Basalt mineral fibre, made directly from basalt rock, has good mechanical behavior, superior thermal stability, better chemical durability, good moisture resistance and can easily be recycled when compared to E-glass fibres (borosilicate glass is called ‘E-glass’ or ‘electric al-grade glass’ because of its high electrical resistance) which are traditionally used in structural composites for industrial applications. Industrial adoption of basalt fibre reinforced composites (FRC) is still very low mainly due to inadequate data and lower production volumes leading to higher cost. These reasons constrain the composites industry from seriously considering basalt as a potential alternative to conventional (e.g., E-glass) fibre reinforced composites for different applications.

- basalt

- mechanical properties

- durability

- life cycle assessment

1. Basalt

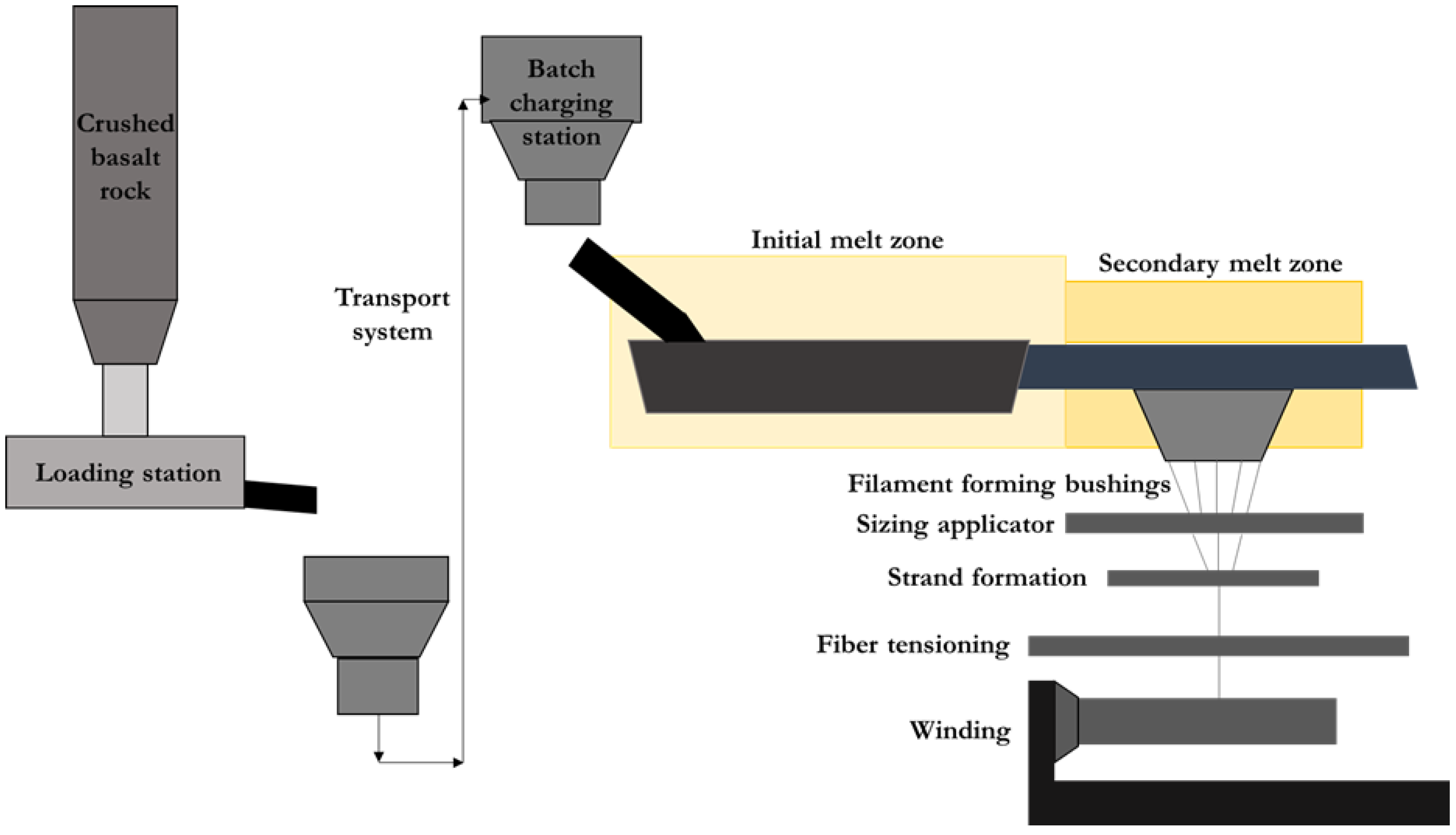

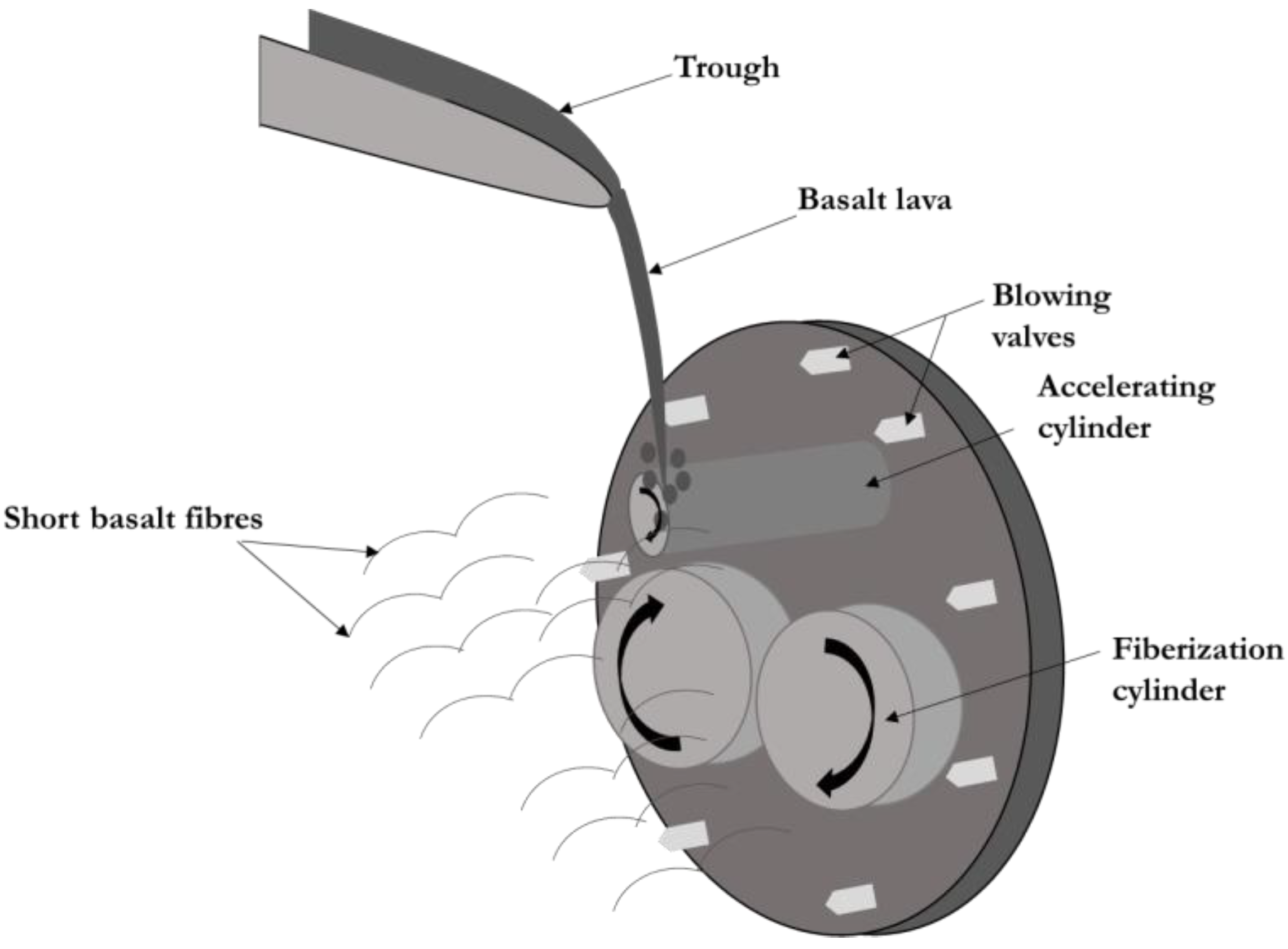

21.1. Manufacturing Techniques for Basalt Fibre Production

21.2. Mechanical Properties of Basalt Fibres

21.3. Chemical Properties of Basalt Fibres

21.4. Thermal Properties of Basalt Fibres

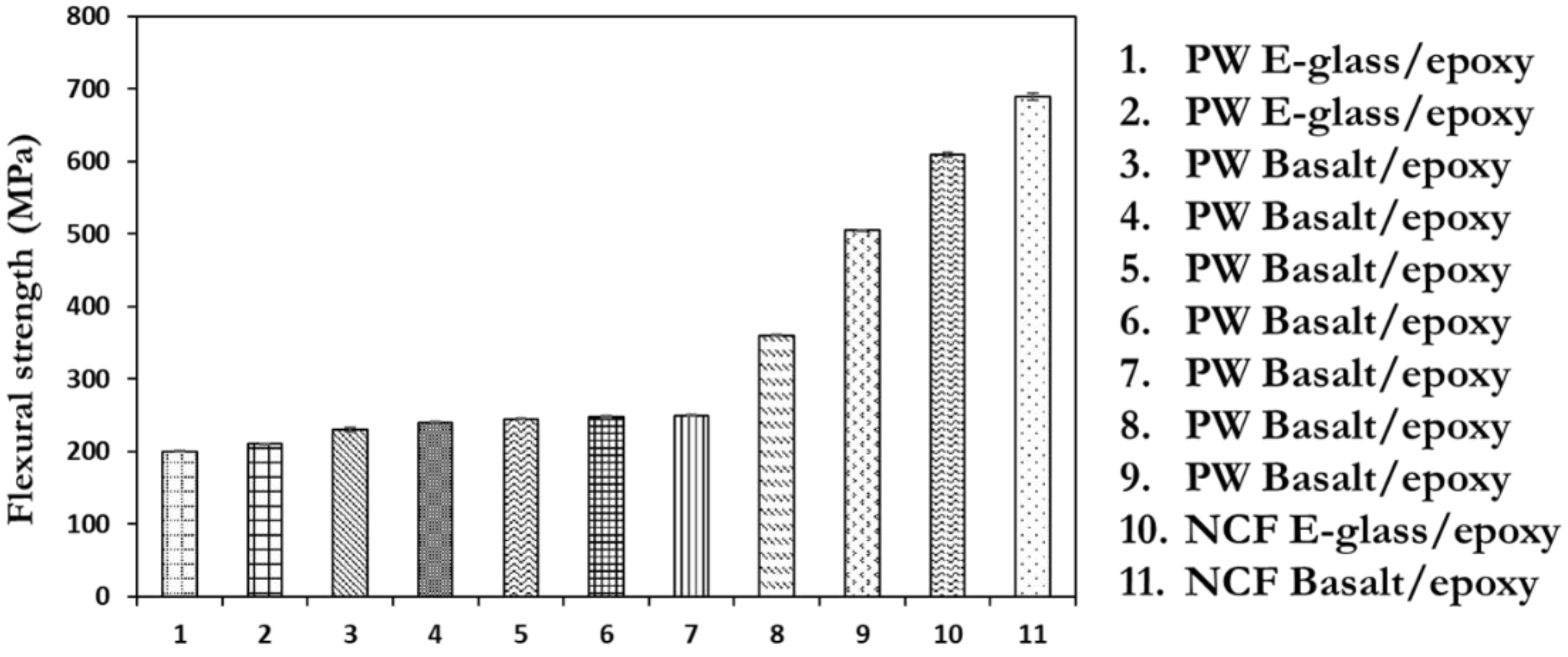

