The building envelope provides thermal comfort, an excellent visual view, and sunlight for the occupants. It consists of two parts: (i) opaque (non-transparent) part (e.g., walls and roofs) and (ii) transparent part (e.g., windows, curtain walls, and skylight devices). Recently, the use of fully-glazed facades, especially in large cities, has been increased due to their aesthetical and structural advantages. Phase Change Materials (PCMs) as latent energy storage material is the focus of this research, as well as other individual and combined techniques, including shading systems, solar cells (photovoltaic), and chromogenic (thermotropic and thermochromic) materials. PCM-integrated glazing systems have been extensively studied and rapidly developed over the past several decades from the standpoint of unique system designs, such as passive, active, and passive/active mixed designs, intelligent management, and sophisticated controls. In the academic literature, numerous studies on PCM-integrated building envelopes have been conducted, a comprehensive review of PCM-integrated GUs combined with other passive and active techniques using dialectical analysis and comparing the climatic conditions of each study using Köppen-Geiger climate classification climate classification has been performed only rarely. Consequently, the primary objective of this research is to reduce this discrepancy for all types of glazing, excluding glazed roofs.

The building envelope provides thermal comfort, an excellent visual view, and sunlight for the occupants. It consists of two parts: (i) opaque (non-transparent) part (e.g., walls and roofs) and (ii) transparent part (e.g., windows, curtain walls, and skylight devices). Recently, the use of fully-glazed facades, especially in large cities, has been increased due to their aesthetical and structural advantages. This has led this study to review the performance of the currently passive smart glazing technologies. Phase Change Materials (PCMs) as latent energy storage material is the focus of this review, as well as other individual and combined techniques, including shading systems, solar cells (photovoltaic), and chromogenic (thermotropic and thermochromic) materials. PCM-integrated glazing systems have been extensively studied and rapidly developed over the past several decades from the standpoint of unique system designs, such as passive, active, and passive/active mixed designs, intelligent management, and sophisticated controls. In the academic literature, numerous studies on PCM-integrated building envelopes have been conducted, but a comprehensive review of PCM-integrated GUs combined with other passive and active techniques using dialectical analysis and comparing the climatic conditions of each study using Köppen-Geiger climate classification climate classification has been performed only rarely. Consequently, the primary objective of this study is to reduce this discrepancy for all types of glazing, excluding glazed roofs. This review article also contains literature tables as well as highlights, limitations and further research suggestions at the end of each subsection.

1. Introduction

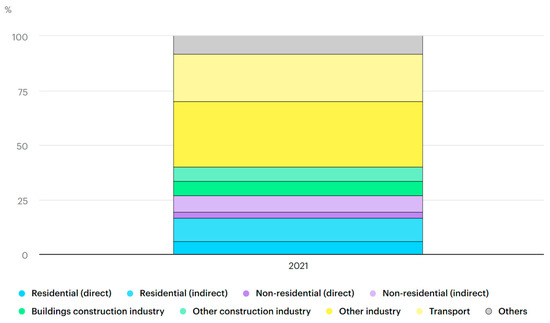

Residential and building construction together account for about one-third of global final energy consumption and almost 15% of direct CO

2 emissions (40–48% direct and indirect CO

2 emissions), according to the International Energy Agency (IEA), as shown in

Figure 1 [1]. Buildings and building construction continue to require more energy as a result of increased energy availability in emerging nations, rising air conditioning demand in tropical regions, increased ownership and usage of energy-intensive equipment, and quick development in building floor space. Energy trends in the building sector prove the high participation of buildings’ heating and cooling share in energy use and CO

2 emissions. If this trend continues, more than 50% of the total energy consumed in the buildings will be used for space cooling and heating up to 2050

[1]. Therefore, applying scientific methods to decrease energy consumption and, consequently, CO

2 emissions in this sector could save the environment and reduce the consequences of global warming to a great extent.

Figure 1. Global energy and process emissions from buildings, including embodied emissions from new construction, 2021

[1].

