Modern innovative models have the possibility of transferring research and development (R&D) output through technology transfer from scientific and research institutions or other enterprises. The complex process of technology transfer is significantly dependent on cooperation among academia, industry, and governments in response to the technological developments driven together through Industry 4.0 (I4.0). As a result, numerous technology transfer factors must be addressed for I4.0 to become a reality. However, the abundance of literature on I4.0 and associated technologies, the key ingredients, and insights for effectively executing I4.0 technology transfer are fairly limited.

- technology transfer

- industry 4.0

- I4.0

1. Introduction

2. Factors Affect the Success of the Technology Transfer for I4.0

2.1. Industry 4.0 Technology Transfer Relation

The focused path of technology transfer has changed over time, according to [18][21]. Before 1980, most technology transfer research concentrated on cross-national technology transfer. At the beginning of the 1980s, research shifted to domestic technology transfer. In the US, interdisciplinary research holds great promise for creativity and innovation, which has become the new focus of technology transfer. The goal of technology transfer is to bring university outcomes into the market. The relationships among universities, industries, and the government are essential. These three partners must work effectively to establish a successful process. This relationship must be contextualized because of the significant changes in productive and organizational systems in I4.0. The technology transfer process in I4.0 will mobilize the entire country based on [19][22] research. [20][23] focus on technology-enhancing innovation in I4.0. Firms should be more adaptable and flexible in responding to changes in client demand and market needs. The flexible and adaptable process is aided by new technologies of I4.0 such as 3D printing. In this vein, technology transfer is seen as a way to give small businesses and countries with less advanced industries a fair chance. Several countries have determined the importance of technology transfer in the transition to I4.0. The UK government invested in Advanced Manufacturing (AM) research and technology transfer £95.6 million. A total of £20.5 million was invested in industry-academia collaboration projects. From 2007 to 2016, the UK government thought that technology transfer would help close the gap between what people knew about AM technology in theory and what they actually knew about it in practice [21][24]. Switzerland has a government effort to support the transition to I4.0 using technology transfer. According to [22][26], Switzerland is well-known for creating and applying innovative and high-value-added products. The federal government established a program targeted at technology transfer in the digitalization field. The production infrastructure must be modernized using the most advanced and efficient available technologies, focused on the I4.0 paradigm. In addition, for a more efficient approach, new and optimized manufacturing strategies were developed. As a result, Switzerland continues to rank among the top countries in this regard. On the other hand, Turkey focuses more on the strategic level. Turkey’s biotechnology strategy and action plan (2015–2018) have significantly promoted R&D. Turkey focuses on supporting innovative companies for I4.0. The R&D expenditures of commercial enterprises increased significantly between 2016 and 2019. Almost three-quarters of all spending in 2019 came from SMEs [23][27]. India works on the collaboration between industry and higher education institutes (HEIs). [24][32] mentioned that there is evidence to advocate how the role of HEIs has changed. In addition, HEIs participation in commercial activities has grown through technology transfer and start-ups. The focus of technology transfer is the commercialization of academic research results through the licensing and leasing of technology. There are several types of relationships between HEIs and industries for knowledge supply:- (1)

-

Industry may look for universities as problem-solution providers.

- (2)

-

Start collaborating with the industry by submitting a research proposal from the HEIs to the industry.

- (3)

-

Industry can outsource a third party to search for the best research centers in HEIs; and

- (4)

-

The industry can receive proposals by working with a third party. The third party is the link between local R&D institutes.

2.2. Excellence and Innovation Centers

Technology transfer is vital to implementing I4.0, especially for developing countries. According to [25][33], developing countries are not established with the characteristics of I4.0. An ongoing and evolutionary process for technology transfer is needed to adopt new technologies. The resource of technology can be from specialized suppliers or their main offices. Developed countries produce knowledge and technology through contracting research centers, internal improvements, and R&D investments.

On the other hand, innovation has also played a key role in technology transfer in the new era of I4.0. [26][29] talk about how closed innovation strategies differ from the global open innovation trend, which is getting even stronger with I4.0. On the contrary, patent commercialization empowered by open innovation increases the chance of commercialization through technology transfer. The empowerment comes from the technical and economic values of the patents.

