Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Catherine Yang and Version 1 by Massimiliano Fenice.

Polyphenols and their intermediate metabolites are natural compounds that are spread worldwide. Polyphenols are antioxidant agents beneficial for human health, but exposure to some of these compounds can be harmful to humans and the environment. A number of industries produce and discharge polyphenols in water effluents. These emissions pose serious environmental issues, causing the pollution of surface or groundwater (which are used to provide drinking water) or harming wildlife in the receiving ecosystems. The treatment of high-polyphenol-content waters is mandatory for many industries.

- polyphenols

- biological treatment

- bioreactors

- water

- aerobic granular sludge

1. Technologies to Remove Phenolic Compounds from Water Sources

Considering the harmful effects of some polyphenols and their derivatives on human health and natural environments, the removal of these compounds from water and wastewater is a great challenge for human and environmental safety, and the search and recognition of effective tools for their treatment, degradation, and removal are worthwhile [2,11][1][2]. Accordingly, great efforts have been spent, using physical, chemical, and biological methods to develop and optimize techniques for finding a sustainable solution to this problem. Undoubtedly, physicochemical technologies are more expensive than biological ones, and sometimes they are not completely effective because undesirable compounds are often produced as intermediates [41][3].

Among the physical-chemical methods, conventional processes have been applied for phenolic compound removal, such as distillation, adsorption, solid-phase extraction, liquid–liquid extraction, and catalytic and wet air oxidation. Furthermore, the last decade has been characterized by the development of phenolic acid degradation technologies. Some of these technologies are based on advanced oxidation, membrane filtration, heterogeneous photocatalysis, ozonization, enzymatic treatment, and the Fenton reaction [1,4][4][5]. However, these technologies have serious disadvantages, which are mainly related to their economical cost (e.g., the high energy consumption) and environmental unsustainability due to the production of secondary pollutants [42][6]. For these reasons, the search for biological alternatives for the treatment of effluents polluted with phenols is a challenge of great biotechnological interest.

The biological technologies for degrading and removing phenolic compounds are considered to represent a promising alternative because their main advantage is phenol degradation into nontoxic products, or even mineralization, accompanied by lower exploitation expenses [23][7]. Hence, there is a vast demand to develop economical, green, and sustainable technologies, in particular for rural areas with low income and highly impacted by agrofood industries [24][8] and/or in petrochemical, paper, and pharmaceutical factories [10,43][9][10].

It is very attention-grabbing to observe that the main development of biological technologies to remove phenolic compounds was based on aerobic conditions [43,44][10][11]. However, in recent years more attention has been paid to the development of anaerobic systems due to their tolerance to high organic loading rates (ORL), lower sludge excess production, and the valorization of methane generation [45,46][12][13]. Moreover, one of the most relevant advantages of anaerobic processes is robustness and resilience against changes in the influent composition [47][14].

The biological treatment of wastewater with high polyphenol content could be seriously compromised, especially when industrial discharges contain flavan-3-ols, flavonols, and tannins due to their wide spectrum of antimicrobial activities [48][15]. Although biological treatments are described as affordable, efficient, and environmentally friendly processes, the stability of the process could be compromised by the high load of phenolic compounds and their inherent toxicity [24][8]. Thus, it is crucial to develop technologies adapted to water composition and origin. In addition, it is important to allow for the adaptation of the initial biomass (inoculum) because microbiota with high activity and robustness are essential for achieving the efficient removal of recalcitrant compounds, mitigating the effect of wastewater discharges into natural environments [49][16].

