Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Ahmed Rezk and Version 2 by Catherine Yang.

The use of fossil fuels has contributed to climate change and global warming, which has led to a growing need for renewable and ecologically friendly alternatives to these. It is accepted that renewable energy sources are the ideal option to substitute fossil fuels in the near future. Significant progress has been made to produce renewable energy sources with acceptable prices at a commercial scale, such as solar, wind, and biomass energies. Hybrid renewable energy systems are needed with good energy management to balance the various renewable energy sources’ production/consumption/storage.

- wind energy

- biomass energy

- hybrid renewable energy

- energy management

- green hydrogen

1. Hybrid Renewable Energy Sources

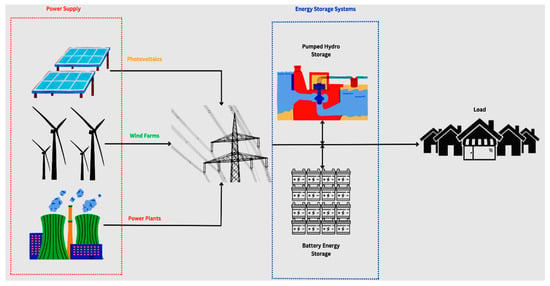

Although renewable energy sources are sustainable and have zero or minimal adverse effects on the surrounding environment, the vast majority, such as wind and solar power, only produce energy intermittently. Therefore, renewable energy sources have to be integrated with energy storage systems. Sometimes there are several different renewable energy sources integrated with one or more other energy storage systems, as shown in Figure 16. The main purpose of these integrations is to guarantee a continuous energy supply all day at the lowest cost [1][2][3][97,98,99]. Many researchers have studied the combination of different renewable energy systems to provide carbon-free, higher energy production, and cheap energy sources [4][100].

Figure 16.

Schematic of hybrid wind/PV/thermal power plants integrated with different energy storage systems.

Using a computational design strategy, Kim et al. [5][101] determined the dimensions of a hybrid power system that included national electric, solar, and fuel cells, and then determined the ratio values of the system. Between 0.46 to 0.54 was the ideal ratio of the amount of energy generated by fuel cells to that generated by solar cells. In addition, the authors provided a revised version of the uDEAS method, which stands for “univariate dynamic encoding algorithm for searches,” as a new optimization strategy. Bauer et al. [6][102] investigated the idea of merging biological power-to-methane conversion to help and maintain the energy transition of power, heat, and gas. To improve the energy system, the Calliope tool was employed.

Gajewski and Piekowski [7][103] examined cutting-edge hybrid renewable energy systems (HRES) via analysis and simulation. The HRES consisted of a generator for the wind turbine called a permanent magnet synchronous generator (PMSG), a system of solar panels, and a system for storing energy in batteries. Research on the multi-converter DC-coupled design of the HRES was carried out. Under a wide range of varied operational situations for renewable energy sources, the system guaranteed that the loads would receive the correct amount of power flow at all times. The PMSG control method with machine-side converter was based on rotor field-oriented control. Additionally, it contained the tip speed ratio (TSR) algorithm which is used in the maximum power point tracking (MPPT) algorithm. The method known as direct power control (DPC) was put into practice to control the grid-side converter. The DPC ensured that the voltage value of the DC connection was appropriately maintained to the reference value and could alter the necessary power flows between the grid and the system. The PV system’s operation control was implemented using the MPPT algorithm, which is founded on the perturbation and observation (P&O) approach. Using this method, the researchers could determine the level of solar irradiation and the temperature of the surrounding environment that would result in the greatest amount of power being produced by photovoltaic cells. The defined energy management procedures made it possible for the wind and solar energy systems to operate as intended in various environmental circumstances, all while keeping the load side’s power supply demand at the required level. The converter system, which used battery energy storage, was incorporated into the design and was connected to the common DC connection. This was done to facilitate communication between the two systems. Even in conditions where wind speeds or solar irradiation values were low, the renewable hybrid system could nevertheless reliably provide the load with the necessary amount of power. The battery system stored any extra power produced by the wind turbine or solar panel system in the event it created more energy than necessary. When the battery was used up to its maximum capacity, any remaining power was sent back into the grid that supplied alternating current electricity. The simulation results showed that the wind turbine control system, consisting of PV panels, a battery energy system, and a directly driven PMSG, was of very high quality.

