Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Alperen Doğru.

Kompozit malzemelerin kullanımı, çok çeşitli uygulamalar için birçok yeni yenilik gördü. Kompozitlerde takviye alanı da hibrit elyafların, sürdürülebilir malzemelerin ve nanoselülozun kullanımı dahil olmak üzere birçok yeni keşifle hızla gelişmektedir.

The use of composite materials has seen many new innovations for a large variety of applications. The area of reinforcement in composites is also rapidly evolving with many new discoveries, including the use of hybrid fibers, sustainable materials, and nanocellulose.

- natural fibers

- hybrid

- nanocomposites

1. Introduction to Hibrit Takviyeli Polimer Kompozitlere Giriş

K

ybrid Reinforced Polymer Composites

Compozsit malzemeler, kil, toprak ve kumdan yapılan buğday lifi dolgulu tuğlalarla (kemikler, ahşap vb.) yaklaşık olarak dünya evriminin ilk yıllarına kadar uzanıre materials date back to approximately the first years of world evolution (bones, wood, etc.) with wheat fiber-filled bricks made from clay, soil, and sand [1 ] [1]. MalzeCome özelliklerinibining materials to optimize etmek için malzemeleri birleştirmek, yeni malzemeler üretmek için her zaman umut verici bir yaklaşım olmuştur. 1920'lerin başında, çelikle güçlendirilmiş beton inşaat endüstrisini değiştirdimaterial properties has always been a promising approach for producing novel materials. In the early 1920s, steel-reinforced concrete changed the construction industry [ 2 , 3 ][2][3].Cam

Although eglyafıass fiber (GF) hala endüstriyel olarak kullanılan baskın elyaf olmasına rağmen, çeşitli mühendislik zorlukları için birçok farklı elyaf kullanılmıştır. Çeşitli lifler arasında, kis still the predominant fiber used industrially, many different fibers have been used for various engineering challenges. Among the various fibers, carbon lifleri (CF'ler) yirminci yüzyılın sonlarında tercih edilen bir malzemeydi ve birçokfibers (CFs) were a choice material of the late twentieth century, used to replace many metal parçayı CF ile güçlendirilmiş bileşenlerle değiştirmek için kullanıldı, böylece havacılık ve uzay ve diğer birçok endüstriyilic parts with CF-reinforced components, thus affecting aerospace and many other industries [4][5]. Betkiledi [4 , 5 ] . sides CF'les, arin yanı sıra, yüksek tamid fibers, with high thermal stabiliteye sahip aramid elyaflar, balistik, yüksek basınçlı oy, have been used in numerous applications, including ballistics, high-pressure automotiv hortumları ve yüksek sıcaklık malzemeleri dahil olmak üzere çok sayıda uygulamada kullanılmıştır. Bazalt lifleri ayrıca inşaat mühendisliği uygulamaları ve nükleer santral yapımında özel kullanım için dikkat çekiyore hoses, and high-temperature materials. Basalt fibers are also garnering attention for civil engineering applications and special use in nuclear plant construction [[3]. 3].A Yneni nesil yüksek w generation of high-performanslı lifler, çeşitli uygulamalara sahip ultra yüksek moleküler ağırlıklı polietilen liflerdir [ce fibers are ultrahigh-molecular weight polyethylene fibers, which have diverse applications 5 ][5]. SCeramik ve bor elyafları da yüksek sıcaklık uygulamalarında oldukça spesifik ve sınırlı kullanıc and boron fibers have also been used for highly specific and limited uses in high-temperature applications [6].

Amlong the var için kullanılmıştır [ 6 ].

Mious available revsourcut çeşitli kaynaklar arasında çevre dostu ve sürdürülebilir lifler ve doğal lifle güçlendirilmiş kompozitler, geleneksel lifle güçlendirilmiş kompozitlees, environmentally-friendly and sustainable fibers and natural fiber-reinforced composites have been an important alternative to conventional fiber-reinforced composites [7][8]. Natureal önemli bir alternatif olmuştur [fibers are primarily comprised 7 , 8 ]. Doğal lifler başlıca selüloz cellulose, hemiselüloz vecellulose, and ligninden [9]. Holuşur [ 9wever, some ]. Ancak bazı doğal lifler (yün, saç, ipek vb.) proteinden oluşur. Bu bileşenlerin yüzdeleri bitkiden bitkiye değişir. Doğal lifler arasında ağaç unu 100 yılı aşkın bir süredir ticari olarak kullanılmaktadır ve yeni ürünlerde küspe, keten ve kenevir lifleri kullanılmaktadır. Birçok doğal lif kapsamlı bir şekilde incelenmektedir [ 10 ].

Gatural fibers (wool, hair, silk, etc.) are comprised of protein. The percentages of these components differ from plant to plant. Among the natural fibers, wood flour has been used commercially for more than 100 years, and new products use bagasse, flax, and hemp fibers. Many natural fibers are being studied extensivelişmişy m[10].

Wikroskopith tekniklerinin sağladığıhe introduction of nanoteknolojinin tanıtılmasıyla, çeşitlichnology enabled by advanced microscopy techniques, various nanomalzemeler keşfedildi ve polimer kompozitlerde ve diğer kompozitlerde kullanıldı. Pek çokaterials have been discovered and used in polymer composites and other composites. Among the many nanomalzeme arasında nanoselüloz, "malzemelerin geleceği" olarak sunulan en önemli malzemelerden biri olmuştur ve son yirmi yılda çok sayıda çalışmada incelenmiştir [11terials, nanocellulose has been one of the most important materials, presented as “the future of materials,” and has been examined in numerous studies over the ,past 12two ,decades 13 , 14 ] [11][12][13][14].

K

Compozsit malzemeler,e materials have been formed using various fibers, as listelendiği gibi çeşitli elyafların yanı sıra td, as well as many different resins, including thermosetler, ts, thermoplastikler vecs, and elastomerlers dahil[15][16]. birçokIn farklı reçine kullanılarak oluşturulmuştur [ 15 , 16 ]. Ythe search for neniw kompozitler arayışında, araştırmacılar hibrit malzeme tekniklerini kullanarak nihai malzeme özelliklerinicomposites, researchers have found new ways to optimize etmenin yeni yollarını bulmuşlardır [the final materials properties using hybrid material techniques 17[17]. ].In Kompozit malzemelerde, araştırmacılar polimerlerin güçlendirilmesi için hibrit lifler kullanmaya başladılar ve birçok çalışma hibritleşencomposite materials, researchers begun using hybrid fibers for the reinforcement of polymers, and many studies have examined hybridizing nanomalzemeleri de inceledi. Birçok çalışma, aynı matristeki farklı lifleri karşılaştırmıştır; ancak, son on yılda, hibrit liflerin ve malzemelerin kullanımı, çeşitli uygulamalar için pek çok yeni sonuç ve ürün yaratmıştırterials, as well. Many studies have compared different fibers in the same matrix; however, in the past decade, the use of hybrid fibers and materials has created many novel results and products for various applications [ 1 ][1].

The hybridization of reinforcing phases is one of the most important topics for composite materials in terms of precisely optimizing the properties of the materials. Composite materials can have the following hybrid forms [18]:

-

Hybrid composite system containing at least two reinforcing fibers;

-

Hybrid composite system containing fibers and micron-nanoscale particles;

-

Hybrid composite system containing at least two nanomaterials.

1.1. An Overview of Hybrid Composites

Hybrid composites are among the multifunctional materials used in advanced structural components when more than one characteristic benefit, such as mechanical strength and/or conductivity, is needed from the materials they contain. Hybrid composites are materials in which one type of reinforcing material is incorporated into two polymer matrix mixtures, or a particular polymer matrix is reinforced with more than one reinforcing material [20][19].

