Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Charles H. Culp.

Energy consumption in buildings is a significant cost to the building’s operation. As faults are introduced to the system, building energy consumption may increase and may cause a loss in occupant productivity due to poor thermal comfort. Research towards automated fault detection and diagnostics has accelerated in recent history. Rule-based methods have been developed for decades to great success, but recent advances in computing power have opened new doors for more complex processing techniques which could be used for more accurate results.

- fault detection

- fault diagnosis

- principal component analysis

- machine learning

- automated fault detection and diagnosis

- rule-based

- knowledge-driven

- data-driven

- feature selection

1. Background

1.1. Building Energy Consumption

The 2018 Global Status Report from the International Energy Agency (IEA) found that building operation accounts for 36% of global energy use [1]. Furthermore, Yang et al. found that heating, ventilation, and air conditioning (HVAC) systems account for 40% of all building energy consumption [2]. This leads to the knowledge that HVAC system consumption accounts for 14% of energy use across the world. Qin et al. found that in Hong Kong, 20.9% of commercial buildings operate continuously with faults, including sensor errors and actuator failures, which degrade their performance [3]. There are many failure points in a building system due to the thousands of sensors, dampers, or other controllable devices in a building. Katipamula et al. found that operational faults in buildings are the cause for 15–30% lost energy in commercial buildings [4].

In modern times, building management systems have been installed in many buildings. These systems provide an interface for continuous measurement and monitoring of the HVAC system components, which creates new possibilities for advanced fault detection and diagnostics.

Building management systems provide information about system components which can be analyzed using software tools. This information includes all sensor measurements in the building, such as actuator positioning or motor control. These measurements can be monitored for stability or anomalies, though interdependencies between components and self-correcting building programming can obscure the fault from detection.

Fault detection in building systems is an important energy conservation measure. HVAC system and lighting faults can increase energy consumption by up to 18% [5] and degrade occupant comfort and productivity when thermal setpoints are not met [6]. A sensor failure can increase energy consumption by misrepresenting the temperature of air through the system, which must be corrected by subsequent components. Failures such as these are represented in the data collected by building systems and may be detected using advanced analytics. Failures may be detected quickly and with limited additional manual analysis by using machine learning algorithms for fault detection and diagnostics in building systems, which reduces the building’s time spent in faulty operation and minimizes wasted energy and occupant productivity.

1.2. History of FDD in Building Systems

Katipamula et al. [4] conducted a review of established methods for fault detection and diagnostics (FDD) in building systems. The authors divide diagnostic methods into three groups: quantitative model based, qualitative model based, and process history based.

As of the time of Katipamula’s publication (2005), the majority of completed research belonged to the qualitative model-based methods, which include the most popular current form of fault detection in industry: the rule-based method. The strengths of these models lie in their simplicity and interpretability. It is easy to explain these rules to engineers of all knowledge levels. Rule-based models also perform strongly in projects with large amounts of data compared to those with less data. Breuker and Braun conducted an experiment on a building with two sets of data: one with six measurements and another with ten measurements. They were able to conclude that performance of a rule-based FDD algorithm increased by a factor of two when doubling the measurements by system sensors and using higher-order models [5].

The first iteration on advanced building analytics came in the form of model-based methods. Gertler et al. define model-based methods as relying on analytical redundancy rather than physical redundancy; the former involves the comparison between sensor values to calculated values from first-principles equations whereas the latter involves sensor values being compared to other sensor values [6]. Bendapudi and Braun developed a chiller model from first-principles equations to be used in FDD calculations [7]. However, these first-principles models are seldom used for FDD because of their required input parameters, which are extensive and may be missing from the building’s measurements. Lebrun and Bourdouxhe conducted a review of dynamic HVAC models, which covered over 500 references for all areas of the building system [8]. Though these models have become more commonplace as computation speeds have improved, there have been comparatively fewer than 25% applied to FDD in commercial buildings [9,10,11,12,13,14,15][9][10][11][12][13][14][15].

Rule-based systems are based on a series of if-then statements to produce rules that govern fault detection. These rules can be as simple as a single threshold limit or more complicated to include several statements chained together using and/or operators. PECI and Battelle conducted a review of commonly applied rules to validate their usefulness in real scenarios [16]. Engineers have also applied rules derived from first-principles equations [17,18][17][18]. House et al. developed a ruleset named “Air-Handling Unit Performance Assessment Rules” (APAR) aimed to detect faults in air handling units. The ruleset includes 28 rules to represent faults in common operation states in the air handling unit and possible causes for violations of these rules. The rules cover faults impacting occupant comfort, indoor air quality, energy, and equipment life. The authors note some drawbacks when using rule-based systems, namely that the concept of fault severity is missing when using singular rules; the output of a rule evaluation is binary and offers limited measures of how far the rule was violated. Fault severity metrics may be introduced by defining multiple rules, with a cost of added complexity to the model.