To lower electricity costs, residential properties must have home energy management (HEM) systems. Energy consumption and expenses might be decreased by combining renewable energy sources (RES) with battery energy storage systems (BESSs) and central battery storage systems (CBSSs). Rashid et al. [8][104] established a cost-effective HEM scheme within the context of a microgrid to encourage the decrease of energy demand while also considering energy storage and the incorporation of renewable sources. The user preferences and the length of time they need the appliance to operate may affect the runtime preferences and lengths of operation of typical household appliances. These preferences and durations of operation can vary. The HEM model allows residential consumers to modify their total energy consumption profile, lowering the expenses connected with it and giving them access to real-time pricing. By merging RES, BESSs, and CBSSs in a shared power environment, the HEM model is able to reduce energy use and save money. Papadopoulou et al. [9][105] compared a hybrid system comprised of photovoltaics (PV) and offshore wind energy, as well as two distinct storage options. In this regard, the aforementioned technologies were compared using two complimentary metrics: the levelized cost of energy and the net present value. The hybrid system was more energy-cost-efficient.

Noor Energy 1 will be responsible for putting into action the 700MW CSP + 250MW PV Project found in the fourth and final phase of the Mohammed bin Rashid Solar Park. By its completion, this project will have created the largest single-site concentrated solar power plant in the world. Additionally, the levelized cost of power has set a new global record at $7.3 cents per kilowatt-hour, making it competitive with electricity generated from fossil fuels without subsidies for reliable solar energy that can be dispatched at all hours of the night. The technique combines the tallest solar tower in the world (at 260 m tall and 100 MW) with parabolic trough concentrated solar power technologies (totaling 600 MW and split into 200 MW for each unit) to harness solar energy and bifacial photovoltaics (250 MW), which convert sunlight from both sides of a solar panel. This project helps Dubai reach its Renewable Strategy goal of using 25% renewable energy by 2030. Moreover, it will prevent the release of 2.4 million tons of carbon dioxide (CO2) into the atmosphere [10][61].

Zebra et al. [11][106] focuses on the application of HRESs for off-grid electrification in developing-country rural populations that lack access to inexpensive, dependable, and sustainable sources of energy. The research examines HRESs as a means of overcoming renewables’ fluctuating nature and compares the levelized cost of electricity (LCOE) of several mini-grids. Diesel is the most costly technology when compared to solar photovoltaic and hybrid solar photovoltaic/diesel. The research also highlights elements that impact the effective integration of HRESs, including as government support and community organization, which are critical for the systems’ long-term viability. Furthermore, the paper tackles hurdles to mini-grid adoption, such as a lack of supporting policies and expensive capital costs, but emphasizes that government incentives may assist minimize these costs. The findings of this research are especially noteworthy for underdeveloped nations, because power provision through HRESs is often faster and less expensive than grid expansion. According to the report, more research on appropriate local design and ownership models might assist speed and decrease the costs of sustainable power provision in distant places.

CleanMax has begun offering a service called wind-solar hybrid (WSH) to businesses and factories that have significant power demands. The WSH projects in India combine solar and wind energy to take advantage of their synergistic effects on electricity output. Under a build-own-operate or energy sale paradigm, CleanMax has implemented this WSH solution for one of the organizations with the most significant data center operations. A 13.5 MW WSH power plant with a solar hybridization rate of less than 52% will provide the client with around 90% of their required energy (wind capacity 13.5 MW and solar capacity 10.5 MW). It is expected that the wind-solar hybrid plant will generate around 57 million units of energy annually, resulting in an annual decrease of about 46,740 tons of CO2 emissions. While the wind turbine capacity has been installed and commissioned, the solar panel capacity is still being added and is expected to be commissioned within the next few of months. The 13.5 MW WSH plant is part of a larger 150 MW WSH project being built by CleanMax [12][107].