The building envelope provides a comfortable zone for the indoor space, including thermal and moisture comfort, acting as a shield against the largely variable and mostly undesired outdoor conditions. In recent years, numerous researchers have adopted various passive and active techniques to enhance the energy performance of the building envelope. Passive options include natural ventilation, solar radiation, and nighttime radiation from the earth and sky, whereas active solutions include mechanical ventilation and active cooling/heating of water or fluids. Active ventilation and active water-based cooling systems, which improve the system’s controllability, heat dissipation, and cooling, consequently boosting the system’s performance, are advantages of active systems over passive techniques. The disadvantages include the energy consumption of pumps and fans, the possibility of liquid leakage, and the high cost of maintenance, etc.

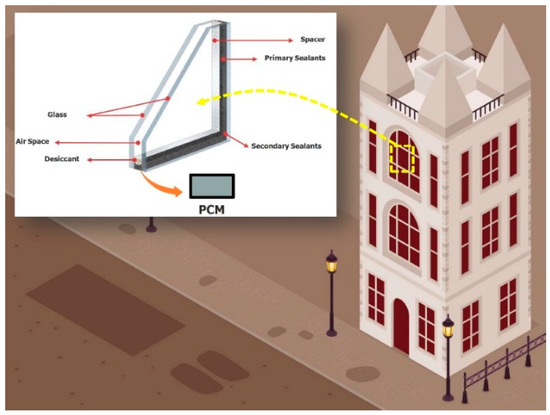

[2]. Utilizing Phase Change Materials (PCMs) as a passive approach incorporated into the building envelope has lately garnered the interest of researchers due to the high latent energy storage resulting in a greater thermal mass for structures. PCMs have been incorporated into the building envelope’s transparent part, which includes windows

[3], curtain walls

[4], and glazed roofs

[5], and the opaque part that includes walls

[6], ceilings

[7], and floors

[8]. The usage of PCMs can play a crucial role in managing the indoor temperature, transferring the peak load to off-peak hours, and reducing the energy required for space cooling and heating; nevertheless, further scientific research is required based on recent review studies on PCMs

[9][10][11][12][9,10,11,12].

Glazing components, such as windows, glazing facades, and glazed roofs, allow daylighting, views of the outdoors, and passive solar gain. Overall, 30% of the building’s energy consumption is accounted for by the glazed portions of the building envelope, and when there is a large window-to-wall ratio (WWR), this can grow to 60% by using windows and 90% by using curtain walls

[13]. Concerning the thermal effect of WWR on building energy efficiency, Saber and Hajiah

[14] developed a numerical model to examine the energy performance of PCM-incorporated building envelopes (walls and roofs) in different WWRs ranging from 10 to 70 percent. They discovered that WWRs of 10% and 40% produce the lowest and largest total annual loads, respectively. Despite the fact that several studies have been conducted on energy-saving methods for the glazing unit (GU) parts of a building, this part still suffers from a high solar transmittance factor, high thermal conductivity (low thermal resistance), and low thermal mass

[15].

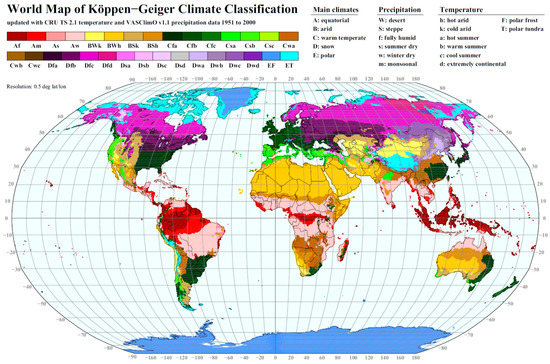

The type of structure and the climate of the building’s location are two of the most powerful aspects determining the energy-saving technologies of glazing units. Based on the Köppen-Geiger climate classification, there are five major climate types, including (A) tropical, (B) arid, (C) temperate, (D) cold, and (E) polar, and the sub-divisions of these five climatic types

[16]. In addition,

Figure 2 depicts the world Map of Köppen-Geiger climate classification updated with mean monthly CRU TS 2.1 temperature and VASClimO v1.1 precipitation data for the period 1951 to 2000 on a regular 0.5 degree latitude/longitude grid. In what follows, all the reviewed studies are designated to a Köppen-Geiger climate class type

[16].

Figure 2 corresponds a code to each location with a specific climatic condition. Hence, locations with similar Köppen-Geiger codes to each other can be treated almost the same.