Zhao et al. also conducted a review of recent innovations in the use of artificial intelligence and machine learning methods for Automated Fault Detection and Diagnostics (AFDD) tasks [19]. Their research divides artificial intelligence (AI) methods into two broad categories: knowledge-driven and data-driven methods. They determined that while there has been increased interest in all artificial intelligence algorithms over the past two decades, a large percentage of these projects have focused on data-driven methods. The authors found that of the articles reviewed, 79% were based on data-driven methods and 21% were based on knowledge-driven methods.

Chen et al. conducted a review of AFDD methods and found that of the major HVAC system categories (building, variable refrigerant flow, heat pump, air handling unit (AHU), variable air volume (VAV) terminal, chiller, and sensor), 33% of reviewed research covered AHUs and 25% covered chillers [20]. Their references include knowledge and data-driven methods and provide a comprehensive picture of research in the field. Their survey is divided into three major sections: knowledge-driven, data-driven, and hybrid approaches. Similar to Katipamula and Zhao, the authors found that knowledge-driven AI approaches, still represent less than 25% of published research. Over 75% of AFDD research completed is in data-driven approaches.

The historical references above provide a summary of how FDD in building systems has evolved. This revisew paperarch discusses key historical developments and expands into Machine Learning (ML) technology research-related developments in the AFDD. It also includes current published applications of ML.

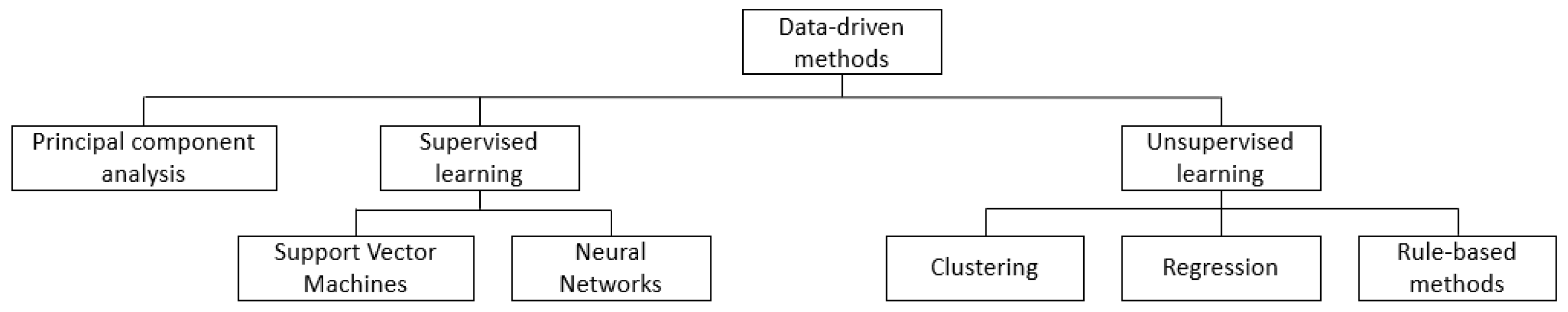

This revisewarch has been divided into the major parts shown in Figure 1, all of which are classified as data-driven methods by Katipamula and other reviews mentioned previously [4]. Within the focus of data-driven methods, there has been significant focus on supervised and unsupervised learning methods as well as accompanying methods such as Principal Components Analysis (PCA), which is often used as a preprocessing step before the former two methods [20]. Historically, less complex methods such as clustering, rule-based methods have been used [4]. Neural networks and Support Vector Machines (SVMs) have seen an exponential increase in attention in recent years as computer processing power has grown. With higher power, computers are able to optimize complicated networks in a fraction of the time and produce more accurate results.

Figure 1. Tree of research.

2. Modern Machine Learning for Fault Detection in Building Systems

Computation power has increased dramatically in recent years along with substantial increases in data collection, creating new possibilities for fault detection methods using machine learning. Zhao et al. conducted a review in 2019 of the trends in industry using artificial intelligence methods for FDD [19]. The preseaperrch divided the methods into two broad categories: data-driven methods and knowledge-driven methods. Subcategories of machine learning algorithms which further divide these broad categories include supervised learning and unsupervised learning.

