The homogenization treatment and the main effects responsible for its application in the food industry are defined. It is shown how the main applications have evolved towards the increase of the functionality of food and valorization of waste from the food industry as a consequence of technological development of valves and the higher pressures applied. Finally, high pressure homogenization technology is recognized as a soft and green technology with great potential for use in the food industry.

- high homogenization pressures

- bioactive compounds

- food functionality

- food sustainability

- encapsulation

- probiotics

- microbial load

- enzyme inactivation

- extraction from waste

1. DefiInitroduction

A fluid is forced to pass through a gap, causing energy transformations that directly affect the dissolved, dispersed or emulsified components. The fluid undergoes mechanical (shear, hydrodynamic and cavitation effects) stress and an increase in temperature (thermal effect) of approximately 2–3 °C for every 10 MPa of homogenization pressure [1]. These affect the fluid structure and properties, and also those of its constituent elements (particles, molecules, globules, droplets, aggregates, granules, etc.). Particle sizes decrease and more homogeneous distribution is achieved, facilitating operations such as mixing and emulsification. The effects are different to those induced by HPP (High Pressure Processing), in which prepacked food is loaded into a pressure vessel and then pressurized at a range of 100–1000 MPa, with water as the pressure-transmitting medium [2].

2. History

Initially, homogenization was introduced as a manufacturing step in the dairy industry. This operation reduced the size of fat globules, increasing the stability of the emulsion and, thus, the physical and chemical stability of milk. It had a great impact on the quality of dairy products such as condensed milk, curd or ice cream. The applied pressure was less than 30 MPa and it was applied in one or two steps. However, significant technological developments have occurred since then, having an impact on the design and geometry of homogenization valves, and making it possible to work at higher pressures and with very short processing times (a few seconds) [3]. High homogenization pressures were introduced at the beginning of the 2000s as an alternative, nonthermal treatment in the food industry, and applications were extended to industries other than dairy, e.g., to fields such as textile or biotechnologic.

The existence of valves of different geometries has given rise to the design of equipment that is able to work at pressures higher than 400 MPa. Thus, a distinction is made among standard homogenization for pressures between 0 and 50 MPa, high pressure homogenization (HPH) for pressures between 50 and 300 MPa and ultrahigh pressure homogenization (UHPH) for pressures equal to or greater than 400 MPa. Processing efficiency is modulated by applying various pressure ranges or combining a pressure value with a specific number of passes through the equipment [4]. In addition, the possibility of operating continuously for a great diversity of pumpable fluids has made it possible to extend applications to the activation/inactivation of enzymes, reduction of microbial load, mixing, dispersion, emulsification or encapsulation processes, cell breakage processes and the modification of proteins or macromolecules to obtain ingredients or additives with various properties.

Nowadays, concern about food functionality and sustainability is driving research interest in increasing the bioavailability and bioaccessibility of active components and probiotics, and in the extraction of macro- and micro- molecules from food byproducts. The challenges of increasing the nutritional characteristics of food must be combined with a reduction in environmental impact and increased food security. In this context, alternative, soft and nonthermal technologies such as high pressures homogenization have huge potential. The objective of this work is to review how the need to combine safety, functionality and sustainability has conditioned the application of high pressure homogenization technology in food. Advances and applications in the last decade have been organized according to the main challenges in the food industry.

2. History

Initially, homogenization was introduced as a manufacturing step in the dairy industry. This operation reduced the size of fat globules, increasing the stability of the emulsion and, thus, the physical and chemical stability of milk. It had a great impact on the quality of dairy products such as condensed milk, curd or ice cream. The applied pressure was less than 30 MPa and it was applied in one or two steps. However, significant technological developments have occurred since then, having an impact on the design and geometry of homogenization valves, and making it possible to work at higher pressures and with very short processing times (a few seconds) [3]. High homogenization pressures were introduced at the beginning of the 2000s as an alternative, nonthermal treatment in the food industry, and applications were extended to industries other than dairy, e.g., to fields such as textile or biotechnologic.

