Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 3 by Ning Wang and Version 2 by Rita Xu.

Triboelectric nanogenerators (TENGs) have attracted much attention because they not only efficiently harvest energy from the surrounding environment and living organisms but also serve as multifunctional sensors toward the detection of various chemical and physical stimuli. In particular, biodegradable TENG (BD-TENG) represents an emerging type of self-powered device that can be degraded, either in physiological environments as an implantable power source without the necessity of second surgery for device retrieval, or in the ambient environment to minimize associated environmental pollution.

- biodegradable polymers

- triboelectric nanogenerator

- energy harvester

1. Introduction

In current era, the rapid growth of the internet of things (IoTs) represented by wearable electronic devices and wireless sensor networks has changed every aspect of our daily life, such as health monitoring, medical treatment, communication, entertainment, transportation, environmental protection, infrastructure monitoring, and security [1][2][3][4]. However, in order to ensure reliable and continuous operation of the sensing nodes, so as to realize the full power of IoTs, there arises an urgent demand for prosperous and sustainable energy harvesting devices which can scavenge energies from the ambient environment or our body and charge energy storage devices in a continuous way [5][6][7][8][9]. Meanwhile, there is also a rising dependence of advanced health monitoring and therapeutic technologies on biocompatibility or biodegradability, where biodegradable electronic components can be degraded and disintegrated into monomeric and oligomeric building blocks, thereby reducing their environmental and physiological impacts [10][11][12][13].

Since the first report of Wang’s team in 2012, TENG has been widely used in green electronic systems, not only for self-powered green electronic systems, but also as an active electronic sensor to detect various chemical and physical inputs [14][15]. By harvesting mechanical energy from the surrounding environment and organisms, it can generate green power for real-time monitoring, such as human/animal body, joint movement, all kinds of vibration, deformation, sound wave, liquid/air flow, wind flow, and even electronic health care monitoring [16][17][18][19][20][21][22]. Since then, many studies have been conducted to improve its electrical performance, sustainability, quality, and adaptability [23][24][25]. Due to the fact that the operation of TNEG is based on the coupled effects of triboelectrification and electrostatic induction, polymers such as polytetrafluoroethylene (PTFE), polyvinylidene fluoride (PVDF), nylon, and other organic–inorganic composites have been quite legitimately explored as triboelectric materials due to their position in the triboelectric polarity series [1][11][26][27][28][29][30]. On the one hand, the wide option of triboelectric materials brings tremendous advantages such as low cost, high efficiency, extensive use, and the possibility of continued ascension. On the other hand, like other non-degradable electronics, TENG also causes environmental problems at the end of its useful life, and will eventually be thrown into a landfill or abandoned in an unprotected dump site [31][32][33][34].

Meanwhile, BD-TENG represents a trend in developing green electronic devices. It can be degraded naturally in our environment or resorbed in the body after completing its work cycle without any adverse long-term effects or secondary surgical removal, thus avoiding environmental pollution and improving our health [35][36]. Presently, tunable electrical output capabilities and degradation features can be achieved by using different biodegradable materials. As a result, BD-TENGs with the advantages of biocompatibility, controllability, and biodegradability are fabricated and will find wide applications in in vivo biomechanical energy harvesting and self-powered sensors [37][38][39][40][41][42].

At present, numerous environmentally friendly biodegradable materials, including cellulose, chitin, and silk fibroin, have been found to have biocompatibility, biodegradability, and triboelectric effects [43][44]. For instance, in 2015, Luca Valentini and colleagues took the initiative to employ biodegradable polymer materials into TENG [45]. The solvent casting approach created a TENG based on a biodegradable sodium alginate/graphene oxide nanocomposite sheet. Zheng et al. reported an implantable BD-TENG in 2016 [46]. Due to the layered structure formed by biodegradable polymers (BDPs) and absorbable metal, the biodegradable polymer materials used are poly (lactic acid glycolic acid) copolymer (PLGA), poly (caprolactone) (PCL), polyvinyl alcohol (PVA), poly (hydroxybutyrate valerate) (PHB/V). These polymers are characterized by low cost, commercial purchase, simple processing, etc. At the same time, the component materials can be selected according to the different ability of the triboelectric layer to gain and lose electrons. As a result, the adjustable output voltage of 10~40 V in vitro can be achieved [40][41][42][43]. BD-TENG can be degraded and reabsorbed after completing its work cycle in animals. What’s more, according to the different degradation rates in vivo, the packaging materials can be changed to make the degradation rate of the whole device controllable. Accordingly, Hyun Jun Kim et al. reported a silk-based Bio-TENG in the same year [47]. Since 2017, many studies on BD-TENG from plants have steadily been carried out. So far, BD-TENG has been studied from multiple perspectives including energy harvesting, signal detection, medical care, and other procedures, among which more BDPs have been utilized [31].

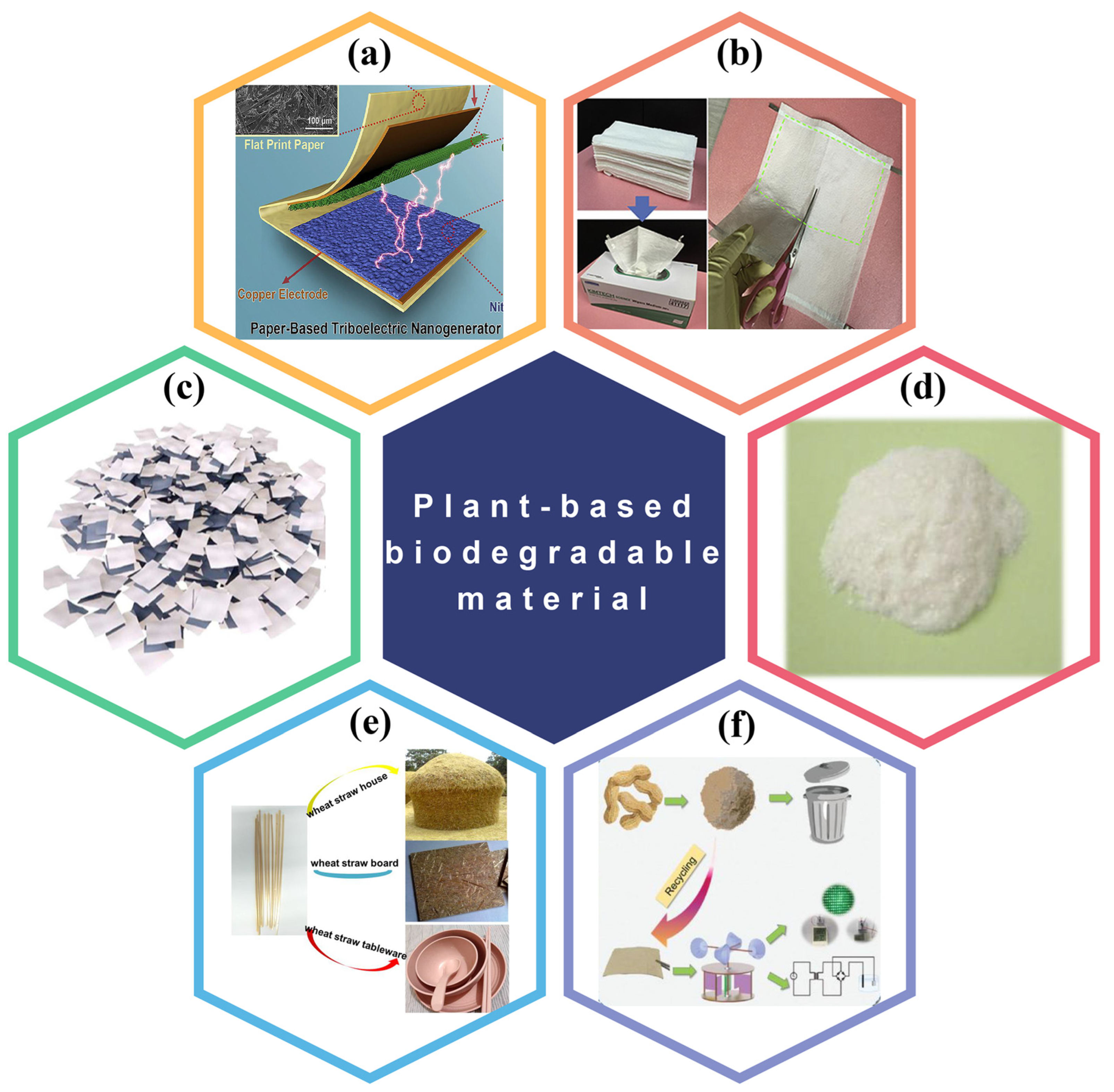

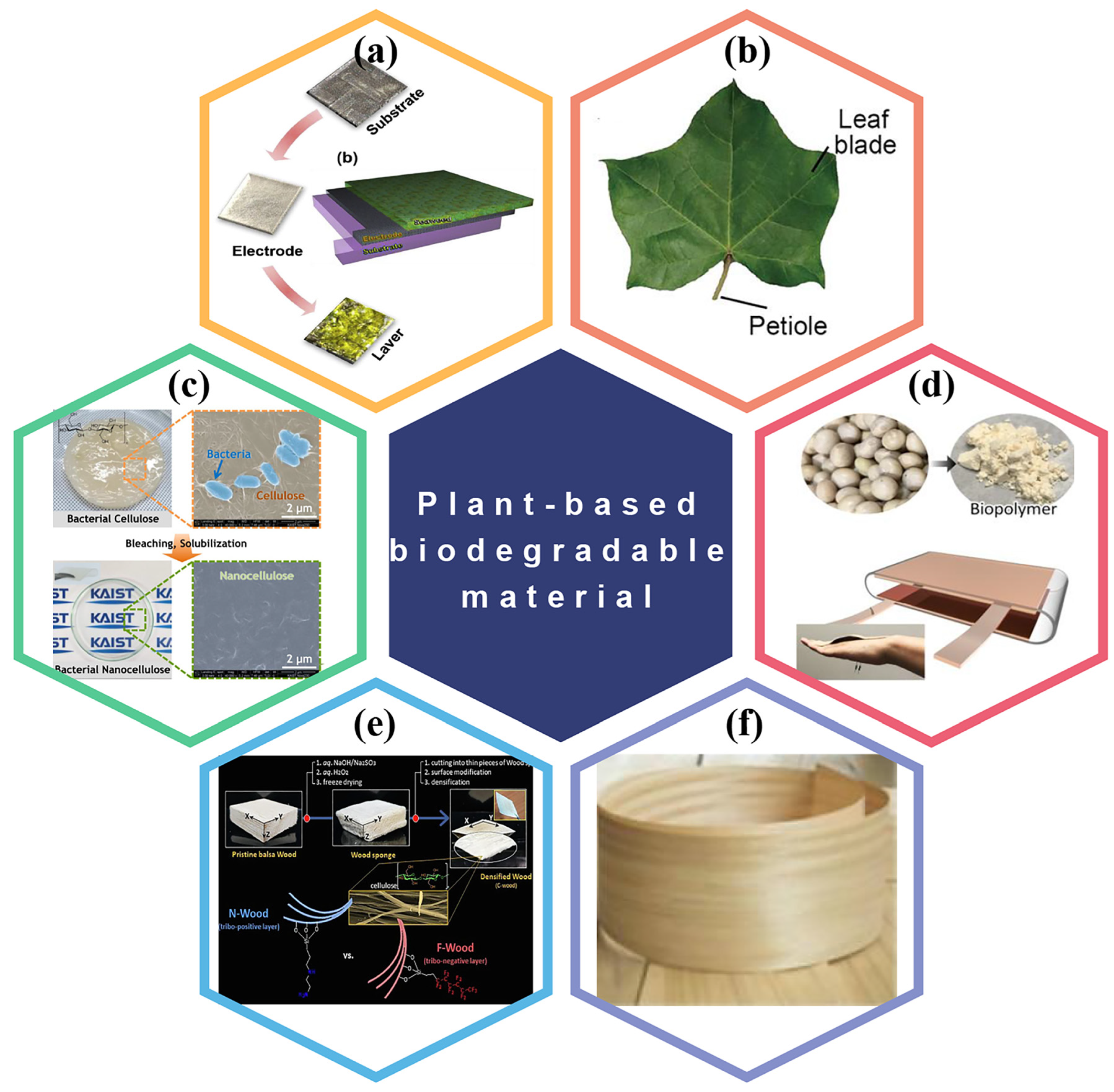

For convenience, BDPs are divided into three categories according to different sources: plant-based BDPs, animal-based BDPs, and synthetic BDPs. Plant-based BDPs are degradable materials that are extracted from plant sources, such as leaves, wood and cellulose molecules, alginate, rice paper, etc. Similarly, animal-based degradable materials refer to BDPs that are from animal sources, such as chitosan, silk fibroin, and gelatin. Synthetic BDPs are biodegradable substances processed in industry, such as PLA (polylactic acid), PHB/V (polyhydroxy butyrate valerate), PCL (polycaprolactone), etc. With the utilization of these green energy materials, energy harvesting technologies have significantly changed in vitro/in vivo biomedical science and made breakthroughs in the pollution-free reuse of biological wastes (Figure 1).