2. Feasible Biological Technologies for the Removal of Phenolic Compounds from Waters

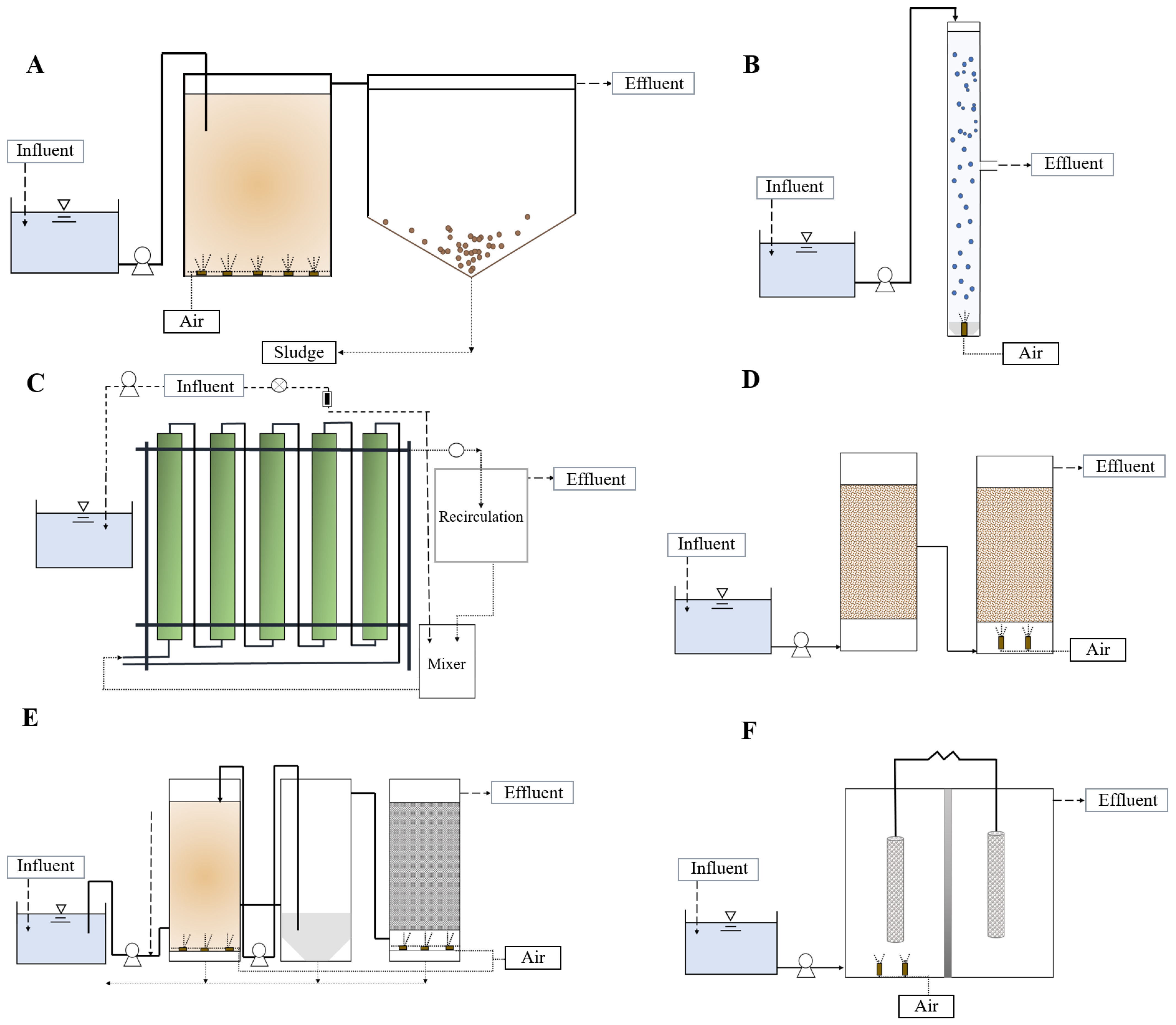

The optimization of biological processes poses attractive alternatives to be implemented, because they are usually eco-friendly and economical, minimizing the generation of subproducts while being generally easy to operate. The microorganisms used in biological technologies may promote the degradation of several organic and inorganic contaminants found in wastewater. The biodegradation could be mediated by extracellular or intracellular enzymes, and the pollutants could be removed by extracellular biosorption or active uptake and then incorporated and bioaccumulated [50,51,52][17][18][19]. Biological treatment could encounter difficulties in removing recalcitrant products, but the removal of polyphenols from water using many technologies has been reported [53][20]. The most useful technologies for the degradation of phenolic compounds based on biological treatments are discussed hereafter (Figure 21).

Figure 21. Diagram of biological water technologies for removing phenolic compounds from water: conventional activated sludge (A); aerobic granular sludge (B); photobioreactor (C); biofilter (D); membrane bioreactor (E); microbial fuel cell (F).

