Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Subham Sharma.

Active packaging improves a packaging system’s effectiveness by actively integrating additional components into the packaging material or the headspace around the packaging. Consumer demand and awareness have grown enough to replace chemical agents with natural active agents. Essential oils (EOs) are extensively distributed throughout nature but at low levels and sometimes with poor recovery yields, which poses an issue with their application in food.

- nanocarriers

- essential oil

- active packaging

1. Introduction

Food packaging is known as a passive barrier that protects food from environmental factors like oxygen, water vapor, microbiological and chemical contaminants, pressure, ultraviolet light, and heat [1]. Food packaging has the main function of prolonging the shelf life of food. Food packaging also ensures that foods are transported and stored safely [1]. The primary goal of food packaging is to keep food in the most cost-effective way possible while also meeting industrial and consumer demands, ensuring food safety, and minimizing environmental impact [1]. The several primary functions of food packaging include preventing contamination or leaking, providing critical information about the food product contained within, such as nutritional value and cooking instructions, making purchasing a food product more convenient for consumers, and providing containment for ease of transportation and handling [2].

Innovative packaging such as active packaging, intelligent packaging, and smart packaging has grown in popularity and is frequently used in conjunction with packaging systems for foods, beverages, and pharmaceuticals [2]. The term “active packaging” refers to the incorporation of certain additives into packaging systems to preserve or expand product quality and shelf life [2]. Active packaging helps to reduce foodborne illness outbreaks and food recalls [3]. Intelligent packaging can be described as packaging that carries out intelligent functions such as monitoring the condition of packaged food, detecting changes in the state of the food and its surroundings (e.g., temperature and pH), and tracing, recording, and communicating these conditions [2,3][2][3]. Smart packaging is a packaging system that combines the functionality of intelligent and active packaging. It monitors the changes in the condition of the food product (intelligent packaging) and its environment, as well as acting on these changes (active packaging) [2].

Essential oils (EOs) have been recognized for their various biological activities for centuries. In ancient times, EOs were widely used in the preservation of foods, and possess some therapeutic properties, such as anti-septic properties for use on wounds and analgesic effects useful for numbing purposes such as clove oil. Currently, wresearchers still follow such practices in the domestic and industrial spheres, but they have been implemented in nature for far longer. Anti-parasitic activity has been observed against Flagellate protozoa when analysed with EOs [4]. To better understand the EOs’ potential for antimicrobial activity, they must be analysed individually, as their composition varies depending on many factors, meaning that the application potential for EOs is very extensive and can be a targeted area of research [5].

EOs are popularly known for their natural antioxidant properties that are increasing consumer demand due to the perception of their ‘safer’ natural origin. Antioxidants are of interest in both the food and pharmaceutical industries for their ability to neutralise free radicals and prevent oxidation which causes damage, producing negative effects. In foods, antioxidants are of use in preventing lipid peroxidation, which produces an off flavour and odour that negatively impacts the nutritional value and quality of the food, mainly in products with fats or oils. Within the body, antioxidants bind with free radicals and reactive oxygen and nitrogen species, which aid in the prevention of multiple diseases proven to be indirectly caused by free radicals, such as heart disease [6].

There are many issues and challenges with existing packaging, such as the use of plastic and environmental factors. Problems such as its non-biodegradable nature, recycling issues, and leaching of harmful chemicals into food lead to problems for the environment and human health [7]. Plastic, paper, glass, and metal are by far the most commonly used materials in existing food packaging. A broad range of plastics are used in food packaging [8]. Plasticizers, monomers, and oligomers found in packaging materials may be transferred to foods during the manufacturing process [8]. The transfer of chemical compounds between food and packaging is referred to as “migration”. The process of migration may cause changes in the quality and safety of the food product, as well as sensory changes due to the transfer of undesirable components from the packaging material to the food product [8].