The existence of valves of different geometries has given rise to the design of equipment that is able to work at pressures higher than 400 MPa. Thus, a distinction is made among standard homogenization for pressures between 0 and 50 MPa, high pressure homogenization (HPH) for pressures between 50 and 300 MPa and ultrahigh pressure homogenization (UHPH) for pressures equal to or greater than 400 MPa. Processing efficiency is modulated by applying various pressure ranges or combining a pressure value with a specific number of passes through the equipment [4]. In addition, the possibility of operating continuously for a great diversity of pumpable fluids has made it possible to extend applications to the activation/inactivation of enzymes, reduction of microbial load, mixing, dispersion, emulsification or encapsulation processes, cell breakage processes and the modification of proteins or macromolecules to obtain ingredients or additives with various properties.

Nowadays, concern about food functionality and sustainability is driving research interest in increasing the bioavailability and bioaccessibility of active components and probiotics, and in the extraction of macro- and micro- molecules from food byproducts. The challenges of increasing the nutritional characteristics of food must be combined with a reduction in environmental impact and increased food security. In this context, alternative, soft and nonthermal technologies such as high pressures homogenization have huge potential. The objective of this work is to review how the need to combine safety, functionality and sustainability has conditioned the application of high pressure homogenization technology in food. Advances and applications in the last decade have been organized according to the main challenges in the food industry.

3. Evolution and Major Applications in the Last Decade

Publications in peer-reviewed journals show that the main applications of HPH in food have the following objectives:

-

Conservation and safety by decreasing the microbial load and inactivating enzymes. This occurs as a consequence of the thermal effect derived from mechanical stress or from structural changes in proteins.

-

Recovery and extraction of proteins, fibrous materials and bioactive compounds (mainly polyphenols) and increase of the functionality considered in terms of technological use (stabilization of emulsions and dispersions, flow capacity and viscosity modifications, emulsifying activity improvement, etc.). Mechanical stresses and hydrodynamic effects induce cell disruption, favoring the release of intracellular content or structural components of the cell wall. Moreover, dispersed particles or fat droplets can be reduced in size and modified in structure.

-

Increase of functionality in terms of health effect (increase bioaccessibility, bioavailability or probiotic effect). These effects result from favoring the release of bioactive compounds, the modification of biopolymer structures and the development of novel particle interactions and networking. Micro- or nano- capsules have also been developed.

-

Conservation and safety by decreasing the microbial load and inactivating enzymes. This occurs as a consequence of the thermal effect derived from mechanical stress or from structural changes in proteins.

-

Recovery and extraction of proteins, fibrous materials and bioactive compounds (mainly polyphenols) and increase of the functionality considered in terms of technological use (stabilization of emulsions and dispersions, flow capacity and viscosity modifications, emulsifying activity improvement, etc.). Mechanical stresses and hydrodynamic effects induce cell disruption, favoring the release of intracellular content or structural components of the cell wall. Moreover, dispersed particles or fat droplets can be reduced in size and modified in structure.

-

Increase of functionality in terms of health effect (increase bioaccessibility, bioavailability or probiotic effect). These effects result from favoring the release of bioactive compounds, the modification of biopolymer structures and the development of novel particle interactions and networking. Micro- or nano- capsules have also been developed.

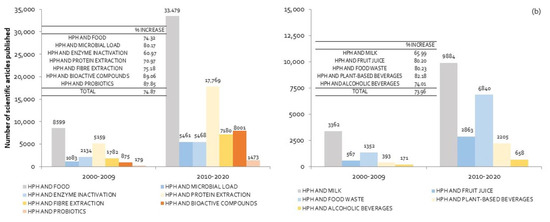

In order to numerically quantify its evolution, the increase in the number of published scientific articles (in %) was calculated, taking into account the difference in the number of items between the last two decades. The results in each of the considered areas are included in

a,b. As shown in

a, between 2000 and 2009, HPH were used mainly for the extraction of proteins, although a large number of research works focused on microorganisms and enzymes inactivation, contributing to food preservation and safety. The last decade (from 2010 until now) revealed a significant increase (74.87%) in the total number of scientific articles published. The main areas in which there was an increase greater than the total value were the use of HPH for microorganism inactivation, fiber extraction, and above all, bioactive and probiotic components. The application of HPH to extract or increase the functionality of bioactive compounds, and to improve the probiotic effect, grew by 89% and 87.9% respectively (

a). The increasing interest among consumers and the food industry in improving the organoleptic and nutritional quality of foods, along with concern for the valorization of food waste, might explain this result.