3. Microorganisms and Their Products Involved in Phenolic Biodegradation

Microorganisms are responsible for the suitable performance of all biological technologies described previously. A high number of microorganisms are able to degrade polyphenols in aquatic environments, including bacteria, fungi, and protozoa. Efficient biodegradation could be carried out by a single species [119,120][21][22] or microbial consortia [24,77][8][23]. During the design of a bioprocess, the selection of microorganisms or microbial consortia according to the nature of the water and the target pollutants is essential. The ability to achieve high performance will depend on the contaminant nature and the metabolic possibilities of the biomass in the bioreactor [91][24]. However, some drawbacks are found in urban or industrial wastewater, given the complexity of the matrices. Therefore, the microbial consortia employed as inoculum are generally selected by the technology configuration and influent composition since some microorganisms have competitive advantages in consuming, digesting, or degrading compounds under different abiotic and biotic parameters.

Given that phenol is widespread, some microorganisms have developed metabolic pathways for using it as carbon and/or energy source in several environments [1][4]. Undoubtedly, some microbial groups are more resistant to phenolic compounds. The microorganisms that are able to degrade polyphenols have been recognized in both the Bacteria and Eukarya domains. Among the best-known microorganisms that can successfully carry out phenol biodegradation, there are bacteria such as Bacillus, Pseudomonas, Flavobacterium, and Alcaligenes, as well as fungal representatives, such as Trichosporon, Aspergillus, Trametes, and the yeast Candida tropicalis [24,121][8][25].