Based on [27][35], entrepreneurial technology in the field of I4.0 can be delivered and supported by technology transfer. Technology transfer has a significant role in the emerging technological paradigm, where strategies to address disruptions of I4.0 require coordinated activities. It should be supported by innovation spaces that offer an early access point to technological innovation. It can come from academic research and help start-up businesses grow faster by providing a variety of resources and services.

Innovation centers played a key role in transferring technology to farmers in the era of Agriculture 4.0; according to [2], Innovation centers aim to accelerate technology transfers to farmers. The main pillars are technology, studies to develop site-specific technology, and counselling to apply technology in the field. The location of laboratories is also essential in terms of accelerating technology transfer. Having several locations of innovation centers near farmers could help them understand, adapt, and integrate I4.0 technology.2.3. Technology Transfer in the 4.0 Industrial Revolution, and Open Innovation

One of the primary drivers of open innovation and subsequent technology transfer is an innovation environment that focuses on dynamics and co-evolution [28][37]. Open innovation allows businesses to establish a structured innovation ecosystem that leverages external partner networks while focusing on developing core internal competencies [13]. Although the phrase "open innovation" was coined in the previous decade, the concept is not new. Open innovation is partly reflected in terms such as open source, user co-creation, user-centered innovation, and distributed innovation [13]. Dynamic open innovation is based on interactions that traverse company boundaries. Some ideas and knowledge originate from outside the company, while others are licensed to outsiders for commercialization [29][38]. Firms can capitalize on opportunities beyond their boundaries and limited internal resources to enhance the innovation rate in high-velocity marketplaces. Firms must have access to the resources of other organizations in addition to their own. Firms seek new ideas outside of their organizations and develop relationships with other enterprises that depend on each other [20][30][31][32][23,39,40,41]. I4.0 stimulates open connections between technology and the market through open innovation [33][42]. I4.0 emphasized the significance for government agencies, research institutions, consultancy businesses, non-profit organizations, and entrepreneurs to form collaborative networks [34][43]. The most effective methods for I4.0 are dynamic open innovation business models and an open innovation culture. It is extremely beneficial to businesses in this technological era. Consequently, company collaboration may spur creativity and innovation, as well as develop novel ideas and concepts [35][44]. Combining I4.0 technology with open innovation is a game changer, allowing firms to drastically reduce costs and time [36][45]. Companies often adopt an open-source approach to building the networks associated with their products rather than a closed-source strategy [37][46]. The strength of local and regional research and innovation (R&I) processes regularly influences the innovative capability of SMEs. Cooperation and networking at the business and organizational levels are crucial for the growth and knowledge transfer at the core of R&I for SMEs [38][47]. Companies with a high level of open innovation, such as in the robotics sector, have a better chance of commercializing their patents via technology transfer [26][29]. Technology transfer has been a foundation of open innovation as the economic and digital industrial eras have accelerated Open innovation improves the innovative performance of digital innovation [39][40][41][48,49,50]. By transferring knowledge, skills, technologies, and technological transfers, this type of innovation can significantly improve foreign-domestic connections and contribute to development [42][51]. This will boost the firm’s ability to innovate and adopt new technologies [38][47] Open innovation also makes it simpler and less expensive for small and medium-sized businesses (SMEs) to use resources from outside their organization. This decreases risk and increases the use of external knowledge sources [20][42][23,51]. Indeed, the era of Industry 4.0 technologies prioritizes open innovation since incorporating external knowledge is more vital than ever in driving organizational innovation [43][52]. Ninety-four percent of the world’s major innovators perform part of their research and development (R&D) efforts abroad [44][53]. This indicates that companies should not depend entirely on their own ideas and in-house research but should also invite other sources to contribute. This is the outside-in branch of open innovation, sometimes called inbound open innovation [45][54].2.4. Manufacturing Culture