The construction industry has shifted toward the usage of lightweight structures due to its major benefits, such as less material consumption and shorter construction times. Using curtain walls as building glazing facades rather than conventional windows or masonry as a lightweight building technology

[17] has resulted in the creation of nearly fully-glazed buildings and skyscrapers, particularly in large cities. It also provides an architecturally desirable view for the residents and a picturesque view of the front from the interior. In contrast, the low thermal resistance of glazing units and their increased use in recent years have piqued the interest of researchers seeking to maximize the energy performance of glazing units by taking into account the smallest change in optical qualities. Yu et al.

[18] addressed to the paradoxical influence of daylight on indoor thermal and visual comfort and energy use, stating that a “thermal-daylighting balance” must be struck between them. The authors determined that the thermal daylighting balance is dependent on the individual properties of the building envelope and the local climate.

Figure 2. World Map of Köppen-Geiger climate classification updated with mean monthly CRU TS 2.1 temperature and VASClimO v1.1 precipitation data for the period 1951 to 2000 on a regular 0.5 degree latitude/longitude grid

[19].

PCM-integrated glazing systems have been extensively investigated and rapidly developed over the past several decades from the perspectives of unique system designs, including passive, active, and passive/active combined designs, intelligent management, and sophisticated controls. In the academic literature, numerous studies have been conducted on PCM-integrated building envelopes, but a comprehensive review of PCM-integrated GUs combined with other passive and active techniques using dialectical analysis and comparing the climatic conditions of each study using Köppen-Geiger climate classification climate classification has been conducted only rarely. Therefore, the primary purpose of this study is to bridge this gap for all types of glazing, except glazed roofs.

2. Phase Change Materials

Thermal energy storage (TES) is a viable method for improving the energy efficiency of buildings and other applications, including concentrated solar power plants

[20], PV panels

[21], and heat pump systems

[22]. TES systems are classified into two main categories as (i) thermal and (ii) thermochemical energy storage. Due to unclear cost and longevity, the second use has not shown to be beneficial

[23]. The first has already been used in many applications and is classified as sensible and latent heat storage

[24].

The driving force for the process of charging and discharging the storage determines whether a system is passive or active; active systems use a pump or fan for the process, whereas in passive systems, the phase change is caused by a temperature difference between the environment and the storage

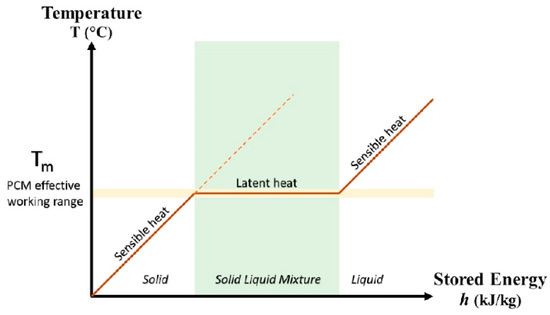

[23]. PCMs supply considerable latent heat throughout their phase transition at a constant temperature, which is a desirable property, particularly during the phase change from solid to liquid and vice versa, as shown in

Figure 3 [25][26]. The phase change could occur in the solid, liquid, and gas states through vaporization and condensation and in solid and liquid through freezing and melting. In building envelopes, solid–liquid and solid–solid phase changes are the most common

[26][27].

Figure 3 illustrates the fluctuating temperature of PCM’s storing heat. As depicted in the figure, when the temperature of the PCM exceeds its melting temperature (MT), the chemical bonds of its molecules begin to dissolve in an endothermic process, allowing the PCM to absorb heat and shift from a solid to a liquid phase. In contrast, as the temperature drops and hits the PCM’s freezing point, the molecules’ chemical bonds begin to renew in an exothermic process, culminating in the PCM’s transition from a liquid to a solid state, a process known as discharge

[27][28].

Figure 3. PCM energy storage by temperature variations

[25][26].