2. Energy Management

As aforementioned, the majority of RES are intermittent, such as solar, wind, and wave energies. Therefore, managing a hybrid energy system composed of one or more renewable energy sources and one or more energy storage systems is frequently used to obtain a sustainable energy source with the lowest energy cost. Energy may be stored through a variety of techniques. These techniques are frequently categorized according to the period that the energy will be stored. The most prevalent methods for categorizing energy storage systems are based on the kind of energy storage used and the time it takes for the system to discharge its stored energy. Based on how long it takes for the stored energy to be discharged, techniques of energy storage may be categorized as either short-term (seconds or minutes), medium-term (minutes or hours), or long-term (hours to days). The type of converted energy has a significant impact on how energy storage techniques are categorized. These can be categorized into five major categories: mechanical, electrochemical, thermal, electrical, and chemical energy storage. These technologies store energy until it is needed [13][109]. Various energy systems are available such as supercapacitors [14][15][110,111], batteries [16][17][112,113], flywheel [18][19][114,115], compressed air [20][21][116,117], thermal energy storage [22][23][118,119], pumped hydro [24][120], and others. Table 16 shows a comparison between the different storage systems, and Table 27 shows the largest energy storage systems installed around the globe.

Pumped hydroelectric storage uses electricity produced during off-peak hours to raise water from a lower tank to a higher tank, dam, or reservoir, where it may be stored as potential energy. To make use of the higher reservoir as a storage space for surplus electrical power, a pump is installed within the conduit that connects the lower and higher pools. This pump moves water from the lower reservoir into the higher reservoir. The amount of energy retained there is determined by the amount of water stored, as well as the difference in level between the two pools of water. If there is a shortage in the grid or in the production of the local sources of energy, the water that is held in the upper reservoir may be released, which will cause turbines and generators to produce electrical energy. This will help make up for the shortage. The energy required to drive these pumps and turbines may be sourced from local energy sources, consumed, or delivered into the grid, all of which are viable options [25][121].

The utilization of the potential energy that is stored during the pressurization of a compressible fluid is the central focus of the design process that goes into creating compressed-air energy storage devices. The execution of the tasks required to run installations based on this concept is not too complicated. When there is less demand for power, fluid is forced into a smaller, more impermeable reservoir, where it is subjected to sustained high pressure over an extended period. During periods of very heavy demand, the available electrical supply will be bolstered. In this scenario, the fluid is released from its high-pressure storage and is fed into a rotating energy extraction mechanism known as an air turbine. This mechanism converts the kinetic energy of the fluid into rotating mechanical energy in a wheel connected to an electrical generator, which is then fed back into the grid [26][122]. Large-scale compressed air energy storage methods, such as pumped hydro storage, reap the benefits of having both cavernous and impermeable subterranean reservoirs simultaneously. Natural salt mines and oil and gas fields that have been drained of their resources would be the best possibilities for meeting such a substantial need for storage space; nevertheless, it is unfortunate that these resources are not commonly available.

A battery storage system is an advanced technological solution that enables electricity to be stored until it is needed. Rechargeable batteries, particularly lithium-ion battery storage systems, have several advantages, including greater renewable energy output, economic savings, and sustainability, owing to reduced consumption. Energy battery storage systems typically have a lifetime of five to 15 years. Supercapacitors are electrochemical energy storage devices that employ the same fundamental equations as control capacitors. However, supercapacitors frequently utilize porous carbon or electrodes with more significant surface areas and thinner dielectrics to collect huge numbers of charge carriers. Numerous benefits are provided by this type of system, such as extraordinarily high capacitance characteristics, on the order of thousands of farads, increased cycle life, low internal resistance, quick charging and discharging, extraordinary reversibility, excellent low-temperature performance, no destructive material, lower cost per cycle, and high cycle efficiency (up to 95%) [27][123].