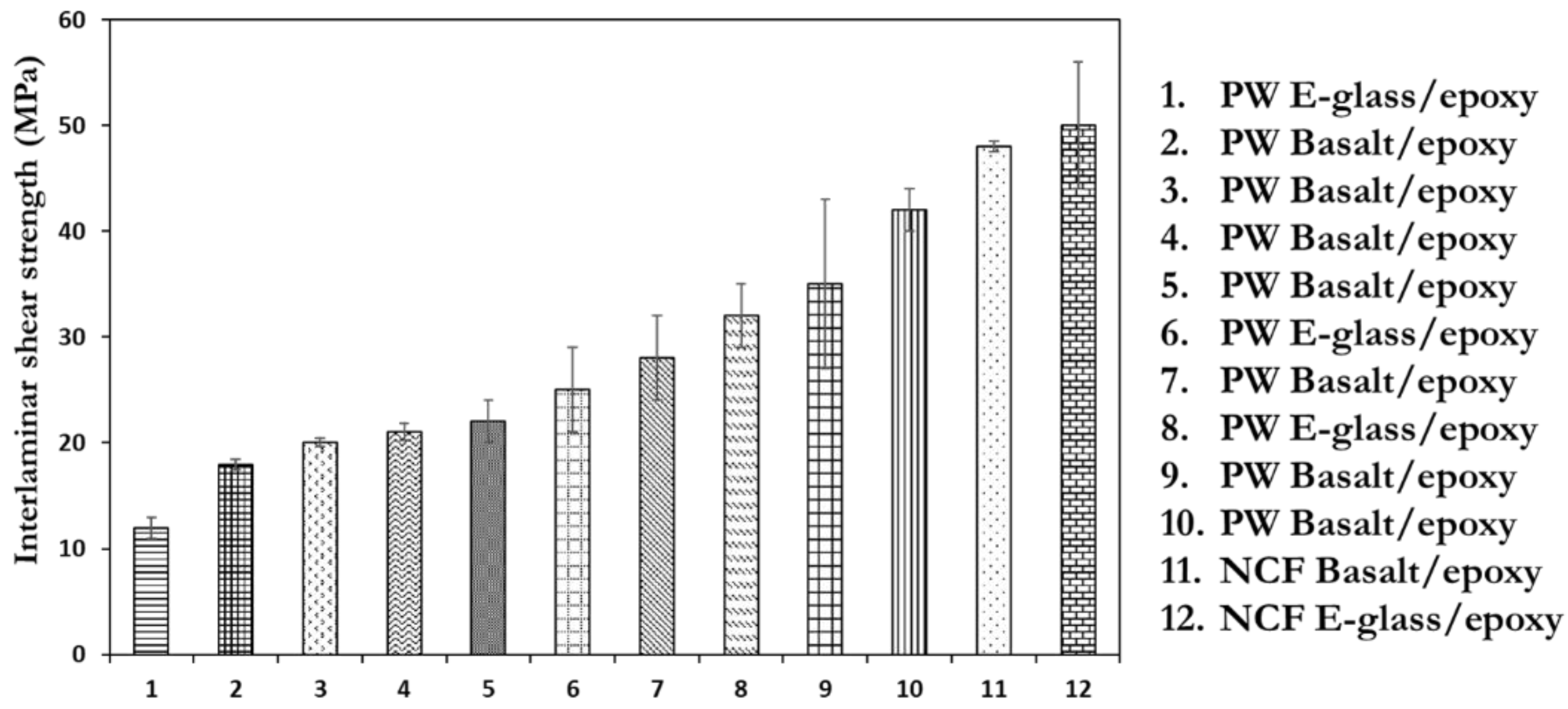

32. Mechanical Properties of Basalt Fibre Reinforced Composites

Failure Mechanisms in Basalt Fibre Reinforced Composites

References

- Dhè, P. Filament Composed of Basalt. U.S. Patent 1438428, 12 December 1922.

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-based fiber-reinforced materials and structural applications in civil engineering. Compos. Structrs. 2019, 214, 246–263.

- Austin, H.F.; Subramanian, R.V. Extrusion in the Presence of a Reducing Agent. U.S. Patent 4149866, 17 April 1979.

- Subramanian, R.V.; Shu, K.H.H. Silane Coupling Agents for Basalt Fibre Reinforced Polymer Composites. In Molecular Characterization of Composite Interfaces; Ishida, K., Kumar, G., Eds.; Springer: New York, NY, USA, 1985; pp. 205–236.

- Park, J.M.; Subramanian, R.V. Interfacial shear strength and durability improvement by monomeric and polymeric silanes in basalt fibre/epoxy single-filament composite specimens. J. Adhes. Sci. Technol. 1991, 5, 459–477.

- Lee, J.J.; Nam, I.; Kim, H. Thermal stability and physical properties of epoxy composite reinforced with silane treated basalt fibre. Fibers Polym. 2017, 18, 140–147.