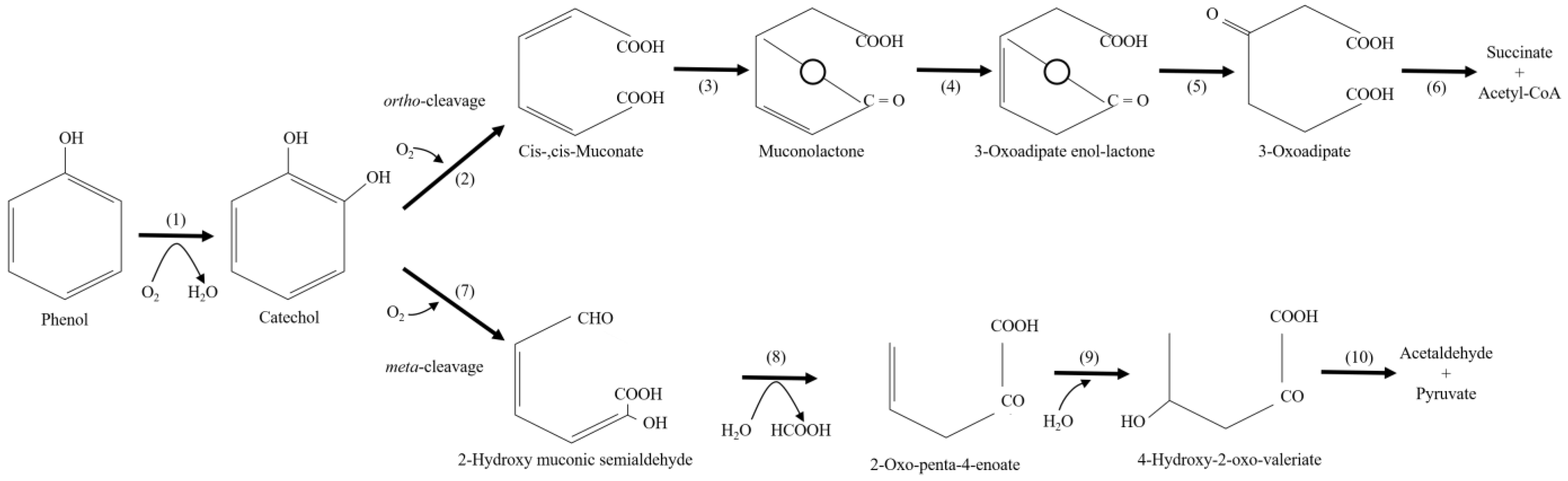

Aerobic bacteria transform phenol into nontoxic intermediate compounds that enter into the tricarboxylic acid cycle through ortho- or meta-pathways of degradation (Figure 32) [12][26]. In both pathways, phenol is firstly converted into catechol by the monohydroxylation of the C6 ring at the ο-position, which is catalyzed by phenol hydroxylase [91][24]. Phenol hydroxylase catalyzes the attachment of a hydroxyl group at the ortho-position of the aromatic ring, and then phenol is converted into catechol. This reaction is carried out by NADP-dependent flavin mono-oxygenase enzyme [12][26]. All mono-oxygenases include one atom of molecular oxygen in the corresponding substrate, while the other oxygen atom is reduced to H2O by a hydrogen donor, which is different for each enzyme. In addition to the hydroxylation of phenol, which is the preferred substrate of the phenol hydroxylase, this enzyme can catalyze the hydroxylation of hydroxyl-, amino-, halogen-, or methyl-substituted phenols [12][26]. Chlorophenol and (choloromethyl) phenol hydroxylases are employed to convert the substrates into chlorinated catechols or chloromethylcatechols, which play a key role in ortho- or meta-pathways. Phenol hydroxylase also catalyzes the conversion of alkylphenols into alkylcatechols. The aromatic ring of catechol is further opened by catechol 1,2-dioxygenase, leading to the formation of succinyl-CoA and acetyl CoA, or by catechol 2,3-dioxygenase, leading to the formation of pyruvate and acetaldehyde. Moreover, long-chain alkylphenols, nitrophenols, chloronitrophenols, and bisphenols require specific peripheral degradation pathways [91][24]. The bacterial degradation of nitrophenols can start with mono-oxygenation (a mono-oxygenase catalyzes the nitro groups elimination as a nitrite ion by adding an oxygen atom), the reduction of the nitro group (a nitroreductase catalyzes the nitrogen group reduction into amino groups or hydroxylamine), reductive dehalogenation from halonitrophenol compounds (a reductive dehalogenase removes the halogen atom, following the oxidative removal of the nitro group), and dioxygenation (insertion of two hydroxyl groups with the removal of the nitro group as nitrite ion) [122,123,124][27][28][29].

Figure 32. Aerobic phenol biodegradation pathways. (1) phenol monooxygenase, (2) catechol 1,2-dioxygenase, (3) muconate lactonizing enzyme, (4) muconolactone isomerase, (5) oxoadipate enol-lactone hydrolase, (6) oxoadipate succinyl-CoA transferase, (7) catechol 2,3-dioxygenase, (8) hydroxymuconic semialdehyde hydrolase, (9) 2-oxopent-4-enoic acid hydrolase, (10) 4-hydroxy-2-oxovalerate aldolase [125][30].

Some nitrophenol-degrading bacteria have been isolated by utilizing media enriched in mononitrophenols, halonitrophenols, or polynitrophenols. Among the isolated strains were Arthrobacter nitrophenolicus sp. [126][31], Burkholderia sp. RKJ [127][32], Pseudomonas sp. [122][27], Rhodotorula glutinis [128][33], Sphingomonas sp. [122][27], and Paraburkholderia [129][34].

In Mediterranean countries, OWW has been widely studied due to its recalcitrant nature that is related to high polyphenol content. For example, Maza-Marquez et al. [26][35] demonstrated that the phenolic pollutants found in an OWW storage basin could be treated using specific bacterial taxa, such as Firmicutes and Clostridiales. Muñoz-Palazon et al. [24][8] observed that the microbial communities in AGS reactors treating high polyphenol concentrations were dominated by Lampropedia, Acinetobacter, Arenimonas, Pseudomonas, and Corynebacterium.

Eukarya microorganisms are widespread in environmental and engineering niches and play an essential role in the bioremediation field. Many studies have focused on phenolic compound degradation by fungi due to their ability to use organic pollutants as substrates for their growth. Some Ascomycota members have been isolated in systems designed for the treatment of OMWW with polyphenols as the sole carbon source, including Aspergillus niger, Penicillium sp., Fusarium sp., and Alternaria sp. [59][36]. The Basidiomycota phylum is the major fungal group that has members able to degrade toxic compounds due to their rich production of tyrosinases, laccases, and peroxidases [130][37]. Tyrosinases oxidate both monophenols and 1,2-diphenols (catechols) to quinones; laccases of a low-molecular-weight use 1,4-diphenols as substrate, which acts as monophenols and polyphenols; peroxidases are oxidoreductases that catalyze peroxide reduction and the concomitant oxidation of various substrates, including phenols [131,132][38][39]. These fungal enzymes are widely employed in industrial processes due to their role in improving organoleptic properties. For this reason, some authors highlighted the need for improved knowledge about the employment of wild-type and bioengineered fungi to obtain these enzymes of industrial interest [130,133][37][40].