In the power industry, only one of the three distinct types of thermal energy storage devices is now available at a commercial scale. The alternatives involve a level of complexity and expense that are not comparable to sensible heat storage. Both thermal-chemical storage systems and latent energy storage are considered to be rather costly and mostly experimental technology. In the field of power production, the method of storing thermal energy is commonly referred to as sensible heat storage. In a sensible heat thermal energy storage system, energy is stored by either heating or cooling a solid or liquid storage medium, such as molten salt, sand, water, or rocks. Other examples of storage mediums include; Sensible heat storage is common in concentrated solar power (CSP) plants. These plants make use of thermal energy storage so that they may continue producing electricity long after the sun has set. Molten salts are the material of choice in most CSP systems that use thermal energy storage because of their ability to withstand extremely high temperatures. Although it is very seldomly used in the field of power production, latent heat storage has shown to be potentially useful in a range of contemporary technologies. A change in the state of the medium used to store heat, such as from solid to liquid, is necessary for the process of latent heat storage. The term “phase change material” (PCMs) may also be used to refer to latent heat storage mediums. The term “thermo-chemical storage,” or TCS, refers to a method of energy storage that makes use of chemical processes. Compared to PCMs, the energy density of TCS systems is much more attractive [28][124].

Power-wise, the Three Gorges Dam far surpasses any other hydroelectric dam. The dam came into use in 2013, so it is still quite new. It can hold 22,500 MW of capacity. The dam is found in the Xilingxia Gorge, one of the three gorges situated in the Hubei province of China along the Yangtze River. It is claimed by NASA to be one of the few man-made structures on Earth visible to the human eye when viewing the world from space. A combined annual output of 84.7 billion kWh is anticipated from the 26 power-producing units, each with a generating capacity of 700 MW. The Three Gorges dam is one of the longest dams in the world at 2.3 kilometers long. Its undertaking required the participation of about 40,000 employees and was carried out over 17 years. Approximately 28 million cubic meters of concrete were used in the construction project, making it a massive structure. To prevent flooding, gates for a spillway were constructed along the concrete pillars. Water may be discharged via these gates and travel more than 100 m downstream. The dam is 2309 m in length and has a height of 185 m. The predicted 85 TW/h of energy from the dam project is nearly one-tenth of China’s current demand. The project was estimated to cost $22.5 billion [29][22].

Florida Power & Light’s (FPL) decision to replace the Manatee Energy Storage Center’s gas-fired generation with solar energy/battery storage was motivated by the utility’s plan to eliminate more than one million tons of CO2 emissions from its portfolio, and to generate savings of one hundred million dollars for its customers. Within the scope of this strategy is the installation of 30 million solar panels by the year 2030 after completing some less extensive battery installations around the state. The FPL concluded that the relatively low prices of battery technology might be utilized to both replace the Manatee plant and provide consumers with clean energy. An energy storage facility with a capacity of 409 MW will take the place of the Manatee plant, which is scheduled for retirement. The information provided by FPL indicates that this will be the largest battery system installed in the world. The energy storage facility will stretch over an area of 40 acres in size and have the capacity to distribute 900 MWh of power. While still in operation, the two outdated gas-fired peaker facilities will be replaced by the Manatee Energy Storage, which will then be fueled by the FPL solar facility and will store the energy. The solar plus storage system provides an added benefit to customers in the form of cost savings (approximately $100 million in savings to ratepayers), a reduction in emissions (one million tons of CO2), an improvement in service reliability, an increase in the integration of clean energy, and the creation of new jobs (approximately 70 new jobs during construction) [30][125]. Companies that manufacture batteries are engaged in a race to develop ever-more-capable utility-scale battery systems. The Moss Landing Energy Storage Facility, owned and operated by Vistra Energy, began operations in 2021 with a 400 MW/1600 MWh capacity. The battery at this site was the largest ever constructed. In January of 2022, Vistra announced that the Moss Landing Energy Storage Facility would gain an expansion that will increase its capacity to 750 MW/3000 GWh by the end of the year 2023 [31][126].