- Jung, T.; Subramanian, R.V. Strengthening of basalt fibre by alumina addition. Scr. Metall. Mater. 1993, 28, 527–532.

- Dzhigiris, D.D.; Volynskii, A.K.; Kozlovskii, P.P. Principles of Production Technology for and Properties of Basalt Fibres. In Basalt Fibre Composite Materials and Structures; Teploenergetik: Moscow, Russia, 1980; pp. 54–81.

- Dzhigiris, D.D.; Makhova, M.F.; Gorobinskaya, V.D. Continuous Basalt Fibre. In Glass Ceram; Teploenergetik: Moscow, Russia, 1983; Volume 40, pp. 467–470.

- Wojnarovits, I. Mechanical change of basalt and glass wool fibres during aqueous corrosion at different temperatures. TIZ-Fachber. 1987, 111, 554–558.

- Aslanova, L.G. Method and Apparatus for Producing Basaltic Fibres. U.S. Patent 20020069678, 13 June 2002.

- Brik, V.B. Multifunctional Apparatus for Manufacturing Mineral Basalt Fibres. U.S. Patent 6647747, 18 November 2003.

- Brik, V.B. Apparatus Integrated with Ceramic Bushing for Manufacturing Mineral/Basalt Fibres. U.S. Patent 20060218972, 19 August 2014.

- IMARC Group. Basalt Fiber Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022–2027; IMARC Group: Sheridan, WY, USA, 2022.