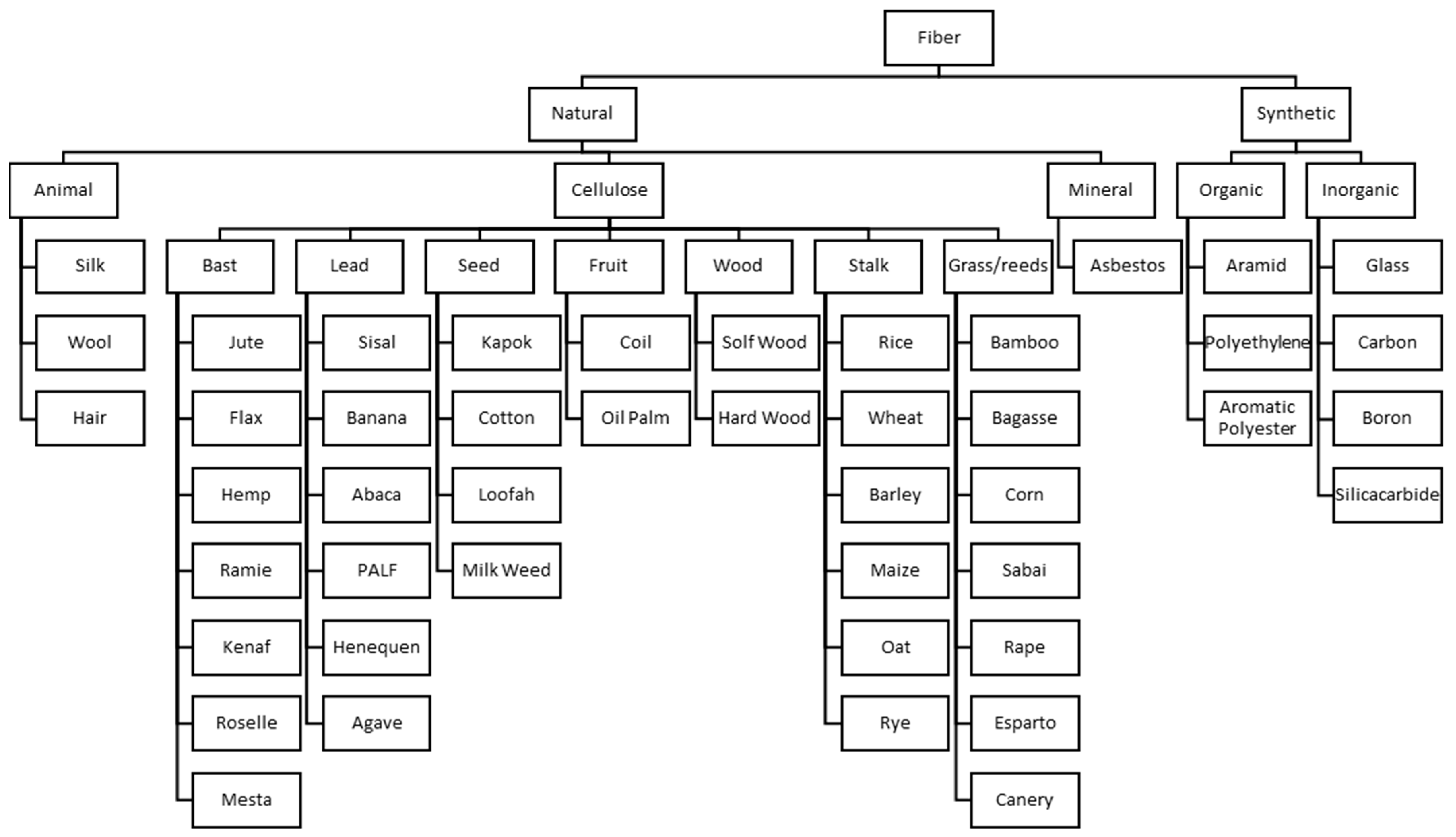

Such hybrid forms affect the weight and geometry of the advanced structural components used in specific applications [21,22][20][21]. Natural fibers are classified as being from flora, fauna, and minerals. Animal fiber components are typically based on proteins. Plant fibers (PFs) primarily comprise stem, leaf, root, wood, and straw which contain lignocellulose. Artificial fibers, however, are materials with synthetic chemical content and are obtained from fossil sources such as petroleum or coal [3]. Figure 1 shows the classification of fibers with examples [23][22].

Figure 1. Classification of various fiber types.

The orientation of the fibers used for reinforcement in composite materials and the manufacturing processes used significantly affect the resulting mechanical properties. Therefore, the fiber orientation and textile processes used are critical when designing hybrid composites. Polymers are widely used as matrix materials in hybrid composites [24][23]. Discussions on matrices for composites are beyond the scope of this review.

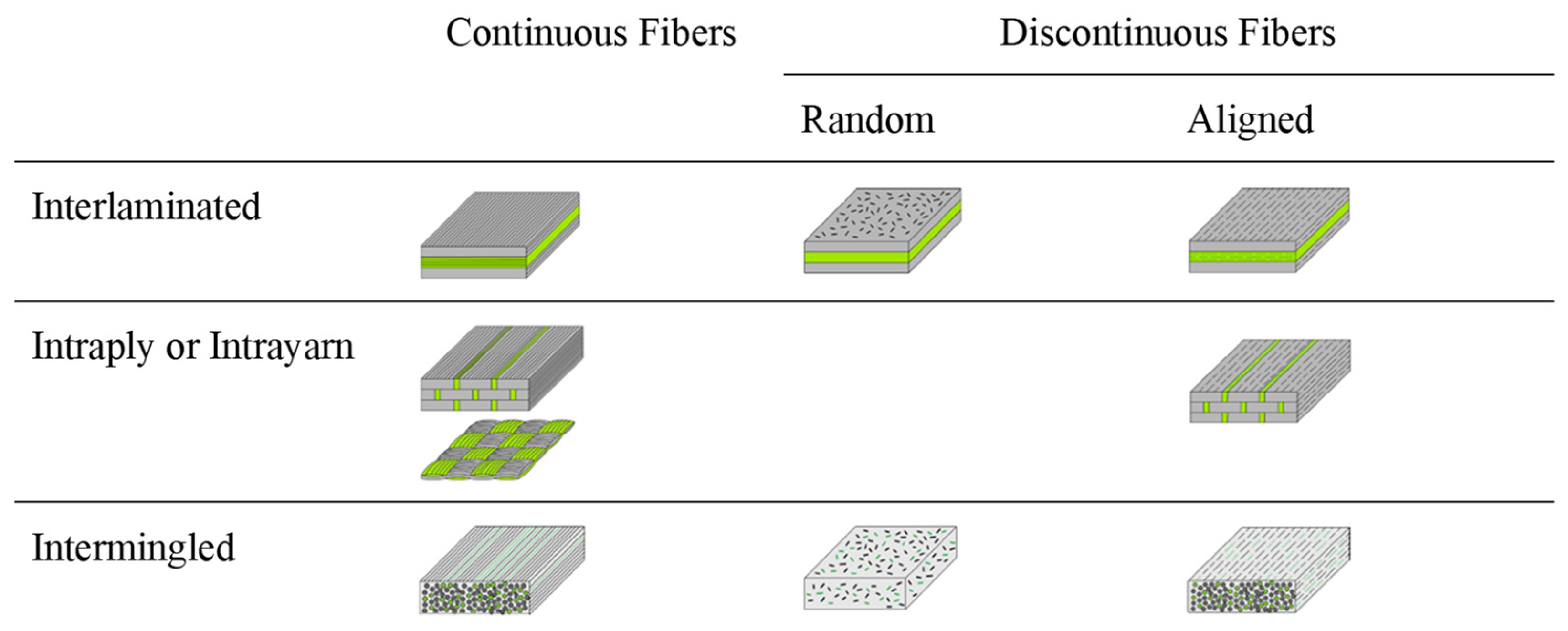

The strength of hybrid composites depends on the properties of the fiber, the fiber length and diameter, fiber orientation, fiber aspect ratio, homogeneous distribution of fibers, matrix/fiber interface bonding, layers, and fiber textile construction type [20,25,26][19][24][25]. Deciding on the type and properties of fibers or fillers is of primary importance in hybrid composite design and production. Hybrid composites can be designed according to the number of layers and different forms and orientations of the reinforcing fibers, as shown in Figure 2 [27][26]. Figure 2 shows different hybrid structures with distinct morphologies.

Figure 2. Hybrid fiber structures.

A subset of hybrid composites is defined as hybrid biocomposites when one of the elements consists of lignocellulosic fibers. While a natural biofiber is used as reinforcement material in these composites, a non-biodegradable polymer or biopolymers are used as the matrix material. Some hybrid biocomposites also contain synthetic fibers as well as hybrid fibers. Hybrid biocomposites are either completely environmentally-friendly hybrid biocomposites or partially environmentally friendly [28,29][27][28]. The completely environmentally-friendly ones are biopolymer matrix structures reinforced with or without cellulosic fibers (i.e., green biocomposites). Hybrid biocomposites are affected by fiber/matrix interfacial bonds and the characteristics of their sustainable components. Natural cellulosic PFs can be used in sizes ranging from micrometers to centimeters.

Natural fibers which are cellulose-based are hydrophilic because they contain hydroxyl groups on the surface and in the bulk. Therefore, they swell when they interact with water or moisture, resulting in unsatisfactory properties. To eliminate this problem, chemical modification of the fiber can be carried out. However, most of these methods are carried out with chemicals that are harmful to the environment [33][29]. An alternative to chemical processing is hybridization, in which natural fibers are combined with synthetic hydrophobic fibers. This method allows for a simultaneous reduction in moisture absorption and improvement in the properties of the designed hybrid composite.