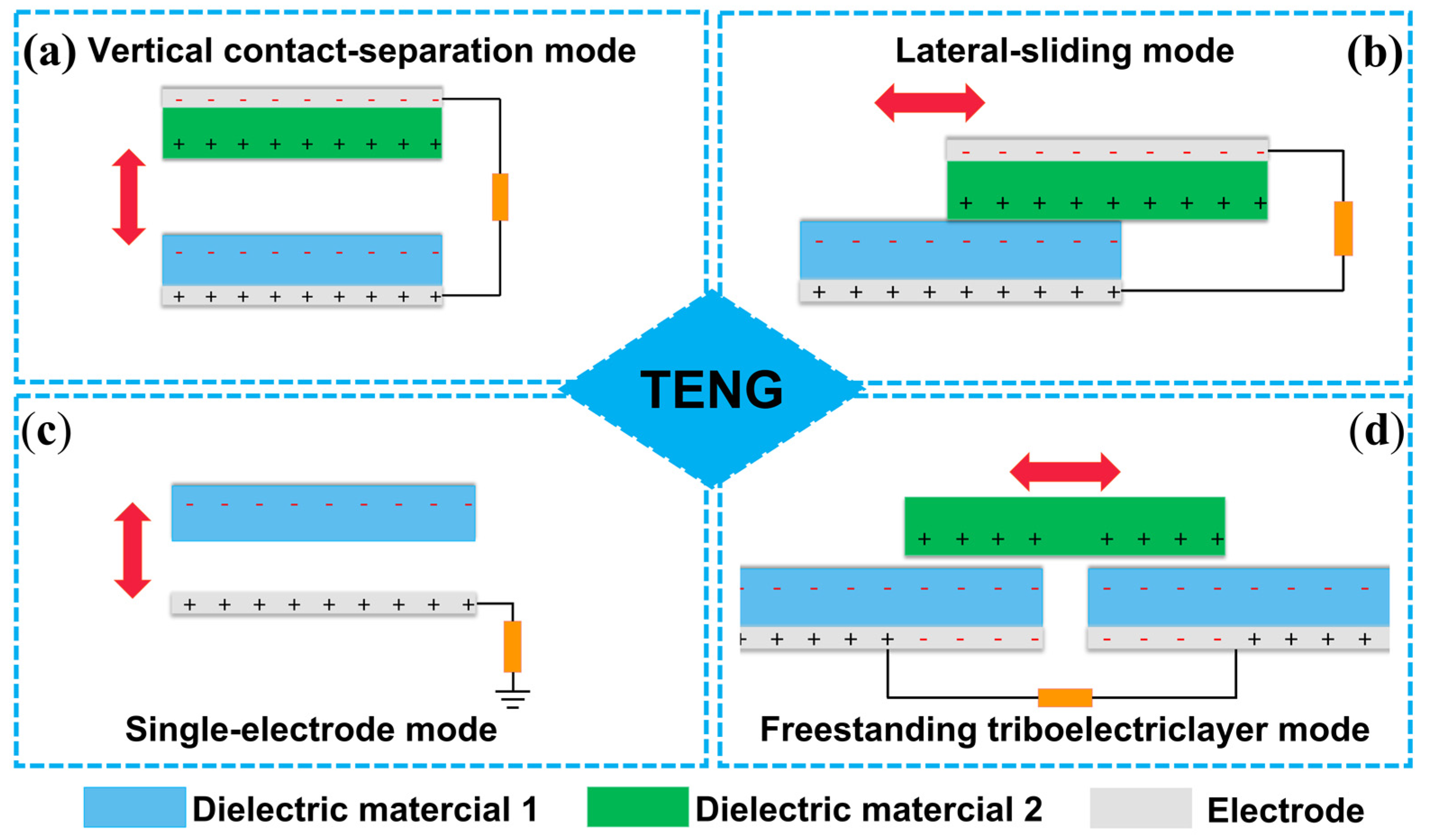

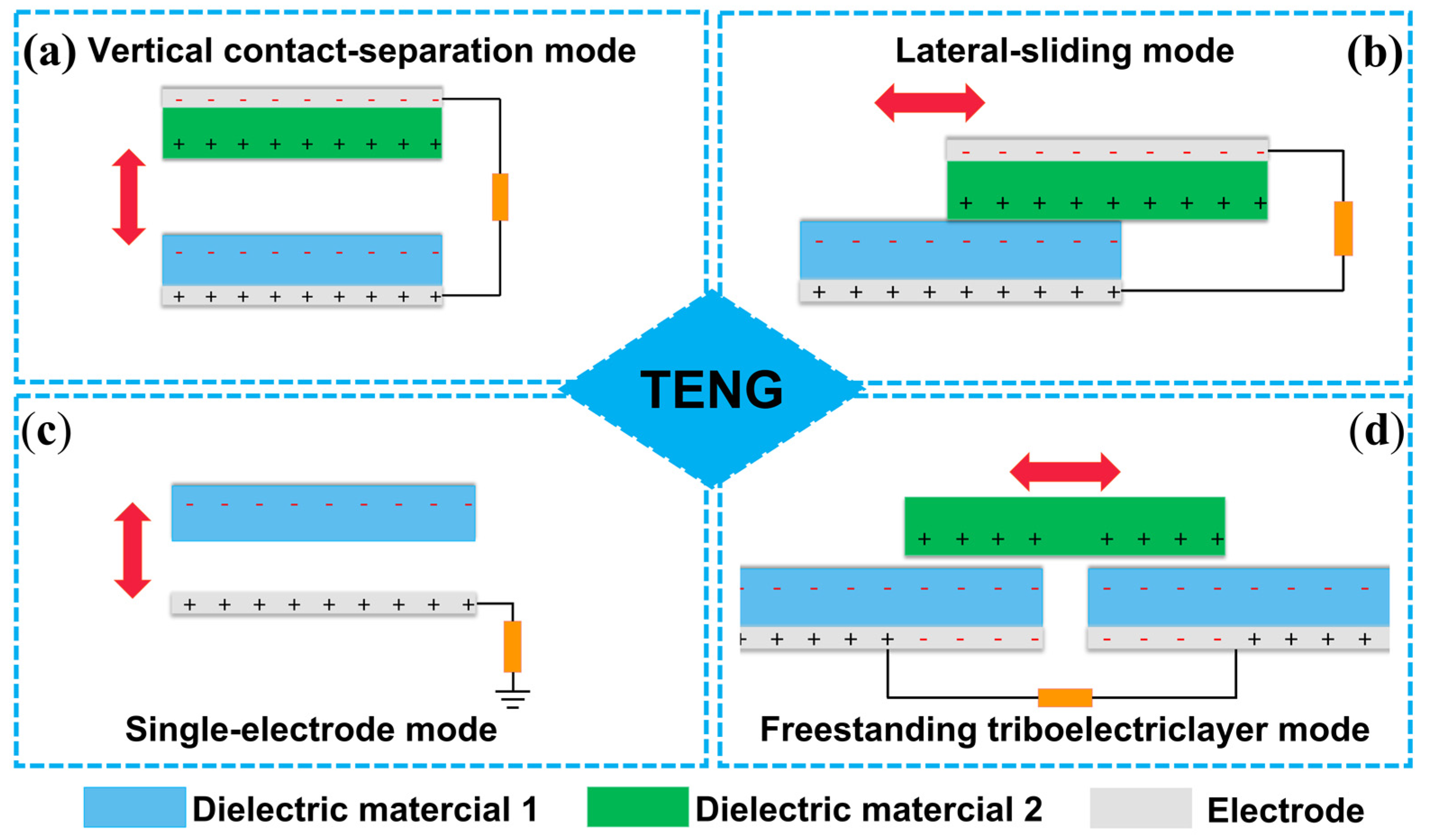

The first mode of TENG development is vertical contact separation (Figure 2a). It consists of two different materials with different triboelectric surface potentials. The triboelectric layers come in touch with one another when an external mechanical force is applied, and this causes the triboelectric layer to produce a surface charge. Potential differences occur due to the separation of the two triboelectric surfaces when the mechanical force is released. Electrostatic induction makes an electric charge on the metal electrode attached to the triboelectric layer’s outer surface. To shield the potential difference created by the free charge carrier, the carrier passes over the electrode, producing a pulse of current [50][51]. The harvester is positioned on the triboelectric layer’s outer surface, and it is made up of two triboelectric layers that are vertically separated. This model has been investigated the most because of its straightforward structure [52][53].

The second is the lateral sliding mode (Figure 2b), which is due to the relative sliding of two triboelectric layers and generates triboelectric surface charges. Sliding can be caused by various mechanical motions, including disk and cylinder rotation, plane motion, and more. Different grating structures have been created for transverse sliding mode TENG with outstanding energy harvesting capability. TENG can also produce energy during stretching and be employed successfully in this mode [54][55].

The third is a single electrode mode consisting of a metal or a triboelectric layer grounded through a load resistor (Figure 2c). This model is independent and unrestricted, where any object in contact with triboelectric materials, including human hands can generate triboelectric surface charges. Besides, the two triboelectric layers can be separated without the use of a spacer. Thanks to the single dielectric layer and electrode-only structure, the deformable or self-repairing TENG is simple to realize [56].

The fourth mode is the freestanding triboelectric layer mode, which is composed of freestanding dielectric layers and symmetrical electrodes (Figure 2d). Currents are caused by the contact and subsequent separation of the separate triboelectric layer from the electrode, which results in a potential difference between the two electrodes. The independent TENG can also be divided into contact separation type and sliding type according to the contact mode of the triboelectric layers. Each mode of TENG has its specific benefits and uses [57][58].

The first mode of TENG development is vertical contact separation (Figure 2a). It consists of two different materials with different triboelectric surface potentials. The triboelectric layers come in touch with one another when an external mechanical force is applied, and this causes the triboelectric layer to produce a surface charge. Potential differences occur due to the separation of the two triboelectric surfaces when the mechanical force is released. Electrostatic induction makes an electric charge on the metal electrode attached to the triboelectric layer’s outer surface. To shield the potential difference created by the free charge carrier, the carrier passes over the electrode, producing a pulse of current [50][51]. The harvester is positioned on the triboelectric layer’s outer surface, and it is made up of two triboelectric layers that are vertically separated. This model has been investigated the most because of its straightforward structure [52][53].

The second is the lateral sliding mode (Figure 2b), which is due to the relative sliding of two triboelectric layers and generates triboelectric surface charges. Sliding can be caused by various mechanical motions, including disk and cylinder rotation, plane motion, and more. Different grating structures have been created for transverse sliding mode TENG with outstanding energy harvesting capability. TENG can also produce energy during stretching and be employed successfully in this mode [54][55].

The third is a single electrode mode consisting of a metal or a triboelectric layer grounded through a load resistor (Figure 2c). This model is independent and unrestricted, where any object in contact with triboelectric materials, including human hands can generate triboelectric surface charges. Besides, the two triboelectric layers can be separated without the use of a spacer. Thanks to the single dielectric layer and electrode-only structure, the deformable or self-repairing TENG is simple to realize [56].

The fourth mode is the freestanding triboelectric layer mode, which is composed of freestanding dielectric layers and symmetrical electrodes (Figure 2d). Currents are caused by the contact and subsequent separation of the separate triboelectric layer from the electrode, which results in a potential difference between the two electrodes. The independent TENG can also be divided into contact separation type and sliding type according to the contact mode of the triboelectric layers. Each mode of TENG has its specific benefits and uses [57][58].

Starch is a widely obtained simple, renewable, eatable, and easily-degrading polymer. Its significant presence of amorphous regions in the form of films and a large number of -OH groups can provide a suitable matrix for cation and ion dissolution, resulting in enhanced dielectric properties in TENGs. Recently, rice paper has been considered as a viable component for constructing biodegradable substrates because it is inexpensive and generally commercially available, compared to other alternatives (such as polymers). Developing high-performance TENG using recyclable rice paper’s has been widely researched. For example, Chi et al. suggested a new BD-TENG that operates on a single electrode [64]. As shown in Figure 3d, Rice paper and transparent conductive ink, both biodegradable materials, are employed as triboelectric materials and conductive electrodes, respectively.

Starch is a widely obtained simple, renewable, eatable, and easily-degrading polymer. Its significant presence of amorphous regions in the form of films and a large number of -OH groups can provide a suitable matrix for cation and ion dissolution, resulting in enhanced dielectric properties in TENGs. Recently, rice paper has been considered as a viable component for constructing biodegradable substrates because it is inexpensive and generally commercially available, compared to other alternatives (such as polymers). Developing high-performance TENG using recyclable rice paper’s has been widely researched. For example, Chi et al. suggested a new BD-TENG that operates on a single electrode [64]. As shown in Figure 3d, Rice paper and transparent conductive ink, both biodegradable materials, are employed as triboelectric materials and conductive electrodes, respectively.