- Militky, J.; Kovacic, V.; Rubnerova, J. Influence of thermal treatment on tensile failure of basalt fibers. Eng. Fract. Mech. 2002, 69, 1025–1033.

- Militky, J.; Kovacic, V. Ultimate Mechanical Properties of Basalt Filaments. Text. Res. J. 1996, 664, 225–229.

- Singha, K.A. Short review on basalt fibre. Int. J. Text Sci. 2012, 1, 19–28.

- Jamshaid, H.; Mishra, R. A green material from rock: Basalt fibre—A review. J. Text I 2016, 107, 923–937.

- Czigány, T.; Vad, J.; Pölöskei, K. Basalt fibre as a reinforcement of polymer composites. Period Polytech. Mech. Eng. 2005, 49, 3–14.

- Fiore, V.; Scalici, T.; Bella, G.D.; Valenza, A. A review on basalt fibre and its composites. Compos. Part B 2015, 74, 74–94.

- Greco, A.; Maffezzoli, A.; Casciaro, G.; Caretto, F. Mechanical properties of basalt fibres and their adhesion to polypropylene matrices. Compos. Part B Eng. 2014, 67, 233–238.

- Deák, T.; Czigány, T. Chemical composition and mechanical properties of basalt and glass fibres: A comparison. Text. Res. J. 2009, 79, 645–651.

- Gutnikov, S.I.; Malakho, A.P.; Lazoryak, B.I.; Loginov, V.S. Influence of alumina on the properties of continuous basalt fibres. Russ. J. Inorg. Chem. 2009, 54, 191–196.

- Gurev, V.V.; Neproshin, E.I.; Mostovoi, G.E. The effect of basalt fibre production technology on mechanical properties of fibre. Glass Ceram. 2001, 58, 62–65.

- Mishnaevsky jr, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sorensen, B.F. Materials for Wind Turbine Blades: An Overview. Materials 2017, 10, 1285.

- Thomsen, O.T. Sandwich materials for wind turbine blades—Present and future. J. Sandw. Struct. Mater. 2009, 11, 7–26.

- Summerscales, J.; Searle, T.J. Low-pressure (vacuum infusion) techniques for moulding large composite structures. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2005, 219, 45–58.

- Grande, J.A. Wind Power Blades Energize Composites Manufacturing, Plastics Technology. 2008. Available online: https://www.ptonline.com/articles/wind-power-blades-energize-composites-manufacturing (accessed on 17 March 2019).

- Carbon fibre, vs. Carbon fibre vs. Fiberglass: A Comparison between the Two Materials Which Material Is Superior? Available online: https://infogr.am/carbon-fiber-vs-fiberglass (accessed on 11 August 2019).

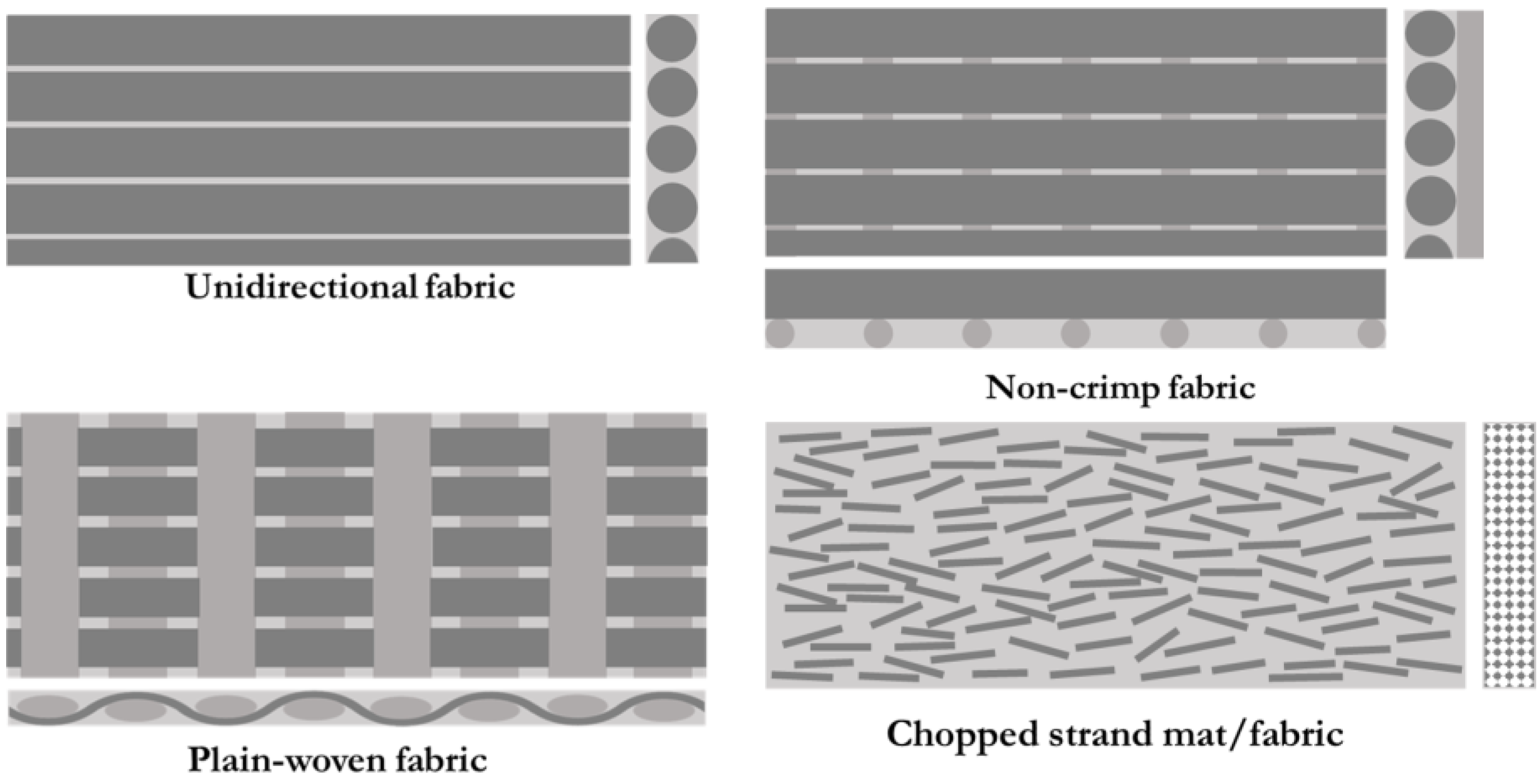

- Haberkern, H. Tailor-made reinforcements. Reinf. Plast. 2006, 50, 28–33.