2. Active Packaging

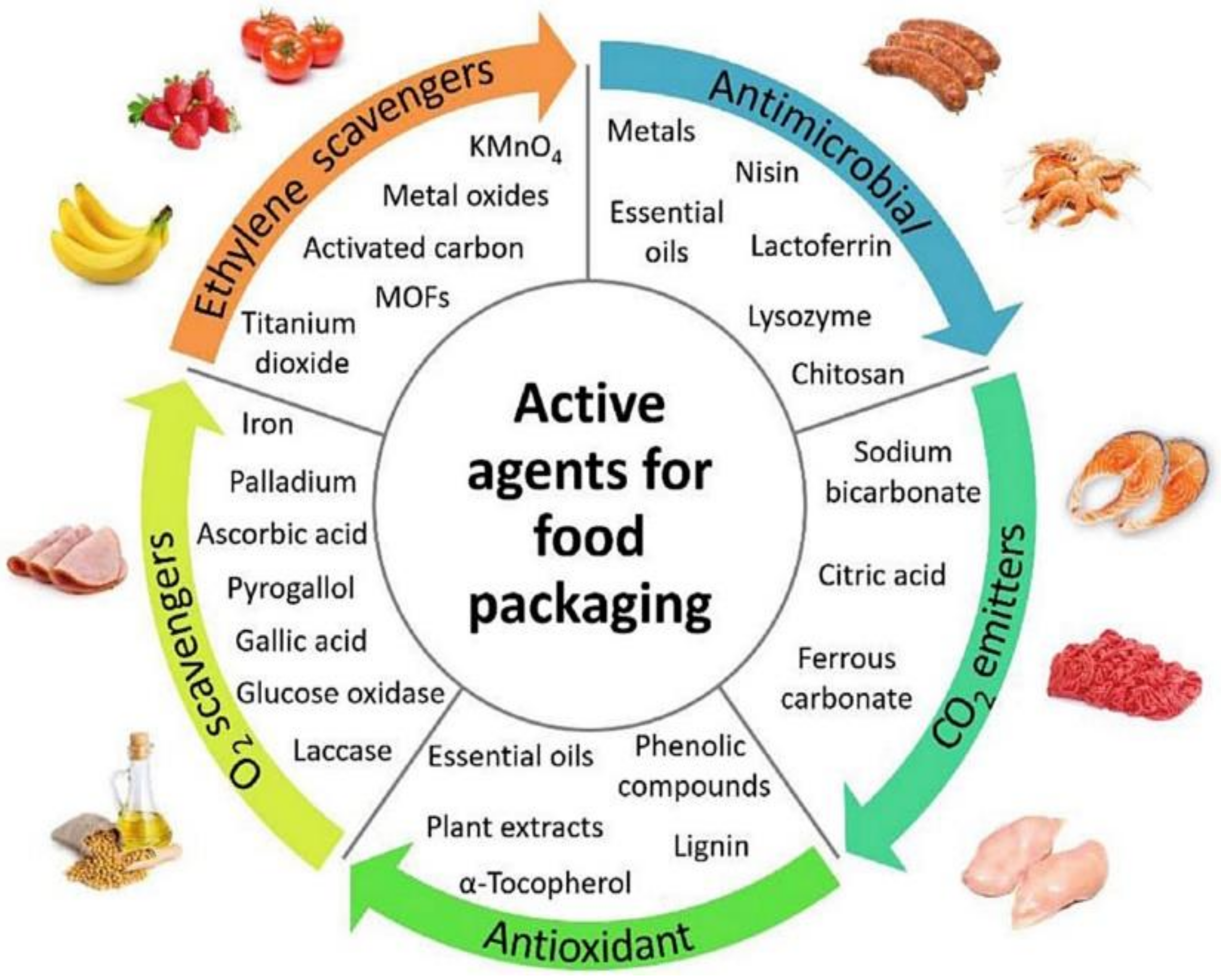

Active packaging is an emerging concept that has sparked a lot of interest and concern over the past decade or two. According to Yucel, (2016) active packaging can be described as a sophisticated packaging system with enhanced protection properties, such as both antioxidant and antimicrobial effects, with an improved capability greater than that obtained through conventional packaging methods [9]. The main aim of active packaging is to enhance the performance of a packaging system by purposely introducing subsidiary constituents in either the packaging material or the headspace surrounding the packaging [10]. This innovative system helps to ensure food quality and safety while also extending the shelf life of products [11]. It has the ability to replace the addition of active substances to foods, limit particle migration from packing materials to food, as well as eliminate industrial processes that can lead to the presence of pathogenic microbes in the product [3]. Active packaging includes ethylene absorbers, carbon dioxide emitters, antioxidant packaging, antimicrobial packaging, moisture absorbers, and O2 absorbers [11]. Active packaging can be created by implementing antimicrobial agents into the packaging composition [1]. The use of antimicrobial agents in packaging can create an environment within the food packaging that can delay or prevent the growth of microorganisms on the food product. This, in turn, increases the shelf life and safety of the food product [12]. Figure 1 concisely highlights the typical active agents used commercially in food packaging that are characterized as antimicrobial agents, antioxidant agents, oxygen scavengers, ethylene scavengers, and carbon dioxide emitters, and examples of each are given [13]. In more recent years, attention has turned to a more ‘natural’ approach to active packaging, as opposed to the current practice of using active packaging materials that may contain modified gases, dyes, and inorganic compounds. EOs, organic acids, enzymes, biopolymers, antimicrobial peptides, and organic acids are all antimicrobial agents [12,14][12][14]. Antioxidant packaging prevents unsuitable oxidation and aerobic microorganism growth. This type of packaging reduces the metabolism of the food product [11]. O2 absorbers lower the oxygen concentration to less than 0.01 percent, reducing O2 diffusion in food packaging [15]. O2 absorbers are made up of chemical substances, including iron, ascorbic acid, or enzymes, that can react with oxygen and absorb up to 2000 cc of O2 from 10,000 ccs of air [16]. Ethylene is a growth hormone that fruits and vegetables produce during storage. Ethylene increases food respiration, lowering the shelf life of food products.