Compared with all of these energy storage systems, a grid is the largest energy storage that can accept huge amounts of energy. Grid protection is becoming more difficult as more renewable energy sources are incorporated and converted to usable forms by power electronic inverters. Inverter-based resources have failure responses that differ from conventional generators due to improved inverter control algorithms. This distinction has the potential to have a significant impact on how the power grid is protected. Ekic et al. [32][127] explored the dynamics of solar inverters by utilizing a real-time digital simulator (RTDS). The researchers focused their attention on the negative-sequence quantities that occurred during the restoration phase after a grid disruption. The authors conducted research on the dynamics of solar inverters by using RTDS-based electromagnetic transient simulations with detailed inverter models that take into account switching dynamics, as well as inverter blocking and deblocking modes. They placed a particular emphasis on the negative-sequence current that occurred during the time when the grid was being restored. In addition to this, they investigated the ways in which these dynamics influenced various protection mechanisms. Solar inverters, after they have been cleared of any obstructions, have been shown to be capable of operating as negative-sequence sources, which reintroduce energy into the power grid over the period of time necessary for the grid to recover from the impacts of a grid disruption. The amplitude of the current flowing in the negative sequence may be influenced by a wide range of operational parameters, such as the number of inverters that are now being put to use, the power of the grid, and the kinds of grid failures that are occurring. These negative-sequence responses have the ability to reduce the performance of protection measures that are based on negative-sequence components and to end up causing relay maloperations in the power grid during the restoration period. Additionally, these negative-sequence responses have the potential to cause a power outage. For this reason, the protection provided by the grid will become less trustworthy and secure.

Table 16.

Energy Storage Systems Comparison.

| Technology | Power Rating (MW) | Cycle Efficiency (%) | Lifetime (Years) | LCOE ($/kWh) |

|---|

27.

Largest energy storage systems projects around the globe.

| Power Plant Name | Technology | Country | Year | Installed Capacity (MW) | Reference | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Compressed Air | 110–1000 | |||||||||

| Three Gorges Dam | Hydroelectric Power | 42–54 | 20–40 | 2–120 | ||||||

| China | 2003 | 22,500 | [ | 29 | ][22] | Pumped Hydro Storage | 30–5000 | 70–87 | 40–60 | 5–100 |

| Itaipu Dam | Hydroelectric Power | Brazil and Paraguay | 1984 | 14,000 | [33] | Thermal Energy Storage | 0.1–300 | 30–60 | 20–30 | 3–60 |

| [ | 23 | ] | ||||||||

| Ouarzazate Solar Power Station | Thermal Storage (Molten Satl) | Morocco | 2018 | Total of 7325 MWt NOOR I (1200) MWt NOOR II (3500) MWt NOOR III (2625) MWt |

[34 | Lead Acid Batteries | 0–40 | 63–90 | 5–15 | 50–400 |

| ] | [ | 128 | ] | |||||||

| Manatee Energy Storage Center | Batteries | United States | 2021 | 409 | [30][125] | Li-ion Batteries | 0–100 | 75–97 | 14–16 | 600–3800 |

| Moss Landing Vistra Battery | Lithium-Ion Batteries | United States | 2020 | 400 | [31][126] | Flywheels | 0.25–20 | 90–95 | 15–20 | 1000–14,000 |

| Supercapacitors | 0–0.3 | 84–97 | 10–30 | 300–2000 | ||||||

| Fuel Cells | <58.5 | 20–66 | ~20 | 2–15 | Super magnetic Conducting Energy Storage | 0.1–10 | 95–98 | 20–30 | 500–72,000 |