- Ralph, C.; Lemoine, P.; Summerscales, J.; Archer, E.; Mcllhagger, A. Relationship among the chemical, mechanical and geometrical properties of basalt fibres. Text. Res. J. 2019, 89, 3056–3066.

- Ramakrishnan, N.S.; Tolmare, V.; Brik, V.B. Performance Evaluation of 3-D Basalt Fibre Reinforced Concrete and Basalt Rod Reinforced Concrete. In NCHRP-IDEA Program Project Final Report; Transportation Research Board: Washington, DC, USA, 1998.

- Wei, B.; Cao, H.; Song, S. Tensile behaviour contrast of basalt and glass fibres after chemical treatment. Mater. Des. 2010, 31, 4244–4250.

- Nasir, V.; Karimipour, H.; Taheri-Behrooz, F.; Shokrieh, M.M. Corrosion behaviour and crack formation mechanism of basalt fibre in sulphuric acid. Corros. Sci. 2012, 64, 1–7.

- Mengal, A.N.; Karuppanan, S.; Wahab, A.A. Basalt carbon hybrid composite for wind turbine rotor blades: A short review. Adv. Mater. Res. 2014, 970, 67–73.

- Abashidze, S.; Marquis, F.D.; Abashidze, G.S. Hybrid fibre and nano powder reinforced composite for wind turbine blades. J. Mater. Res. Technol. 2015, 4, 60–67.

- Soukhanov, A.V.; Dalinkevich, A.A.; Gumargalieva, K.Z.; Marakhovsky, S.S. Modern Basalt Fibres, and Epoxy Basalt to Plastics: Properties and Applications. In Key Engineering Materials. Volume II: Interdisciplinary Concepts and Research; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: Oxford, UK, 2014; pp. 69–94.

- Wang, S.; Zhong, J.; Gu, Y.; Li, G.; Cui, J. Mechanical properties, flame retardancy, and thermal stability of basalt fibre reinforced polypropylene composites. Polymer Composites 2020, 41, 4181–4191.

- Ralph, C.; Lemoine, P.; Boyd, A.; Archer, E.; Mcllhagger, A. The effect of fibre sizing on the modification of basalt fibre surface in preparation for bonding to polypropylene. Appl. Surf. Sci. 2019, 475, 435–445.

- Wei, B.; Cao, H.; Song, S. Environmental resistance and mechanical performance of basalt and glass fibres. Mat. Sci. Eng. A-Struct. 2010, 527, 4708–4715.

- . Mingchao, W.; Zuoguang, Z.; Yubin, L.; Min, L.; Zhijie, S. Chemical durability and mechanical properties of alkali-proof basalt fiber and its reinforced epoxy composites. J. Reinf. Plast. Compos. 2008, 27, 393–407.

- Lilli, M.; Sarasini, F.; Fausto, L.D.; González, C.; Fernández, A.; Lopes, C.S.; Tirillo, J. Chemical Regeneration of Thermally Conditioned Basalt Fibres. Appl. Sci. 2020, 10, 6674.

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fibre as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512.

- Rabinovich, F.N.; Zueva, V.N.; Makeeva, L.V. Stability of basalt fibres in a medium of hydrating cement. Glass Ceram. 2001, 58, 431–434.

- Scheffler, C.; Förster, T.; Mäder, E.; Heinrich, G.; Hempel, S.; Mechtcherine, V. Aging of alkali-resistant glass and basalt fibres in alkaline solutions: Evaluation of the failure stress by Weibull distribution function. J. Non-Cryst. Solids 2009, 355, 2588–2595.

- Hao, L.; Yu, W. Evaluation of thermal protective performance of basalt fibre nonwoven fabrics. J. Therm. Anal. Calorim. 2009, 100, 551–555.

- Ying, S.; Zhou, X. Chemical and thermal resistance of basalt fibre in inclement environments. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2013, 28, 560–565.

- Moiseev, E.A.; Gutnikov, S.I.; Malakho, A.P.; Lazoryak, B.I. Effect of iron oxides on the fabrication and properties of continuous glass fibres. Inorg. Mater. 2008, 44, 1026–1030.

- Gutnikov, S.I.; Manylov, M.S.; Lipatov, Y.a.V.; Lazoryak, B.I.; Pokholok, K.V. Effect of the reduction treatment on the basalt continuous fibre crystallization properties. J. Non-Cryst. Solids 2013, 368, 45–50.

- Lipatov, Y.a.V.; Arkhangelsky, I.V.; Dunaev, A.V.; Gutnikov, S.I.; Manylov, M.S.; Lazoryak, B.I. Crystallization of zirconia doped basalt fibres. Thermochim. Acta 2014, 575, 238–243.

- Varley, R.J.; Tian, W.; Leong, K.H.; Leong, A.Y.; Fredo, F.; Quaresimin, M. The effect of surface treatments on the mechanical properties of basalt-reinforced epoxy composites. Polym. Compos. 2013, 34, 320–329.

- Wei, B.; Cao, H.; Song, S. Surface modification and characterization of basalt fibres with hybrid sizing. Compos. Part A Appl. S 2011, 42, 22–29.

- Chen, W.; Shen, H.B.; Auad, M.L.; Huang, C.Z.; Nutt, S. Basalt fibre epoxy laminates with functionalized multi-walled carbon nanotubes. Compos. Part A 2009, 40, 1082–1089.

- Kim, M.T.; Rhee, K.Y.; Park, S.J.; Hui, D. Effects of silane-modified carbon nanotubes on flexural and fracture behaviours of carbon nanotube-modified epoxy/basalt composites. Compos. B Eng. 2012, 43, 2298–2302.

