S., Deformable Thermo-Responsive Smart Windows Based on a Shape Memory Polymer for Adaptive Solar Modulations. ACS Appl Mater Interfaces 2021, 13, 61196-61204.

Figure 9b. The strategy of thermal driving mode of mechanoresponsive smart windows: (a) formation of dynamic network structure[59], Zhao, J.; Zhang, L.; Du, X.; Xu, J.; Lin, T.; Li, Y.; Yang, X.; You, J., Panther chameleon-inspired, continuously-regulated, high-saturation structural color of a reflective grating on the nano-patterned surface of a shape memory polymer. Nanoscale Adv 2022, 4, 2942-2949.

Figure 9c. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of nanostripes structure[60], Xu, Z.-Y.; Li, L.; Du, L.; Wang, L.; Shi, L.-Y.; Yang, K.-K.; Wang, Y.-Z., Multiscale shape-memory effects in a dynamic polymer network for synchronous changes in color and shape. Applied Materials Today 2022, 26, 101276.

Figure 9d. The strategy of thermal driving mode of mechanoresponsive smart windows: formation of dynamic network structure[61], Zhang, W.; Wang, H.; Wang, H.; Chan, J. Y. E.; Liu, H.; Zhang, B.; Zhang, Y. F.; Agarwal, K.; Yang, X.; Ranganath, A. S.; Low, H. Y.; Ge, Q.; Yang, J. K. W., Structural multi-colour invisible inks with submicron 4D printing of shape memory polymers. Nat Commun 2021, 12, (1), 112-120.

Figure 10a. The strategy of electric driving mode mechanoresponsive smart windows: controlling movement of nanoparticles via the electrophoresis to modulate transmittance and color[64], Wang, J. L.; Liu, J. W.; Sheng, S. Z.; He, Z.; Gao, J.; Yu, S. H., Manipulating Nanowire Assemblies toward Multicolor Transparent Electrochromic Device. Nano Lett 2021, 21, 9203-9209.

Figure 10b. The strategy of electric driving mode mechanoresponsive smart windows: controlling movement of nanoparticles via the electrophoresis to modulate transmittance and color[65], Liu, S.; Zhang, D.; Peng, H.; Jiang, Y.; Gao, X.; Zhou, G.; Liu, J.-M.; Kempa, K.; Gao, J., High-efficient smart windows enabled by self-forming fractal networks and electrophoresis of core-shell TiO2@SiO2 particles. Energy and Buildings 2021, 232, 110657.

Figure 10c. The strategy of electric driving mode mechanoresponsive smart windows: based on carbon nanotube materials to adjust transmittance[66], Zhang, W.; Weng, M.; Zhou, P.; Chen, L.; Huang, Z.; Zhang, L.; Liu, C.; Fan, S., Transparency-switchable actuator based on aligned carbon nanotube and paraffin-polydimethylsiloxane composite. Carbon 2017, 116, 625-632.

Figure 10d. The strategy of electric driving mode mechanoresponsive smart windows: based on surface wrinkle to modulate transmittance[67], Shrestha, M.; Asundi, A.; Lau, G.-K., Smart Window Based on Electric Unfolding of Microwrinkled TiO2 Nanometric Films. ACS Photonics 2018, 5, 3255-3262.

Figure 11a. The strategy of magnetic driving mode mechanoresponsive smart windows: adjusting the ratio of magnetic nanoparticles to change transmittance[70], Yang, J.; Lee, H.; Heo, S. G.; Kang, S.; Lee, H.; Lee, C. H.; Yoon, H., Squid‐Inspired Smart Window by Movement of Magnetic Nanoparticles in Asymmetric Confinement. Advanced Materials Technologies 2019, 4, 1900140.

Figure 11b. The strategy of magnetic driving mode mechanoresponsive smart windows: forming the magnetic nanopillars array to adjust transmittance[71], Luo, Z.; Evans, B. A.; Chang, C. H., Magnetically Actuated Dynamic Iridescence Inspired by the Neon Tetra. ACS Nano 2019, 13, 4657-4666.

Figure 11c. The strategy of magnetic driving mode mechanoresponsive smart windows: forming magnetothermal hydrogel to modulate transmittance[72], Wang, W.; Fan, X.; Li, F.; Qiu, J.; Umair, M. M.; Ren, W.; Ju, B.; Zhang, S.; Tang, B., Magnetochromic Photonic Hydrogel for an Alternating Magnetic Field-Responsive Color Display. Advanced Optical Materials 2018, 6, 1701093.

