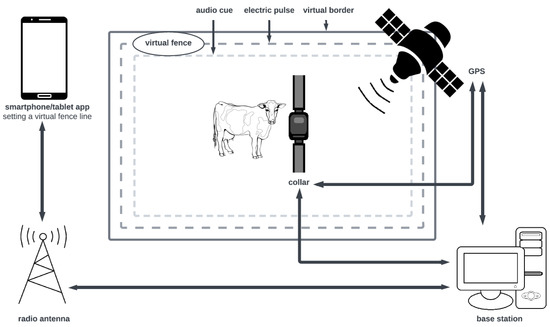

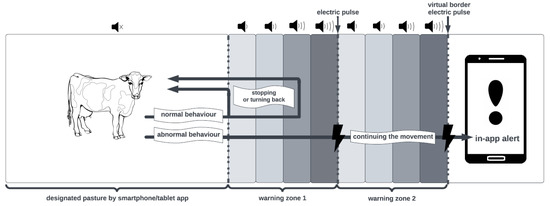

, developed and commercialized by the Australian company Agersens (Melbourne, VIC, Australia) (acquired by the New Zealand company Gallagher). This system utilizes intellectual property that has been licensed and developed by the Commonwealth Scientific and Industrial Research Organization [44,50,79,80] and is commercialized for cattle. The cost of eShepherd technology is estimated as €60–90 for one collar and €5000 for infrastructure [81]. Virtual fencing uses the global positioning system (GPS) to assign location, movement, position, heading, and speed to cattle, and it communicates this information using neckband-mounted devices. Moreover, the GPS is used to specify the virtual fence boundary (separating inclusion vs. exclusion zones), which is transmitted to the unit using a radio frequency link. The cattle neckband consisted of a strap and hanging counterweight (total weight ~1.40 kg), and the unit (~725 g and 170 mm length × 120 mm width × 130 mm height) on the top of the animal neck and the solar-powered base station. The system controls animal behavior through a radio-controlled device. A transmitter on the neckband generates two types of stimuli—audio and electric [53,82]. An animal approaching the boundary of the virtual fence (determined by the mobile app) receives a signal to stop or change direction in the form of a sound of about 785 Hz. In addition, in the absence of the desired response to the auditory stimulus, an electric pulse with a relatively low voltage of 800 V is sent [24,54,83,84,85]. An audio cue followed by an electric pulse sequence was repeated if the animal continued through the fence line and into the exclusion zone. At this point, it should be added that in the case of conventional electric fences, the electric pulse voltage generated by the electrizer (so-called electric shepherd), among other things, is 2000 and 4000 V in summer and winter, respectively. When the animal reacts positively to the first signal (i.e., stops or turns back), the device does not generate another stimulus, i.e., an electric pulse.

2.2. Nofence

In Europe, Brunberg et al.

[36][94] conducted a study to determine the ability of ewes with lambs to learn a prototype virtual fencing technology produced by the Norwegian company Nofence (Nofence

®, AS, Batnfjordsøra, Norway), which operates in a similar manner to eShepherd

®. The differences are due to the design elements of the technology (solar panels for easy battery recharging, motion sensors, Bluetooth, and a GNSS receiver based on GPS and GLONASS and applications for diverse clients, and their PCs, smartphones, or tablets). The Nofence technology consists of a neck strap and collar with a battery with a total weight of ~1.45 kg positioned on the neck (153.5 mm length × 145.4 mm width × 54.2 mm height)

[37][38][39][55,95,96]. The collar has an integrated GPS and sound and electric pulse generators which are connected to the neck chain using two electrodes. The estimated cost of one collar for virtual fencing in the Nofernce technology is €195

[28][81]. Nofence app can be used to establish virtual boundaries. When an animal approaches the virtual boundary, an audio warning with a rising pitch tone is emitted. If an animal approaches a virtual fence and does not respond to the audio warning (82 dB at 1 m), it will receive a short electric pulse (0.2 J at 3 kV duration = 1.0 s). If the animal responds appropriately by turning away from the virtual boundary, it will not receive any further stimuli (audio warnings or electric pulses). This system relies on the principles of associative learning and operant conditioning, which means that the animal should be able to control and predict it. The collar produces an electric pulse after all warning tones have been played. The warning tones increase in pitch and duration (from 5 to 20 s) depending on whether the animal keeps ignoring the warning or responds appropriately. The desired response depends on which collar mode is activated. In the teaching mode, the animal can stop the audio warning by simply turning its head. The collar-mounted accelerometer detects the movement and allows a prompt response to the animal’s behavior in order to help it effectively learn the virtual fencing system. When the animal has correctly responded to 20 consecutive audio warnings without receiving an electric pulse, the collar will switch to operating mode. Following activation of the operating mode, the animal must move at least 2 m away from the virtual boundary towards the virtual pasture to stop the acoustic signal. In either mode, when the animal ignores the audio warning and continues walking towards the virtual boundary, it may receive up to three electric pulses if it does not respond appropriately to the warnings before each pulse. After that, the collar notifies the owner that “the animal has escaped” and continues to monitor its location. However, the animal will not receive any more audio warnings or electric pulses. When the animal that has crossed the virtual boundary returns to the virtual pasture, the collar will resume normal function without requiring any manual intervention