Table

Connecting a large number of decentralized sources to the grid that operates at medium and low voltage presents a number of challenges. Pijarski and Kacejk [35][129] brought to light the potentially disastrous effects on voltage that might result from the connection of a large number of dispersed sources to a grid that operates at medium voltage. Due to the fact that they are situated at various points along medium voltage (MV) lines and have the potential to reach their maximum generation during off-peak hours, the voltage that they produce may fluctuate over a wide range. The fact that the voltages can occasionally reach values that are outside of the acceptable range is unfavorable for customers. With the help of specialized management and control systems that are self-sufficient, it is possible to get rid of the negative voltage phenomena that come from RES. Managing excessively large voltage changes is possible not only through the conventional control of the ratio of high voltage to medium voltage (HV/MV) transformers, but also through the control of power consumption of flexible loads and the simultaneous use of the possibilities offered by RES in the context of reactive power generation or consumption. Both of these methods are complementary to the traditional HV/MV transformer ratio control. It has been established that including electrolyzer installations into MV networks has a good influence, not only on the optimal voltage values from the point of view of the quality indicator that is being used, but also on minimizing the amount of power that is lost in the network. The method of optimum voltage control is one that has the potential to be carried out effectively if certain requirements are met. One of these factors is that the real network must be precisely mapped before the optimization process can begin. In order to develop a calculating model, it is necessary to make an assessment of the current condition of the MV networks. The measurements of current and voltage that are carried out are what allow for the creation of this estimate in the first place. Due to the radial topology of the network, which consists of just a few numbers of nodes, the complexity of the computations required to solve this issue is significantly decreased when compared to multi-node closed HV networks. It would seem that the application of the suggested voltage control system is feasible in practice due to the relatively small scale of the computational task, and as a result, the short length of time required to obtain outcomes. This allows for the process of optimal control to be carried out in real-time, which is advantageous.

Utilizing distributed generating systems (DGSs) is one of the most significant advances facilitating the energy transition. The DGSs provide for more user agency over energy use and production, but are more complex to set up and maintain. The optimization models that are being applied under uncertainty in DGSs is summarized by Alonso-Travesset et al. [36][130]. The authors analyzed more than 170 articles that optimized DGSs while considering uncertainty. The authors showed that adding elements, such as grid testbed validation, a battery aging model, taking into account demand response or controlled loads, correlating unknown parameters, and decentralization, all added to the complexity of the models. All of these improvements, along with others under development, will allow optimization models to be used in practice. It is expected that the number of DGS-focused research initiatives will grow, making a significant contribution to the energy transition and paving the way toward a totally green society free of carbon emissions.

The EMSs and control algorithms of HEVs were compared by Xue et al. [37][131] in terms of features, applicability, real-time capabilities, and the technological advancement that has occurred over time. Various control systems each have their own set of limitations when it comes to the difficulties associated with the management of energy that comes along with HEVs. Existing EMSs only take fuel economy into account, and there have only been a handful of in-depth studies done on economy, emissions, battery life, and driving style. Deciding the maximum power point at which any device is operated is important to increase efficiency and decrease the cost. Thermoelectric generators (TEG) are effectively used to harvest power from different resources, including the waste heat generated in various processes. Deciding the MPP of the thermoelectric generators will also improve the efficiency; therefore, Kanagaraj et al. [38][132] introduced an innovative MPPT method that is based on VFOFLC, which stands for “variable fractional order fuzzy logic controller.” This method is intended to extract the most amount of energy that can be obtained from the TEG. The fractional factor was included into the MPPT approach that was presented so that the length of time required to track up to the peak level in the P-V curve could be reduced, and the steady-state output could be maintained at a level that was centered around the MPP. The findings of the research indicated that the MPPT technique based on VFOFLC was able to modify the duty cycle of the DC–DC boost converter in an appropriate manner by employing the variable fractional factor. This was demonstrated by the fact that the technique made use of the variable fractional factor.

3. Fuel Cells and Green Hydrogen

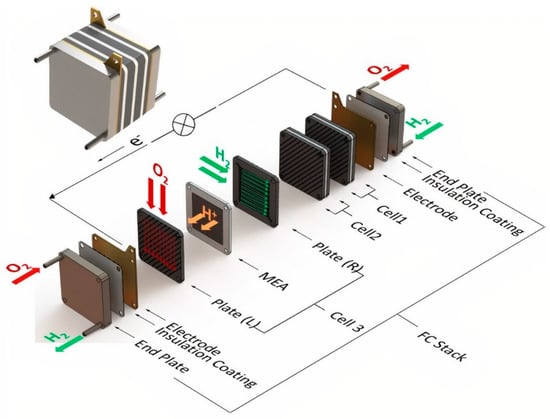

Fuel cells have shown encouraging results in a variety of applications, including transportation, i.e., fuel cell vehicles [39][40][41][133,134,135], off-grid applications [42][136], portable devices [43][137], stationary [44][45][138,139], etc. Figure 27 presents an illustration of the primary components that make up fuel cells.