3. Essential Oils as an Active Agent

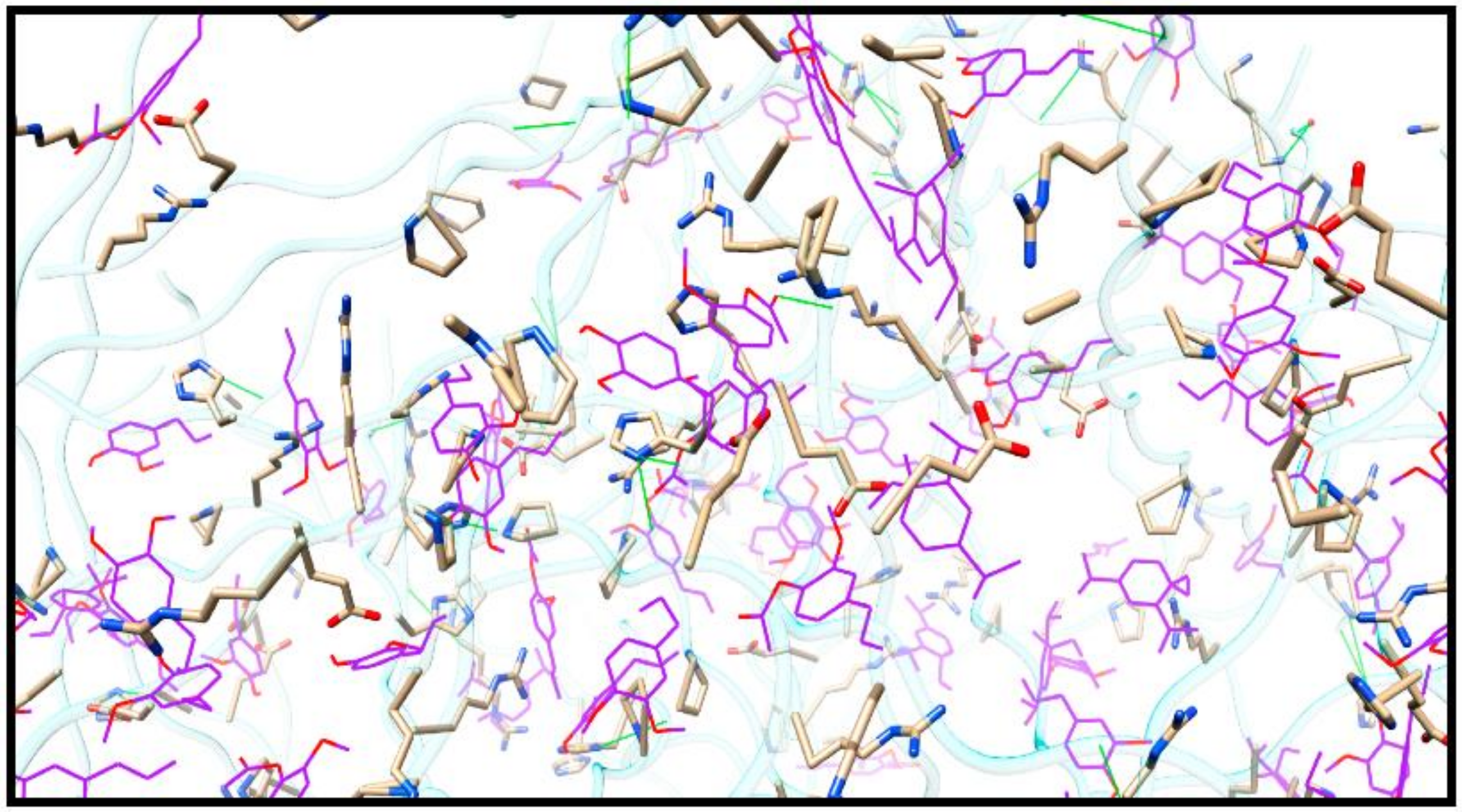

EOs are derived from aromatic plants and are classified as volatile liquids, commonly obtained through different processes such as solvent extraction, hydro-distillation, steam distillation, and hydro-diffusion [3,24,25][3][24][25]. An EO is defined as a ‘product obtained from a natural raw material of plant origin, by steam distillation, by mechanical processes from the epicarp of citrus fruits, or by dry distillation, after separation of the aqueous phase, if any, by physical processes’, according to the International Organization for Standardization (ISO) [3]. EOs vary greatly, partly due to genetic causes, as well as climate, rainfall, or geographic origin [24]. EOs consist of mainly lipophilic and highly volatile secondary plant metabolites, primarily monoterpenes and sesquiterpenes; however, other compounds like allyl and isoallyl phenols, along with alkaloids and coumarins, are also common. EOs include lavender (Lavandula angustifolia), peppermint (Mentha piperita), tea tree (Melaleuca alternifolia), clove (Syzygium aromaticum), sage (Salvia officinalis), cinnamon (Cinnamomum zeylanicum), eucalyptus (Eucalyptus globulus), lemongrass (Cymbopogon citratus), and origanum vulgar [26]. The composition of EOs varies from plant to plant and depends on the type of plant it is derived from, the environment in which it grows, and the part of the plant required to obtain the EO (stem/bud/leaf), etc. For this reason, EOs contain many properties of interest to consumers, producers, and medical practitioners with the potential to perform anticancer, anti-inflammatory, antimicrobial, antidepressant, antianxiety, antidiabetic, and many other beneficial biological functions [27]. Because of their hydrophobic nature and lower density than water, they are lipophilic, soluble in organic solvents, and insoluble in water [28]. The process of hydro-distillation involves submerging plant materials in a water-filled vessel and boiling the mixture. The main advantage of hydro-distillation is the extraction of hydrophobic plants with a high boiling point, and the technique enables the extraction of plant material at temperatures below 100 °C [3]. Steam distillation is the most common method for the commercial production of EOs [29]. In this process, the plant substance is heated with the use of steam. The steam can only pass through the plant while the boiling water does not mix with the plant substance. The heat supplied by the steam releases the EOs [3]. Hydro-diffusion extraction