The industry represents the transfer recipient in the technology transfer process. Manufacturing culture is one factor that affects the success of technology transfer. According to [46][55], manufacturing culture consists of firm behaviour, routines, norms, and attitudes that shape it. Culture works as the link bundled with norms, traditions, and social conventions as part of informal or ‘soft’ institutions [47][56]. Manufacturing culture has a significant impact when focuing on technological changes, such as the transmission toward I4.0 [46][55]. This required an alignment between several business entities, industries, and technology strategies [48][57]. Manufacturing culture must be considered a key factor for a successful technology shift [46][55]. Based on research done by [47][56], culture and formal institutions (rules, laws, and regulations) produced specific institutional settings. Culture is highlighted as the key element that leads to spatial variations in economic activities and performance. Company-wide acceptability can be obtained only if senior management is explicitly committed to implementing I4.0. It is required to make faster and more effective decisions. Collaboration between departments and groups, even beyond business borders, is essential for a successful Industry 4.0. A clear strategy and suitably trained employees can increase employee acceptance and decrease employee uncertainty about the unknown as well as the unfamiliar use of new media [49][58].2.5. Human Capital Technical Experience

I4.0 technology transfer is a complex, interdisciplinary environment. The staff must have the knowledge and skills to deal with its complexity. The experience of the TTO staff is essential. According to [50][59], these technologies can be (1) highly implicit or (2) the commercial application is difficult and complex, or both. This concept was supported by [51][60]. She stated that special emphasis should be placed on people’s involvement in technology transfer and selection. The staff includes people working on the TTO and the technology recipient (industry). The lack of skilled staff and the necessary know-how to implement I4.0 was a crucial success factor; it counted as a vital barrier [49][52][58,61]. The workforce was cited as a barrier to the adoption of nearly all smart manufacturing [53][62], which arises with the change in the manufacturing scenario and the new technologies [54][63].2.6. Legal Protection

However, with the deployment of I4.0, the focus was on IP protection for intangibles. Some protection methods include virtual system setup, data ownership, management, storage, processing algorithms, and brand recognition. Therefore, this protection must be broadened. The deployment of I4.0 puts the existing knowledge and application of IP protection and commercialization methods to the test [55][64]. The creation of new techniques requires a better suited to fast-changing, highly linked corporate networks. Businesses must carefully consider ways to protect their IP. The consequences of installing interconnected communications and using application programming interfaces are more collaborative inter-company models. I4.0 outcome is a novel environment that is highly collaborative and interoperable. China recognizes that with the I4.0 technologies, countries that do not care about protecting these technologies will be less competitive and place themselves out of the world’s stage for exporting end products [55][64]. Ref. [17][18] emphasized the need to protect I4.0 products and techniques. The protection comprises a pressing need to preserve innovative products and procedures from being easily imitated. It also erodes an organization’s competitive advantage. As a result, IPRs may preserve an invention’s originality, which can subsequently be marketed to promote knowledge and technology transfer for public purposes. However, a national technology transfer framework has not yet been developed. Universities and public research organizations have been recognized as having significantly contributed to technology transfer policies in numerous nations. They are both actively engaging in capacity-building and allowing the commercial application of IPs.3. Industry 4.0 Technology Transfer Models and Conceptual Framework

3.1. Industry 4.0 Technology Transfer Models

Several institutions have successfully used a technology transfer approach for commercial profits. One of the goals of practical research on new technology innovation is to commercialize inventions. Universities have witnessed an increase in the identification of possibilities and their capacity to take inventions by boosting TTOs and innovation spaces [27][35]. Ref. [56][65] examined the role of open innovation, technological crowding, and technological diversity in the relationship between competitive behaviors and firm performance. The model used in the panel set evaluates the role of the independent, moderating, and control variables on firm performance. The results showed that the inbound open innovation mitigates the negative effects of vulnerability on firm performance and that external innovation through technology transfer the positive effects of competitive initiatives on firm performance. External outsourcing of technology is better suited for commercializing a technology owned by the company or incorporating it into in-house applications [56][65]. On the other hand, [57][66] presented a conceptual model of the technology delivery system (TDS). TDS offers an essential framework for collecting information, organizing it, and concluding results regarding the implications that can be used for decisions regarding emerging technology supply chains. The TDS is a core part of the “Forecasting Innovation Pathways” (FIP) approach. FIP combines a range of future-oriented technology analysis tools to assist decision-makers in discovering opportunities (and threats) to achieve successful innovation while recognizing the inherent uncertainties of innovation pathways.3.2. The Conceptual Framework for Industry 4.0 Technology Transfer