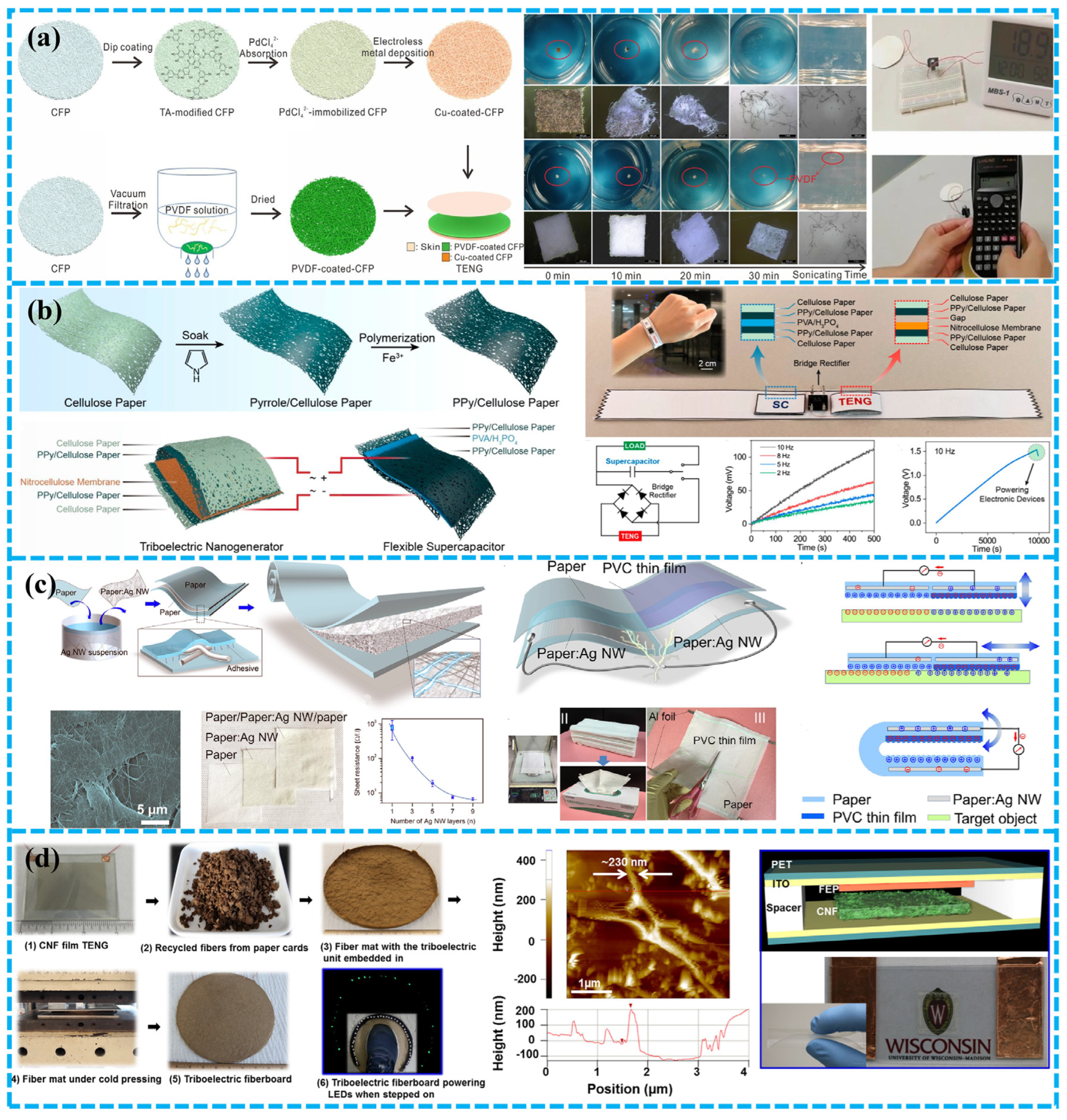

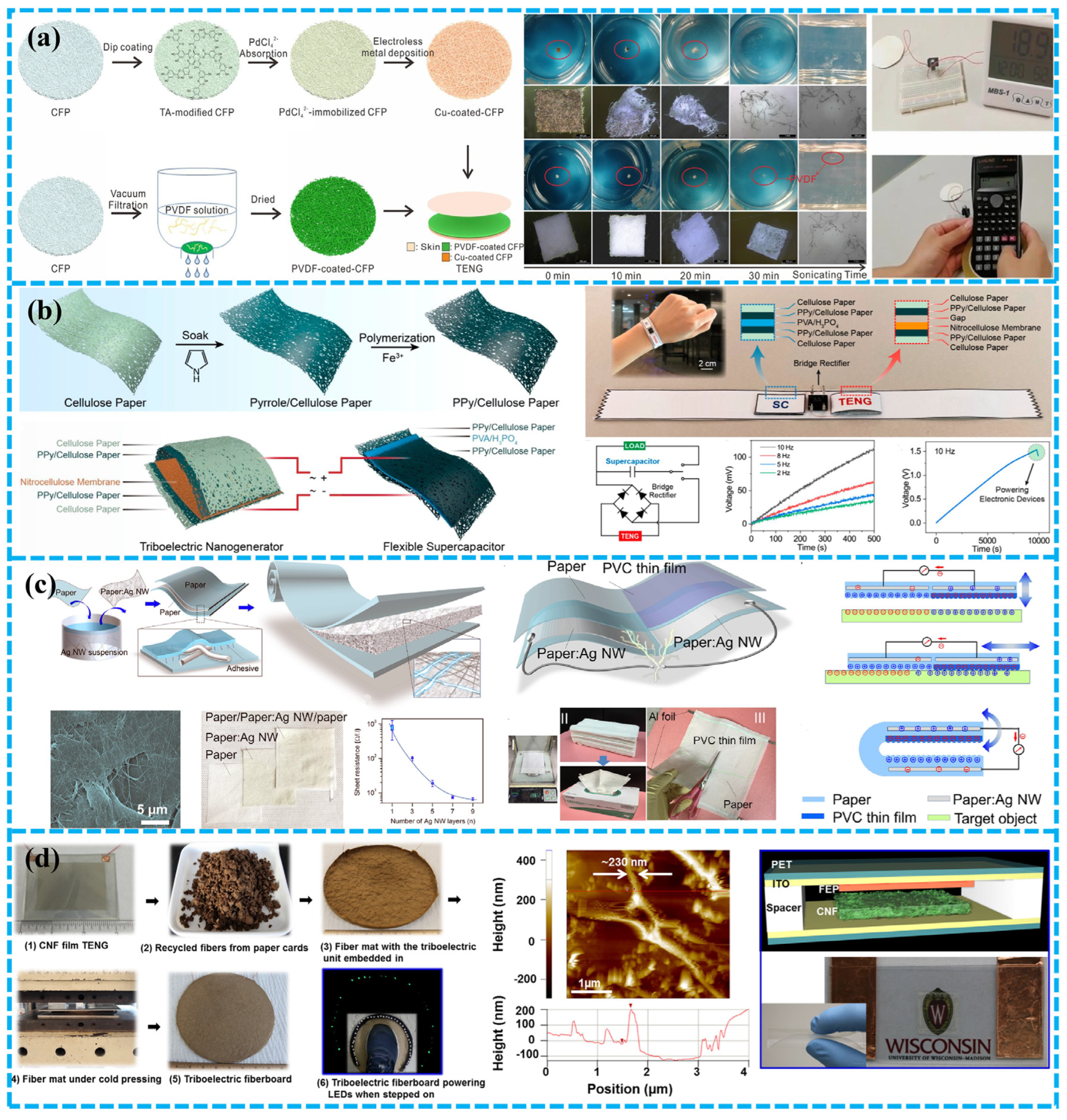

Cellulose paper can be used as an electrode along with a substrate and triboelectric layers. Shi et al. created portable and long-lasting SCPs by combining paper-based TENG with paper-based SC [83]. Cellulose paper showed excellent conductivity after coating with polypyrrole (PPy), The cellulose paper/PPy composite material was then employed as an electrode, cellulose paper was used as the positive triboelectric layer, and nitrocellulose membrane NCM as the negative triboelectric layer (Figure 5b). P-TENG exhibited good triboelectric characteristics (with a Voc of 60 V and a power density of 0.83 W m−2). In addition to this, the technology was also developed for applications in self-powered devices. As a flexible, ultralight, and renewable power source, the created SCP can be used to power various electronic devices, demonstrating its potential in flexible and compact green technologies. This research provides essential inspiration for developing degradable TENG made of cellulose paper.

Considering portability, Wu et al. have demonstrated a cutting P-TENG to collect mechanical energy [40]. P-TENG has the advantages of excellent flexibility, lightweight, high conductivity and low cost, and can work normally after being cut into any shape. It can obtain mechanical energy, body movement energy, sound energy and wind energy. By measuring the effectiveness of electronic transmission, the TENG can distinguish many materials, including glass, cotton and wood (Figure 5c).

CNF is a renewable, biodegradable and rich material, and Yao et al. have studied its application in TENG structures, [84]. The flexible transparent CNF film with its nano-structure was used as positive triboelectric material (Figure 5d). When it is trampled by normal people, it can generate up to ~30 V and ~90 μA current to illuminate the 35 LEDs integrated with a power fiberboard which has strong recyclability and excellent mechanical integrity. When it is trampled by normal people, it will generate up to ~30 V and ~90 μA current to illuminate the 35 LEDs integrated with the power fiberboard. This proves the great potential of producing friction electric Bakelite/fiberboard or flooring on a wide range of eco-friendly scales. It can be predicted that CNF and other woods will play an important role in the dynamic development of flooring, packaging and auxiliary infrastructure, as well as the unique ability to efficiently obtain mechanical energy from the environment.

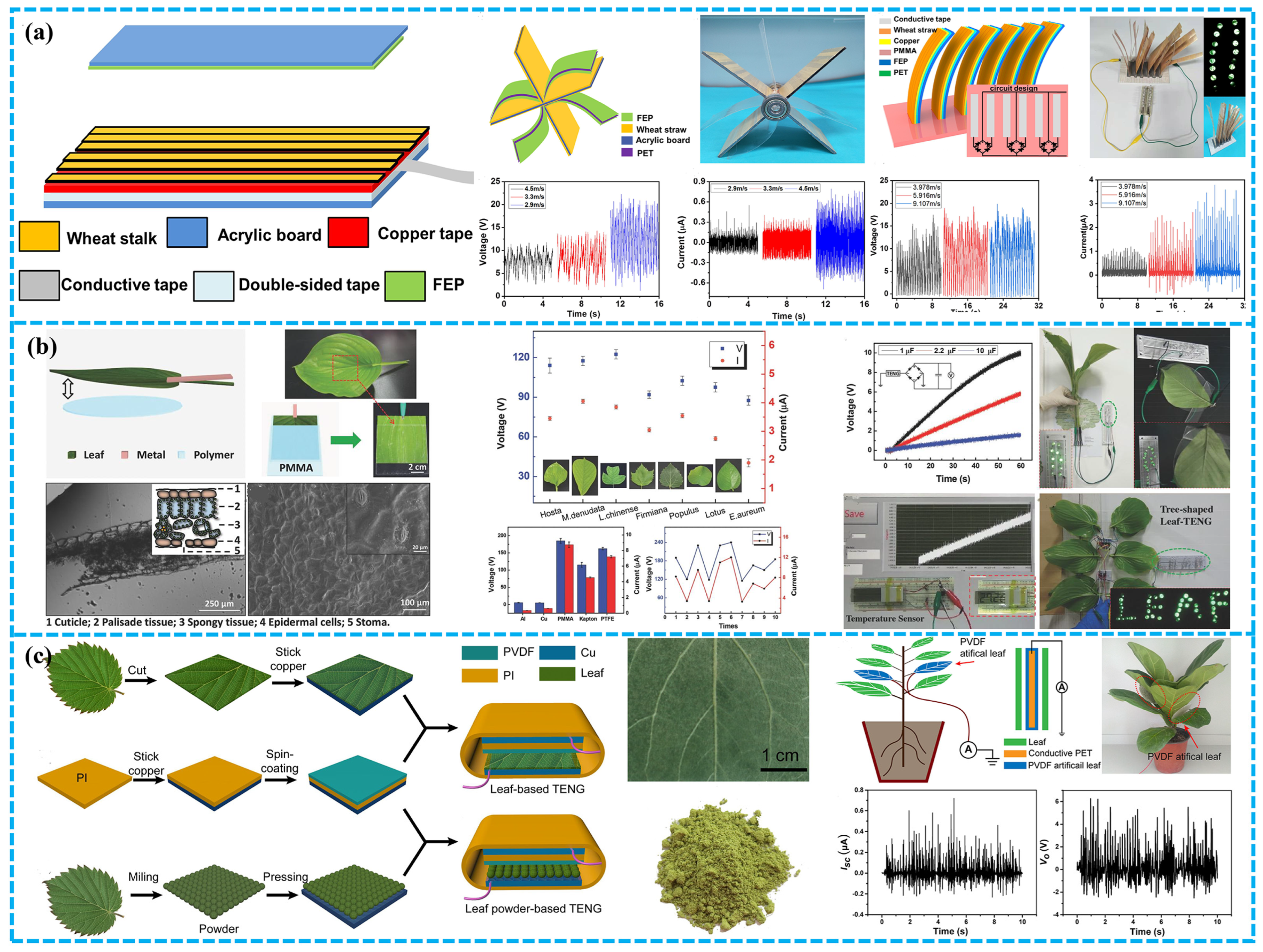

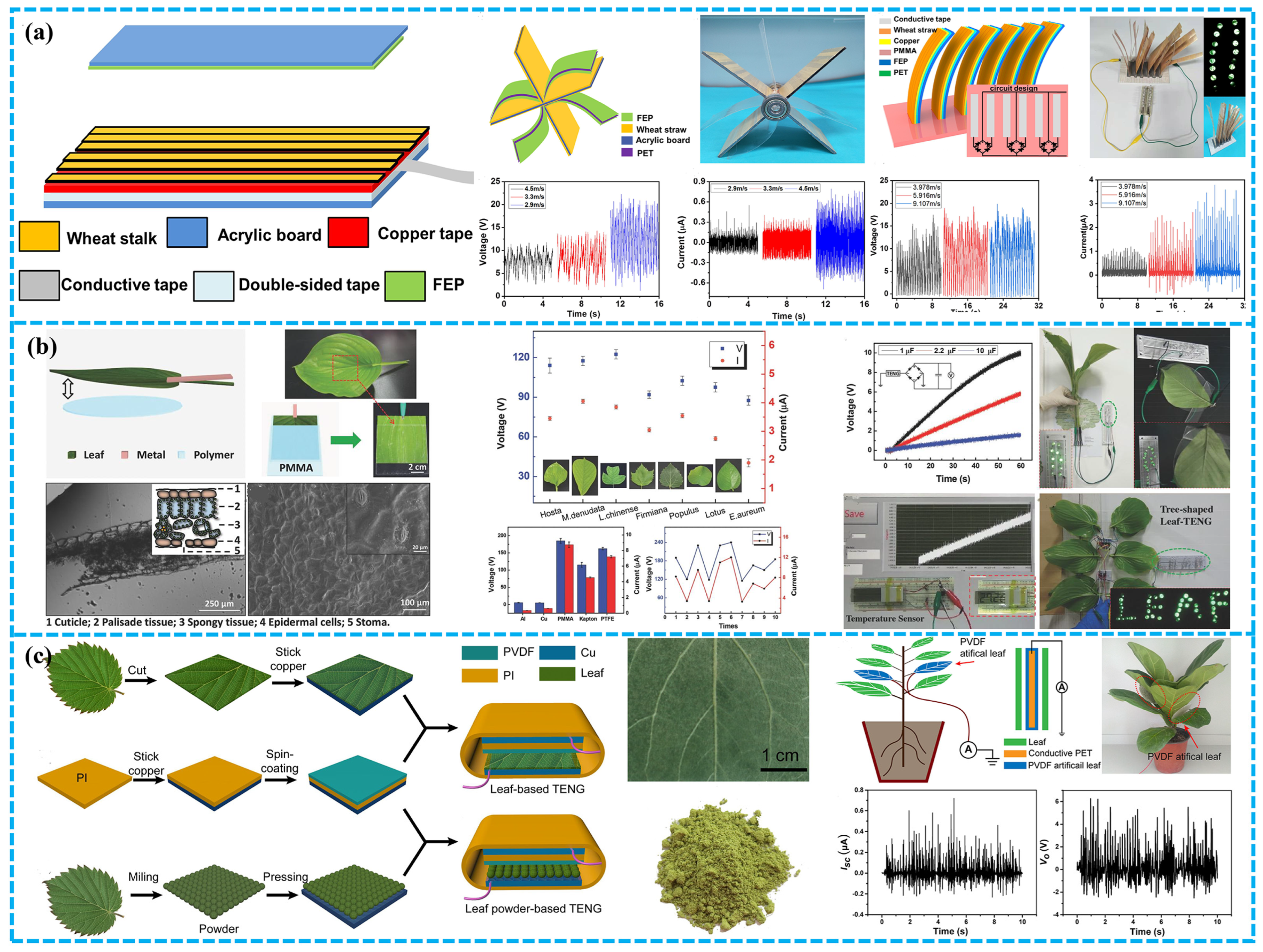

Ma et al. has structured a wheat straw natural WS-TENG that can switch from mechanical energy to electrical energy [70]. WS-TENG performs well in terms of output and it can charge not just capacitors but also several portable electronic devices such as hygrometers and electronic watches (Figure 6a). More intriguingly, the researcher built WS-TENG into a windmill and bionic lawn, which can be used as a wind speed sensor. This BD-TENG offers a novel answer for advanced science and technology employed in agricultural production and self-powered sensors used for energy harvesting and application.