involves reducing the steam temperature to under 100 °C. The vacuum is provided by the top of the generator, which is kept at a low temperature. In this process, the dried plant materials and the steam are supplied in a container [3]. The solvent extraction method involves solvents such as hexane being mixed with the plant material and slightly heated and filtrated, the solvent eventually evaporating. To dissolve the EO, the final mixture is mixed with alcohol, and finally, at a low temperature, the distillation process occurs [3]. EO’s primary function is antimicrobial and antioxidant activity [1]. According to recent studies, EOs are natural preservatives and are recognized as fresh and safe chemical additives. Research findings have shown that high intakes of EOs can reduce the risk of various cancers as well as cardiovascular disease [26]. EOs are natural substances that have been shown to be effective in replacing synthetic food additives. They can be incorporated into food packaging by slowly releasing their compounds into the food product. Many essential oils derived from plants, such as basil (Ocimum basilicum L.), chamomile flowers (Matricaria chamomilla L.), and rosemary (Rosmarinus officinalis L.), have been used in food packaging. These essential oils used in food packaging are classified as GRAS [30]. Fernández-Pan et al. investigated the effectiveness of oregano and garlic EOs in immediate contact with chicken breast, and incorporated them into a protein matrix. After 13 days of storage, it was discovered that EOs controlled microbial action when applied directly to the chicken’s surface [31]. However, there was less adhesion of the antimicrobials on the chicken surface when compared to their use within a structural matrix. This meant that antimicrobials were distributed uniformly and remained at ineffective doses throughout the storage time [31,32][31][32]. Cruz et al. studied the bioactive compounds in Piper divaricatum EO, and the molecular interactions established with a biofilm. The gelatin matrix included small amounts of the main EO components. The polypeptide chain that makes up the biofilm was subject to non-covalent interactions by these substances. The biofilm’s structural, mechanical, and antioxidant characteristics changed as a result of oil impregnation. Additionally, EO changed the biofilm’s physical characteristics, reducing its traction resistance and boosting its ability to extend [33]. Researchers have also represented the chemical interactions of the hydrophobic nature, as can be seen in Figure 2.