-

Actuator malfunction

-

Sensor faults

-

Blocked ducts

-

Filtration issues

-

Fluctuation of pressure setpoints

-

Motor failure

-

Fan malfunction

-

Coil fouling

Supervised learning methods utilize the input features of a dataset and the known output classes to train a model. These methods require more processed data than other types of algorithms, since the input datasets require additional information to represent their output classes. These output classes may be provided from the sensors in the building, or they may be assigned manually.

Unsupervised learning problems differ from supervised learning in that the training datasets contain only input values and lack output values. The unsupervised algorithm determines a probable output based on a set of inputs measured from the system. An unsupervised learning problem is often solved using clustering, where a dataset becomes grouped into several clusters forming density clouds. The supervised learning counterpart to this problem is classification, where a dataset is classified based on the known characteristics of the classified input data. Each of these are basic examples of algorithms used for supervised and unsupervised learning; many other algorithms exist to solve each problem.

Tidriri et al. considered a hybrid approach that combines data-driven and model-driven methods [22]. The authors found that performance of data-driven methods is highly dependent on the training data, while performance of model-driven methods is highly dependent on the mathematical model used in the analysis. The authors propose that a hybrid approach using data-driven methods for fault detection and model-driven methods for fault diagnostics could prove more successful than using data- or model-driven methods would individually. The authors also found that many researchers face problems bridging the two methods without an established framework, which makes the combination difficult to implement. While these are several examples of hybrid model applications [23[23][24][25][26],24,25,26], research in this area is just beginning to increase in the number publications.

2.1. Feature Selection

Feature selection is applicable to both supervised and unsupervised learning algorithms and is used to trim the input dataset of redundant or unnecessary data, which improves its training speed and accuracy, depending on the approach. Researchers have investigated to find optimal approaches to feature selection.

Changrashekar et al. conducted a review of the impact of feature selection in an analysis [27]. Changrashekar found that for one of their datasets, reducing from 34 features to just 9 features improved its modeled performance from 90% to 95%. Models containing excessive features may overfit the dataset and perform worse in testing. Though this suggests that pruning some features from the data is beneficial, another dataset including all features produced an accuracy of almost 80%, while reducing that dataset by 1 feature, to a total of 7, reduced its accuracy to just 71%. These examples show that pruning features from a dataset may degrade performance. The authors’ conclusions are that feature selection should be cross validated for each application.

Yan et al. evaluated the benefits of a feature selection algorithm for data preprocessing [26]. Yan found that feature selection can help define the information which improves model performance most significantly. This may be used when deciding which sensors to purchase because each sensor has been ranked according to its importance to the model. Cost-limited analysis, which simulates projects with a limited financial budget, evaluated this tradeoff and found that using just 16 sensors in their chiller system can provide enough information for machine learning analysis with greater than 95% accuracy.

Yan et al. used the ReliefF algorithm, which calculates a feature score for each feature to determine their importance, alongside SVM analysis for feature selection with success [28]. The authors used just 6 variables in the final model instead of the original 65 variables and produced models with greater than 90% accuracy.