In addition to synthetic fibers, natural fibers are reinforced to improve the properties of the materials designed and produced in hybrid composites, reduce moisture absorption, balance the costs of the fibers, and reduce the negative environmental impact, and energy and carbon footprint [34][30].

Nanocomposites are possible alternative materials to overcome the disadvantages and inadequacies of traditional composites. Nanocomposites are composites in which nano-sized fillers (nanoparticles) are added to reinforce the polymer matrix to improve specific properties of the material. With the addition of nano-sized fillers to the polymer matrix, changes in chemical, electrical, mechanical, and physical properties are observed. Researchers in applied materials science have conducted intensive studies on nanocomposites [6].

By adding nanoparticles to the matrix material, the material’s mechanical behavior can be changed without changing the total mass of the structure. Hybrid nanocomposites are obtained by adding nano-sized fillers in addition to fiber-reinforced or nanoparticle-doped polymer matrix composites. When a biodegradable product is used as a supplement, the term biocomposite can be used. For example, hybrid nanobiocomposites are formed by the incorporation of nano-sized filler into polymer matrix composites reinforced with natural fibers.

The surface areas of nano-sized materials are quite high [35][31]. Therefore, the inclusion of such substances in the structure affects the connection between the fiber and the matrix, and enables the improvement of mechanical properties [23][22]. Including particulate reinforcements in composite structures increases stiffness, reduces cost, and prevents discontinuities. It provides a more efficient load transfer between the fibers and the matrix [36][32].

1.2. Manufacturing Methods

Composite parts are produced through many different methods. For the successful production of a material or a component, the method must be cost-effective and reliable [37,38][33][34]. The cost-effective paradigm is highly dependent on production speed, consumables, and infrastructure requirements. For reliability, all parts after production must be of the same quality. The part must be able to be shaped into the desired geometry, be in suitable tolerances during shaping, and show the expected mechanical properties which were determined during the design. In line with these requirements, different manufacturing methods have been used.

Each method provides inherently different advantages. The selected matrix materials and reinforcement elements are important to the production method of hybrid composites. It is critical to ensure a homogeneous distribution of fibers and/or particles in hybrid composites containing at least two reinforcing fibers, containing fibers and micro-nano-scale particles, and containing at least two different nanomaterials.

Hybrid composites, especially with thermoset matrices, can be produced by a wide variety of methods, such as autoclave molding, cold press, compression molding, hand lay-up, hydraulic pressing, vacuum bagging, and infusion methods [20,39,40,41][19][35][36][37]. Extrusion, injection molding, and thermoforming are widely used as production techniques in thermoplastic composites [42,43][38][39]. Other production methods include spray-up, filament winding, pultrusion, and additive manufacturing [44,45][40][41].

1.3. Applications

Various nano-sized fillers are used to enhance the properties of polymer matrix composites. Shanker and Rhim reported that nanofillers can be used in the formation of hybrid nanobiocomposites [46][42]. The most suitable and promising carbon nanofillers, carbon nanotubes (CNTs), carbon nanofibers (CNFs), graphite, graphene, and nano-clay are used to develop hybrid nanobiocomposites with multifunctional applications. Among these, graphene and CNTs are the most widely-used nanofiller materials because of their superior morphological properties, structures, and physicochemical properties that can have applications in high-strength composites.

The addition of different nano-sized materials (1–5 wt. % of nanoparticles, fly ash, and metallic nanoparticles) to hybrid nanobiocomposites reinforced with natural fibers increases tensile strength and impact strength compared with epoxy matrix materials reinforced with only one natural fiber type [47,48,49][43][44][45]. Furthermore, significant changes in material behavior are occurring and can lead to new applications in composite-based industries. More studies on this topic will enable the usage area to become widespread.

Further research on biofiber/nanofiber-based hybrid composites is crucial for automotive parts, ballistics, and biomedical applications. The increase in fuel costs, the desire to increase the useful load-carrying capabilities of aircraft, and the desire to improve their maneuverability has motivated scientists to research innovative materials with low weight and excellent mechanical properties [50][46]. Puttegowa et al. showed the important requirements of aerospace and defense industry components and the effects of these requirements on structural design [30][47]. In the aerospace industry, many commercial aircraft manufacturers have turned to the use of low-cost hybrid composites with customized features to meet the high demands regarding energy and safety. In addition, hybrid composites have greater elastic strain energy, storage ability, and strength, and a higher strength-to-weight ratio than conventional metallic materials such as aluminum and steel. The use of composite materials in the production of aircraft structural components has been supported by the development of strong reinforcing materials such as glass, CFs, and advanced polymers [51][48].

The development of strong reinforcing materials such as glass, CFs, and advances in polymers have also been supported in the development of suitable materials that can be used in the manufacture of the latest aircraft components [51][48]. In the latest technological studies, glass and CFs such as artificial fibers and flax, kenaf, and jute have been used as biofibers for hybrid composites reinforced with biofibers.

1.4. Nanocellulose

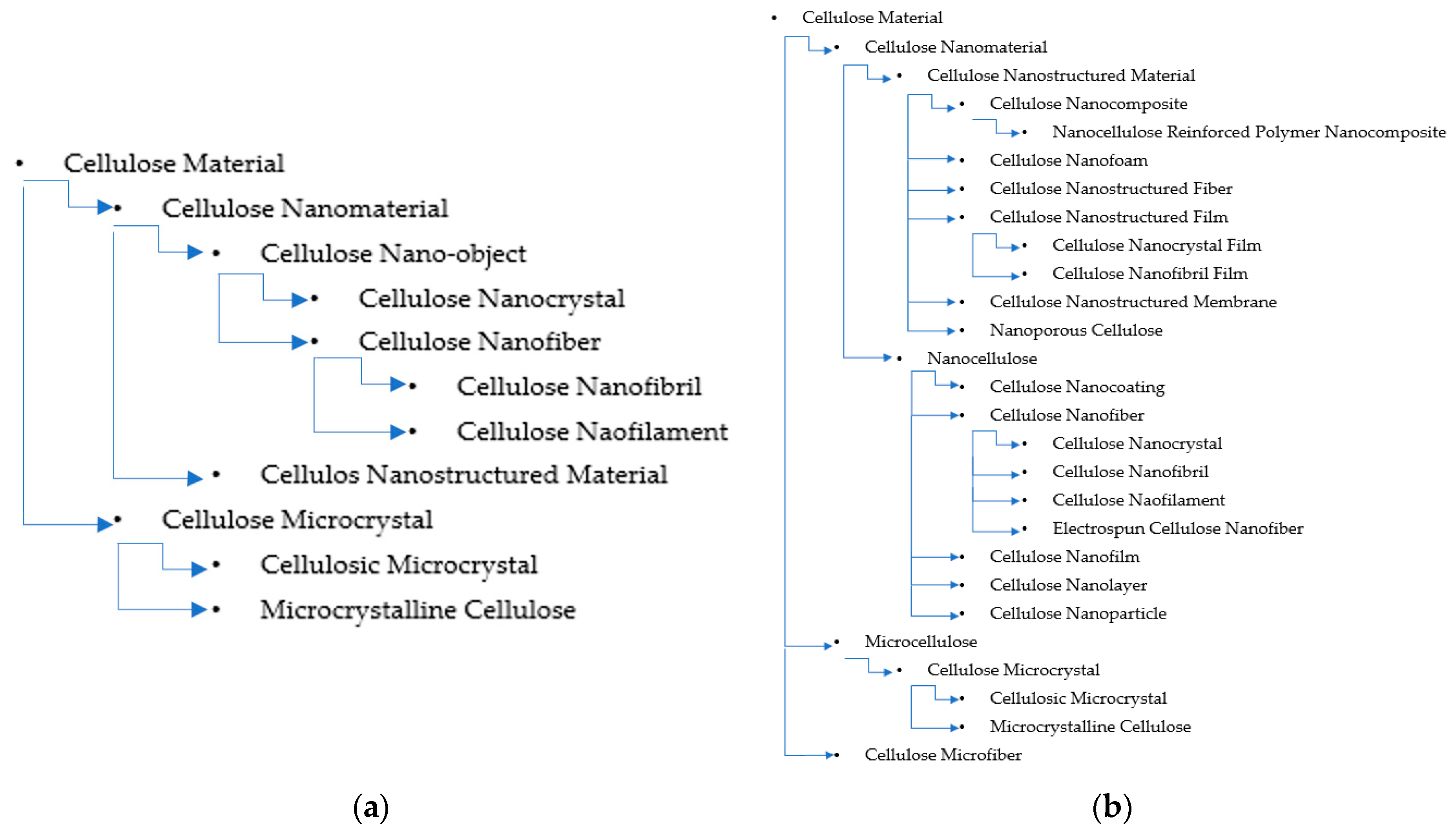

Figure 3 shows the classification of cellulose nanomaterials (CNMs) by ISO/TS 20,477 and the modified classification. Each subclass (subcategory) is indented farther than its superordinate class; sibling classes are listed with the same indentation. For some classes, a few subclass terms are also listed. The class and subclass terms are not comprehensive; additional classes and subclasses can be added. For example, cellulosic materials do not only include CNMs and microcellulose.