Figure 2. View of the EO-impregnated biofilm in greater detail, showing the side chains of the amino acids that interact with the EO molecules (colour purple). Sticks are used to symbolize the side chains of amino acids, while the wire is used to represent EO compounds. Hydrogen bonds are represented by the green lines. Atoms are represented by colour; for example, oxygen is red, and nitrogen is blue (Adopted from Cruz et al. [33]).

References

- Bahrami, A.; Delshadi, R.; Assadpour, E.; Jafari, S.M.; Williams, L. Antimicrobial-loaded nanocarriers for food packaging applications. Adv. Colloid Interface Sci. 2020, 278, 102140.

- Schaefer, D.; Cheung, W.M. Smart Packaging: Opportunities and Challenges. Procedia CIRP 2018, 72, 1022–1027.

- Sharma, S.; Barkauskaite, S.; Jaiswal, A.K.; Jaiswal, S. Essential oils as additives in active food packaging. Food Chem. 2021, 343, 128403.

- Mancianti, F.; Ebani, V.V. Biological activity of essential oils. Molecules 2020, 25, 678.

- Nartey, D.; Gyesi, J.N.; Borquaye, L.S. Chemical composition and biological activities of the essential oils of Chrysophyllum albidum G. Don (African star apple). Biochem. Res. Int. 2021, 2021, 9911713.

- Herrera, P.; Aydin, M.; Park, S.H.; Khatiwara, A.; Ahn, S. Utility of egg yolk antibodies for detection and control of foodborne Salmonella. Agric. Food Anal. Bacteriol. 2013, 3, 195–217.

- Sid, S.; Mor, R.S.; Kishore, A.; Sharanagat, V.S. Bio-sourced polymers as alternatives to conventional food packaging materials: A review. Trends Food Sci. Technol. 2021, 115, 87–104.

- Alamri, M.S.; Qasem, A.A.; Mohamed, A.A.; Hussain, S.; Ibraheem, M.A.; Shamlan, G.; Alqah, H.A.; Qasha, A.S. Food packaging’s materials: A food safety perspective. Saudi J. Biol. Sci. 2021, 8, 4490–4499.

- Yucel, U. Intelligent Packaging. Ref. Modul. Food Sci. 2016, 1.

- Bodbodak, S.; Rafiee, Z. Recent trends in active packaging in fruits and vegetables. In Eco-Friendly Technology for Postharvest Produce Quality; Academic Press: Cambridge, MA, USA, 2016; pp. 77–125.

- Qian, M.; Liu, D.; Zhang, X.; Yin, Z.; Ismail, B.B.; Ye, X.; Guo, M. A review of active packaging in bakery products: Applications and future trends. Trends Food Sci. Technol. 2021, 114, 459–471.

- Hosseinnejad, M.; Jafari, S.M. Evaluation of different factors affecting antimicrobial properties of chitosan. Int. J. Biol. Macromol. 2016, 85, 467–475.

- Vilela, C.; Kurek, M.; Hayouka, Z.; Röcker, B.; Yildirim, S.; Antunes, M.; Nilsen-Nygaard, J.; Pettersen, M.; Freire, C. A concise guide to active agents for active food packaging. Trends Food Sci. Technol. 2018, 80, 212–222.

- Quesada, J.; Sendra, E.; Navarro, C.; Sayas-Barberá, E. Antimicrobial active packaging including chitosan films with Thymus vulgaris L. essential oil for ready-to-eat meat. Foods 2016, 5, 57.

- Gonçalves, A.; Mendes, R.; Nunes, M.L. Effect of Oxygen Absorber on the Shelf Life of Gilthead Seabream (Sparus aurata). J. Aquat. Food Prod. Technol. 2008, 13, 49–59.