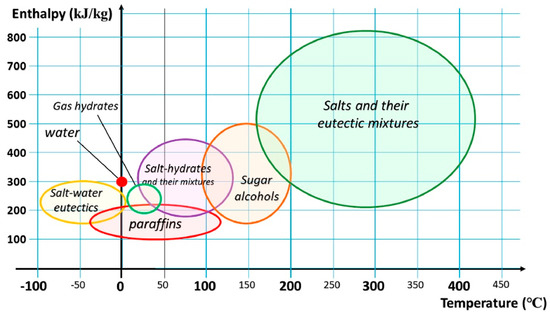

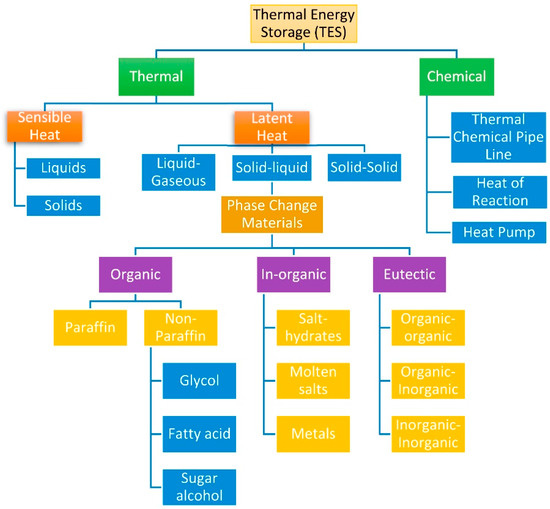

Solid–liquid PCMs are divided into three major categories: organic, inorganic, and eutectic, as well as the subgroups depicted in

Figure 4 [25][26]. Each class has distinct thermal qualities that can be employed depending on the storage system’s operational conditions.

Figure 5 [25][26] depicts the melting range and enthalpy of the specified PCM classes. The MT range of paraffin as an organic form of PCM is within a suitable range for heating and cooling applications in buildings, as depicted in this figure. This material (paraffin) has been utilized in the majority of GU-related applications due to its wide range of phase transition temperatures within a thermal comfort range, low cost, and good optical and light transmission properties

[28][29].

Figure 4. Classification of PCMs

[25][26].

Figure 5. Temperature and enthalpy ranges for various PCMs

[25][26].

3. Energy-Saving Technologies of GUs

Different energy-saving technologies, applied to the transparent parts of building envelope, have been studied by the researchers, including multiple-glazing windows, blind and shading devices, exhaust air windows, water glazing systems, thermotropic and thermochromic materials, low-e coatings, aerogels, PV systems, Prisma solar glasses, different insulating methods, different laminated glasses, phase change materials, and so forth

[29][30]. The following is a summary and discussion of the aforementioned technologies, with an emphasis on the application of PCMs in GUs. Since the primary purpose

of is tthis study is to examine the possible energy-saving technologies coupled with PCMs applied to curtain walls, all glazing units, excluding glazed roofs, were examined. In addition, the examined research is divided into two categories: (i) technologies of GUs with PCM and (ii) technologies of GUs without PCM.

3.1. Technologies of GUs with PCM Utilization

3.1.1. PCM-Incorporated Multi-Layered GUs

In numerous studies, PCMs have been employed in double-glazed units (DGUs) to improve the thermal performance of the system while maintaining the optical and light transmittance that resident’s desire. Goia et al.

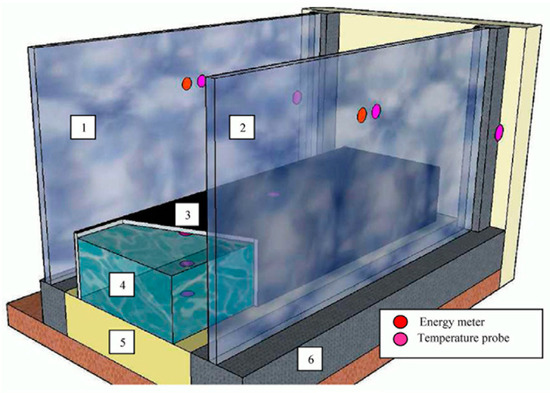

[30][31] conducted a numerical and experimental investigation to compare the thermal performance of PCM-incorporated double glazing windows (DGWs) to that of standard DG windows in warmer areas (Cfa).

Figure 6 depicts the test cells employed by the authors, one DGU with PCM and the other without PCM. For their research, the authors utilized RT35 paraffin with a nominal MT of 35 °C. The results demonstrated that the PCM-DG system has the potential to improve the indoor thermal environment, and its efficacy increases as solar irradiation rises. On a cloudy day, however, the thermal comfort produced by the two systems is the same. The presence of PCM in the fenestration system minimizes glare risk and improves eye comfort, according to the study. Later, Goia et al.