Cellulose paper can be used as an electrode along with a substrate and triboelectric layers. Shi et al. created portable and long-lasting SCPs by combining paper-based TENG with paper-based SC [83]. Cellulose paper showed excellent conductivity after coating with polypyrrole (PPy), The cellulose paper/PPy composite material was then employed as an electrode, cellulose paper was used as the positive triboelectric layer, and nitrocellulose membrane NCM as the negative triboelectric layer (Figure 5b). P-TENG exhibited good triboelectric characteristics (with a Voc of 60 V and a power density of 0.83 W m−2). In addition to this, the technology was also developed for applications in self-powered devices. As a flexible, ultralight, and renewable power source, the created SCP can be used to power various electronic devices, demonstrating its potential in flexible and compact green technologies. This research provides essential inspiration for developing degradable TENG made of cellulose paper.

Considering portability, Wu et al. have demonstrated a cutting P-TENG to collect mechanical energy [40]. P-TENG has the advantages of excellent flexibility, lightweight, high conductivity and low cost, and can work normally after being cut into any shape. It can obtain mechanical energy, body movement energy, sound energy and wind energy. By measuring the effectiveness of electronic transmission, the TENG can distinguish many materials, including glass, cotton and wood (Figure 5c).

CNF is a renewable, biodegradable and rich material, and Yao et al. have studied its application in TENG structures, [84]. The flexible transparent CNF film with its nano-structure was used as positive triboelectric material (Figure 5d). When it is trampled by normal people, it can generate up to ~30 V and ~90 μA current to illuminate the 35 LEDs integrated with a power fiberboard which has strong recyclability and excellent mechanical integrity. When it is trampled by normal people, it will generate up to ~30 V and ~90 μA current to illuminate the 35 LEDs integrated with the power fiberboard. This proves the great potential of producing friction electric Bakelite/fiberboard or flooring on a wide range of eco-friendly scales. It can be predicted that CNF and other woods will play an important role in the dynamic development of flooring, packaging and auxiliary infrastructure, as well as the unique ability to efficiently obtain mechanical energy from the environment.

Ma et al. has structured a wheat straw natural WS-TENG that can switch from mechanical energy to electrical energy [70]. WS-TENG performs well in terms of output and it can charge not just capacitors but also several portable electronic devices such as hygrometers and electronic watches (Figure 6a). More intriguingly, the researcher built WS-TENG into a windmill and bionic lawn, which can be used as a wind speed sensor. This BD-TENG offers a novel answer for advanced science and technology employed in agricultural production and self-powered sensors used for energy harvesting and application.

Jie et al. presented a green and environmentally friendly innovative blade-assembled Leaf-TENG that can efficiently harvest environmentally and mechanical energy using natural leaves [85]. Under optimal circumstances, the peak values of Voc, Isc, and maximum output power of natural Leaf-TENG in single electrode mode can reach around 230 V, 9.5 µA, and 45 mW m−2 (Figure 6b). Natural Leaf-TENG has been indicated to be competent for powering LEDs and charging capacitors, indicating that it has excellent mechanical energy harvesting capability. The natural Leaf-TENG was constructed autonomously into a tree-shaped energy harvester to gather mechanical energy from the environment over a vast region. Similarly, Feng et al. constructed a TENG using biodegradable natural plant leaves and dry leaf powder to harvest wind energy and obtained high Voc (430, 560 V) and Isc (15, 25 µA) accordingly [86]. To tackle the problem of delicate contact and make maximum use of the leaves, dry leaves are ground into powder (Figure 6c). Poly-L-lysine is utilized to optimize the outputting capability of TENG. Because fresh leaves contain complimentary water, which lowers the electronic generation of natural plant leaves, the performance of dry powder leaf based TENG is better than that of plant leaves. As is shown, the TENG tree consists of both living and artificial foliage, which has promising application potential in distant areas and can be utilized for early warning and indicator lighting. Consequently, plentiful biodegradable materials can be employed to develop future energy.

BD-TENG has also been reported in the application of blue energy; for example, Pang et al. designed a BD-TENG using alginate membrane [63]. It can be used to collect water wave energy. This biodegradable and ecologically responsible TENG based on marine plants have broadened the application field of blue energy.

Jie et al. presented a green and environmentally friendly innovative blade-assembled Leaf-TENG that can efficiently harvest environmentally and mechanical energy using natural leaves [85]. Under optimal circumstances, the peak values of Voc, Isc, and maximum output power of natural Leaf-TENG in single electrode mode can reach around 230 V, 9.5 µA, and 45 mW m−2 (Figure 6b). Natural Leaf-TENG has been indicated to be competent for powering LEDs and charging capacitors, indicating that it has excellent mechanical energy harvesting capability. The natural Leaf-TENG was constructed autonomously into a tree-shaped energy harvester to gather mechanical energy from the environment over a vast region. Similarly, Feng et al. constructed a TENG using biodegradable natural plant leaves and dry leaf powder to harvest wind energy and obtained high Voc (430, 560 V) and Isc (15, 25 µA) accordingly [86]. To tackle the problem of delicate contact and make maximum use of the leaves, dry leaves are ground into powder (Figure 6c). Poly-L-lysine is utilized to optimize the outputting capability of TENG. Because fresh leaves contain complimentary water, which lowers the electronic generation of natural plant leaves, the performance of dry powder leaf based TENG is better than that of plant leaves. As is shown, the TENG tree consists of both living and artificial foliage, which has promising application potential in distant areas and can be utilized for early warning and indicator lighting. Consequently, plentiful biodegradable materials can be employed to develop future energy.

BD-TENG has also been reported in the application of blue energy; for example, Pang et al. designed a BD-TENG using alginate membrane [63]. It can be used to collect water wave energy. This biodegradable and ecologically responsible TENG based on marine plants have broadened the application field of blue energy.

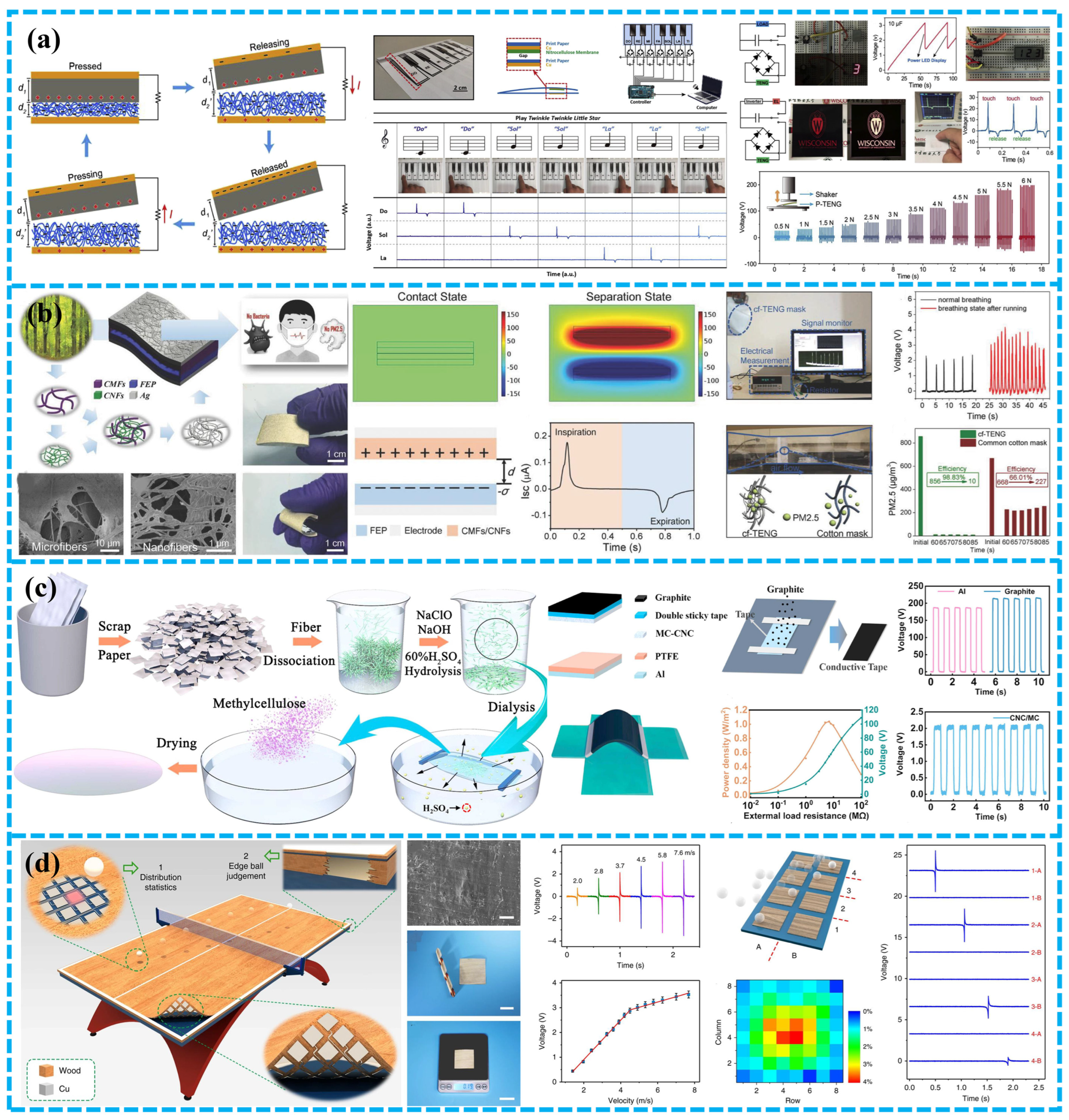

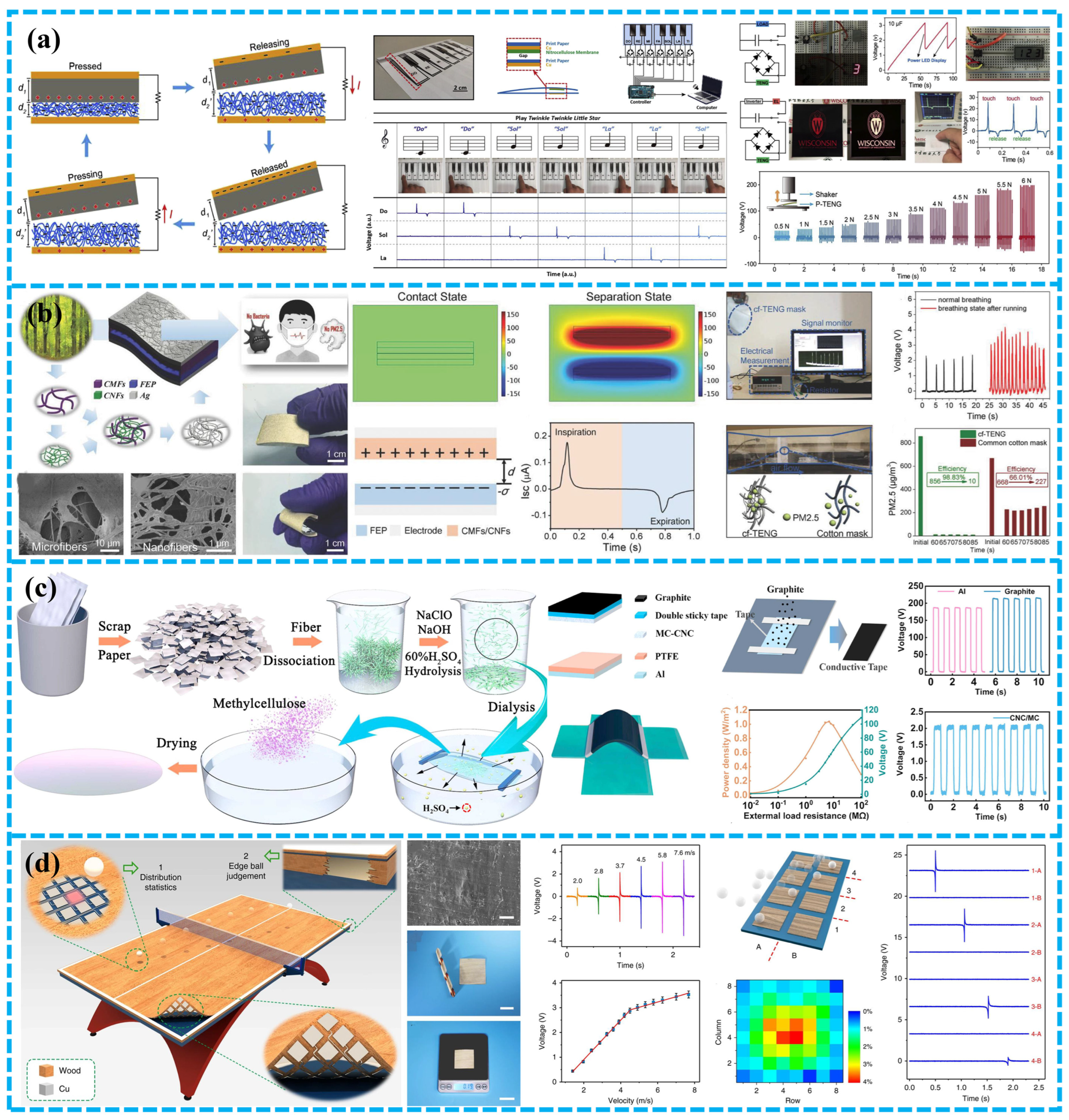

Real-time monitoring of human activities and vital signs is critical for health diagnosis and treatment. He et al. presented a cellulose fiber-based self-powered CF-TENG by converting one-dimensional environmentally friendly CMFs/CNFs into two-dimensional CMFs/CNFs/Ag hierarchical nanostructures [88]. The CF-TENG system exhibited an efficiency of 98.83% in removing PM2.5 and can monitor respiratory health without an external power source because of its perfect porous nanostructure and extraordinary power-generating properties (Figure 7b).