- Church, N. Developments in modified-atmosphere packaging and related technologies. Trends Food Sci. Technol. 1994, 5, 345–352.

- Gaikwad, K.K.; Singh, S.; Ajji, A. Moisture absorbers for food packaging applications. Environ. Chem. Lett. 2019, 17, 609–628.

- Busolo, M.A.; Lagaron, J.M. Oxygen scavenging polyolefin nanocomposite films containing an iron modified kaolinite of interest in active food packaging applications. Innov. Food Sci. Emerg. Technol. 2012, 16, 211–217.

- Pop, A.; Kiss, B.; Loghin, F. Endocrine disrupting effects of butylated hydroxyanisole (BHA—E320). Clujul Med. 2013, 86, 16–20. Available online: https://www.ncbi.nlm.nih.gov/pmc/articles/PMC4462476/pdf/cm-86-16.pdf (accessed on 7 June 2022).

- Domínguez, R.; Barba, F.J.; Gómez, B.; Putnik, P.; Kovačević, D.B.; Pateiro, M.; Santos, E.M.; Lorenzo, J.M. Active packaging films with natural antioxidants to be used in meat industry: A review. Food Res. Int. 2018, 113, 93–101.

- Cao, W.; Hench, L.L. Bioactive materials. Ceram. Int. 1996, 22, 493–507.

- Coma, V. Bioactive packaging technologies for extended shelf life of meat-based products. Meat Sci. 2008, 78, 90–103.

- Azadbakht, E.; Maghsoudlou, Y.; Khomiri, M.; Kashiri, M. Development and structural characterization of chitosan films containing Eucalyptus globulus essential oil: Potential as an antimicrobial carrier for packaging of sliced sausage. Food Packag. Shelf Life 2018, 17, 65–72.

- Ríos, J.L. Essential Oils: What They Are and How the Terms Are Used and Defined, Essential Oils in Food Preservation. In Essential Oils in Food Preservation, Flavor and Safety; Preedy, V.R., Ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 3–10.

- Aziz, Z.A.; Ahmad, A.; Setapar, S.H.M.; Karakucuk, A.; Azim, M.M.; Lokhat, D.; Rafatullah, M.; Ganash, M.; Kamal, M.A.; Ashraf, G.M. Essential oils: Extraction techniques, pharmaceutical and therapeutic potential-a review. Curr. Drug Metab. 2018, 19, 1100–1110.

- Rehman, A.; Jafari, S.M.; Aadil, R.M.; Assadpour, E.; Randhawa, M.A.; Mahmood, S. Development of active food packaging via incorporation of biopolymeric nanocarriers containing essential oils. Trends Food Sci. Technol. 2020, 101, 106–121.

- Ribeiro-Santos, R.; de Melo, N.R.; Andrade, M.; Sanches-Silva, A. Potential of migration of active compounds from protein-based films with essential oils to a food and a food simulant. Packag. Technol. Sci. 2017, 30, 791–798.

- El Asbahani, A.; Miladi, K.; Badri, W.; Sala, M.; Addi, E.A.; Casabianca, H.; El Mousadik, A.; Hartmann, D.; Jilale, A.; Renaud, F.N.R.; et al. Essential oils: From extraction to encapsulation. Int. J. Pharm. 2015, 483, 220–243.

- Burt, S. Essential oils: Their antibacterial properties and potential applications in foods—A review. Int. J. Food Microbiol. 2004, 94, 223–253.

- Food and Drug Administration (FDA) CFR—Code of Federal Regulations Title 21, 2021. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/CFRSearch.cfm?fr=182.20 (accessed on 20 May 2022).

- Fernández-Pan, I.; Carrión-Granda, X.; Maté, J.I. Antimicrobial efficiency of edible coatings on the preservation of chicken breast fillets. Food Control 2014, 36, 69–75.

- Dainelli, D.; Gontard, N.; Spyropoulos, D.; Zondervan-van den Beuken, E.; Tobback, P. Active and intelligent food packaging: Legal aspects and safety concerns. Trends Food Sci. Technol. 2008, 19, S103–S112.

- Cruz, J.N.; de Oliveira, M.S.; Andrade, E.H.D.A.; Rodrigues Lima, R. Molecular Modeling Approaches Can Reveal the Molecular Interactions Established between a Biofilm and the Bioactive Compounds of the Essential Oil of Piper divaricatum. Molecules 2022, 27, 4199.

More