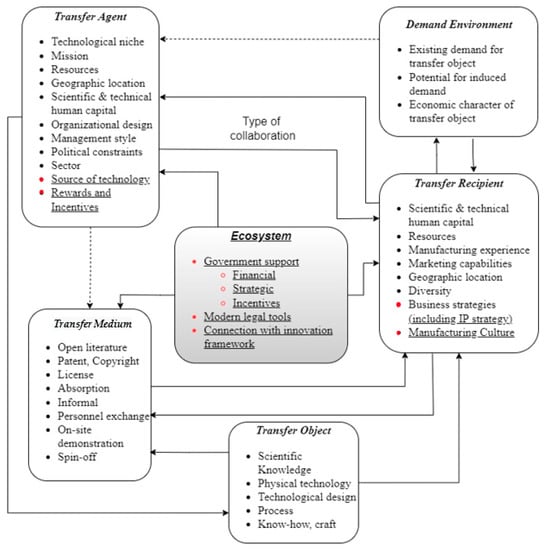

The conceptual framework was developed. The framework is based on the available contingent effectiveness model by [18][21] to match the finding for the I4.0 technology transfer. The framework summarized the literature on what work was done related to factors that enhance the success of the technology transfer process, elaborated in Figure 5. The contingent effectiveness model was created by [18][21] and revised by [58][69]. The model is wide enough to cover the technology transfer process. Figure 5. A conceptual framework of technology transfer for I4.0.

Figure 5. A conceptual framework of technology transfer for I4.0.4. Conclusions

-

The government plays a significant role in encouraging the industry to strive towards I4.0 through technology transfer. The government can facilitate the transition toward I4.0 via technology transfer by enacting legislation, financing support, and offering incentives for this transition.

-

A more collaborative environment must be established to enhance the effectiveness of the technology transfer process. The type and level of collaboration between technology recipients, technology agents, and inventors are required for I4.0 technology transfer. Collaborations that begin before submitting a patent application are more likely to succeed in marketing and selling inventions.

-

Under I4.0, the role of universities in economic growth has shifted dramatically. Universities’ duties extend beyond the commercialization of inventions to include the transfer of knowledge and skills. Universities are considered the main engine of economic development.

-

The source of this technology is critical. Excellence innovation centers and laboratories support the industry (especially SMEs) in transitioning to I4.0.

-

Dynamic open innovation and open innovation culture are the most effective ways to address I4.0. Technology commercialization, aided by open innovation, enhances the likelihood of commercialization via technology transfer.

-

The I4.0 technology transfer environment is complex and multidisciplinary. The skills and expertise of related employees in TTO directly impact the technology transfer process of I4.0 technologies. The more availability of the skills and knowledge, the better the performance. Furthermore, the TTO requires a financial incentive structure to motivate inventors to participate and follow up on innovation commercialization. Incentives are one of the essential aspects in motivating individuals to perform harder.

-

Manufacturing culture influences the success of I4.0 technology transfer when we focus on technological advancements such as the transition to I4.0. It is vital to make quicker and more effective choices, to collaborate between departments and groups, to have a clear strategy, and to have appropriately trained staff. Consequently, employee adoption of the technology will increase, as will employee uncertainty.

-

The legal tools available to protect the I4.0 technologies are inadequate. A modern legal tool is required to cover the intangibles technology with IP. These tools should have better suited for rapidly evolving technologies.

-

New technologies establish a new ecosystem with new practices and tactics for securing and commercializing IP. This will facilitate the adoption of I4.0 technology.