Recently, Wang et al. developed a BD-TENG to monitor human physiological signals using CNC and MC [69]. This low-cost, light weight, biodegradable WS-TENG bandage sensor can be directly rinsed with water. According to the change of output voltage, it can accurately distinguish various respiratory states (Figure 7c). This kind of real-time physiological signal monitoring sensor further expands the application of TENG in the medical monitoring field.

Zhu et al. has demonstrated a piece of disposable TENG equipment using environmentally friendly biodegradable starch paper [65]. The materials utilized are both inexpensive and widely available. S-TENG can be made with a simple procedure that combines starch paper and metal wire. This TENG can function as a self-powering human sweat sensor, indicating its potential application in wearable electronic products.

To create a flexible, robust, and high-performance TENG for self-powering sensing in motion big data analysis, Luo et al. used a straightforward and efficient two-step method to prepare wood films with outstanding physical and triboelectric characteristics as the triboelectric materials [89]. Adaptable and long-lasting W-TENG can produce a charge density of 36 C m−2, more than 70% greater than natural wood-based TENG (Figure 7d). W-TENG was also employed as an active sensor for intelligent table tennis tables with a speed-sensing system for motion tracking.

Recently, Wang et al. produced a flexible, biodegradable, and flame-resistant FR-TENG using biodegradable black phosphorus and phytic acid as flame retardants. Tannic acid-modified BPNS (TA-BPNS), and PA were added to CNF as non-toxic synergistic flame retardants as the triboelectric layer, and AgNWs were used as the conductive layer. The FR-TENG can be utilized for temperature sensing and as a fire alarm [90]. As a wearable micro/nano power source, FR-TENG can also harness the mechanical energy of human movement to power small electronic gadgets. Being a humidity sensor, the FR-TENG’s output voltage responds linearly to the surrounding humidity. In brief, FR-TENG has a wide range of potential applications in temperature monitoring, fire alarms, and multifunctional wearable electronic devices.

Real-time monitoring of human activities and vital signs is critical for health diagnosis and treatment. He et al. presented a cellulose fiber-based self-powered CF-TENG by converting one-dimensional environmentally friendly CMFs/CNFs into two-dimensional CMFs/CNFs/Ag hierarchical nanostructures [88]. The CF-TENG system exhibited an efficiency of 98.83% in removing PM2.5 and can monitor respiratory health without an external power source because of its perfect porous nanostructure and extraordinary power-generating properties (Figure 7b).

Recently, Wang et al. developed a BD-TENG to monitor human physiological signals using CNC and MC [69]. This low-cost, light weight, biodegradable WS-TENG bandage sensor can be directly rinsed with water. According to the change of output voltage, it can accurately distinguish various respiratory states (Figure 7c). This kind of real-time physiological signal monitoring sensor further expands the application of TENG in the medical monitoring field.

Zhu et al. has demonstrated a piece of disposable TENG equipment using environmentally friendly biodegradable starch paper [65]. The materials utilized are both inexpensive and widely available. S-TENG can be made with a simple procedure that combines starch paper and metal wire. This TENG can function as a self-powering human sweat sensor, indicating its potential application in wearable electronic products.

To create a flexible, robust, and high-performance TENG for self-powering sensing in motion big data analysis, Luo et al. used a straightforward and efficient two-step method to prepare wood films with outstanding physical and triboelectric characteristics as the triboelectric materials [89]. Adaptable and long-lasting W-TENG can produce a charge density of 36 C m−2, more than 70% greater than natural wood-based TENG (Figure 7d). W-TENG was also employed as an active sensor for intelligent table tennis tables with a speed-sensing system for motion tracking.

Recently, Wang et al. produced a flexible, biodegradable, and flame-resistant FR-TENG using biodegradable black phosphorus and phytic acid as flame retardants. Tannic acid-modified BPNS (TA-BPNS), and PA were added to CNF as non-toxic synergistic flame retardants as the triboelectric layer, and AgNWs were used as the conductive layer. The FR-TENG can be utilized for temperature sensing and as a fire alarm [90]. As a wearable micro/nano power source, FR-TENG can also harness the mechanical energy of human movement to power small electronic gadgets. Being a humidity sensor, the FR-TENG’s output voltage responds linearly to the surrounding humidity. In brief, FR-TENG has a wide range of potential applications in temperature monitoring, fire alarms, and multifunctional wearable electronic devices.

Figure 1. The schematic diagram shows the material sources (plant based, animal based, synthetic) and potential applications (energy collection, self-powered sensing, implantable medical devices) of BDPs proposed in BD-TENG. BD-TENG needs to combine biodegradability, biocompatibility and environmental friendliness.

2. Basic Principle and Working Modes of TENG

TENG was invented for harvesting mechanical energy on the base of the coupling of friction electrification and electrostatic induction [48][49]. In the triboelectric series, the relative position of two triboelectric layers determines the polarity of their surface electrostatic charges. TENG is divided into four different types according to the operation mode. There are four different modes: (1) vertical-contact separation mode, (2) lateral sliding mode, (3) single-electrode mode, and (4) freestanding triboelectric layer mode. (Figure 2) The electrodes and triboelectric layers of the four modes are arranged differently. The contact and separation of the triboelectric layer will change to generate electrostatic surface charges [50].

Figure 2. The four fundamental modes of TENG: (a) vertical contact-separation mode; (b) lateral-sliding mode; (c) single-electrode mode; and (d) freestanding triboelectric layer mode.

3. Current Progress in BD-TENGs

3.1. BD-TENGs Based Plant Polymers

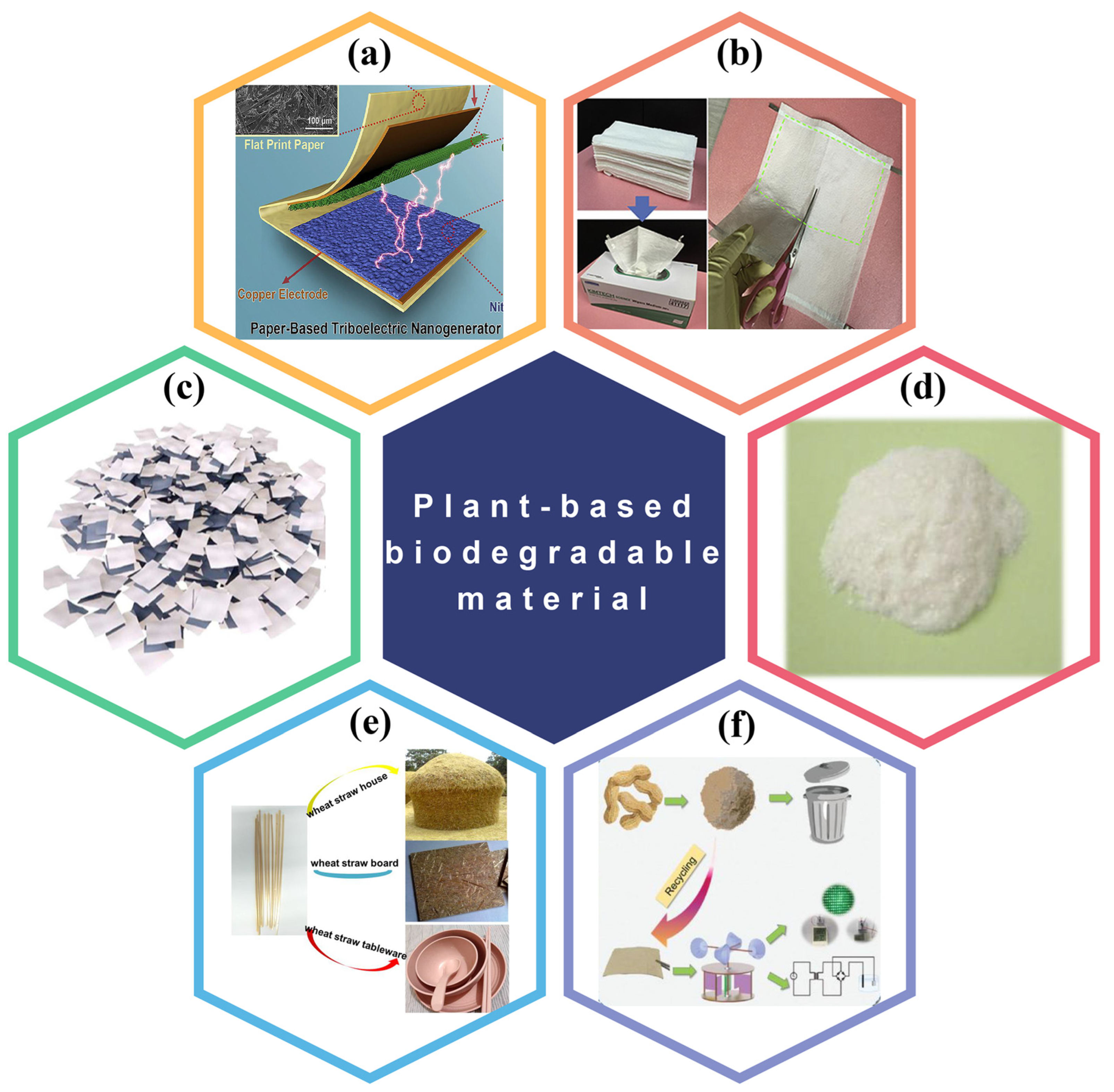

Recently, the fabrication of TENG has been combined with many plant-based BDPs for environmental protection and biodegradability. Currently, six types of plant degradable materials are used in TENG: paper-based cellulose, bacterial cellulose, leaves, wood, rice paper, plant straw and alginate, etc. [59][60]. Cellulose is one of the most common and abundant macromolecular polysaccharides in nature, accounting for more than half of the carbon in the plant kingdom. In plants, it is usually combined with hemicellulose, pectin, and lignin. Cellulose is one of the bottom materials in the triboelectric series, which has better electron loss capacity. Although these materials deteriorate in the presence of an acid, alkali, and specialized enzymes, the rate of deterioration depends on the material’s particular structure, and the specifically altered molecules can provide cellulose with improved physical and chemical characteristics, as well as greater capacity to transmit electrons [61][62]. For instance, alginate is a byproduct of iodine and mannitol extraction from kelp or Sargassum of brown algae [63], which is typically mixed with other components to generate a composite membrane by cross-linking. Furthermore, alginate materials are polysaccharide derivatives with good biocompatible and simple degradation; the presence of ions makes it easy to dissolve in water or other solutions. These features allow TENG’s manageable degeneration. In addition to the above, rice paper is also an excellent plant-based biodegradable material commonly utilized in TENG, one which can be easily degraded under natural conditions [64]. Starch, a popular edible polysaccharide derived from rice, corn, and other crops, is also the main raw material of BD-TENG. The main components of leaves are cellulose, a small amount of polysaccharide, and protein [65].3.1.1. BD-TENGs Based on Paper Cellulose and Starch

Paper-based cellulose is an excellent candidate material for environmentally friendly BD-TENG production because of its good biocompatibility, biodegradability, and recyclability. Biocompatibility is critical for implantation of wearable TENG to prevent rejection, pain, skin irritation, or inflammation [12][61]. Since TENG is biodegradable, it can be dissolved in the human body or in the environment with fewer side effects [66]. In addition, cellulose nanofibers (CNF) have special properties of transparency and high mechanical strength after special treatment, which provides a variety of possibilities for the design of BD-TENG [67]. Up to date, numerous cellulose paper-based TENGs have been produced on the basis of the material’s outstanding flexibility, portability, biodegradability, and reusability, where cellulose paper can be used as an electrode, triboelectric layer, substrate, or perhaps all three materials of TENG at the same time. By modifying cellulose paper, for example, increasing surface roughness and introducing functional groups, the output performance of paper based TENG can be significantly improved. By integrating cellulose paper-based TENG with other types of energy collectors (such as electromagnetic generators and solar panels), the hybrid nano generators can simultaneously collect multiple types of energy. In practical applications, cellulose paper-based TENG can be used as a sustainable power source for self-powered anti-corrosion and antifouling, self-powered electrochemical reaction and droplet controllable operation. It can also be used as an active sensor for pressure sensing, motion monitoring, sound recording and human-computer interaction. For example, Chen et al. developed a paper-based TENG (PTENG) using widely available cellulose derivatives [68]. The substrate of PTENG is made of printing paper, while the triboelectric layer of PTENG is made of crepe cellulose paper (CCP) and nitrocellulose membrane (NCM) (Figure 3a). This simple and economical method is essential to fabricate environmentally friendly electrical equipment. Wu et al. used a simple and scalable manufacturing process to obtain a PTENG with low cost and high mechanical energy harvesting capability (Figure 3b) [40]. These PTENGs are of great significance for developing green and portable energy-harvesting equipment.