Figure 12a. The strategy of humidity driving mode mechanoresponsive smart windows: based on thermosensitive hydrogels[73], Wang, M.; Gao, Y.; Cao, C.; Chen, K.; Wen, Y.; Fang, D.; Li, L.; Guo, X., Binary Solvent Colloids of Thermosensitive Poly(N-isopropylacrylamide) Microgel for Smart Windows. Industrial & Engineering Chemistry Research 2014, 53, , 18462-18472.

Figure 12b. The strategy of humidity driving mode mechanoresponsive smart windows: based on the humidity driving mode wrinkles[74] Zeng, S.; Li, R.; Freire, S. G.; Garbellotto, V. M. M.; Huang, E. Y.; Smith, A. T.; Hu, C.; Tait, W. R. T.; Bian, Z.; Zheng, G.; Zhang, D.; Sun, L., Moisture-Responsive Wrinkling Surfaces with Tunable Dynamics. Adv Mater 2017, 29, 1700828.

Figure 12c. The strategy of humidity driving mode mechanoresponsive smart windows: base on humidity sensitive porous structure[75],Castellón, E.; Zayat, M.; Levy, D., Novel Reversible Humidity-Responsive Light Transmission Hybrid Thin-Film Material Based on a Dispersive Porous Structure with Embedded Hygroscopic and Deliquescent Substances. Advanced Functional Materials 2018, 28, 1704717.

References

- Searchinger, T.D.; Beringer, T.; Holtsmark, B.; Kammen, D.M.; Lambin, E.F.; Lucht, W.; Raven, P.; van Ypersele, J.-P. Europe’s renewable energy directive poised to harm global forests. Nat. Commun. 2018, 9, 3741.

- Pérez-Lombard, L.; Ortiz, J.; Pout, C. A review on buildings energy consumption information. Energy Build. 2008, 40, 394–398.

- Shin, M.; Baltazar, J.-C.; Haberl, J.S.; Frazier, E.; Lynn, B. Evaluation of the energy performance of a net zero energy building in a hot and humid climate. Energy Build. 2019, 204, 109531.

- Ma, Z.Y.; Guan, B.W.; Liu, X.H.; Zhang, T. Performance analysis and improvement of air filtration and ventilation process in semiconductor clean air-conditioning system. Energy Build. 2020, 228, 110489.

- Dussault, J.-M.; Gosselin, L.; Galstian, T. Integration of smart windows into building design for reduction of yearly overall energy consumption and peak loads. Sol. Energy 2012, 86, 3405–3416.

- Wang, M.; Xing, X.; Perepichka, I.F.; Shi, Y.H.; Zhou, D.Y.; Wu, P.H.; Meng, H. Electrochromic Smart Windows Can Achieve an Absolute Private State through Thermochromically Engineered Electrolyte. Adv. Energy Mater. 2019, 9, 1900433.

- Ke, Y.J.; Chen, J.W.; Lin, C.J.; Wang, S.C.; Zhou, Y.; Yin, J.; Lee, P.S.; Long, Y. Smart Windows: Electro-, Thermo-, Mechano-, Photochromics, and Beyond. Adv. Energy Mater. 2019, 9, 1902066.

- Zhou, Y.; Fan, F.; Liu, Y.P.; Zhao, S.S.; Xu, Q.; Wang, S.C.; Luo, D.; Long, Y. Unconventional smart windows: Materials, structures and designs. Nano Energy 2021, 90, 106613.

- Svensson, J.S.E.M.; Granqvist, C.G. Electrochromic Coatings for Smart Windows. Sol. Energy Mater. 1985, 12, 391–402.

- Tällberg, R.; Jelle, B.P.; Loonen, R.; Gao, T.; Hamdy, M. Comparison of the energy saving potential of adaptive and controllable smart windows: A state-of-the-art review and simulation studies of thermochromic, photochromic and electrochromic technologies. Sol. Energy Mater. Sol. Cells 2019, 200, 109828.

- Wang, X.J.; Narayan, S. Thermochromic Materials for Smart Windows: A State-of-Art Review. Front. Energy Res. 2021, 9, 837–841.

- Chun, S.Y.; Park, S.; Lee, S.I.; Nguyen, H.D.; Lee, K.-K.; Hong, S.; Han, C.-H.; Cho, M.; Choi, H.-K.; Kwak, K. Operando Raman and UV-Vis spectroscopic investigation of the coloring and bleaching mechanism of self-powered photochromic devices for smart windows. Nano Energy 2021, 82, 105721.