[31][32] experimentally evaluated the energy performance of a PCM-DG system in a similar study, using the same test cells as in

[30][31]. They utilized the identical weather and PCM data as in

[30][31]. Comparing the PCM-DG window to the conventional DG window, they determined that the PCM-DG window results in a 50% decrease in summertime energy gain. However, they argued that in the winter, the energy performance is more complex and requires additional study, as the daytime heat loss lowers while the direct solar gain decreases dramatically. In addition, they suggested control measures such as night ventilation to improve the system’s performance. King et al.

[32][33] conducted an experiment to determine the thermal performance of a PCM-DG window in Coimbatore, India (Aw) during the cooling season. As PCM material, the paraffin RT35 with MT of 29–36 was chosen. The PCM-DG window reduces energy usage by 3.76%, temperature fluctuations from 21 °C to 11 °C, interior air temperature by 9 °C, and inner glass temperature by 8.5 °C, according to the findings of the study’s authors. Liu et al.

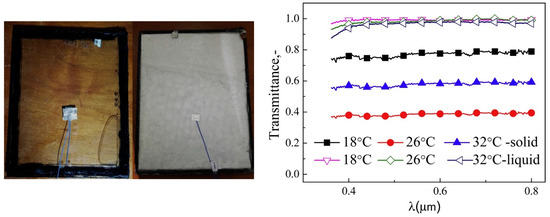

[33][34] executed an additional experiment to examine the thermal and optical performance of PCM-DG windows with varying solar energy intensities including 270 (W/m

2), 600 (W/m

2), and 950 (W/m

2). The authors utilized three MTs of 18 °C, 26 °C, and 32 °C with paraffin wax PCM.

Figure 7 depicts the solid and liquid states of the PCM used by the authors and the transmittance of the studied PCMs with different MTs. This figure shows that the transmittance in liquid phase is almost 1 regardless of the MT of PCM, while the PCM’s MT significantly affects the transmittance in solid phase. Considering PCM’s volume growth during the phase change, these researchers filled 97% of the total volume between the panes with PCM. The results indicated that the glazing unit containing PCM in liquid form has a 50% transmittance. Moreover, in order to maintain the optical performance of the GU, these researchers recommend avoiding PCM layers thicker than 16 mm. Tafakkori and Fattahi

[34][35] in Tehran, Iran (Bwh), proposed and evaluated various configurations for PCM-DG windows of simple cubic (as the reference case), partition-arranged simple cubic, simple cubic with a cylindrical wall, trapezoidal prism, partition-arranged trapezoidal prism, and trapezoidal prism with the cylindrical wall to reduce energy losses from building envelope. These scientists utilized paraffin MG29 with a melting point of 27 °C. According to their findings, the proposed configurations reduce energy consumption by around 20%. Musial

[35][36] numerically and experimentally analyzed the energy performance of a DG unit containing RT28 PCM with MT of 27.5 °C as a thermal accumulator unit inside the inner-pane space in Rzeszów, Poland (Cfb) instead of filling the cavity space between the panes of a DGU (see

Figure 8). In the winter, the author demonstrated that the suggested system produces a 10% more desired daily heat balance than a DG unit with no PCM; however, in the summer, there was no significant change in the daily heat balance. During the cooling interval, the PCM storage unit was also discovered to be overheating. In another study, Musial and Licholai

[36][37] implemented a PCM heat accumulator between the panes of a DG window with an external mobile shading system to examine its thermal performance through a numerical and experimental study during the summer season (June to August) in Rzeszów in Poland (Cfb), Naples in Italy (Csa), and Tallinn in Estonia (Dfb). The author chose a eutectic combination of propyl palmitate and butyl stearate as the PCM. The results showed a 29.4% decrease in room overheating in summer for the system with PCM storage compared to the system without it. A reduction in the amount of heat flowing through the building was also reported as 5.5%, 29.4%, and 24.8% Tallinn, Rzeszów, and Naples, respectively. Durakovi et al.