In addition to bacteria and fungi, microalgae have also been recognized for their high capability to resist toxic compounds due to their extraordinary ability to produce extracellular laccases that allow for the biodegrading and transforming of aromatic compounds [134,135][41][42]. Microalgae can biotransform, mineralize, and remove compounds under phototrophic or mixotrophic conditions. Some phylotypes, such as Chlorella sp., can remove polyphenols under light or dark conditions [136,137][43][44]; moreover, it has been reported that Scenedesmus quadricauda and Ankistrodesmus braunii biotransform polyphenols in simpler compounds [138][45].

The immense diversity of the metabolic pathways and resistance of prokaryotic and eukaryotic microorganisms allows for the development of various strategies for biotechnological tools in order to provide a high-quality water effluent. However, further combined efforts among chemical, engineering, and microbiological areas have to be made to obtain higher yields via the microorganisms dwelling in engineering systems.

References

- Peeters, K.; Višnjevec, A.M.; Esakkimuthu, E.S.; Schwarzkopf, M.; Tavzes, Č. The Valorisation of Olive Mill Wastewater from Slovenian Istria by Fe3 O4 Particles to Recover Polyphenolic Compounds for the Chemical Specialties Sector. Molecules 2021, 26, 6946.

- Raza, W.; Lee, J.; Raza, N.; Luo, Y.; Kim, K.H.; Yang, J. Removal of Phenolic Compounds from Industrial Waste Water Based on Membrane-Based Technologies. J. Ind. Eng. Chem. 2019, 71, 1–18.

- Hasan, M.; Hakim, A.; Iqbal, A.; Bhuiyan, F.R.; Begum, M.K.; Sharmin, S.; Abir, R.A. Computational Study and Homology Modeling of Phenol Hydroxylase: Key Enzyme for Phenol Degradation. Int. J. Comput. Bioinform. Silico Model. 2015, 4, 691–698.

- Mohd, A. Presence of Phenol in Wastewater Effluent and Its Removal: An Overview. Int. J. Environ. Anal. Chem. 2022, 102, 1362–1384.

- Cladis, D.P.; Weaver, C.M.; Ferruzzi, M.G. (Poly)Phenol Toxicity in Vivo Following Oral Administration: A Targeted Narrative Review of (Poly)Phenols from Green Tea, Grape, and Anthocyanin-Rich Extracts. Phytother. Res. 2022, 36, 323–335.

- Xiao, J.; Xie, Y.; Han, Q.; Cao, H.; Wang, Y.; Nawaz, F.; Duan, F. Superoxide Radical-Mediated Photocatalytic Oxidation of Phenolic Compounds over Ag+/TiO2: Influence of Electron Donating and Withdrawing Substituents. J. Hazard. Mater. 2016, 304, 126–133.

- Mohammadi, S.; Kargari, A.; Sanaeepur, H.; Abbassian, K.; Najafi, A.; Mofarrah, E. Phenol Removal from Industrial Wastewaters: A Short Review. Desalination Water Treat 2015, 53, 2215–2234.

- Muñoz-Palazon, B.; Rodriguez-Sanchez, A.; Hurtado-Martinez, M.; de Castro, I.M.; Juarez-Jimenez, B.; Gonzalez-Martinez, A.; Gonzalez-Lopez, J. Performance and Microbial Community Structure of an Aerobic Granular Sludge System at Different Phenolic Acid Concentrations. J. Hazard. Mater. 2019, 376, 58–67.

- Villegas, L.G.C.; Mashhadi, N.; Chen, M.; Mukherjee, D.; Taylor, K.E.; Biswas, N. A Short Review of Techniques for Phenol Removal from Wastewater. Curr. Pollut. Rep. 2016, 2, 157–167.

- Vashi, H.; Iorhemen, O.T.; Tay, J.H. Aerobic Granulation: A Recent Development on the Biological Treatment of Pulp and Paper Wastewater. Environ. Technol. Innov. 2018, 9, 265–274.

- Jemaat, Z.; Suárez-Ojeda, M.E.; Pérez, J.; Carrera, J. Sequentially Alternating Pollutant Scenarios of Phenolic Compounds in a Continuous Aerobic Granular Sludge Reactor Performing Simultaneous Partial Nitritation and O-Cresol Biodegradation. Bioresour. Technol. 2014, 161, 354–361.

- Shi, X.; Leong, K.Y.; Ng, H.Y. Anaerobic Treatment of Pharmaceutical Wastewater: A Critical Review. Bioresour. Technol. 2017, 245, 1238–1244.