- Liu, S.; Tso, C.Y.; Lee, H.H.; Zhang, Y.; Yu, K.M.; Chao, C.Y.H. Bio-inspired TiO2 nano-cone antireflection layer for the optical performance improvement of VO2 thermochromic smart windows. Sci. Rep. 2020, 10, 11376.

- Quan, Y.-J.; Kim, Y.-G.; Kim, M.-S.; Min, S.-H.; Ahn, S.-H. Stretchable Biaxial and Shear Strain Sensors Using Diffractive Structural Colors. ACS Nano 2020, 14, 5392–5399.

- Lee, E.; Zhang, M.; Cho, Y.; Cui, Y.; Van der Spiegel, J.; Engheta, N.; Yang, S. Tilted Pillars on Wrinkled Elastomers as a Reversibly Tunable Optical Window. Adv. Mater. 2014, 26, 4127–4133.

- Fan, Z.; Razavi, H.; Do, J.W.; Moriwaki, A.; Ergen, O.; Chueh, Y.L.; Leu, P.W.; Ho, J.C.; Takahashi, T.; Reichertz, L.A. Three-dimensional nanopillar-array photovltaics on low-cost and flexible substrates. Nat. Mater. 2009, 8, 648–653.

- Zhao, P.; Li, B.; Tang, Z.; Gao, Y.; Tian, H.; Chen, H. Stretchable photonic crystals with periodic cylinder shaped air holes for improving mechanochromic performance. Smart Mater. Struct. 2019, 28, 075037.

- Li, J.; Shim, J.; Deng, J.; Overvelde, J.T.B.; Zhu, X.; Bertoldi, K.; Yang, S. Switching periodic membranes via pattern transformation and shape memory effect. Soft Matter. 2012, 8, 10322–10328.

- Wang, K.; Li, C.; Li, Z.; Li, H.; Li, A.; Li, K.; Lai, X.; Liao, Q.; Xie, F.; Li, M.; et al. A facile fabrication strategy for anisotropic photonic crystals using deformable spherical nanoparticles. Nanoscale 2019, 11, 14147–14154.

- Li, P.; Han, Y.; Wang, W.; Chen, X.; Jin, P.; Liu, S. Self-Erasable Nanocone Antireflection Films Based on the Shape Memory Effect of Polyvinyl Alcohol (PVA) Polymers. Polymers 2018, 10, 756.

- Lee, S.G.; Lee, D.Y.; Lim, H.S.; Lee, D.H.; Lee, S.; Cho, K. Switchable transparency and wetting of elastomeric smart windows. Adv. Mater. 2010, 22, 5013–5017.

- Zhao, P.; Chen, H.; Li, B.; Tian, H.; Lai, D.; Gao, Y. Stretchable electrochromic devices enabled via shape memory alloy composites (SMAC) for dynamic camouflage. Opt. Mater. 2019, 94, 378–386.

- Ji, C.; Chen, M.; Wu, L. Patternable and Rewritable Retroreflective Structural Color Shape Memory Polymers. Adv. Opt. Mater. 2021, 9, 2100739.

- Thomas, A.V.; Andow, B.C.; Suresh, S.; Eksik, O.; Yin, J.; Dyson, A.H.; Koratkar, N. Controlled Crumpling of Graphene Oxide Films for Tunable Optical Transmittance. Adv. Mater. 2015, 27, 3256–3265.

- Zang, J.; Ryu, S.; Pugno, N.; Wang, Q.; Tu, Q.; Buehler, M.J.; Zhao, X. Multifunctionality and control of the crumpling and unfolding of large-area graphene. Nat. Mater. 2013, 12, 321–325.

- Ke, Y.; Zhang, Q.; Wang, T.; Wang, S.; Li, N.; Lin, G.; Liu, X.; Dai, Z.; Yan, J.; Yin, J.; et al. Cephalopod-inspired versatile design based on plasmonic VO2 nanoparticle for energy-efficient mechano-thermochromic windows. Nano Energy 2020, 73, 104785.

- Lin, G.; Chandrasekaran, P.; Lv, C.; Zhang, Q.; Tang, Y.; Han, L.; Yin, J. Self-similar Hierarchical Wrinkles as a Potential Multifunctional Smart Window with Simultaneously Tunable Transparency, Structural Color, and Droplet Transport. ACS Appl. Mater. Interfaces 2017, 9, 26510–26517.

- Cao, C.; Chan, H.F.; Zang, J.; Leong, K.W.; Zhao, X. Harnessing localized ridges for high-aspect-ratio hierarchical patterns with dynamic tunability and multifunctionality. Adv. Mater. 2014, 26, 1763–1770.