Figure 3. Cellulose material taxonomies (a) classification by ISO/TS 20477-2017 and (b) modified classification.

In the modified classification, for simplicity, the term nanocellulose is substituted for cellulose nano-object. Nanomaterial refers to a substance or material that is in the nanoscale and at least in one dimension less than 100 nm, and nanocellulose is a parallel term. Although nanomaterials include those having internal or surface structures according to ISO/TS 20477, nanocellulose generally includes those with any external dimension in the nanoscale, equivalent to nano-object, including cellulose nanofibers, nanofilms, and cellulose nanoparticles. ISO/TS 8004-2 defines nanoparticles as materials with all external dimensions in the nanoscale; the lengths of the longest and the shortest axes do not differ significantly. In most of the literature, nanoparticle is inclusive of various-shaped nano-objects. By this definition, there are rare reports of cellulose nanoparticles in the literature. According to ISO/TS 20477, nanofiber is a nano-object with a significantly large aspect ratio. It should include cellulose nanocrystals (CNCs) and cellulose nanofibrils; however, this understanding is not in agreement with ISO/TS 20477, which states that nanofibril and nanofilament are equivalent terms to nanofiber. CNCs obtained from wood or other cellulose sources have been reported to have diameters and lengths in the range of 3–5 nm and 100–300 nm, meaning that their dimensions meet both the definition of nanofiber according to both ISO/TS 20,477 and 80004-2, implying that they are both a nanocrystal and a nanofiber. Furthermore, if electrospun cellulose fibers have diameters in the nanoscale, they should also be classified into nanofibers [53][49], although their crystalline structure is cellulose II. Assigning the terms nanolayer, nanocoating, and nanofilm to nanocellulose (i.e., nano-objects) and the terms nanostructured films, coatings, and layers to nanostructured material follows the hierarchy of nanomaterial terms in ISO/TS 80004-11.

Similar reasoning follows for the term micro-cellulose, after nanocellulose, referring to any cellulose materials in the microscale, such as those having one or more dimensions less than 10 μm. When the diameter of cellulose fibers is less than 10 μm, the fibers can be classified as cellulose microfibers. Cellulose microfibers are often manufactured cellulose fibers with diameters in the range of 100 nm to 10 µm, which includes most electrospun cellulose fibers [53][49]. Most PFs are larger than 10 µm and, hence, cannot be classified as microfibers. In general, when naming an object, the name of the material is not typically the head noun but, rather, the modifier. However, naming micro- or nano-fibrillated cellulose does not follow this standard. The term micro-fibrillated cellulose emphasizes the fibrillation process that produces it by using a size prefix with a process. Micro-fibrillated cellulose could have been better named cellulose microfibrils;however, the term microfibril has been historically used by plant anatomists to designate the cellulose organization structure in plant cell walls along with microfibril and elementary fibril. Isolated cellulose in the micrometer range should not use the term microfibril to avoid confusion. With this consideration, use of the term micro-fibrillated cellulose should be discouraged.

Microcrystalline cellulose consists of fragmented cellulose fibers at a size distribution around tens of micrometers with small aspect ratios. It could be better named cellulose microparticle, cellulose fines, or cellulose microcrystal, as suggested by ISO/TS 20477. However, the term has been widely accepted commercially and in the pharmaceutical industry as an excipient. The modifier microcrystalline or nanocrystalline designates the state of material with crystallites in the micrometer or nanometer range and does not give clues about external dimensions. Nanocrystalline materials generally refer to polycrystalline materials with grains in the nanoscale or semicrystalline materials with a significant fraction of dispersed nanoscale crystallites in a matrix of the amorphous phase. Therefore, charcoal treated at high temperatures beyond 1400 °C can also be classified as a nanocrystalline material since it contains nanoscale carbon crystallites in an amorphous carbon matrix (c). Nanocrystalline materials such as nanocrystalline metals and nanocrystalline ceramics often refer to bulk materials with a nanocrystalline phase. Following these practices, use of the term nanocrystalline cellulose to refer to CNCs should be discouraged.

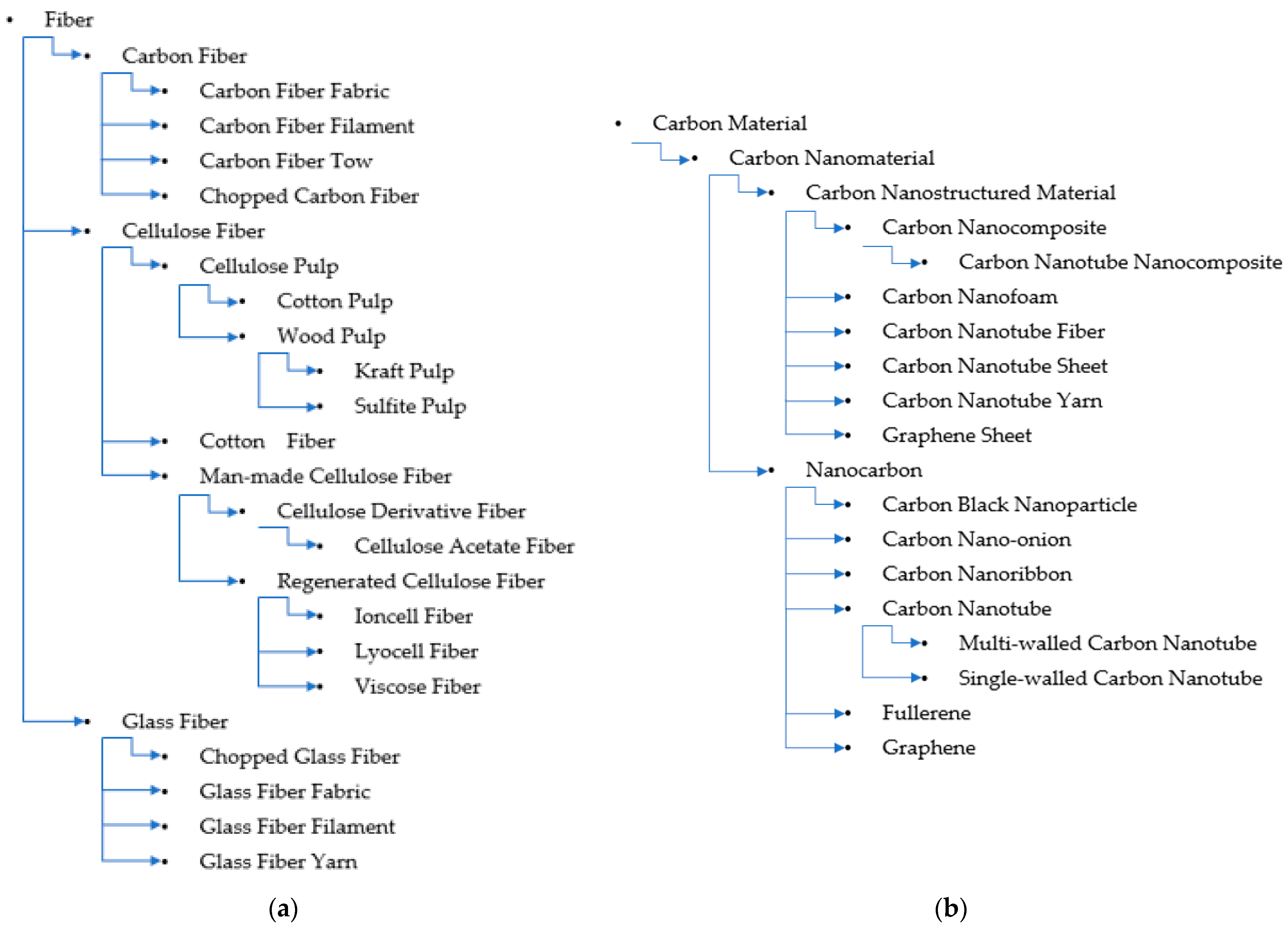

The word fiber has many definitions. It can be a mass word referring to any object with an acicular shape with macromolecular chains usually orienting along the long axle. Those without oriented macromolecular chains might be called nanowire or nano-thread. In the materials, paper, and textile industries, fiber is a broad term referring to a type of cell or cell aggregate in hardwood, bast, and cotton fibers, as well as various polymeric, carbonaceous, and inorganic materials for textiles or reinforcements. The term cellulose fiber is also an inclusive concept referring to manufactured cellulose fibers such as rayon and lyocell fibers in the form of filaments, chopped short fibers (in most cases), chopped yarns, yarns, and fabrics. Cellulose ester fibers are also included in cellulose fibers. The core structure of cellulose fibers is the presence of linear chains of thousands of glucose units linked together, which enables significant hydrogen bonding between OH groups on adjacent chains, causing them to pack closely into fibrils. When fibers have diameters in the nanometer range, they can be classified as nanofibers. Since fiber is an inclusive term, nanofiber should also be inclusive of all fiber in the nanometer range. Fibers are usually presented in the form of yarns, fabrics, filaments, and chopped short fibers in filaments or yarns, as shown in Figure 4a.