2.2. Data-Driven Methods

Principal Component Analysis

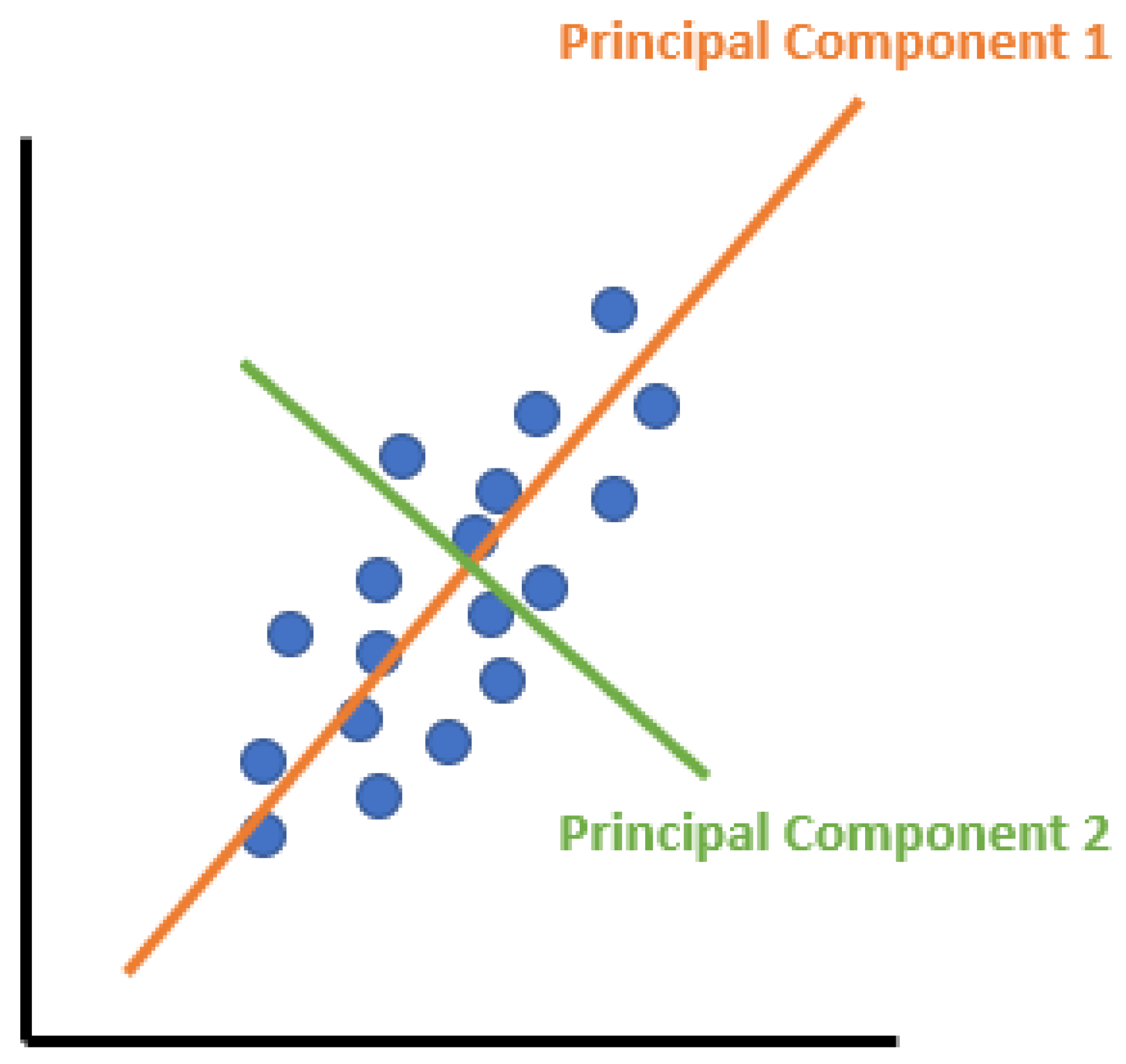

Principal Component Analysis methods have been used extensively in sensor fault detection. PCA maps high-dimensional data into a lower dimension representing the dataset’s variance; the first Principal Component of the dataset is the dimension capturing the most of its variance. This process is illustrated in Figure 2. Wang and Xiao applied PCA to AHU sensors in their studies [29]. Li and Wen combined PCA methods and wavelet transforms to detect faults in AHUs [30]. Du et al. combined PCA and Fisher’s Discriminant Analysis for FDD in sensors in VAV systems [31].

Figure 2. Visual Representation of principal component analysis.

Hu et al. studied the sensitivity of fault detection in different fault severity levels in chiller sensors [32]. However, there are limitations in using PCA methods for FDD. Zhao et al. found that principal components analysis uses linear assumptions, which are detrimental to performance because the chiller data are often nonlinear [33].

Beghi et al. used PCA to distinguish anomalies from normal operation and reconstructed the contributions of each variable to order variables according to their improvement to the model’s accuracy [34]. Mahadevan et al. used PCA and dynamic PCA to detect faults using established procedures and combined those results with a one-class support vector machine to perform fault diagnostics [35]. Zhang et al. combined PCA and clustering to detect and diagnose faults in building sensors [36].

Xiao et al. developed PCA models which monitor heat- and pressure-flow-balance in an AHU [37]. Wang and Xiao expanded on this research by employing expert rules to assist in diagnosing faults and developing separate models for heat and pressure-flow balance [38]. The authors research concludes with a third iteration that evaluates these models on simulated results [39]. Many researchers have studied the abilities of PCA to detect and diagnose sensor faults throughout an HVAC system [40,41,42][40][41][42].