Figure 3. Plant-based biodegradable materials used in BD-TENG. (a) A TENG based on CCP and NCM. Reproduced with permission [68]. Copyright 2019, Elsevier Ltd. (b) Conductive paper made of commercial tissue paper. Reproduced with permission [40], Copyright 2017, Elsevier Ltd. (c) Waste paper used in BD-TENG. Reproduced with permission [69], Copyright 2021, Elsevier Ltd. (d) Rice paper powder used in BD-TENG. Reproduced with permission [64], Copyright 2019, Elsevier B.V. (e) Wheat straw used as raw material for BD-TENG. Reproduced with permission [70], Copyright 2021, Elsevier Ltd. (f) Peanut shell powder used in BD-TENG. Reproduced with permission [71], Copyright 2022, Wiley & Sons, Ltd.

3.1.2. BD-TENGs Based on Micro/Nano Cellulose

Microcrystalline cellulose (MCC), cellulose nanofibers (CNF), and cellulose nanocrystals (CNC) are all types of micro/nano cellulose. The functional materials derived from cellulose have outstanding mechanical characteristics, perfect micro/nano surface roughness, and are lightweight [72]. For instance, Wang et al. developed a water-soluble TENG (WS-TENG) utilizing biodegradable recycled paper and a water-soluble graphite electrode [69]. CNC and methylcellulose (MC) are combined to form CNC/MC films, which are utilized as positive triboelectric materials, and regular MC films are as negative triboelectric materials (Figure 3c). This low-cost, lightweight, BD-WS-TENG can be directly washed away by water and developed as a bandage sensor.3.1.3. BD-TENGs Based on Crop Wastes and Edible Materials

As a renewable and readily biodegradable environmental protection material, plant straw shows excellent potential in replacing the traditional triboelectric layer. Wheat straw is commonly utilized as natural green manure because of its excellent degradability. For instance, Ma et al. structured a wheat straw natural WS-TENG that can switch from mechanical energy to electrical energy (Figure 3e) [70]. Similarly, peanut shell is a common crop waste generally treated as garbage, and occasionally simply burned in production. As a biodegradable material, however, it has certain advantages in developing BD-TENG due to its rich cellulose and lignin (Figure 3f) [71]. Meanwhile, using edible food materials to develop BD-TENG is also a meaningful research direction. For example, Khandelwal et al. designed a light edible TENG (E-TENG) [73]. The active layer is laver covered with edible silver leaves, the base is rice flakes, and the electrode is edible silver leaves (usually used for candy and oriental food) (Figure 4a). It can be quickly digested in phosphate-buffered saline (PBS) and gastric juice. It is expected to promote the development of edible energy and other electronic equipment such as edible and digestible functional equipment in the future.

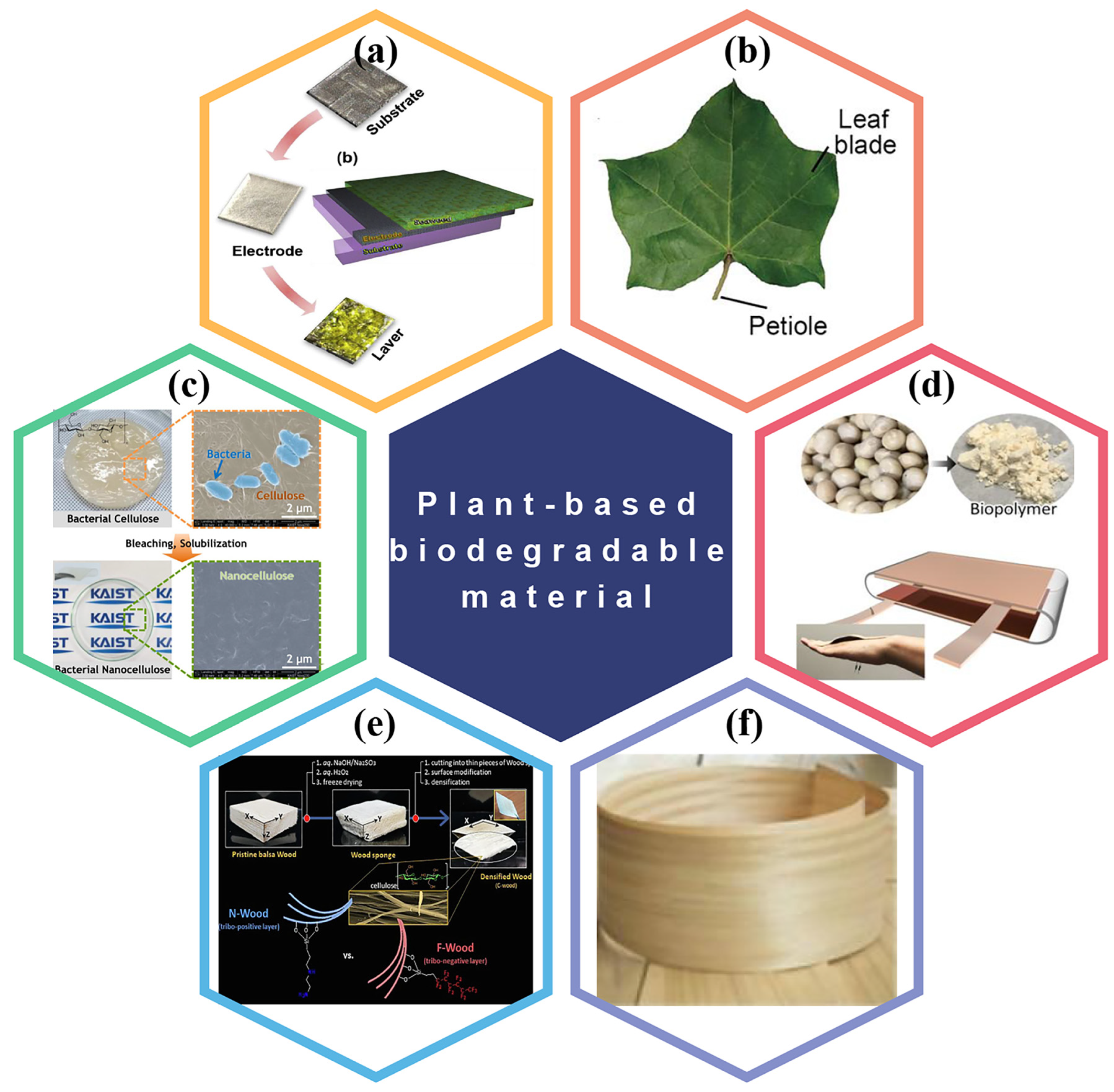

Figure 4. Plant-based biodegradable polymers used in BD-TENG. (a) All edible materials derived BD-TENG. Reproduced with permission [73], Copyright 2019, Elsevier Ltd. (b) Natural plant leaves used as triboelectric materials. Reproduced with permission [74], Copyright 2020, American Chemical Society. (c) Bacterial cellulose used as triboelectric material. Reproduced with permission [75], Copyright 2017, Elsevier Ltd. (d) Soybean protein and lignin used as triboelectric materials. Reproduced with permission [76], American Chemical Society. (e,f) Natural wood used as triboelectric material. Reproduced with permission [77], Copyright 2021, Elsevier B.V. Reproduced with permission [78], Copyright 2022, American Chemical Society.

3.1.4. BD-TENGs Based on Leaves

Building an intelligent interface between plants and the environment is important for real-time monitoring of plant health while harvesting energy. Harvesting wind energy and raindrops in the environment through plants can be used for various sensors, making agricultural automatic monitoring possible. The leaf is a naturally degradable material utilized in the manufacturing of BD-TENG. For example, Wu et al. reported a green TENG with blade cuticle and internal conductive tissue as the friction material and electrode, and water droplets as the corresponding substance (Figure 4b) [74]. This technology can be combined with urban greening, family gardens, woodlands, and islands for energy harvesting and sensing.3.1.5. BD-TENGs Based on Bacterial Cellulose

Bacterial cellulose is a porous reticular nanoscale biopolymer synthesized by microbial fermentation, and it is also a polymer with good degradation performance. It has unique biological affinity, biocompatibility, biodegradability, biological adaptability, and no allergic reaction. Therefore, bacterial cellulose shows excellent potential in biodegradable and environmentally friendly triboelectric active materials. For example, Kim et al. were the first to develop a bio-TENG based on bacterial nano-cellulose [75]. The triboelectric layer was made of a transparent, bendable bacterial nano-cellulose sheet. As a positive triboelectric material, the strong electrical feeding capabilities of copper film allows the bacterial nano-cellulose film to generate 4.8 mW m−2 of output power (Figure 4c). Zhang et al. built an environmentally friendly and renewable all-cellulose energy harvesting and interaction equipment using bacterial cellulose (BC) and conductive BC [79]. Under the condition of the cellulolytic enzyme, the active substance can be completely degraded within 8 h.3.1.6. BD-TENGs Based on Lignocellulose

Lignocellulose is an organic flocculent fiber material made from naturally regenerated wood through chemical treatment and mechanical processing [80]. For self-powered equipment such as TNEGs for environmental monitoring and medical rehabilitation, biodegradable environmental protection materials are frequently employed. For example, An et al. developed a BD-TENG based on nanofibers (NF) by using an industrially scalable solution blow-molding process to prepare NF from solutions containing soybean protein and lignin. This TENG based on biopolymers has excellent efficiency in biomedical applications, which makes it a piece of sustainable and environmentally friendly self-powered equipment (Figure 4d) [76]. In addition to being a positive triboelectric material for TENG, lignocellulose has also been developed as a negative triboelectric by adding strong electron absorption groups through modification. For instance, Bang et al. explored an all-wood green TENG [77]. Flexible porous wood triboelectric layers were utilized as positive and negative materials to increase the triboelectric output of TENG. The positive triboelectric layer was treated with trichloro (1H, 1H, 2H, 2H-perfluorooctyl) silane. In contrast, the negative triboelectric layer was treated with N-(2-aminoethyl)-3-aminopropyltrimethoxysilane (Figure 4e). The output voltage of chemically treated TENG was about 20.5 times than that of solemn TENG. Similarly, Yao et al. proposed a straightforward technique, including pretreatment and post-modification to produce flexible wood triboelectric layer materials with excellent mechanical properties [78]. They attached the positively charged quaternary ammonium group using the cationic modifier 3-chloro-2-hydroxypropyl trimethylammonium chloride (CHPTAC) to the free hydroxyl group on the cellulose backbone. The modified veneer displayed a high surface potential, demonstrating a significant energy difference between the positive and negative triboelectric layers (Figure 4f).3.1.7. BD-TENGs Based on Alginate and Agar

Sodium alginate is a by-product of extracting iodine and mannitol from kelp or sargassum of brown algae. It is a polysaccharide with good biodegradability and biocompatibility, and also a promising candidate material for BD-TENG [63]. Carrageenan (ϰC) and agar are natural, low-cost edible polysaccharides extracted from red algae and are also used to develop BD-TENG. Kang et al. developed a natural derivative-Carrageenan agar (ϰC-Agar) composite using as high-performance triboelectric material for BD-TENG [81].3.1.8. Potential Applications of Plant-Based BD-TENGs

Plant-Based BD-TENGs for Energy Harvesting

Since the first invention of TENG, obtaining energy from the environment and organisms has always been the most important goal of TENG. The emergence of BD-TENG has brought dawn for providing new environmental protection and degradable energy. Yang et al. built a human-computer interaction and environmentally friendly energy collection system. Cellulose filter paper was used as the triboelectric layer [82]. The unique three-dimensional porous network structure and high crystallinity of cellulose filter paper enable the TENG to have good output performance. Their degradation experiments showed that the prepared CFP-based TENG dispersed and dissolved the composite membrane materials in ultrapure water within 30 min through ultrasonic treatment, which could fully demonstrate its environmentally friendly nature. (Figure 5a). They also deeply investigated the output characteristics of TENGs based on CFP, with a maximum output voltage of 192 V and output current of 9.3 μA. The output power was 736.7 mW m−2. The TENG based on CFP can be conveniently used to power commercial electronic products and control computer programs as a wearable interface. This green TENG is of great significance for realizing environmental protection of electronic equipment, promoting energy conservation and emission reduction, and realizing carbon neutralization.

Figure 5. Plant-based BD-TENGs. (a) A green, recyclable, and biodegradable CFP-based TENG; A schematic illustration of the fabrication of Cu-coated CFP and PVDF-coated CFP; degradation process of various membranes and the application of TENG based on CFP. Reproduced with permission [82]. Copyright 2022, Elsevier B.V. (b) A portable self-charging power supply system integrated with TENG and SC based on cellulose paper and PPy-coated cellulose paper; a schematic diagram of the manufacturing process of PPy coated cellulose paper and the structure diagram of the self-charging power system. Reproduced with permission [83]. Copyright 2020, WILEY-VCH. (c) An ultra-soft and cuttable paper-based TENG for mechanical energy harvesting; a schematic illustration of the process used to fabricate the conductive paper; a P-TENG schematic diagram and various working modes; demonstrations of its portability and ability to be tailored. Reproduced with permission [40]. Copyright 2019, American Chemical Society. (d) A renewable and BD-CNF-based TENG; manufacturing and performance of CNF-based TENG fiberboard. Reproduced with permission [84], Copyright 2016, Elsevier Ltd. BD-TENG based on rice paper and bacterial cellulose.

Figure 6. Plant-based BD-TENGs. (a) Structure of natural wheat straw assembled TENG; structural diagram of windmill and structural diagram of WS-TENG lawn and various output performance. Reproduced with permission [70], Copyright 2021, Elsevier Ltd. (b) A Leaf-TENG assembled from natural leaves for effectively harvesting environmental mechanical energy; photographs of Hosta leaf and Leaf-TENG directly assembled with Hosta leaf and PMMA; photomicrograph of cross section of Hosta leaf, with the inset showing the structure of cross section of common leaves; SEM images of morphology of Hosta leaf; the effect of materials and stability of Leaf-TENG. Reproduced with permission [85], Copyright 2018, WILEY-VCH. (c) A blade-based TENG and TENG tree for wind energy harvesting; the schematic illustration of the fabrication process of leaf and leaf powder based TENGs and TENG tree. Reproduced with permission [86], Copyright 2018, Elsevier Ltd.