b shows the evolution in the number of published research works related to the application of HPH according to food type. Although the majority of works focused on fruit juices, the largest growth occurred in plant-based beverages and food waste. The huge increase in the consumption of plant-based beverages [5] and general concern about food waste-related issues are responsible for this increase. HPH technology is recognized as a green technology due to short processing times, low energy consumption, low CO

emissions and the fact that it does not require polluting solvents.

This increase in research works based on HPH technology is also due to the development of new homogenization equipment that works at elevated pressures (i.e., up to 400 MPa) and supports specific conditions. Since the invention of adjustable valves in 1930 [6], the potential of homogenization technology has increased. The geometry and design of the valve determines the mechanical effect on the treated fluid. In 1982, the invention of the Gaulin Micro-Gap valve [7] greatly boosted the efficiency of the process, making high homogenization pressures possible in subsequent years and leading, more recently, to the development of ultrahigh homogenization pressure technology. In general, improvements have been obtained in all fields of application, making HPH an efficient tool with great potential for use in the food industry [8].

4. Conclusions

Although in the beginning, the application of high homogenizing pressures was aimed at more efficient homogenizing and increasing the stability of emulsions such as milk, advances in valve design have allowed for an increase in working pressure extending the scope of possible applications.

In the last decade, the number of research works related to the implementation of HPH—for extracting bioactive components from agri-food wastes, to improve the bioavailability and probiotic properties of bioactive components and microorganisms, and also as an encapsulation technique—has grown by more than 80%. At the same time, progress has been made in the application of HPH to reduce the microbial load or modulate the activity of some enzymes.

References

- Augusto, P.E.; Tribst, A.A.; Cristianini, M. High Hydrostatic Pressure and High-Pressure Homogenization Processing of Fruit Juices. In Fruit Juices; Elsevier BV: Amsterdam, The Netherlands, 2018; pp. 393–421.

- Koutchma, T. Fundamentals of HPP Technology. In Adapting High Hydrostatic Pressure for Food Processing Operations; Elsevier BV: Amsterdam, The Netherlands, 2014; pp. 5–10. [Google Scholar]

- Osorio-Arias, J.C.; Vega-Castro, O.; Martínez-Monteagudo, S.I. Fundamentals of High-Pressure Homogenization of Foods. In Reference Module in Food Science; Elsevier BV: Amsterdam, The Netherlands, 2020.

- Bevilacqua, A.; Campaniello, D.; Speranza, B.; Altieri, C.; Sinigaglia, M.; Corbo, M.R. Two Nonthermal Technologies for Food Safety and Quality—Ultrasound and High-Pressure Homogenization: Effects on Microorganisms, Advances, and Possibilities: A Review. J. Food Prot. 2019, 82, 2049–2064.

- Picart-Palmade, L.; Cunault, C.; Chevalier-Lucia, D.; Belleville, M.-P.; Marchesseau, S. Potentialities and Limits of Some Non-thermal Technologies to Improve Sustainability of Food Processing. Front. Nutr. 2019, 5, 130.

- McClatchie, J.M. The Borden Company. Valve Homog. Dev. 1930, 28, 131–134. [Google Scholar]

- Pandolfe, W.D. Development of the New Gaulin Micro-Gap™ Homogenizing Valve. J. Dairy Sci. 1982, 65, 2035–2044.

- Patrignani, F.; Siroli, L.; Braschi, G.; Lanciotti, R. Combined use of natural antimicrobial based nanoemulsions and ultra-high-pressure homogenization to increase safety and shelf-life of apple juice. Food Control. 2020, 111, 107051.