References

- Global Status Report towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. Available online: https://www.iea.org/reports/2018-global-status-report (accessed on 19 April 2022).

- Yang, H.; Zhang, T.; Li, H.; Woradechjumroen, D.; Liu, X. HVAC Equipment, Unitary: Fault Detection and Diagnosis; CRC Press: Boca Raton, FL, USA, 2014; pp. 854–864.

- Qin, J.; Wang, S. A fault detection and diagnosis strategy of VAV air-conditioning systems for improved energy and control performances. Energy Build. 2005, 37, 1035–1048.

- Katipamula, S.; Brambley, M.R. Review Article: Methods for Fault Detection, Diagnostics, and Prognostics for Building Systems—A Review, Part I. HVACR Res. 2005, 11, 3–25.

- Roth, K.W.; Detlef, W.; Patricia, L.; Michael, Y.; Feng, N.D. The Energy Impact of Faults in U.S. Commercial Buildings. In Proceedings of the 2004 International Refrigeration and Air Conditioning Conference, West Lafayette, Indiana, 12–15 July 2004.

- Seppänen, O.; Fisk, W.J.; Lei, Q.H. Effect of Temperature on Task Performance in Office Environment. 2006. Available online: https://indoor.lbl.gov/publications/effect-temperature-task-performance (accessed on 25 July 2022).

- Bendapudi, S.; Braun, J.E.; Groll, E.A. A Dynamic Model of a Vapor Compression Liquid Chiller. International. Available online: http://docs.lib.purdue.edu/iracc/568 (accessed on 1 April 2020).

- Bourdouxh, J.P.; Grodent, M.; Lebrun, J. HVAC1kit—A toolkit for primary HVAC system energy calculation. Energy 1999, 4, 694.

- Breuker, M.S.; Braun, J.E. Evaluating the Performance of a Fault Detection and Diagnostic System for Vapor Compression Equipment. HVACR Res. 1998, 4, 401–425.

- Gertler, J.J. Fault Detection and Diagnosis in Engineering Systems; CRC Press: Boca Raton, FL, USA, 1998.

- Wagner, J.; Shoureshi, R. Failure Detection Diagnostics for Thermofluid Systems. J. Dyn. Syst. Meas. Control 1992, 114, 699–706.

- Haves, P.; Salsbury, T.I.; Wright, J.A. Condition monitoring in HVAC subsystems using first principles models. ASHRAE Trans. 1996, 102, 519–527.

- Salsbury, T.; Diamond, R. Fault detection in HVAC systems using model-based feedforward control. Energy Build. 2001, 33, 403–415.

- Norford, L.K.; Wright, J.A.; Buswell, R.A.; Luo, D.; Klaassen, C.J.; Suby, A. Demonstration of fault detection and diagnosis methods for air-handling units (ASHRAE 1020-RP). HVAC R Res. 2002, 8, 41–71.

- Castro, N. Performance Evaluation of a Reciprocating Chiller Using Experimental Data and Model Predictions for Fault Detection and Diagnosis. 2002. Available online: https://www.nist.gov/publications/performance-evaluation-reciprocating-chiller-using-experimental-data-and-model (accessed on 12 August 2019).

- PECI, B. Methods for Automated and Continuous Commissioning of Building Systems; Air-Conditioning and Refrigeration Technology Institute (US): Arlington, VA, USA, 2003; pp. 6–8.

- Katipamula, S.; Pratt, R.G.; Chassin, D.P.; Taylor, Z.T.; Gowri, K.; Brambley, M.R. Automated fault detection and diagnostics for outdoor-air ventilation systems and economizers: Methodology and results from field testing. Trans. -Am. Soc. Heat. Refrig. Air Cond. Eng. 1999, 105, 555–567.

- House, J.M.; Vaezi-Nejad, H.; Whitcomb, J.M. An Expert Rule Set for Fault Detection in Air-Handling Units. Ashrae Trans. 2001, 107, 858.

- Zhao, Y.; Li, T.; Zhang, X.; Zhang, C. Artificial intelligence-based fault detection and diagnosis methods for building energy systems: Advantages, challenges and the future. Renew. Sustain. Energy Rev. 2019, 109, 85–101.

- Chen, J.; Zhang, L.; Li, Y.; Shi, Y.; Gao, X.; Hu, Y. A review of computing-based automated fault detection and diagnosis of heating, ventilation and air conditioning systems. Renew. Sustain. Energy Rev. 2022, 161, 112395.