[37][38] also examined the use of PCM and water in a DG south-facing window as thermal storage materials in Sarajevo, Bosnia (Cfa) between June and December (25 °C in the summer and 4.5 °C in the winter) to evaluate their experimental performance. The paraffin RT27 was chosen as the PCM material. Compared to air-filled DG windows, the water glazing system exhibited a significantly more desirable damping temperature (more uniform and stable temperature values with fewer fluctuations) but a significantly less desirable average temperature. The PCM glazing system, on the other hand, has a promising average temperature and damping temperature.

Figure 6. Test cells composing DGU with clear glasses and DGU-PCM

[30][31][31,32].

Figure 7. Paraffin wax PCM in liquid and solid phases along with their transmittance variations in different MTs

[33][34].

Figure 8. A schematic diagram of DGU containing PCM accumulator between the panes. 1—exterior glazing, 2—interior glazing, 3—thermal storage unit, 4—PCM, 5—XPS thermal insulation, 6—window frames

[35][36].

As depicted in

Figure 9, Khetib et al.

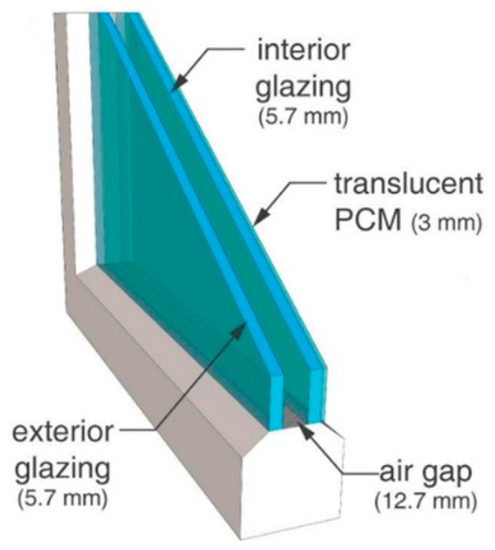

[38][39] explored the placement of PCM between the window frames of a DGW. They evaluated the impact of window angle variation from 0 (vertical mode) to 60° and space cavity depth on the PCM and window heat transfer. Between the window frames, n-eicosane was employed as the PCM with an MT of 37 degrees Celsius. Due to the decrease in natural convection heat transfer within the window, deviating a window from its vertical position by 60 degrees decreases heat transfer by 10%. It was also discovered that expanding the air gap to 40 mm decreases the Nusselt number by 44%. Moreover, it was demonstrated that the heat transmission decreases during the phase change of PCM from solid to liquid, but that PCM loses its heat transfer effectiveness when it totally melts. Gao et al.

[39][40] researched the phase transition of the PCM in the solid state on the interior layer of the inner pane of a DGW, as demonstrated in

Figure 10. Using EnergyPlus software, the optical and thermal performance of the solid–solid translucent PCM window was numerically studied. In warm, mixed, and cold regions, 3 mm PCM integration reduces building energy consumption by up to 9.4%, 6.7%, and 3.2%, respectively. Yang et al.

[40][41] applied an optimization model to look into the optical characteristics of PCM-based nanofluid, namely the nanoparticle concentration and diameter in GUs. The PCM was paraffin wax and the nanofluid was TiO

2. The scientists concluded that increasing the nanoparticle diameter from 10 nm to 30 nm increases the scattering coefficient of PCM nanofluid by a factor of 28.7.

Figure 9. Schematic of fenestration system

[38][39].

Figure 10. Schematic of DG system

[39][40].

PCMs have also been used in triple-glazing (TG) and quadruple-glazing (QG) windows. In Nanjing, China (Cfa)., Li et al.

[41][42] empirically and mathematically assessed the cooling and heating energy performance of a PCM-TG window. The numerical simulations were carried out utilizing ANSYS Fluent. The PCM material paraffin MG29 with an MT of 27–29 °C was inserted in the outside gap cavity space of the TG window, while the inner cavity was filled with air compared to a TGU and PCM-DGU with an entirely air-filled cavity. Using the PCM-TG window prevents overheating during the cooling time, as demonstrated by the findings. In a typical sunny summer day, comparing the PCM-TG window to the PCM-DG window and hollow TG window, 21.30% and 32.80% reductions in energy consumption were noted. Wieprzkowicz and Heim