- Kim, M.T.; Rhee, K.Y.; Lee, B.H.; Kim, C.J. Effect of carbon nanotube addition on the wear behaviour of basalt/epoxy woven composites. J. Nanosci. Nanotechnol. 2013, 13, 5631–5635.

- Lee, J.H.; Rhee, K.Y.; Park, S.J. The tensile and thermal properties of modified CNT reinforced basalt/epoxy composites. Mat. Sci. Eng. A Struct. 2010, 527, 6838–6843.

- Bashar, M.T.; Sundararaj, U.; Mertiny, P. Mode-I interlaminar fracture behaviour of nanoparticle modified epoxy/basalt fibre-reinforced laminates. Polym. Test. 2013, 32, 402–412.

- Wei, B.; Song, S.; Cao, H. Strengthening of basalt fibres with nano-SiO2–epoxy composite coating. Mater. Des. 2011, 32, 4180–4186.

- Wang, G.J.; Liu, Y.W.; Guo, Y.J.; Zhang, Z.X.; Xu, M.X.; Yang, Z.X. Surface modification and characterizations of basalt fibres with non-thermal plasma. Surf. Coat. Tech. 2007, 201, 6565–6568.

- Kim, M.T.; Kim, M.H.; Rhee, K.Y.; Park, S.J. Study on an oxygen plasma treatment of a basalt fibre and its effect on the interlaminar fracture property of basalt/epoxy woven composites. Compos. Part B 2011, 42, 499–504.

- Dorigato, A.; Pegoretti, A. Fatigue resistance of basalt fibres-reinforced laminates. J. Compos. Mater. 2012, 46, 1773–1785.

- Wu, Z.; Wang, X.; Iwashita, K.; Sasaki, T.; Hamaguchi, Y. Tensile fatigue behaviour of FRP and hybrid FRP sheets. Compos. Part B Eng. 2010, 41, 396–402.

- Lopresto, V.; Leone, C.; Iorio, I.D. Mechanical characterization of basalt fibre reinforced plastic. Compos. Part B 2011, 42, 717–723.

- Palmieri, A.; Matthys, S.; Tierens, M. Basalt Fibres: Mechanical Properties and Applications for Concrete Structures. In Concrete Solutions, Proceedings of the International Conference on Concrete Solutions, International Conference on Concrete Solutions, Padua, Italy, 22–25 June 2009; Granham, M., Majorana, G., Eds.; CRC Press/Balkema: Leiden, The Netherlands, 2009; pp. 165–169.

- Chairman, C.A.; Kumaresh Babu, S.P. Mechanical and abrasive wear behaviour of glass and basalt fabric-reinforced epoxy composites. J. Appl. Polym. Sci. 2013, 130, 120–130.

- Carmisciano, S.; Rosa, I.M.; Sarasini, F.; Tamburrano, A.; Valente, M. Basalt woven fiber reinforced vinylester composites: Flexural and electrical properties. Mater. Des. 2011, 32, 337–342.

- Černý, M.; Glogar, P.; Sucharda, Z. Mechanical properties of basalt fibre reinforced composites prepared by partial pyrolysis of a polymer precursor. J. Compos. Mater. 2009, 43, 1109–1120.

- Ary Subagia, I.D.G.; Tijing, L.D.; Kim, Y.; Kim, C.S.; Vista, F.P., IV; Shon, H.K. Mechanical performance of multiscale basalt fibre–epoxy laminates containing tourmaline micro/nanoparticles. Compos. Part B 2014, 58, 611–617.

- Bulut, M. Mechanical characterization of Basalt/epoxy composite laminates containing graphene nano pellets. Compos. Part B 2017, 122, 71–78.

- Petrucci, R.; Santulli, C.; Puglia, D.; Sarasini, F.; Torre, L.; Kenny, J.M. Mechanical characterization of hybrid composite laminates based on basalt fibres in combination with flax, hemp and glass fibres manufactured by vacuum infusion. Mater. Des. 2013, 49, 728–735.

- Sun, G.; Tong, S.; Chen, D.; Gong, Z.; Li, Q. Mechanical properties of hybrid composites reinforced by carbon and basalt fibres. Int. J. Mech. Sci. 2018, 148, 636–651.

- Sarasini, F.; Tirillo, J.; Ferrante, L.; Valente, M.; Valente, T.; Lampani, L.; Gaudenzi, P.; Cioffi, S.; Iannance, S.; Sorrentino, L. Drop-weight impact behaviour of woven hybrid basalt-carbon/epoxy composites. Compos. Part B 2014, 59, 204–220.

- Scalici, T.; Pitarresi, G.; Badagliacco, D.; Fiore, V.; Valenza, A. Mechanical properties of basalt fibre reinforced composites manufactured with different vacuum-assisted impregnation techniques. Compos. Part B 2016, 104, 35–43.

- Dorigato, A.; Pegoretti, A. Flexural and impact behaviour of carbon/basalt fibres hybrid laminates. J. Compos. Mater. 2014, 48, 1121–1130.

- He, C.; Li, Y.; Zhang, Z.; Sun, Z. Impact damage modes and residual flexural properties of composites beam. J. Reinf. Plast. Compos. 2008, 27, 1163–1175.

- Sfarra, S.; Ibarra-Castanedo, C.; Santulli, C.; Paoletti, A.; Paoletti, D.; Sarasini, F. Falling weight impacted glass and basalt fibre woven composites inspected using non-destructive techniques. Compos. Part B 2013, 45, 601–608.

- Shishevan, F.A.; Akbulut, H.; Mohtabdi-Bonab, M.A. Low velocity impact behavior of basalt fibre reinforced polymer composites. J. Mater. Eng. Perform. 2017, 26, 2890–2900.

- Fu, H.; Feng, X.; Liu, J.; Yang, Z.; He, C.; Li, S. An investigation on anti-impact and penetration performance of basalt fibre composites with different weave and lay-up modes. Def. Technol. 2020, 16, 787–801.

- Sanchez-Galvez, V.; Sancho, R.; Galvez, F.; Cendon, D.; Re de Pedraza, V. High speed impact performance of basalt fibre reinforced vinylester composites at room and low temperatures. Int. J. Lightweight Mater. Manuf. 2020, 3, 416–425.