- Mirnaghi, M.S.; Haghighat, F. Fault detection and diagnosis of large-scale HVAC systems in buildings using data-driven methods: A comprehensive review. Energy Build. 2020, 229, 110492.

- Tidriri, K.; Chatti, N.; Verron, S.; Tiplica, T. Bridging data-driven and model-based approaches for process fault diagnosis and health monitoring: A review of researches and future challenges. Annu. Rev. Control 2016, 42, 63–81.

- Maurya, M.R.; Rengaswamy, R.; Venkatasubramanian, V. A Signed Directed Graph and Qualitative Trend Analysis-Based Framework for Incipient Fault Diagnosis. Chem. Eng. Res. Des. 2007, 85, 1407–1422.

- Siswantoro, J.; Prabuwono, A.S.; Abdullah, A.; Idrus, B. A linear model based on Kalman filter for improving neural network classification performance. Expert Syst. Appl. 2016, 49, 112–122.

- Zhao, Y.; Wang, S.; Xiao, F. Pattern recognition-based chillers fault detection method using Support Vector Data Description (SVDD). Appl. Energy 2013, 112, 1041–1048.

- Yan, K.; Zhong, C.; Ji, Z.; Huang, J. Semi-supervised learning for early detection and diagnosis of various air handling unit faults. Energy Build. 2018, 181, 75–83.

- Chandrashekar, G.; Sahin, F. A survey on feature selection methods. Comput. Electr. Eng. 2014, 40, 16–28.

- Yan, K.; Shen, W.; Mulumba, T.; Afshari, A. ARX model based fault detection and diagnosis for chillers using support vector machines. Energy Build. 2014, 81, 287–295.

- Wang, S.; Cui, J. Sensor-fault detection, diagnosis and estimation for centrifugal chiller systems using principal-component analysis method. Appl. Energy 2005, 82, 197–213.

- Li, S.; Wen, J. Application of pattern matching method for detecting faults in air handling unit system. Autom. Constr. 2014, 43, 49–58.

- Du, Z.; Jin, X. Detection and diagnosis for sensor fault in HVAC systems. Energy Convers. Manag. 2007, 48, 693–702.

- Hu, Y.; Li, G.; Chen, H.; Li, H.; Liu, J. Sensitivity analysis for PCA-based chiller sensor fault detection. Int. J. Refrig. 2016, 63, 133–143.

- Zhao, Y.; Wang, S.; Xiao, F. A statistical fault detection and diagnosis method for centrifugal chillers based on exponentially-weighted moving average control charts and support vector regression. Appl. Therm. Eng. 2013, 51, 560–572.

- Beghi, A.; Brignoli, R.; Cecchinato, L.; Menegazzo, G.; Rampazzo, M.; Simmini, F. Data-driven Fault Detection and Diagnosis for HVAC water chillers. Control Eng. Pract. 2016, 53, 79–91.

- Mahadevan, S.; Shah, S.L. Fault detection and diagnosis in process data using one-class support vector machines. J. Process Control 2009, 19, 1627–1639.

- Zhang, H.; Chen, H.; Guo, Y.; Wang, J.; Li, G.; Shen, L. Sensor fault detection and diagnosis for a water source heat pump air-conditioning system based on PCA and preprocessed by combined clustering. Appl. Therm. Eng. 2019, 160, 114098.

- Xiao, F.; Wang, S.; Zhang, J. A diagnostic tool for online sensor health monitoring in air-conditioning systems. Autom. Constr. 2005, 15, 489–503.

- Wang, S.; Xiao, F. Detection and diagnosis of AHU sensor faults using principal component analysis method. Energy Convers. Manag. 2004, 45, 2667–2686.

- Wang, S.; Xiao, F. AHU sensor fault diagnosis using principal component analysis method. Energy Build. 2004, 36, 147–160.

- Hu, Y.; Chen, H.; Xie, J.; Yang, X.; Zhou, C. Chiller sensor fault detection using a self-Adaptive Principal Component Analysis method. Energy Build. 2012, 54, 252–258.

- Xu, X.; Xiao, F.; Wang, S. Enhanced chiller sensor fault detection, diagnosis and estimation using wavelet analysis and prin-cipal component analysis methods. Appl. Therm. Eng. 2008, 28, 226–237.

- Yan, R.; Ma, Z.; Zhao, Y.; Kokogiannakis, G. A decision tree based data-driven diagnostic strategy for air handling units. Energy Build. 2016, 133, 37–45.

More