[37][38][39][40][55,95,96,97].

2.3. Vence

Vence

® is another virtual fencing technology dedicated to cattle herd management, marketed by the US company Vence (Vence Corporation, San Francisco, CA, USA). This technology controls animal movement, designates virtual paddocks, and monitors cow welfare. The solution uses advanced GPS tracking to monitor the location of animals in the pasture using mobile devices with Android or iOS

[41][42][43][98,99,100]. Moreover, Vence

® is deployed in large-scale operations with over 500 animals and has been proven effective on small ranches of a few hundred hectares and large ones with hundreds of thousands of hectares. The virtual fencing is created by Herd Manager based on GPS coordinates. In this system, the end user communicates with a solar-powered base station through a cellular link using the Herd Manager software platform. The base station sends radio signals to the GPS collar worn by the animal, communicating user-defined coordinates of virtual boundaries and other information. The estimated cost of one collar for virtual fencing in the Vence technology is $35

[44][76]. The collar is powered by a lithium battery and tracks the animal’s location at intervals specified by the user. It also has a speaker for auditory cues and two metal electrical contacts that are spaced 5 cm apart. The collar is equipped with a weight ballast that ensures that the electrical contacts only touch one side of the animal’s neck. This means that when the animal receives an electric stimulus, it should turn away from the stimulus, changing its direction away from the virtual boundary. When an animal approaches a virtual boundary, it will first receive an auditory cue (“auditory zone”), and if it continues in the undesirable direction (entering the “electric stimulus zone”), it will receive a mild electric stimulus. The user can define the spatial locations of the auditory and electric stimulus zones. When an animal moves into the audio zone, it hears an electronic tone that lasts for 0.5 s, followed by a 1.5-s pause. This pattern is repeated until the animal leaves the auditory zone. When the animal enters the electric stimulus zone, it receives a 0.5-s shock (at a voltage of 800 V), followed by a 1-s sound stimulus and then a 3.5-s pause. If the animal remains in the electric stimulus zone, the pattern will repeat up to 20 times, after which the animal will not receive any auditory or electric stimuli for 3 min. If the animal stays in the electric stimulus zone for more than four cycles, the collar will be disabled, and all cues will stop unless it is remotely reactivated by the end user. The collar transmits animal location data to the base station, which then sends it to cloud-based storage within the Herd Manager platform.

2.4. Halter

New Zealand-based Halter has developed Halter

® based on patented Cowgorithm

®, which controls animal behavior based on audible, electric, and vibration signals and enables health monitoring based on body temperature measurements

[45][46][65,101]. A neck-collar and combined head-halter (collar-halter) device was designed to carry the electronics, batteries (6 V, 4.2 Ah Panasonic lithium batteries), and stimuli-providing equipment, including audio, vibration, light, and electrical stimulation (of a linear range of 1–10 s duration and 600–4000 V). The neck collar was made from 100-mm-wide nylon webbing and contained compartments for the electronics box, GPS, radio antenna, and two batteries. The wiring for the radio and GPS antenna was routed through pockets in the collar to the top of the animal’s neck to ensure optimal reception. The batteries and electronics were located at the bottom of the animal’s neck. The weight of the batteries, which were on the heavier side of the electronics box, helped to balance the collar and prevent it from rotating around the animal’s neck. External wires were connected from the electronics box to the head halter once the collar and head halter had been fitted to the animal.

3. Conclusions

Precision livestock farming is increasingly being used in pasture feeding systems. Especially the evolving virtual fencing designed for grazing dairy and beef cattle opens up new opportunities for using available pasture land. Virtual fencing has the potential to reduce the amount of labor required for fencing, increase the flexibility of fencing to adapt to changing pasture conditions, improve precision and efficiency, and provide more options for grazing management. However, this innovative technology should be further developed, and improvements should include decreasing the total costs of the system and increasing its application to other technological groups of ruminants, e.g., suckler cows with calves, increasing the efficiency of the system operation in large areas and a larger number of animals.