- Muñoz Sierra, J.D.; Oosterkamp, M.J.; Wang, W.; Spanjers, H.; van Lier, J.B. Comparative Performance of Upflow Anaerobic Sludge Blanket Reactor and Anaerobic Membrane Bioreactor Treating Phenolic Wastewater: Overcoming High Salinity. Chem. Eng. J. 2019, 366, 480–490.

- Muñoz Sierra, J.D.; Oosterkamp, M.J.; Wang, W.; Spanjers, H.; van Lier, J.B. Impact of Long-Term Salinity Exposure in Anaerobic Membrane Bioreactors Treating Phenolic Wastewater: Performance Robustness and Endured Microbial Community. Water Res. 2018, 141, 172–184.

- Daglia, M. Polyphenols as Antimicrobial Agents. Curr. Opin. Biotechnol. 2012, 23, 174–181.

- Huang, Y.; Hou, X.; Liu, S.; Ni, J. Correspondence Analysis of Bio-Refractory Compounds Degradation and Microbiological Community Distribution in Anaerobic Filter for Coking Wastewater Treatment. Chem. Eng. J. 2016, 304, 864–872.

- More, T.T.; Yadav, J.S.S.; Yan, S.; Tyagi, R.D.; Surampalli, R.Y. Extracellular Polymeric Substances of Bacteria and Their Potential Environmental Applications. J. Environ. Manag. 2014, 144, 1–25.

- Vashi, H.; Iorhemen, O.T.; Tay, J.H. Extensive Studies on the Treatment of Pulp Mill Wastewater Using Aerobic Granular Sludge (AGS) Technology. Chem. Eng. J. 2019, 359, 1175–1194.

- Gupta, S.; Nayak, A.; Roy, C.; Yadav, A.K. An Algal Assisted Constructed Wetland-Microbial Fuel Cell Integrated with Sand Filter for Efficient Wastewater Treatment and Electricity Production. Chemosphere 2021, 263, 128132.

- Rengaraj, S.; Moon, S.H.; Sivabalan, R.; Arabindoo, B.; Murugesan, V. Agricultural Solid Waste for the Removal of Organics: Adsorption of Phenol from Water and Wastewater by Palm Seed Coat Activated Carbon. Waste Manag. 2002, 22, 543–548.

- Juárez-Jiménez, B.; Manzanera, M.; Rodelas, B.; Martínez-Toledo, M.V.; Gonzalez-López, J.; Crognale, S.; Pesciaroli, C.; Fenice, M. Metabolic characterization of a strain (BM90) of Delftia tsuruhatensis showing highly diversified capacity to degrade low molecular weight phenols. Biodegradation 2010, 21, 475–489.

- Juarez Jimenez, B.; Reboleiro Rivas, P.; Gonzalez Lopez, J.; Pesciaroli, C.; Barghini, P.; Fenice, M. Immobilization of Delftia Tsuruhatensis in Macro-Porous Cellulose and Biodegradation of Phenolic Compounds in Repeated Batch Process. J. Biotechnol. 2012, 157, 148–153.

- Maza-Márquez, P.; González-Martínez, A.; Martínez-Toledo, M.V.; Fenice, M.; Lasserrot, A.; González-López, J. Biotreatment of Industrial Olive Washing Water by Synergetic Association of Microalgal-Bacterial Consortia in a Photobioreactor. Environ. Sci. Pollut. Res. 2017, 24, 527–538.

- Prasad, R.; Aranda, E. Approaches in Bioremediation: The New Era of Environmental Microbiology and Nanobiotechnology; Springer: Cham, Switzerland, 2018; ISBN 978-3-030-02368-3.

- Satish, K.; Neeraj; Viraj, K.M.; Santosh, K.K. Biodegradation of Phenol by Free and Immobilized Candida Tropicalis NPD1401. Afr. J. Biotechnol. 2018, 17, 57–64.

- Krastanov, A.; Alexieva, Z.; Yemendzhiev, H. Microbial Degradation of Phenol and Phenolic Derivatives. Eng. Life Sci. 2013, 13, 76–87.

- Arora, P.K.; Srivastava, A.; Singh, V.P. Bacterial Degradation of Nitrophenols and Their Derivatives. J. Hazard. Mater. 2014, 266, 42–59.

- Arora, P.K.; Srivastava, A.; Garg, S.K.; Singh, V.P. Recent Advances in Degradation of Chloronitrophenols. Bioresour. Technol. 2018, 250, 902–909.

