Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Jeffrey Scott Cross and Version 2 by Catherine Yang.

The gasification of biomass aims to transform heterogeneous feedstocks into syngas and heat that could be used for various purposes. Lignin is a biomass feedstock of special interest due to its particular properties and its ability to be obtained in abundant quantities as a side product from the paper pulp industry as well as the growing cellulosic ethanol industry.

- lignin

- gasification

- hydrogen

- syngas

- biomass

1. Economic and Energetic Perspective

From the economic perspective of lignin, assessing the value of lignin as a resource is difficult. Other kinds of biomass, such as agricultural waste, are thought to have negative or zero economic value until they are valorized, but in the case of lignin, this is harder to assess, as it is currently combusted in the recovery boilers of pulping plants to regenerate the chemicals used in pulping and provide heat to power the cooking process, in addition to the regulations that specify the disposal methods available, high-temperature incineration among them. Similarly, in the case of cellulosic ethanol plants, lignin is burned to generate steam, heat, and electricity [1][69].

Because of the previously mentioned current applications of lignin, the minimum economic value that it holds is the equivalent that it produces in energy, be it directly as heat or in the form of electricity if combusted. This is a perspective shared by other authors [2][70]. This means that the hypothetical value of lignin is tied to its geographical location in this context, as the cost of heat and electricity change depending on the country and location within a particular country.

Lignin gasification could provide heat, syngas, and small amounts of gaseous hydrocarbons depending on the choice of gasification method, reactor design, process conditions, and catalyst choice, if any, as discussed in the previous sections. In view of this, three different possible approaches are identified with regard to the previously discussed gasification methods:

-

Syngas production via the SCWG of lignin; the focus of the process is purely the production of H2-rich syngas that would then be used as feedstock for other processes, ideally at high lignin concentrations to minimize the degree of endothermicity of the process.

-

Syngas and heat co-production via oxidative lignin gasification; this process is focused on the production of syngas in addition to heat by integrating the gasification process with heat exchangers to valorize the residual heat of the products.

-

The gasification of black liquor; this process only applies to pulping processes and prioritizes the production of H2 gas over other co-products. This process is possibly the easiest to integrate with existing pulping facilities, as it overcomes the need to precipitate the lignin from black liquor and could be more seamlessly integrated into the rest of the process.

Of these, oxidative lignin gasification is possibly the most straightforward alternative to implement, as it is inherently exothermic and is a more mature technology compared to the other two, showing parallels with coal gasification [3][71].

Additionally, H2 gas is foreseen to gain great importance over the next few decades as part of the energy mix of many countries that aim to achieve carbon neutrality [4][5][72,73], representing an opportunity for lignin. Whether the production cost of H2 from lignin gasification would be competitive with current natural gas-derived hydrogen or green hydrogen produced from renewable energy remains to be seen and would ultimately depend on the energy policies and pricing mechanisms implemented in the near future.

From a purely energy-centric point of view, many authors criticized the feasibility of using biomass in general as a source of energy [6][74], touted to be CO2-neutral and renewable, but also suffering from limitations that restrict its potential in supplanting the role currently fulfilled by crude oil and natural gas. Because of this, authors point to the fact that the usage of lignocellulosic biomass as building materials may be a more sustainable and less CO2-intense [7][75] application. From this perspective, lignin derived from pulping streams occupies a specially interesting spot due to its unique structure composed of aromatic units and the fact that it is potentially available in large quantities as side-streams of already economically feasible processes. With this in mind, in the following section, a brief forecast of lignin valorization technology in the upcoming future is provided.

2. Comparison to Other Lignin Conversion Methods and Recommendations

Currently, lignin has limited but relatively well-established applications, primarily for heat and power generation to regenerate pulping chemicals in the case of pulp production or to provide heat for processes within cellulosic ethanol biorefineries. Other notable current applications, albeit at a lower scale, include the usage of lignin as a binder for coal and mineral dust briquettes, as well as a binder for wood-related materials [8][76] and its application in cement mixtures, where it improves the concrete performance [9][77]. It is worth noting that these last two current applications are comparatively very small to lignin’s usage in heat and power generation.

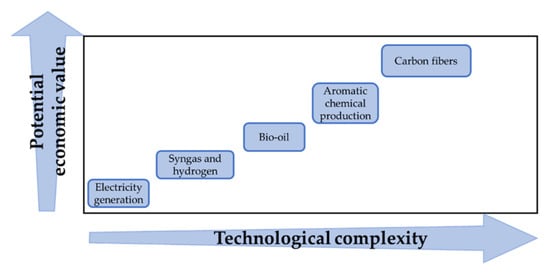

Having stated this, emergent methods for lignin valorization stray away from energy generation-related focuses and move more towards higher complexity technologies that intend to take advantage of the fact that lignin is already a highly functionalized polymer. This means that rather than breaking down lignin’s complex structure into simpler C1 molecules or H2, the aim is to transform it into materials that benefit from the existing functional groups already found in lignin. Some of the most notable examples include carbon materials [10][78], phenolic compounds, and resins [11][79], with applications in automotive and spacecraft industries, medicine, and biomedical materials.

Whether these emerging technologies would partially or entirely supplant lignin’s current role as a source of energy and syngas would ultimately depend on the concurrent developments of other technologies, price fluctuations, and forecasts of crude oil and policy that may enhance lignin’s competitiveness over other raw materials. Figure 13 demonstrates an interpretation of how the current and emergent lignin applications would change over time as technologies mature and move towards potentially more economically attractive applications.

Figure 13.

Applications of lignin as feedstock in terms of economic value vs. technological complexity.

Because of the aforementioned emerging technologies, the outlook for lignin gasification as a stand-alone technology in the long-term is uncertain. However, currently and in the near future, the increased interest in H2 production and the demand for biomass-derived syngas to synthesize sustainable hydrocarbons may allow it to retain or gain importance, at least in the short term.

In light of the expected increase in H2 demand and the likelihood that lignin-derived H2 would have to compete in terms of cost with other renewable sources of H2 as well as other applications of lignin, the cost of feedstock beyond the minimum energy value in terms of heat or electricity may increase. Lignin gasification research should focus not only on optimizing the yields of H2 or syngas but also on the recovery of heat in exothermic processes to minimize costs; this could potentially be achieved through innovative catalyst designs that are both active and resistant to deactivation, but simultaneously cheap to deploy in large quantities.