- Arunprasath, K.; Naresh, K.; Amuthakkannan, P.; Manikandan, V.; Kavitha, S. Study of low velocity impact failure responses of woven basalt fibre reinforced polymer composites using ultrasonic A, B and C scan techniques. Adv. Mater. Process. Technol. 2022, 1–24.

- Dhakal, H.M.; Mener, E.L.; Feldner, M.; Jiang, C.; Zhang, Z. Falling weight impact damage characterization of flax and flax basalt vinyl ester hybrid composites. Polymers 2020, 12, 806.

- Zuccarello, B.; Bongjorno, F.; Militello, C. Basalt fibre hybridization effects on high performance sisal-reinforced biocomposites. Polymers 2022, 14, 1457.

- Saleem, A.; Medina, L.; Skrifvars, M. Mechanical performance of hybrid bast and basalt fibres reinforced polymer composites. J. Polym. Res. 2020, 27, 61.

- De La Rosa García, P.; Escamilla, A.C.; Nieves Gonzalez García, M. Bending reinforcement of timber beams with composite carbon fibre and basalt fibre materials. Compos. Part B 2013, 55, 528–536.

- Davies, P.; Verbouwe, W. Evaluation of basalt fibre composites for marine applications. Appl. Compos. Mater. 2018, 25, 299–308.

- Chowdhury, I.R.; O’Dowd, N.P.; Comer, A.J. Experimental study of hygrothermal ageing effects on failure modes of non-crimp basalt fibre-reinforced epoxy composite. Compos. Struct. 2021, 275, 114415.

- De Rosa, I.M.; Marra, F.; Pulci, G.; Santulli, C.; Sarasini, F.; Tirillo, J. Post-impact mechanical characterisation of glass and basalt woven fabric laminates. Appl. Compos. Mater. 2012, 19, 475–490.

- Gideon, R.K.; Hu, H.; Wambua, P.; Gu, B. Characterizations of basalt unsaturated polyester laminates under static three-point bending and low-velocity impact loadings. Polym. Compos. 2014, 35, 2203–2213.

- Akinci, A. Mechanical and morphological properties of basalt filled polymer matrix composites. J. Mater. Sci. Eng. 2009, 35, 29–32.

- Akinci, A.; Yilmaz, S.; Sen, U. Wear behaviour of basalt filled low density poly- ethylene composites. Appl. Compos. Mater. 2012, 19, 499–511.

- Zhang, X.; Pei, X.; Wang, Q. Friction and wear properties of polyimide matrix composites reinforced with short basalt fibres. J. Appl. Polym. Sci. 2009, 111, 2980–2985.

- Zhang, X.; Pei, X.; Wang, Q. Friction and wear properties of basalt fibre rein- forced/solid lubricants filled polyimide composites under different sliding conditions. J. Appl. Polym. Sci. 2009, 114, 1746–1752.

- Dak, T.; Cziany, T.; Tamas, P.; Nemeth, C. Enhancement of interfacial properties of basalt fibre reinforced nylon 6 matrix composites with silane coupling agents. Express Polym. Lett. 2010, 4, 590–598.

- Meszaros, L.; Deak, T.; Balogh, G.; Czvikovszky, T.; Czigany, T. Preparation and mechanical properties of injection moulded polyamide 6 matrix hybrid nanocomposite. Compos. Sci. Technol. 2013, 75, 22–27.

- Daniel, I.M.; Ishai, O. Engineering Mechanics of Composite Materials, 2nd ed.; Oxford University Press: New York, NY, USA, 2006.

- Herakovich, C.T. Mechanics of Fibrous Composites; Wiley: Hoboken, NJ, USA, 1997.

- Llorca, J.; Gonzalez, C.; Molina-Aldareguia, J.M.; Sergurado, J.; Seltzer, R.; Sket, F.; Rodriguez, M.; Sadaba, S.; Munoz, R.; Canal, P.L. Multiscale modelling of composite materials: A roadmap towards virtual testing. Adv. Mater. 2011, 23, 5130–5147.