Figure 4. (a) Fiber taxonomies and (b) carbon nanomaterial classification.

Cellulose is sometimes used with carbon. There are many carbon nano-objects, i.e., nanocarbons, such as CNTs and graphene, which are classified as shown in Figure 2b. Researchers and industrialists have integrated the remarkable properties of individual nanocarbons into useful, macroscopic ensembles (i.e., carbon-nanostructured materials such as fibers, films, membranes, foams, and nanocomposites).

2. Nanocellulose-Fiber Hybrid Composites

2.1. Nanocellulose-Hybrid Fibers with Synthetic Fibers

The hybridization of multiple reinforcing additives has been heavily researched to synergize the benefits from each additive. The most researched reinforcing additives are GFs, CFs, and various natural fibers, such as wood fibers and PFs. The use of reinforcing fibers typically aims to improve the mechanical properties, although it is also used as a reinforcement for gas barriers. The mechanical performance of the composites hybridized with multiple additives, however, is slightly degraded because of the lack of performance of the natural additive [54][50]. Despite the slightly decreased performance of the hybridized composites, the benefits of the natural fibers are significant in terms of material sustainability and decreased carbon footprint.

Epoxy composites have been reinforced using mixtures of GF and sisal/jute fibers [55][51]. The fibers were laid to generate multiple layers in the dry state, and epoxy resin was added to the multi-layers to wet the fibers and was later cured. The composite materials showed excellent mechanical properties, although they did not show the interfacial interactions among the fibers, since the epoxy coated the fibers before the fibers were attached to others.

Epoxy, a thermosetting resin, is preferred for manufacturing hybrid composite materials, especially for application in the structures of aircraft, which requires low-dielectric constants that can be provided from the natural fibers [54][50]. The hybridizing of GF and kenaf fibers with epoxy resins showed good low-velocity impact performance, which is required in aircraft applications [54][50].

In general, the synergetic effects from the hybridized composite materials result in better performance than those predicted by the rule of hybrid mixtures [56][52]. In one study, a mixture of GF and CF was thermally compounded with polypropylene (PP) [55][51]. The strength of the hybridized composite samples showed a positive deviation from the elastic modulus and showed no existence of a hybrid effect. The hybrid reinforcement effect in mechanical performance was hypothesized by suggesting that microcracks starting at the ends of CFs do not lead to the composite’s failure because the GFs act as crack arrestors [56][52].

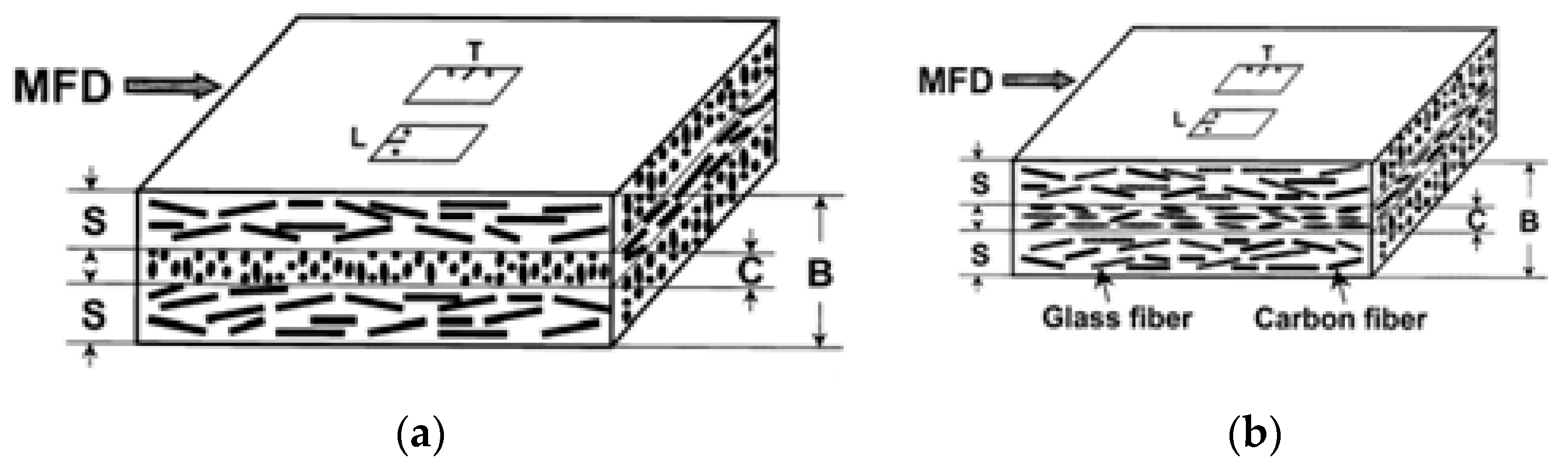

The hybrid fiber reinforcement was also demonstrated in another method for the orientation of additive fibers. A hybrid of CFs and GFs was thermally compounded with PP, and the compound samples were molded into tensile specimens by injection molding [57][53]. The authors reported that the fiber orientation was different in different layers, thus affecting the fracture toughness performance of the composite materials (Figure 5). Fiber orientation occurred during injection molding, depending on the species of the reinforcing fibers and flow direction of the composite melts. A more oblique orientation of the fibers contributed to the good mechanical performance of the hybrid composite materials. The hybridizing of two fibers tended toward parallel alignment to the molding flow direction.

Figure 5. Schematic illustration showing the three-layer structures for (a) single-additive and (b) hybrid composites with GFs/CFs.

The hybridized reinforcing additives can result in modification to the crystallization mechanisms of semi-crystalline thermoplastics. A mixture of nanoparticles of silica fibers and GFs was thermally compounded with PP with the aim of modifying the mechanical and crystallinity properties of the hybrid composite materials [58][54]. The PP matrix showed different crystallinities in the addition of hybrid additives, leading to a heterogeneous nucleating effect of GFs being larger than the effect of nanosilica with different nucleating mechanisms as shown in Reference [58][54]. The synergistic hybrid effects were noticeable in the reduced thermal degradation. Notably, the hybrid effects come from the additives’ mechanical properties and also from the different morphological properties of the additives.

Mechanical properties can be significantly improved by hybridizing the conventional reinforcing fibers and nanofillers of alumina, silica, clay, CNTs, and others [59][55]. The addition of a small amount of a nanofiller can improve the strength and elastic modulus of a composite. Alumina, silica, and CNT have positive effects on the strength of the composite, whereas clay decreases the mechanical properties.

The interfacial properties of hybrid composite materials are critical to their mechanical and physical performance. The type of surface treatments can be selected based on the target matrices and the reinforcing fibers. A study was conducted with various surface treatments of the reinforcing fibers of sisal and glass [60][56]. Chemical surface modifications, such as alkali, acetic anhydride, stearic acid, permanganate, maleic anhydride, silane, and peroxides, of the fibers and matrix were successful in improving interfacial adhesion and compatibility between the fiber and matrix. The nature and extent of chemical modifications were analyzed by infrared spectroscopy, and the improvement in fiber–matrix adhesion was determined by studying the fractography of composite samples via scanning electron microscopy.

A study was conducted to compare the reinforcing effects from CF and GF [61][57], which are two dominating reinforcements for polymer composites. Fiber-reinforced thermoplastics are widely used in many applications. The study reported that the mechanical performances of CFs/GFs were well matched to the result found by multiple sources in the literature, which is that CFs are 20% stronger in tensile and flexural strengths than GFs, but that GFs increased the elastic modulus to double that of CFs. Also, GFs can improve the impact resistance of the composite materials more than CFs.