[42][43] evaluated the cooling and lighting energies, glare effect, and thermal and optical discomforts of a PCM-TG window in Lodz, Poland (Dfb), by means of a numerical and experimental investigation. Five PCMs of paraffin RT18HC, RT22HC, RT25HC, RT28HC, and RT31 were chosen to fill the outer cavity space of the glazing system, while Argon gas was used to fill the interior cavity space. The acquired results indicate that there is no optimal unit type of PCM for the system, and that employing PCMs with varied MTs is advantageous from an energy and optical standpoint, as liquid PCM provides an excellent view of the sky and visual comfort, although this is not true for solid PCM. The authors advised covering the lower half of the window with a PCM to ensure the occupant’s optical view and filling the upper half of the window with a PCM to prevent overheating caused by energy demand

.

.

.

.

43. Summary and Conclusions

The transparent parts in the building envelopes are responsible for the most energy losses. The initial sources of these energy losses came from burning fossil fuels. As such, the heat losses from building envelopes also contribute to global warming and CO2 emissions. Increasing demand for the use of fully glazed façade systems makes it essential to optimize the energy performance of these systems. This researchtudy reviewed the potential active and passive methods focusing on phase change materials (PCMs) as latent energy storage material for energy enhancement of fenestration systems while providing a desirable optical view as well as enough sunlight for the occupants. Other technologies were also reviewed for smart glazing combined with PCM, including shading systems, solar cells (photovoltaic), and chromogenic (thermotropic and thermochromic). Since the climatic condition has been identified as the most influential factor for choosing the appropriate technology for smart glazing systems, almost all reviewed studies in this paper were designated by a Köppen-Geiger climate classification code. The main observations of this researchview study are as follows:

- PCM performs better in places where solar heat gain is greater. In addition, PCM is more successful in the summer and on clear days, whereas its efficacy in the winter and on overcast days is uncertain, necessitating the use of other passive and active approaches such as night ventilation.

- The PCM's volume expansion during phase transition is an additional factor that must be considered. Another potential problem that has been discussed is the reduced solar transmittance of PCM solid phase in comparison to liquid phase. Using solid-solid translucent PCM, which can also remove leakage and volume-changing issues, is one way to avoid this problem.

- During the summer, when the PCM-integrated blind system is on the interior side of the GUs, the absorbed daytime heat must not be vented inside, necessitating nighttime ventilation. On the other hand, during winter it collects heat during the day time and releases it to the inside, which is a beneficial effect but it filters more sunlight during the day as additional opaque material has been added to the blind system. To minimize losing sunlight, cascaded PCM integration with multiple MTs is recommended.

- Combining a PV layer and a PCM layer in the glazing units appears to be a promising technique that requires additional research to be fully exploited. The PCM enables the PV module to operate safely, which improves the thermal performance of the smart glazing system. As the PV layer blocks sunlight transmittance, it might be employed to keep the PCM from overheating while also producing electricity.

- Since PV-window technology alone has been used more frequently than in combination with other smart glazing technologies, and has demonstrated a promising energy-saving performance, it could be combined with other passive technologies to achieve a higher thermal performance for smart glazing technology. In addition, solar cells show better performance in regions with less cloudy days.

- There are numerous individual utilization of chromogenic materials, but only a few use them in combination with other passive techniques. Using their dynamic control of the sunlight entering buildings, PCM overheating may be prevented and other technologies can work in a safer environment. They function better in locations with warm summers

As per this review searchtudy, the scientific gaps for future works would include the following:

- An unsteady state analysis of the use of PCMs, along with other glazing technologies, over a long period of time is missing in the literature as the available studies were mainly conducted on typical days in summer and winter.

- The hysteresis analysis for a large number of cycles for PCMs, as well as PV and chromogenic layers, is missing in the literature.

- A hygrothermal analysis and risk of mold growth due to using PCM combined with other technologies in the glazing systems is missing in the literature.

- The use of various technologies in smart glazing and identifying the optimum case for each climatic condition is also less studied in the literature.

- Incorporating Prisma glasses with other technologies to enhance the energy performance of the glazing units needs to be expanded to cover various operating conditions.

- The economic viability of incorporating PCMs in smart glazing is not justified in the previous studies.

- Optical characteristics of smart glazing are of vital importance that need to be studied more deeply.