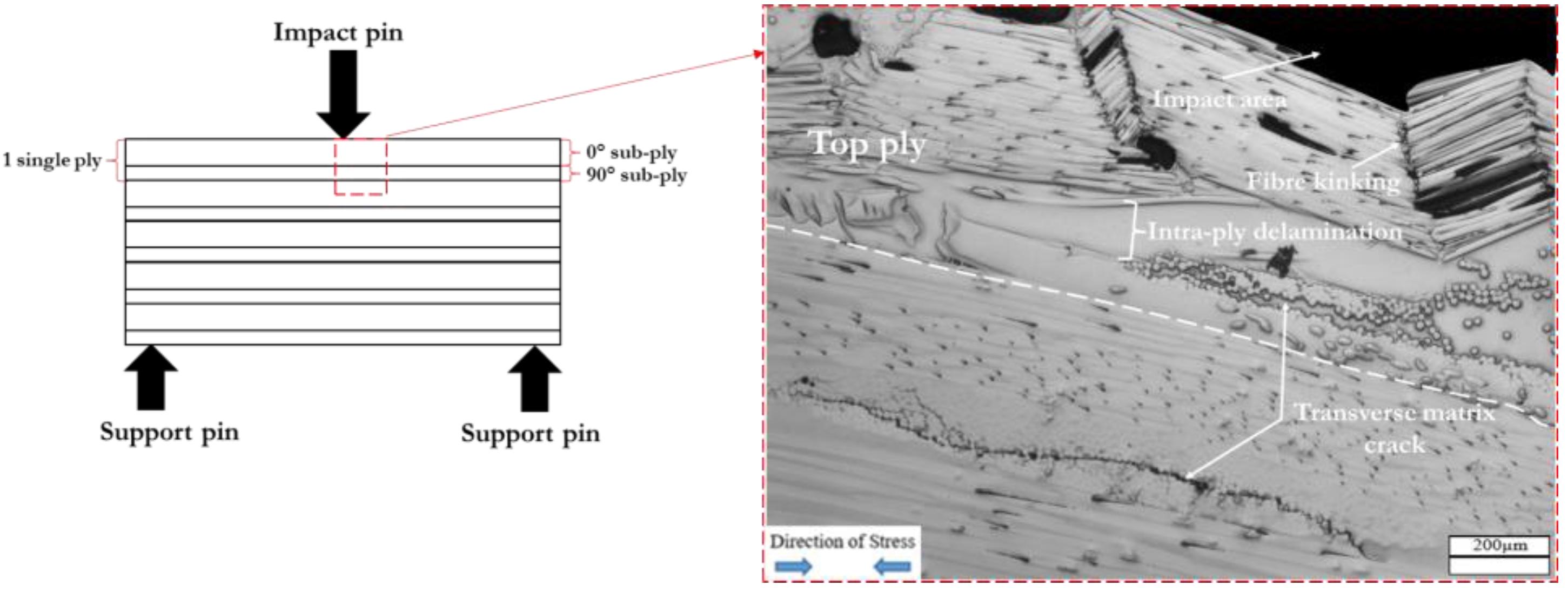

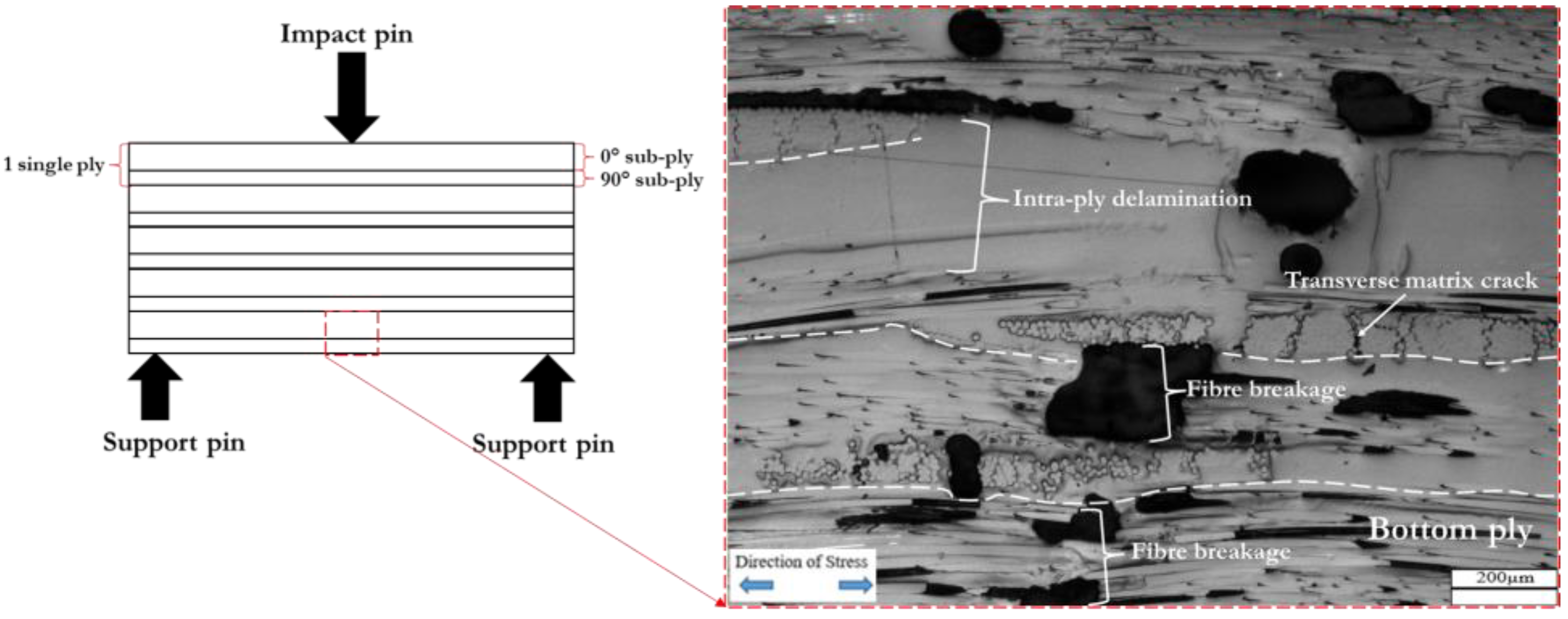

- Mortell, D.; Taneer, D.A.; Mccarthy, C.T. An experimental investigation into multi-scale damage progression in laminated composites in bending. Compos. Struct. 2016, 149, 33–40.

- Smith, P.A.; Bonafice, L.; Glass, N.F.C. A comparison of transverse cracking phenomena in (0/90)s CFRP laminates. Appl. Compos. Mater. 1998, 53, 11–23.

- Swofs, Y.; McMeeking, R.M.; Verpoest, I.; Gorbatikh, L. Matrix cracks around fiber breaks and their effect on stress redistribution and failure development in UD composites. Compos. Sci. Technol. 2015, 11, 16–22.

- Arteiro, A.; Catalanotti, G.; Melro, A.; Linde, P.; Camanho, P. Micro-mechanical analysis of the in-situ effect in polymer composite laminates. Compos Struct. 2014, 150, 827–840.

- Greenhalgh, E.; Hiley, M.; Meeks, C. Failure Analysis and Fractography of Polymer Composites, 1st ed.; Woodhead publishing Ltd.: Cambridge, UK, 2010.

- Martyniuk, K.; Sorensen, B.F.; Modregger, P.; Lauridsen, E.M. 3D in-situ observations for glass fibre/matrix interfacial debonding. Compos. Part A 2013, 12, 63–73.

- Mahmood, A.S.; Summerscales, J.; James, M.N. Resin-rich volumes (RRV) and the performance of fibre-reinforced composites: A review. J. Compos. Sci. 2022, 6, 53.

- Jespersen, K.M.; Glud, J.A.; Zangenberg, J.; Hosoi, A.; Kawada, H.; Mikkelsen, L.P. Uncovering the fatigue damage initiation and progression in UD non-crimp fabric reinforced polyester composite. Compos. Part A 2018, 109, 481–497.

- Truong, T.C.; Vettori, M.; Lomov, S.; Verpoest, I. Carbon composites based on multi-axial multi-ply stitched preforms. Part 4. Mechanical properties of composites and damage observation. Compos. Part A 2005, 36, 1207–1221.