Plant-Based BD-TENGs for Self-Powered Sensing System

TENG can not only be used as an energy harvesting device, but also an excellent sensor in mechanical sensing due to its high sensitivity and short response time. From the perspective of active sensors, TENG can convert mechanical movement into changing electrical signals; the information from a trigger source (amplitude, frequency, position, trajectory, etc.) can be retrieved by analyzing these output signals (voltage, current, frequency, etc.). Environmentally friendly, biocompatible and biodegradable materials also make TENG more unique in the application of transient electronic equipment. Zhang et al. designed a page marking and anti-theft sensor using commercial printing paper [51]. The printing paper was used as the substrate of the TENG, and then the film made of PET and ITO was placed on the friction surface. This self-powered anti-theft sensor can be inserted into a book. When it contacts the book, the Isc increases from 30 nA to 300 nA with the increase of the grid. When someone gently touches the book, the TENG output voltage of the TENG can light the LED alarm bulb as a warning. More interestingly, TENG can identify matching pages according to different signal amplitudes, accurately determine the number of pages in the book, and record the number of pages turned. These studies are a good starting point for creating simple, portable, flexible and green paper made equipment, as well as the progress of self-powered paper made equipment. Stephan et al. has developed a CFP-based TENG by dip coating [87]. The CFP-based TENG displayed the Voc and current density of ≈42 V and ≈1 µA cm−2, and a power density of ≈25 µW cm−2. It can light 40 LED bulbs and charge 0.22 µF capacitors to 8 V within 5 s. The TENG can detect simple human movements, finger tapping, finger friction, and trampling. These results prove that cellulose paper can be employed as the base material for manufacturing superior-behavior BD-TENG. With the development of intelligent electronic devices, human-machine interaction (HMI) technology plays an increasingly important role in daily life. TENG based on cellulose paper can also be employed as an active sensor for HMI because its electrical signal can be utilized as the input signal for operating the machine. Chen et al. reported that a Voc of paper-based PTEN was 196.8 V, Isc was 31.5 µA, power density was 16.1 W m−2, and duration exceeded 10,000 times [68]. This PTENG was used as a keyboard for designing and manufacturing paper pianos to achieve automatic human-computer interaction. PTENG can detect human movement, such as finger contact. PTENG array keyboard can realize self-powered real-time interaction with computer (Figure 7a). These studies show the potential of using widely available low-cost cellulose fiber derivatives to produce high-performance paper-based TENG. They also show great potential in HMI, which is critical to creating green and sustainable devices.

Figure 7. Plant-based BD-TENGs. (a) A TENG based on crepe cellulose paper and nitrocellulose film for energy harvesting and self-powered human-machine interaction; a schematic illustration of the P-TENG working principle; a P-TENG-based paper piano for self-powered human–machine interfacing; output voltage of the P-TENG under periodic pressing by a shaker with different applied forces. Reproduced with permission [68]. Copyright 2019, Elsevier Ltd. (b) A hierarchically nanostructured cellulose fiber-based TENG for self-powered healthcare products; schematic, microstructure, and photographs of the cf-TENG; working principle of the cf-TENG and Breathing monitoring and PM2.5 removal effect of the cf-TENG. Reproduced with permission [88], WILEY-VCH. (c) A recyclable and fully biodegradable water-soluble paper-based TENG; fabrication of CNC from wasted paper and schematic illustration of contact-separation mode TENG between CNC/MC film adhered with graphite electrode and PTFE. Reproduced with permission [69], Copyright 2021, Elsevier Ltd. (d) A flexible and durable wood TENG for self-powered sensing in sports big data analysis; fabrication and schematic of the flexible wood-based TENG and smart ping-pong table and application of the W-TENG in a self-powered falling point distribution statistical system. Reproduced with permission [89], Copyright 2019, Springer Nature.

Plant-Based BD-TENGs for Implantable Medical Devices

Implantable electronic devices for medical care and health monitoring have advanced quickly. TENG-based biodegradable power supplies have advantages over batteries in preventing issues like secondary medical surgery. For instance, based on biocompatible medical 317L stainless steel (317L SS) plate and ethyl cellulose (EC) membrane, Wang et al. proposed a healthcare TENG. TENG’s Isc and Voc can reach 245 V and 50 µA under ideal circumstances [91]. After being submerged in simulated bodily fluid for a period of time, the capabilities of the device had not altered appreciably, indicating that it was well-suited for use as a biomedical power source and had good biocompatibility. This shows that cellulose-based BD-TENG has a bright prospect in the application of implantable medical devices.References

- Zhang, S.; Bick, M.; Xiao, X.; Chen, G.; Nashalian, A.; Chen, J. Leveraging triboelectric nanogenerators for bioengineering. Matter 2021, 4, 845–887.

- Chen, M.; Zhou, Y.; Lang, J.; Li, L.; Zhang, Y. Triboelectric nanogenerator and artificial intelligence to promote precision medicine for cancer. Nano Energy 2022, 92, 106783.

- Zhu, J.; Cheng, Y.; Hao, S.; Wang, Z.L.; Wang, N.; Cao, X. A self-healing triboelectric nanogenerator based on feathers for sensing and energy harvesting. Adv. Funct. Mater. 2021, 31, 2100039.

- Ji, F.; Sun, Z.; Hang, T.; Zheng, J.; Li, X.; Duan, G.; Zhang, C.; Chen, Y. Flexible piezoresistive pressure sensors based on nanocellulose aerogels for human motion monitoring: A review. Compos. Commun. 2022, 35, 101351.

- Yang, H.J.; Lee, J.W.; Seo, S.H.; Jeong, B.; Lee, B.; Do, W.J.; Kim, J.H.; Cho, J.Y.; Jo, A.; Jeong, H.J. Fully stretchable self-charging power unit with micro-supercapacitor and triboelectric nanogenerator based on oxidized single-walled carbon nanotube/polymer electrodes. Nano Energy 2021, 86, 106083.

- Tat, T.; Libanori, A.; Au, C.; Yau, A.; Chen, J. Advances in triboelectric nanogenerators for biomedical sensing. Biosens. Bioelectron. 2021, 171, 112714.

- Dos Santos, C.C.; Lucena, G.N.; Pinto, G.C.; Júnior, M.J.; Marques, R.F.C. Advances and current challenges in non-invasive wearable sensors and wearable biosensors—A mini-review. Med. Devices Sens. 2020, 4, e10130.

- Cao, X.; Jie, Y.; Wang, N.; Wang, Z.L. Triboelectric nanogenerators driven self-powered electrochemical processes for energy and environmental science. Adv. Energy Mater. 2016, 6, 1600665.

- Zhao, Z.; Lu, Y.; Mi, Y.; Meng, J.; Cao, X.; Wang, N. Structural flexibility in triboelectric nanogenerators: A review on the adaptive design for self-powered systems. Micromachines 2022, 13, 1586.

- Dudem, B.; Dharmasena, R.D.I.G.; Graham, S.A.; Leem, J.W.; Patnam, H.; Mule, A.R.; Silva, S.R.P.; Yu, J.S. Exploring the theoretical and experimental optimization of high-performance triboelectric nanogenerators using microarchitectured silk cocoon films. Nano Energy 2020, 74, 104882.

- Zhang, R.; Olin, H. Material choices for triboelectric nanogenerators: A critical review. EcoMat 2020, 2, 12062.

- Liang, S.; Wang, Y.; Liu, Q.; Yuan, T.; Yao, C. The recent progress in cellulose paper-based triboelectric nanogenerators. Adv. Sustain. Syst. 2021, 5, 2100034.

- Lu, Y.; Mi, Y.; Wu, T.; Cao, X.; Wang, N. From triboelectric nanogenerator to polymer-based biosensor: A review. Biosensors 2022, 12, 323.

- Parandeh, S.; Etemadi, N.; Kharaziha, M.; Chen, G.; Nashalian, A.; Xiao, X.; Chen, J. Advances in triboelectric nanogenerators for self-powered regenerative medicine. Adv. Funct. Mater. 2021, 31, 2105169.

- Dong, K.; Peng, X.; Wang, Z.L. Fiber/fabric-based piezoelectric and triboelectric nanogenerators for flexible/stretchable and wearable electronics and artificial intelligence. Adv. Mater. 2019, 32, 1902549.

- Liu, M.; Zhang, Y.; Tao, T.H. Recent progress in bio-integrated intelligent sensing system. Adv. Intell. Syst. 2022, 4, 2100280.

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282.

- Zheng, L.; Cheng, G.; Chen, J.; Lin, L.; Wang, J.; Liu, Y.; Li, H.; Wang, Z.L. A hybridized power panel to simultaneously generate electricity from sunlight, raindrops, and wind around the clock. Adv. Energy Mater. 2015, 5, 1501152.

- Guo, H.; Yeh, M.H.; Lai, Y.C.; Zi, Y.; Wu, C.; Wen, Z.; Hu, C.; Wang, Z.L. All-in-one shape-adaptive self-charging power package for wearable electronics. ACS Nano 2016, 10, 10580–10588.

- Zhao, D.; Zhuo, J.; Chen, Z.; Wu, J.; Ma, R.; Zhang, X.; Zhang, Y.; Wang, X.; Wei, X.; Liu, L.; et al. Eco-friendly in-situ gap generation of no-spacer triboelectric nanogenerator for monitoring cardiovascular activities. Nano Energy 2021, 90, 106580.

- Zhang, X.; Hu, J.; Yang, Q.; Yang, H.; Yang, H.; Li, Q.; Li, X.; Hu, C.; Xi, Y.; Wang, Z.L. Harvesting multidirectional breeze energy and self-powered intelligent fire detection systems based on triboelectric nanogenerator and fluid-dynamic modeling. Adv. Funct. Mater. 2021, 31, 2106527.

- Zhang, C.; He, L.; Zhou, L.; Yang, O.; Yuan, W.; Wei, X.; Liu, Y.; Lu, L.; Wang, J.; Wang, Z.L. Active resonance triboelectric nanogenerator for harvesting omnidirectional water-wave energy. Joule 2021, 5, 1613–1623.

- Chen, L.; Shi, Q.; Sun, Y.; Nguyen, T.; Lee, C.; Soh, S. Controlling surface charge generated by contact electrification: Strategies and applications. Adv. Mater. 2018, 30, e1802405.

- Shi, Q.; Dong, B.; He, T.; Sun, Z.; Zhu, J.; Zhang, Z.; Lee, C. Progress in wearable electronics/photonics—Moving toward the era of artificial intelligence and internet of things. InfoMat 2020, 2, 1131–1162.

- Bai, Z.; Xu, Y.; Lee, C.; Guo, J. Autonomously adhesive, stretchable, and transparent solid-state polyionic triboelectric patch for wearable power source and tactile sensor. Adv. Funct. Mater. 2021, 31, 2104365.

- Wang, Z.L. From contact electrification to triboelectric nanogenerators. Rep. Prog. Phys. 2021, 84, 096502.

- Peng, X.; Dong, K.; Ning, C.; Cheng, R.; Yi, J.; Zhang, Y.; Sheng, F.; Wu, Z.; Wang, Z.L. All-nanofiber self-powered skin-interfaced real-time respiratory monitoring system for obstructive sleep apnea-hypopnea syndrome diagnosing. Adv. Funct. Mater. 2021, 31, 2103559.

- Liu, Y.; Ping, J.; Ying, Y. Recent progress in 2D-nanomaterial-based triboelectric nanogenerators. Adv. Funct. Mater. 2021, 31, 2009994.

- Zhu, J.; Zhu, M.; Shi, Q.; Wen, F.; Liu, L.; Dong, B.; Haroun, A.; Yang, Y.; Vachon, P.; Guo, X.; et al. Progress in TENG technology—A journey from energy harvesting to nanoenergy and nanosystem. EcoMat 2020, 2, 1–45.

- Yan, L.; Mi, Y.; Lu, Y.; Qin, Q.; Wang, X.; Meng, J.; Liu, F.; Wang, N.; Cao, X. Weaved piezoresistive triboelectric nanogenerator for human motion monitoring and gesture recognition. Nano Energy 2022, 96, 107135.

- Yu, A.; Zhu, Y.; Wang, W.; Zhai, J. Progress in triboelectric materials: Toward high performance and widespread applications. Adv. Funct. Mater. 2019, 29, 1900098.

- Parandeh, S.; Kharaziha, M.; Karimzadeh, F.; Hosseinabadi, F. Triboelectric nanogenerators based on graphene oxide coated nanocomposite fibers for biomedical applications. Nanotechnology 2020, 31, 385402.

- Bao, Y.; Wang, R.; Lu, Y.; Wu, W. Lignin biopolymer based triboelectric nanogenerators. APL Mater. 2017, 5, 074109.

- Yang, B.; Yao, C.; Yu, Y.; Li, Z.; Wang, X. Nature degradable, flexible, and transparent conductive substrates from green and earth-abundant materials. Sci. Rep. 2017, 7, 4936.

- Rajabi-Abhari, A.; Kim, J.N.; Lee, J.; Tabassian, R.; Mahato, M.; Youn, H.J.; Lee, H.; Oh, I.K. Diatom bio-silica and cellulose nanofibril for bio-triboelectric nanogenerators and self-powered breath monitoring masks. ACS Appl. Mater. Interfaces 2021, 13, 219–232.

- Niu, Q.; Wei, H.; Hsiao, B.S.; Zhang, Y. Biodegradable silk fibroin-based bio-piezoelectric/triboelectric nanogenerators as self-powered electronic devices. Nano Energy 2022, 96, 107101.

- Jiang, W.; Li, H.; Liu, Z.; Li, Z.; Tian, J.; Shi, B.; Zou, Y.; Ouyang, H.; Zhao, C.; Zhao, L.; et al. Fully bioabsorbable natural-materials-based triboelectric nanogenerators. Adv. Mater. 2018, 30, e1801895.

- Yang, H.; Fan, F.R.; Xi, Y.; Wu, W. Bio-derived natural materials based triboelectric devices for self-powered ubiquitous wearable and implantable intelligent devices. Adv. Sustain. Syst. 2020, 4, 2000108.