Aramid fiber is a well-known reinforcing fiber, especially used for military applications because of its superior mechanical properties. Long fibers of aramid and kenaf were used in their woven forms, which is typical in military applications, to manufacture composite samples for ballistic testing [62][58]. The testing results showed that hybrid composites (14 layers of Aramid and 2 layers of kenaf) significantly improved ballistic performance as compared with other hybrid composites. The combination of natural fibers and aramid is rare since the aramid fibers are expensive and specialized for high-end applications, whereas natural fibers are more common in low-cost building material applications.

Over the past decade, researchers have examined the benefits of including nanocellulose in GF/CF composites for enhanced properties and performance. In a study comparing GFs and microfibrillated cellulose fibers in a polamide-6/PP blend, the tensile and flexural stiffness increased from the neat polymer blend [63][59]. Through incorporating GFs with microfibrillated cellulose fibers, the water absorption in the composite was decreased, which helps to improve the mechanical properties and ease of processability. The GF/microfibrillated cellulose fiber content was optimized at 15 wt. % and 10 wt. %, respectively; however, it could not match the mechanical properties of a 30 wt. % GF/polamide-6/PP composite.

One main area of nanocellulose use with GF composites is the coating of GFs with nanocellulose to enhance their mechanical properties. A research group found that, by immersing chopped GFs in an aqueous suspension containing 1 wt. % CNC, the interfacial shear strength (IFSS) of the fibers in an epoxy matrix was enhanced [64][60]. The proposed mechanism for IFSS enhancement is that the CNCs have a better chemical affinity to the epoxy than the GFs, thus increasing the interfacial adhesion between the fiber and the matrix. However, by coating GFs in a higher weight-percentage CNC solution, IFSS was found to decrease because of the inherent brittleness of the CNCs [64,65][60][61].

Traditionally, GFs are coated with CNCs through dip coating from an aqueous suspension. Some researchers have investigated alternative coating methods, such as CNC emulsions, spray coating, and slot die coating, all of which improve the IFSS compared with non-coated GFs [64,65,66][60][61][62]. The differentiator between these methods is the scalability; aqueous suspensions are more easily scaled than emulsions and spray coatings, and slot die coating methods are more easily scalable than dip coating. Regardless, using CNCs as a coating on GFs in epoxies has been shown to increase the IFSS when compared with GFs without CNC coatings.

GF/nanocellulose composites have also been investigated for sheet molding compounding (SMC) of epoxy composites [64,67][60][63]. By adding CNCs during SMC processing of GF/epoxy composites, the viscosity, flexural strength and stiffness, and tensile strength and stiffness increased. The major advantage of using CNCs in SMC is the ability to achieve similar properties while reducing the overall weight of the composite. Asadi et al. replaced 10 wt. % GFs with 1.5 wt. % CNCs in SMC, producing a lighter-weight composite while still achieving enhanced mechanical properties [67][63]. Overall, the use of nanocellulose with GF composites has mainly focused on using CNCs as a GF coating in epoxy matrices, although it has been used in other ways to create lighter-weight composites.

Shariatnia et al. coated CFs with CNCs and CNTs in CF-reinforced epoxy matrix samples. They used CNCs to disperse and stabilize the CNTs. In hybrid CFRPs, the addition of CNCs and CNTs increased flexural stiffness by 15% and strength by 33% [68][64]. According to Kaynan et al., CNCs were used to effectively coat CFs with CNTs and graphene nanoplatelets (GnPs). CNCs provided a suitable platform for designing the interface of the hybrid composites [69][65]. These studies showed that CNCs are a good dispersing aide for nanomaterials and are easily coated onto CFs. Shao et al. studied the fatigue performance of CNF-doped, CF-reinforced epoxy composites. An increase in adhesive strength between CF and the epoxy matrix was observed, which is attributable to physical modification with CNFs [70][66]. Chai et al. investigated the damping properties of CF epoxy hybrid composites reinforced with polysulfone/CNC nanofiber membranes using dynamic mechanical analysis tests. In this study, the 10% polysulfone/0.5% CNC membrane additive increased the damping properties of CF epoxy hybrid composites with minimal loss of mechanical performance [71][67].

The major motivation of research in hybrid composites is to maximize the effects of reinforcements from various additives, leading to synergistic property improvements that are greater than singular reinforcing additives. The hybrid effects have been proven in many polymeric matrices; however, to be certain of the synergistic effects, the most important aspect of hybrid composite manufacturing is how to design the hybrids according to the target properties. Some of the most sought-after properties include mechanical, thermal, gas permeability, optical, and material sustainability with the aim of low carbon footprints and environmental protection. A comprehensive understanding for each additive is required to obtain the desired hybrids designed for specific material property targets. In some cases, hybridization can be designed to adjust the strength performance of the composite materials by partially replacing the expensive additives with less expensive but weaker additives, thus creating a balance between performance and manufacturing costs.

2.2. Nanocellulose-Hybrid Fibers with Natural Fibers

Natural fiber–reinforced polymer (NFRP) composites are a unique member of the fiber-reinforced polymer (FRP) composite category. Compared with FRPs that contain synthetic fibers (GFs, CFs, etc.), NFRPs provide balanced benefits among mechanical performance, cost, and environmental impact [72][68]. However, for more performance-demanding applications, NFRPs are often mixed with high-performance (nano) fibers to improve performance [73][69]. Nanocellulose has been investigated as a replacement for traditional nanomaterials to reinforce polymers because of their superior (estimated) mechanical properties [74][70].

Early studies of NFRPs started with thermoplastics as the polymer matrix. CNFs were used by Li et al.to reinforce wood fiber-filled HDPE composites [75][71]. While keeping the weight percentage of HDPE constantly at 40 wt. % and the coupling agent (maleic anhydride grafted polyethylene) constantly at 3 wt. %, the wood flour content was changed as the CNF content was changed from 5 wt. % to 20 wt. %. Powdery polymers were blended in CNF suspension and freeze dried before extrusion compounding and compression molding. The mechanical properties of wood-filled HDPE composites were largely increased as CNF content increased. For example, the bending strength, stiffness, impact strength, and storage modulus of wood–plastic composites (WPCs) were improved by approximately 50%, 30%, 60%, and 20%, respectively, with a 10% CNF loading level. However, no data were reported for the tensile properties of the composites. In another study, only CNF suspension and wood flour were premixed, dried (oven drying or freeze drying), and milled before being compounded with PP and maleic anhydride-grafted PP [76][72]. Oven drying caused more severe agglomeration of CNFs than freeze drying, as shown in Figure 8. A fiber content of 3 wt. % freeze-dried CNFs was identified as the best reinforcement for wood flour-filled PP composites; the bending strength, bending modulus, tensile strength, and impact strength of the WPCs were improved by 5%, 10%, 7%, and 9%, respectively. Dried CNCs (1 wt. %) and maple wood flours (20 wt. %) were directly melt compounded with PP and maleic anhydride-grafted PP (2 wt. %) before compression molding [77][73]. The mechanical properties of CNC-reinforced WPCs, in most cases, were not significantly different from the original WPCs, likely because of the lower CNC content and the agglomeration of CNCs during drying. Apart from the powder form, a preform of bamboo fibers and CNFs was prepared by compression molding the dehydrated mixture of those fibers after they were comingled in an aqueous suspension [78][74]. The preforms were then compression molded with polybutylene succinate (PBS) to form hybrid composites. Although the hybrid composites exhibited higher tensile properties than pure PBS, no experiments were carried out for bamboo fiber-filled PBS composites, making it impossible to analyze the individual effects of CNFs.

T

Besides thermoplastikcs, naturalerin yanı sıra, WPC'leri t nanofibers have also been used to reinforce WPCs with thermoset matrislerle güçlendirmek için doğal nanolifler de kullanılmıştır. Palmiye yağı boş meyve salkımı nanolifleri (ağırlıkça %3) epoksi reçineye dahil edildi ve ardından hibrit kompozitler oluşturmak için dokunmamışces. Oil palm empty fruit bunch nanofibers (3 wt. %) were incorporated into epoxy resin and then infiltrated into non-woven kenaf hasırlara sızdımats to form hybrid composites [[44][75][76]. 48In ,the 79 , 80 ]. Kkenaf/epoksixy kompozitlerde, nanolifler depolama modülünü %20 iyileştirdi ve cam geçiş sıcaklığını 8 °C artırdı, bu da yüksek sertliğe atfedildicomposites, the nanofibers improved the storage modulus by 20% and increased the glass transition temperature by 8 °C, which was attributed to high stiffness [ 48 ][44].

References

- Khalid, M.Y.; Al Rashid, A.; Arif, Z.U.; Ahmed, W.; Arshad, H.; Zaidi, A.A. Natural fiber reinforced composites: Sustainable materials for emerging applications. Results Eng. 2021, 11, 100263.