- Li, Z.W.; Liu, Y.; Marin, M.; Yin, Y.D. Thickness-dependent wrinkling of PDMS films for programmable mechanochromic responses. Nano Res. 2020, 13, 1882–1888.

- Lin, R.; Qi, Y.; Kou, D.; Ma, W.; Zhang, S. Bio-Inspired Wrinkled Photonic Elastomer with Superior Controllable and Mechanically Stable Structure for Multi-Mode Color Display. Adv. Funct. Mater. 2022, 32, 2207691.

- Jiang, B.; Liu, L.; Gao, Z.; Feng, Z.; Zheng, Y.; Wang, W. Fast Dual-Stimuli-Responsive Dynamic Surface Wrinkles with High Bistability for Smart Windows and Rewritable Optical Displays. ACS Appl. Mater. Interfaces 2019, 11, 40406–40415.

- Shrestha, M.; Lau, G.-K. Tunable window device based on micro-wrinkling of nanometric zinc-oxide thin film on elastomer. Opt. Lett. 2016, 41, 4433–4436.

- Zeng, S.; Zhang, D.; Huang, W.; Wang, Z.; Freire, S.G.; Yu, X.; Smith, A.T.; Huang, E.Y.; Nguon, H.; Sun, L. Bio-inspired sensitive and reversible mechanochromisms via strain-dependent cracks and folds. Nat. Commun. 2016, 7, 11802.

- Mao, Z.; Zeng, S.; Shen, K.; Chooi, A.P.; Smith, A.T.; Jones, M.D.; Zhou, Y.; Liu, X.; Sun, L. Dynamic Mechanochromic Optics with Tunable Strain Sensitivity for Strain-Responsive Digit Display. Adv. Opt. Mater. 2020, 8, 2001472.

- Li, Z.; Zhai, Y.; Wang, Y.; Wendland, G.M.; Yin, X.; Xiao, J. Harnessing Surface Wrinkling–Cracking Patterns for Tunable Optical Transmittance. Adv. Opt. Mater. 2017, 5, 1700425.

- Jiang, Y.; Zeng, S.; Yao, Y.; Xu, S.; Dong, Q.; Chen, P.; Wang, Z.; Zhang, M.; Zhu, M.; Xu, G.; et al. Dynamic Optics with Transparency and Color Changes under Ambient Conditions. Polymers 2019, 11, 103.

- Zhao, H.; Sun, Q.; Zhou, J.; Deng, X.; Cui, J. Switchable Cavitation in Silicone Coatings for Energy-Saving Cooling and Heating. Adv. Mater. 2020, 32, e2000870.

- Ge, D.; Lee, E.; Yang, L.; Cho, Y.; Li, M.; Gianola, D.S.; Yang, S. A Robust Smart Window: Reversibly Switching from High Transparency to Angle-Independent Structural Color Display. Adv. Mater. 2015, 27, 2489–2495.

- Liu, Y.; Song, S.; Liu, M.; Hu, Y.; Zhang, L.-W.; Yoon, H.; Yang, L.; Ge, D. Gecko-inspired ultrasensitive multifunctional mechano-optical smart membranes. Chem. Eng. J. 2021, 429, 132159.

- Cho, D.; Shim, Y.S.; Jung, J.W.; Nam, S.H.; Min, S.; Lee, S.E.; Ham, Y.; Lee, K.; Park, J.; Shin, J.; et al. High-Contrast Optical Modulation from Strain-Induced Nanogaps at 3D Heterogeneous Interfaces. Adv. Sci. 2020, 7, 1903708.

- Han, J.; Freyman, M.C.; Feigenbaum, E.; Han, T.Y.-J. Electro-Optical Device with Tunable Transparency Using Colloidal Core/Shell Nanoparticles. ACS Photonics 2018, 5, 1343–1350.

- Li, J.; Lu, X.; Zhang, Y.; Ke, X.; Wen, X.; Cheng, F.; Wei, C.; Li, Y.; Yao, K.; Yang, S. Highly Sensitive Mechanoresponsive Smart Windows Driven by Shear Strain. Adv. Funct. Mater. 2021, 31, 2102350.

- Qi, Y.; Zhou, C.; Zhang, S.; Zhang, Z.; Niu, W.; Wu, S.; Ma, W.; Tang, B. Bar-coating programmable mechanochromic bilayer PDMS film with angle-dependent and angle-independent structural colors. Dyes Pigments 2021, 189, 109264.

- Kim, H.N.; Ge, D.; Lee, E.; Yang, S. Multistate and On-Demand Smart Windows. Adv. Mater. 2018, 30, e1803847.