- Zhang, Y.; Zhou, Z.; Fan, Z.; Zhang, S.; Zheng, F.; Liu, K.; Zhang, Y.; Shi, Z.; Chen, L.; Li, X.; et al. Self-powered multifunctional transient bioelectronics. Small 2018, 14, e1802050.

- Wu, C.; Kima, T.W.; Sung, S.; Park, J.H.; Li, F. Ultrasoft and cuttable paper-based triboelectric nanogenerators for mechanical energy harvesting. Nano Energy 2018, 44, 279–287.

- Jao, Y.T.; Yang, P.K.; Chiu, C.M.; Lin, Y.J.; Chen, S.W.; Choi, D.; Lin, Z.H. A textile-based triboelectric nanogenerator with humidity-resistant output characteristic and its applications in self-powered healthcare sensors. Nano Energy 2018, 50, 513–520.

- Guo, Y.; Zhang, X.S.; Wang, Y.; Gong, W.; Zhang, Q.; Wang, H.; Brugger, J. All-fiber hybrid piezoelectric-enhanced triboelectric nanogenerator for wearable gesture monitoring. Nano Energy 2018, 48, 152–160.

- Shi, B.; Liu, Z.; Zheng, Q.; Meng, J.; Ouyang, H.; Zou, Y.; Jiang, D.; Qu, X.; Yu, M.; Zhao, L.; et al. Body-integrated self-powered system for wearable and implantable applications. ACS Nano 2019, 13, 6017–6024.

- Zhou, Y.; Shen, M.; Cui, X.; Shao, Y.; Li, L.; Zhang, Y. Triboelectric nanogenerator based self-powered sensor for artificial intelligence. Nano Energy 2021, 84, 105887.

- Valentini, L.; Rescignano, N.; Puglia, D.; Cardinali, M.; Kenny, J. Preparation of alginate/graphene oxide hybrid films and their integration in triboelectric generators. Eur. J. Inorg. Chem. 2014, 2015, 1192–1197.

- Zheng, Q.; Zou, Y.; Zhang, Y.L.; Liu, Z.; Shi, B.J.; Wang, X.X.; Jin, Y.M.; Ouyang, H.; Li, Z.; Wang, Z.L. Biodegradable triboelectric nanogenerator as a life-time designed implantable power source. Sci. Adv. 2016, 2, e1501478.

- Kim, H.J.; Kim, J.H.; Jun, K.W.; Kim, J.H.; Seung, W.C.; Kwon, O.H.; Park, J.Y.; Kim, S.W.; Oh, I.K. Silk nanofiber-networked bio-triboelectric generator: Silk bio-TEG. Adv. Energy Mater. 2016, 6, 1502329.

- Zhu, G.; Peng, B.; Chen, J.; Jing, Q.S.; Lin Wang, Z. Triboelectric nanogenerators as a new energy technology: From fundamentals, devices, to applications. Nano Energy 2015, 14, 126–138.

- Wu, Y.; Qu, J.; Chu, P.K.; Shin, D.M.; Luo, Y.; Feng, S.P. Hybrid photovoltaic-triboelectric nanogenerators for simultaneously harvesting solar and mechanical energies. Nano Energy 2021, 89, 106376.

- Parida, K.; Xiong, J.; Zhou, X.; Lee, P.S. Progress on triboelectric nanogenerator with stretchability, self-healability and bio-compatibility. Nano Energy 2019, 59, 237–257.

- Zhang, L.; Xue, F.; Du, W.; Han, C.; Zhang, C.; Wang, Z. Transparent paper-based triboelectric nanogenerator as a page mark and anti-theft sensor. Nano Res. 2014, 7, 1215–1223.

- Song, Y.; Wang, N.; Hu, C.; Wang, Z.L.; Yang, Y. Soft triboelectric nanogenerators for mechanical energy scavenging and self-powered sensors. Nano Energy 2021, 84, 105919.

- Miao, P.; Ma, X.; Xie, L.; Tang, Y.; Sun, X.; Wen, Z.; Wang, Z. Tetrahedral DNA mediated direct quantification of exosomes by contact-electrification effect. Nano Energy 2022, 92, 106781.

- Luo, J.; Gao, W.; Wang, Z.L. The triboelectric nanogenerator as an innovative technology toward intelligent sports. Adv. Mater. 2021, 33, e2004178.

- Wan, J.; Wang, H.; Miao, L.; Chen, X.; Song, Y.; Guo, H.; Xu, C.; Ren, Z.; Zhang, H. A flexible hybridized electromagnetic-triboelectric nanogenerator and its application for 3D trajectory sensing. Nano Energy 2020, 74, 104878.

- Su, Y.; Yang, T.; Zhao, X.; Cai, Z.; Chen, G.; Yao, M.; Chen, K.; Bick, M.; Wang, J.; Li, S. A wireless energy transmission enabled wearable active acetone biosensor for non-invasive prediabetes diagnosis. Nano Energy 2020, 74, 104941.

- Zhang, C.; Liu, Y.; Zhang, B.; Yang, O.; Yuan, W.; He, L.; Wei, X.; Wang, J.; Wang, Z.L. Harvesting wind energy by a triboelectric nanogenerator for an intelligent high-speed train system. ACS Energy Lett. 2021, 6, 1490–1499.

- Wang, Y.; Yu, X.; Yin, M.; Wang, J.; Gao, Q.; Yu, Y.; Cheng, T.; Wang, Z.L. Gravity triboelectric nanogenerator for the steady harvesting of natural wind energy. Nano Energy 2021, 82, 105740.

- Lee, K.Y.; Mooney, D.J. Alginate: Properties and biomedical applications. Prog. Polym. Sci. 2012, 37, 106–126.

- Chao, S.; Ouyang, H.; Jiang, D.; Fan, Y.; Li, Z. Triboelectric nanogenerator based on degradable materials. EcoMat 2020, 3, e12072.

- Li, M.; Jie, Y.; Shao, L.H.; Guo, Y.; Cao, X.; Wang, N.; Wang, Z.L. All-in-one cellulose based hybrid tribo/piezoelectric nanogenerator. Nano Res. 2019, 12, 1831–1835.

- Qian, C.; Li, L.; Gao, M.; Yang, H.; Cai, Z.; Chen, B.; Xiang, Z.; Zhang, Z.; Song, Y. All-printed 3D hierarchically structured cellulose aerogel based triboelectric nanogenerator for multi-functional sensors. Nano Energy 2019, 63, 103885.

- Pang, Y.; Xi, F.; Luo, J.; Liu, G.; Guo, T.; Zhang, C. An alginate film-based degradable triboelectric nanogenerator. RSC Adv. 2018, 8, 6719–6726.

- Chi, Y.; Xia, K.; Zhu, Z.; Fu, J.; Zhang, H.; Du, C.; Xu, Z. Rice paper-based biodegradable triboelectric nanogenerator. Microelectron. Eng. 2019, 216, 111059.

- Zhu, Z.; Xia, K.; Xu, Z.; Lou, H.; Zhang, H. Starch paper-based triboelectric nanogenerator for human perspiration sensing. Nanoscale Res. Lett. 2018, 13, 365.

- Nie, S.; Guo, H.; Lu, Y.; Zhuo, J.; Mo, J.; Wang, Z.L. Superhydrophobic cellulose paper-based triboelectric nanogenerator for water drop energy harvesting. Adv. Mater. Technol. 2020, 5, 2000454.

- Zhang, Z.; Jie, Y.; Zhu, J.; Zhu, Z.; Chen, H.; Lu, Q.; Zeng, Y.; Cao, X.; Wang, N.; Wang, Z. Paper triboelectric nanogenerator designed for continuous reuse and quick construction. Nano Res. 2021, 15, 1109–1114.

- Chen, S.; Jiang, J.; Xu, F.; Gong, S. Crepe cellulose paper and nitrocellulose membrane-based triboelectric nanogenerators for energy harvesting and self-powered human-machine interaction. Nano Energy 2019, 61, 69–77.

- Wang, T.; Li, S.; Tao, X.; Yan, Q.; Wang, X.; Chen, Y.; Huang, F.; Li, H.; Chen, X.; Bian, Z. Fully biodegradable water-soluble triboelectric nanogenerator for human physiological monitoring. Nano Energy 2022, 93, 106787.

- Ma, P.; Zhu, H.; Lu, H.; Zeng, Y.; Zheng, N.; Wang, Z.L.; Cao, X. Design of biodegradable wheat-straw based triboelectric nanogenerator as self-powered sensor for wind detection. Nano Energy 2021, 86, 106032.

- Zhang, R.; Xia, R.; Cao, X.; Wang, N. Nutshell powder-based green triboelectric nanogenerator for wind energy harvesting. Adv. Mater. Interfaces 2022, 9, 2200293.

- Wang, J.; Han, X.; Zhang, C.; Liu, K.; Duan, G. Source of nanocellulose and its application in nanocomposite packaging material: A review. Nanomaterials 2022, 12, 3158.

- Khandelwal, G.; Minocha, T.; Yadav, S.K.; Chandrasekhar, A.; Maria Joseph Raj, N.P.; Gupta, S.C.; Kim, S.J. All edible materials derived biocompatible and biodegradable triboelectric nanogenerator. Nano Energy 2019, 65, 104016.

- Wu, H.; Chen, Z.; Xu, G.; Xu, J.; Wang, Z.; Zi, Y. Fully biodegradable water droplet energy harvester based on leaves of living plants. ACS Appl. Mater. Interfaces 2020, 12, 56060–56067.

- Kim, H.J.; Yim, E.C.; Kim, J.H.; Kim, S.J.; Park, J.Y.; Oh, I.K. Bacterial nano-cellulose triboelectric nanogenerator. Nano Energy 2017, 33, 130–137.

- An, S.; Sankaran, A.; Yarin, A.L. Natural biopolymer-based triboelectric nanogenerators via fast, facile, scalable solution blowing. ACS Appl. Mater. Interfaces 2018, 10, 37749–37759.

- Bang, J.; Moon, I.K.; Jeon, Y.P.; Ki, B.; Oh, J. Fully wood-based green triboelectric nanogenerators. Appl. Surf. Sci. 2021, 567, 150806.

- Yao, L.; Zhou, Z.; Zhang, Z.; Du, X.; Zhang, Q.L.; Yang, H. Dyeing-inspired sustainable and low-cost modified cellulose-based TENG for energy harvesting and sensing. ACS Sustain. Chem. Eng. 2022, 10, 3909–3919.

- Zhang, J.; Hu, S.; Shi, Z.; Wang, Y.; Lei, Y.; Han, J.; Xiong, Y.; Sun, J.; Zheng, L.; Sun, Q.; et al. Eco-friendly and recyclable all cellulose triboelectric nanogenerator and self-powered interactive interface. Nano Energy 2021, 89, 106354.

- Yang, J.; Li, H.; He, S.; Du, H.; Liu, K.; Zhang, C.; Jiang, S. Facile electrodeposition of NiCo2O4 nanosheets on porous carbonized wood for wood-derived asymmetric supercapacitors. Polymers 2022, 14, 2521.

- Kang, M.; Bin Mohammed Khusrin, M.S.; Kim, Y.J.; Kim, B.; Park, B.J.; Hyun, I.; Imani, I.M.; Choi, B.O.; Kim, S.W. Nature-derived highly tribopositive ϰ-carrageenan-agar composite-based fully biodegradable triboelectric nanogenerators. Nano Energy 2022, 100, 107480.

- Yang, M.; Tian, X.; Hua, T. Green and recyclable cellulose based TENG for sustainable energy and human-machine interactive system. Chem. Eng. J. 2022, 442, 136150.

- Shi, X.; Chen, S.; Zhang, H.; Jiang, J.; Ma, Z.; Gong, S. Portable self-charging power system via integration of a flexible paper-based triboelectric nanogenerator and supercapacitor. ACS Sustain. Chem. Eng. 2019, 7, 18657–18666.

- Yao, C.; Hernandez, A.; Yu, Y.; Cai, Z.; Wang, X. Triboelectric nanogenerators and power-boards from cellulose nanofibrils and recycled materials. Nano Energy 2016, 30, 103–108.

- Jie, Y.; Jia, X.; Zou, J.; Chen, Y.; Wang, N.; Wang, Z.L.; Cao, X. Natural leaf made triboelectric nanogenerator for harvesting environmental mechanical energy. Adv. Energy Mater. 2018, 8, 1703133.

- Feng, Y.; Zhang, L.; Zheng, Y.; Wang, D.; Zhou, F.; Liu, W. Leaves based triboelectric nanogenerator (TENG) and TENG tree for wind energy harvesting. Nano Energy 2019, 55, 260–268.

- Sriphan, S.; Charoonsuk, T.; Maluangnont, T.; Pakawanit, P.; Rojviriya, C.; Vittayakorn, N. Multifunctional nanomaterials modification of cellulose paper for efficient triboelectric nanogenerators. Adv. Mater. Technol. 2020, 5, 2000001.

- He, X.; Zou, H.; Geng, Z.; Wang, X.; Ding, W.; Hu, F.; Zi, Y.; Xu, C.; Zhang, S.L.; Yu, H.; et al. A hierarchically nanostructured cellulose fiber-based triboelectric nanogenerator for self-powered healthcare products. Adv. Funct. Mater. 2018, 28, 1805540.

- Luo, J.; Wang, Z.; Xu, L.; Wang, A.C.; Han, K.; Jiang, T.; Lai, Q.; Bai, Y.; Tang, W.; Fan, F.R.; et al. Flexible and durable wood-based triboelectric nanogenerators for self-powered sensing in athletic big data analytics. Nat. Commun. 2019, 10, 5147.

- Wang, R.; Ma, J.; Ma, S.; Zhang, Q.; Li, N.; Ji, M.; Jiao, T.; Cao, X. A biodegradable cellulose-based flame-retardant triboelectric nanogenerator for fire warning. Chem. Eng. J. 2022, 450, 137985.

- Wang, M.; Li, W.; You, C.; Wang, Q.; Zeng, X.; Chen, M. Triboelectric nanogenerator based on 317L stainless steel and ethyl cellulose for biomedical applications. RSC Adv. 2017, 7, 6772–6779.

More