- Chawla, K. Composite Materials Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2019; ISBN 9783030289829.

- Mallilck, P. Fibre-Reinforced Composites Materials, Manufacturing and Design; CRC Press: Boca Raton, FL, USA, 2007; ISBN 9780849342059.

- Morgan, P. Carbon Fibers and Their Composites; CRC Press: Boca Raton, FL, USA, 2005; ISBN 9780429116827.

- Oksman, K.; Aitomäki, Y.; Mathew, A.P.; Siqueira, G.; Zhou, Q.; Butylina, S.; Tanpichai, S.; Zhou, X.; Hooshmand, S. Review of the recent developments in cellulose nanocomposite processing. Compos. Part A Appl. Sci. Manuf. 2016, 83, 2–18.

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99.

- Peng, Y.; Gardner, D.J.; Han, Y. Characterization of mechanical and morphological properties of cellulose reinforced polyamide 6 composites. Cellulose 2015, 22, 3199–3215.

- Chakrabarty, A.; Teramoto, Y. Recent Advances in Nanocellulose Composites with Polymers: A Guide for Choosing Partners and How to Incorporate Them. Polymers 2018, 10, 517.

- Seydibeyoğlu, M.Ö.; Misra, M.; Mohanty, A.; Blaker, J.J.; Lee, K.-Y.; Bismarck, A.; Kazemizadeh, M. Green polyurethane nanocomposites from soy polyol and bacterial cellulose. J. Mater. Sci. 2013, 48, 2167–2175.

- Dogru, A.; Sozen, A.; Neser, G.; Seydibeyoglu, M.O. Effects of Aging and Infill Pattern on Mechanical Properties of Hemp Reinforced PLA Composite Produced by Fused Filament Fabrication (FFF). Appl. Sci. Eng. Prog. 2021, 14, 651–660.

- Phuong, H.T.; Thoa, N.K.; Tuyet, P.T.A.; Van, Q.N.; Hai, Y.D. Cellulose Nanomaterials as a Future, Sustainable and Renewable Material. Crystals 2022, 12, 106.

- Pui, K.; Shak, Y.; Pang, Y.L.; Keat, S.; Review, M.; Rahman, A.; Long, J.S.; Long, S.; Kajang, D.; Ehsan, M.; et al. Nanocellulose: Recent advances and its prospects in environmental remediation. Beilstein J. Nanotechnol. 2018, 9, 2479–2498.

- Abdellaoui, H.; el kacem Qaiss, A.; Bouhfid, R. Review of Nanocellulose and Nanohydrogel Matrices for the Development of Sustainable Future Materials. In Sustainable Nanocellulose and Nanohydrogels from Natural Sources; Elsevier: Amsterdam, The Netherlands, 2020; pp. 155–176.

- Trache, D.; Tarchoun, A.F.; Derradji, M.; Hamidon, T.S.; Masruchin, N.; Brosse, N.; Hussin, M.H. Nanocellulose: From Fundamentals to Advanced Applications. Front. Chem. 2020, 8, 392.

- Gardner, D.J.; Oporto, G.S.; Mills, R.; Samir, M.A.S.A. Adhesion and Surface Issues in Cellulose and Nanocellulose. J. Adhes. Sci. Technol. 2012, 22, 545–567.

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68.

- Bai, J. Introduction. In Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1–4.

- Chu, W.S.; Kim, C.S.; Lee, H.T.; Choi, J.O.; Park, J.I.; Song, J.H.; Jang, K.H.; Ahn, S.H. Hybrid manufacturing in micro/nano scale: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2014, 1, 75–92.

- Sathishkumar, T.P.; Naveen, J.; Satheeshkumar, S. Hybrid fiber reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 454–471.

- Kumar, P.A.; Irudhayam, J.S. A Review on Importance and Recent Applications of Polymer Composites in Orthopaedics. Int. J. Eng. Res. Dev. 2012, 5, 40–43.

- Supian, A.B.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S.; Ya, H.H. Hybrid reinforced thermoset polymer composite in energy absorption tube application: A review. Def. Technol. 2018, 14, 291–305.

- Saba, N.; Tahir, P.M.; Jawaid, M. A review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 2014, 6, 2247–2273.

- Akash, M.S.H.; Rehman, K.; Chen, S. Natural and Synthetic Polymers as Drug Carriers for Delivery of Therapeutic Proteins. Polym. Rev. 2015, 55, 371–406.

- Jawaid, M.; Abdul Khalil, H.P.S. Cellulosic/synthetic fibre reinforced polymer hybrid composites: A review. Carbohydr. Polym. 2011, 86, 1–18.

- Pickering, K.L. Properties and Performance of Natural-Fibre Composites; Elsevier: Amsterdam, The Netherlands, 2008; p. 542.

- Yu, H.; Longana, M.L.; Jalalvand, M.; Wisnom, M.R.; Potter, K.D. Pseudo-ductility in intermingled carbon/glass hybrid composites with highly aligned discontinuous fibres. Compos. Part A Appl. Sci. Manuf. 2015, 73, 35–44.

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable Bio-Composites from Renewable Resources: Opportunities and Challenges in the Green Materials World. J. Polym. Environ. 2002, 10, 19–26.

- John, M.J.; Thomas, S. Biofibres and biocomposites. Carbohydr. Polym. 2008, 71, 343–364.

- Kelly, P.V.; Cheng, P.; Gardner, D.J.; Gramlich, W.M. Aqueous Polymer Modification of Cellulose Nanofibrils by Grafting-Through a Reactive Methacrylate Group. Macromol. Rapid Commun. 2021, 42, 2000531.

- Ashori, A.; Nourbakhsh, A.; Tabrizi, A.K. Thermoplastic Hybrid Composites using Bagasse, Corn Stalk and E-glass Fibers: Fabrication and Characterization. Polym.-Plast. Technol. Eng. 2014, 53, 1–8.

- Gardner, D.; Blumentritt, M.; Kiziltas, A.; Kiziltas, E.; Peng, Y.; Yildirim, N. Polymer nanocomposites from the surface energy perspective. Rev. Adhes. Adhes. 2013, 1, 175–215.

- Saghir, F.; Gohari, S.; Mozafari, F.; Moslemi, N.; Burvill, C.; Smith, A.; Lucas, S. Mechanical characterization of particulated FRP composite pipes: A comprehensive experimental study. Polym. Test. 2021, 93, 107001.

- Mahieux, C. Cost effective manufacturing process of thermoplastic matrix composites for the traditional industry: The example of a carbon-fiber reinforced thermoplastic flywheel. Compos. Struct. 2001, 52, 517–521.

- Bader, M.G. Selection of composite materials and manufacturing routes for cost-effective performance. Compos. Part A Appl. Sci. Manuf. 2002, 33, 913–934.

- Razzaq, M.E.A.; Moma, S.E.; Rabbi, M.S. Mechanical properties of biofiber/glass reinforced hybrid composites produced by hand lay-up method: A review. Mater. Eng. Res. 2021, 3, 144–155.

- Balasubramanian, K.; Sultan, M.T.H.; Rajeswari, N. Manufacturing Techniques of Composites for Aerospace Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780081021316.

- McIlhagger, A.; Archer, E.; McIlhagger, R. Manufacturing Processes for Composite Materials and Components for Aerospace Applications. In Polymer Composites in the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2014; pp. 53–75.

- Yassin, K.; Hojjati, M. Processing of thermoplastic matrix composites through automated fiber placement and tape laying methods: A review. J. Thermoplast. Compos. Mater. 2017, 31, 1676–1725.

- Grünewald, J.; Parlevliet, P.; Altstädt, V. Manufacturing of thermoplastic composite sandwich structures: A review of literature. J. Thermoplast. Compos. Mater. 2015, 30, 437–464.

- Fallon, J.J.; McKnight, S.H.; Bortner, M.J. Highly loaded fiber filled polymers for material extrusion: A review of current understanding. Addit. Manuf. 2019, 30, 100810.

- Zhuo, P.; Li, S.; Ashcroft, I.A.; Jones, A.I. Material extrusion additive manufacturing of continuous fibre reinforced polymer matrix composites: A review and outlook. Compos. Part B Eng. 2021, 224, 109143.

- Shankar, S.; Rhim, J.-W. Bionanocomposite Films for Food Packaging Applications. Ref. Modul. Food Sci. 2018.

- Seshanandan, G.; Ravindran, D.; Sornakumar, T. Mechanical properties of nano titanium oxide particles-hybrid jute-glass FRP composites. Mater. Today Proc. 2016, 3, 1383–1388.