Figure 27. Fuel cells stack and components schematic [46]. (With permission, license number: 5430310482582).

Proton exchange membrane fuel cells (PEMFCs) are the most prevalent kind of fuel cells that can function in a variety of applications, even when the temperature is rather low [47][48][141,142]. Due to the importance of this type of fuel cells, proton exchange membrane fuel cells, including their materials and methods of manufacture, were summed up by Olabi et al. [49][143]. The authors showed that a considerable amount of focus was spent on the newly created materials that were utilized for PEMFC, as well as the features of these materials. In spite of the progress that has been achieved with PEMFCs, there are still challenges that need to be handled before these devices can be deemed inexpensive and extensively utilized. These concerns include the cost of these devices as well as their durability. Two of the difficulties that the FC must overcome are its low power density and its poor mechanical durability. When it comes to the components that make up the membrane, the Nafion membrane delivers the highest level of performance. The search for new materials that are capable of entirely replacing Nafion and platinum is the primary focus of efforts being put forth right now by those who are making those attempts. When it comes to end plates, the most major challenge is the deflection, which is particularly troublesome for stacks that include a big number of cells. This is because the deflection causes the end plates to bend out of shape. This problem may be solved by using a material with a high tensile strength, yet still relatively lightweight.

The most significant trends in the expansion of renewable energy, as well as the chances for further scaling up this expansion via the use of green hydrogen solutions and the participation of resource-based nations in energy transition processes, were analyzed by Kopteva et al. [50][144] These included three potential strategic scenarios for the development of the energy industry: (1) the diffusion of renewable energy sources into the current energy system via the development of power accumulators; (2) the prerequisites for the development of green hydrogen; and (3) other related areas. The authors also analyzed a pilot project’s technical and economic feasibility to produce green hydrogen in the Magadan area (Russia). The authors concluded that most businesses’ projections regarding the hydrogen demand level in international markets are optimistic. At the moment, the majority of hydrogen is produced through a process known as steam methane reforming. This process results in significant emissions of carbon dioxide, which in turn exacerbate the greenhouse effect. This concern for the environment gives impetus to the process of methane cracking, which is one of the most promising alternatives to the production of hydrogen and has the potential to produce zero CO2 or carbon monoxide (CO) emissions. The cracking of methane has been the subject of extensive research, utilizing both metallic and carbonaceous catalysts. Researchers have recently concentrated their efforts on pyrolyzing methane in molten metals and salts to avoid the problems of reactor coking and rapid catalyst deactivation. A further advantage that is anticipated to arise is an improvement in heat transfer due to the high heat capacity of molten media. The energy used in the endothermic process can help lessen adverse environmental impacts in addition to the reaction that takes place and produces solid carbon and hydrogen. For pyrolysis in molten medium, concentrated solar energy has not been substantially investigated. The majority of studies have relied on electrical heating or the burning of fossil fuels as nonrenewable sources. However, it has the potential to be a viable and innovative route to further enhance the sustainability of hydrogen generation obtained from methane cracking. Msheik et al. [51][145] provided a summary of the research conducted on the generation of hydrogen by catalytic and molten media pyrolysis. The authors showed that the use of solid metals and carbonaceous catalysts for catalyzed methane cracking highlighted several noteworthy problems. These issues were principally concerned with the deactivation of the catalysts and the accompanying regeneration procedures. As a consequence, there was a limitation in the overall efficiency of the process, and it was unable to maintain the environmentally friendly qualities of methane cracking. The utilization of solar energy could be a feasible alternative for building a sustainable pyrolysis process to overcome the limits imposed by the catalyst. The high operating temperatures that may be obtained via the concentration of solar energy have made it feasible to do away with the need to use catalysts in the process of thermal methane pyrolysis. In addition, there is no production of CO or CO2 emissions, and the heat that is necessary for this endothermic process is obtained only from the concentrated energy that is provided by the sun.