- Saba, N.; Paridah, M.T.; Abdan, K.; Ibrahim, N.A. Dynamic mechanical properties of oil palm nano filler/kenaf/epoxy hybrid nanocomposites. Constr. Build. Mater. 2016, 124, 133–138.

- Saba, N.; Paridah, M.T.; Abdan, K.; Ibrahim, N.A. Effect of oil palm nano filler on mechanical and morphological properties of kenaf reinforced epoxy composites. Constr. Build. Mater. 2016, 123, 15–26.

- Arockiam, N.J.; Jawaid, M.; Saba, N. Sustainable Bio Composites for Aircraft Components; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780081021316.

- Puttegowda, M.; Rangappa, S.M.; Jawaid, M.; Shivanna, P.; Basavegowda, Y.; Saba, N. Potential of Natural/Synthetic Hybrid Composites for Aerospace Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780081021316.

- Jamir, M.R.M.; Majid, M.S.A.; Khasri, A. Natural Lightweight Hybrid Composites for Aircraft Structural Applications; Elsevier Ltd.: Amsterdam, The Netherlands, 2018; ISBN 9780081021316.

- Kerwald, J.; de Moura Junior, C.F.; Freitas, E.D.; de Moraes Segundo, J.d.D.P.; Vieira, R.S.; Beppu, M.M. Cellulose-based electrospun nanofibers: A review. Cellulose 2021, 29, 25–54.

- Majid, D.L.; Jamal, Q.M.; Manan, N.H. Low-velocity Impact Performance of Glass Fiber, Kenaf Fiber, and Hybrid Glass/Kenaf Fiber Reinforced Epoxy Composite Laminates. BioResources 2018, 13, 8839–8852.

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Comparative Evaluation on Properties of Hybrid Glass Fiber- Sisal/Jute Reinforced Epoxy Composites. Procedia Eng. 2013, 51, 745–750.

- Fu, S.Y.; Lauke, B.; Mäder, E.; Yue, C.Y.; Hu, X.; Mai, Y.W. Hybrid effects on tensile properties of hybrid short-glass-fiber-and short-carbon-fiber-reinforced polypropylene composites. J. Mater. Sci. 2001, 36, 1243–1251.

- Fu, S.Y.; Mai, Y.W.; Lauke, B.; Yue, C.Y. Synergistic effect on the fracture toughness of hybrid short glass fiber and short carbon fiber reinforced polypropylene composites. Mater. Sci. Eng. A 2002, 323, 326–335.

- Rasana, N.; Jayanarayanan, K. Experimental and micromechanical modeling of fracture toughness: MWCNT-reinforced polypropylene/glass fiber hybrid composites. J. Thermoplast. Compos. Mater. 2018, 32, 1031–1055.

- Arao, Y.; Yumitori, S.; Suzuki, H.; Tanaka, T.; Tanaka, K.; Katayama, T. Mechanical properties of injection-molded carbon fiber/polypropylene composites hybridized with nanofillers. Compos. Part A Appl. Sci. Manuf. 2013, 55, 19–26.

- Kalaprasad, G.; Francis, B.; Thomas, S.; Kumar, C.R.; Pavithran, C.; Groeninckx, G.; Thomas, S. Effect of fibre length and chemical modifications on the tensile properties of intimately mixed short sisal/glass hybrid fibre reinforced low density polyethylene composites. Polym. Int. 2004, 53, 1624–1638.

- Chu, P.F.; Iwasawa, S.; Schell, P.L.; Lin, C.Y. Carbon fiber versus glass fiber reinforcements: A novel, true comparison in thermoplastics. Polym. Compos. 2021, 42, 6173–6181.

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Measurement of ballistic impact properties of woven kenaf–aramid hybrid composites. Measurement 2016, 77, 335–343.

- Annandarajah, C.; Langhorst, A.; Kiziltas, A.; Grewell, D.; Mielewski, D.; Montazami, R. Hybrid Cellulose-Glass Fiber Composites for Automotive Applications. Materials 2019, 12, 3189.

- Asadi, A.; Miller, M.; Moon, R.J.; Kalaitzidou, K. Improving the interfacial and mechanical properties of short glass fiber/epoxy composites by coating the glass fibers with cellulose nanocrystals. Express Polym. Lett. 2016, 10, 587–597.

- Goswami, J.; Haque, E.; Fox, D.M.; Gilman, J.W.; Holmes, G.A.; Moon, R.J.; Kalaitzidou, K. The Effect of Cellulose Nanocrystal Coatings on the Glass Fiber–Epoxy Interphase. Materials 2019, 12, 1951.

- Haque, E.; Shariatnia, S.; Jeong, T.J.; Jarrahbashi, D.; Asadi, A.; Harris, T.; Moon, R.J.; Kalaitzidou, K. Scalable coating methods for enhancing glass fiber–epoxy interactions with cellulose nanocrystals. Cellulose 2021, 28, 4685–4700.

- Asadi, A.; Miller, M.; Singh, A.V.; Moon, R.J.; Kalaitzidou, K. Lightweight sheet molding compound (SMC) composites containing cellulose nanocrystals. Compos. Struct. 2017, 160, 211–219.

- Shariatnia, S.; Kumar, A.V.; Kaynan, O.; Asadi, A.; Asadi, A.; Asadi, A. Hybrid Cellulose Nanocrystal-Bonded Carbon Nanotubes/Carbon Fiber Polymer Composites for Structural Applications. ACS Appl. Nano Mater. 2020, 3, 5421–5436.

- Kaynan, O.; Pérez, L.M.; Asadi, A. Cellulose Nanocrystal-Enabled Tailoring of the Interface in Carbon Nanotube- and Graphene Nanoplatelet-Carbon Fiber Polymer Composites: Implications for Structural Applications. ACS Appl. Nano Mater. 2022, 5, 1284–1295.

- Shao, Y.; Yashiro, T.; Okubo, K.; Fujii, T. Effect of cellulose nano fiber (CNF) on fatigue performance of carbon fiber fabric composites. Compos. Part A Appl. Sci. Manuf. 2015, 76, 244–254.

- Cai, S.; Li, Y.; Liu, H.Y.; Mai, Y.W. Damping properties of carbon fiber reinforced composites hybridized with polysulfone (PSF)/cellulose nanocrystal (CNC) interleaves. Compos. Sci. Technol. 2021, 213, 108904.

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K.; Arora, S. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376.

- Nurazzi, N.M.; Asyraf, M.R.M.; Fatimah Athiyah, S.; Shazleen, S.S.; Rafiqah, S.A.; Harussani, M.M.; Kamarudin, S.H.; Razman, M.R.; Rahmah, M.; Zainudin, E.S.; et al. A review on mechanical performance of hybrid natural fiber polymer composites for structural applications. Polymers 2021, 13, 2170.

- Wang, L.; Gardner, D.J.; Wang, J.; Yang, Y.; Tekinalp, H.L.; Tajvidi, M.; Li, K.; Zhao, X.; Neivandt, D.J.; Han, Y. Towards the scale-up production of cellulose nanocomposites using melt processing: A critical review on structure-processing-property relationships. Compos. Part B Eng. 2020, 201, 108297.

- Li, J.; Li, D.; Song, Z.; Shang, S.; Guo, Y. Preparation and properties of wood plastic composite reinforced by ultralong cellulose nanofibers. Polym. Compos. 2016, 37, 1206–1215.

- Murayama, K.; Yamamoto, M.; Kobori, H.; Kojima, Y.; Suzuki, S.; Aoki, K.; Ito, H.; Ogoe, S.; Okamoto, M. Mechanical and physical properties of wood-plastic composites containing cellulose nanofibers added to wood flour. For. Prod. J. 2019, 68, 398–404.

- Yousefian, H.; Ben Azouz, K.; Rodrigue, D. New Multi-Scale Hybrid System Based on Maple Wood Flour and Nano Crystalline Cellulose: Morphological, Mechanical and Physical Study. J. Polym. Environ. 2016, 24, 48–55.

- Bang, J.; Lee, H.; Yang, Y.; Oh, J.K.; Kwak, H.W. Nano/micro hybrid bamboo fibrous preforms for robust biodegradable fiber reinforced plastics. Polymers 2021, 13, 636.

- Saba, N.; Paridah, M.T.; Abdan, K.; Ibrahim, N.A. Thermal properties of oil palm nano filler/kenaf reinforced epoxy hybrid nanocomposites. AIP Conf. Proc. 2016, 1787, 050020.

- Saba, N.; Paridah, M.T.; Abdan, K.; Ibrahim, N.A. Physical, structural and thermomechanical properties of oil palm nano filler/kenaf/epoxy hybrid nanocomposites. Mater. Chem. Phys. 2016, 184, 64–71.

More