- Arora, P.K.; Sasikala, C.; Ramana, C.V. Degradation of Chlorinated Nitroaromatic Compounds. Appl. Microbiol. Biotechnol. 2012, 93, 2265–2277.

- Singh, T.; Bhatiya, A.K.; Mishra, P.K.; Srivastava, N. An effective approach for the degradation of phenolic waste. In Abatement of Environmental Pollutants; Singh, P., Kumar, A., Borthaku, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2020; pp. 203–243.

- Arora, P.K.; Jain, R.K. Arthrobacter Nitrophenolicus Sp. Nov. a New 2-Chloro-4-Nitrophenol Degrading Bacterium Isolated from Contaminated Soil. 3 Biotech 2013, 3, 29–32.

- Arora, P.K.; Jain, R.K. Metabolism of 2-Chloro-4-Nitrophenol in a Gram Negative Bacterium, Burkholderia Sp. RKJ 800. PLoS ONE 2012, 7, e38676.

- Dulak, K.; Sordon, S.; Matera, A.; Kozak, B.; Huszcza, E.; Popłoński, J. Novel Flavonoid C-8 Hydroxylase from Rhodotorula Glutinis: Identification, Characterization and Substrate Scope. Microb. Cell Fact. 2022, 21, 175.

- Wilhelm, R.C.; Cyle, K.T.; Martinez, C.E.; Karasz, D.C.; Newman, J.D.; Buckley, D.H. Paraburkholderia Solitsugae Sp. Nov. and Paraburkholderia Elongata Sp. Nov., Phenolic Acid-Degrading Bacteria Isolated from Forest Soil and Emended Description of Paraburkholderia Madseniana. Int. J. Syst. Evol. Microbiol. 2020, 70, 5093–5105.

- Maza-Márquez, P.; Martínez-Toledo, M.V.; González-López, J.; Rodelas, B.; Juárez-Jiménez, B.; Fenice, M. Biodegradation of Olive Washing Wastewater Pollutants by Highly Efficient Phenol-Degrading Strains Selected from Adapted Bacterial Community. Int. Biodeterior. Biodegrad. 2013, 82, 192–198.

- Elmansour, T.E.; Mandi, L.; Ahmali, A.; Elghadraoui, A.; Aziz, F.; Hejjaj, A.; Del Bubba, M.; Ouazzani, N. Effect of Polyphenols on Activated Sludge Biomass during the Treatment of Highly Diluted Olive Mill Wastewaters: Biomass Dynamics and Purifying Performances. Water Sci. Technol. 2020, 82, 1416–1429.

- Martínková, L.; Kotik, M.; Marková, E.; Homolka, L. Biodegradation of Phenolic Compounds by Basidiomycota and Its Phenol Oxidases: A Review. Chemosphere 2016, 149, 373–382.

- Baldrian, P. Fungal Laccases-Occurrence and Properties. FEMS Microbiol. Rev. 2006, 30, 215–242.

- Ikehata, K.; Buchanan, I.D.; Smith, D.W. Recent Developments in the Production of Extracellular Fungal Peroxidases and Laccases for Waste Treatment. J. Environ. Eng. Sci. 2004, 3, 1–19.

- Shukla, A.C. Applied Mycology Entrepreneurship with Fungi; Springer: Cham, Switzerland, 2022; ISBN 9783030906481.

- Otto, B.; Schlosser, D. First Laccase in Green Algae: Purification and Characterization of an Extracellular Phenol Oxidase from Tetracystis Aeria. Planta 2014, 240, 1225–1236.

- Lindner, A.V.; Pleissner, D. Utilization of Phenolic Compounds by Microalgae. Algal. Res. 2019, 42, 101602.

- Wang, L.; Xue, C.; Wang, L.; Zhao, Q.; Wei, W.; Sun, Y. Strain Improvement of Chlorella Sp. for Phenol Biodegradation by Adaptive Laboratory Evolution. Bioresour. Technol. 2016, 205, 264–268.

- Di Caprio, F.; Scarponi, P.; Altimari, P.; Iaquaniello, G.; Pagnanelli, F. The Influence of Phenols Extracted from Olive Mill Wastewater on the Heterotrophic and Mixotrophic Growth of Scenedesmus sp. J. Chem. Technol. Biotechnol. 2018, 93, 3619–3626.

- Pinto, G.; Pollio, A.; Previtera, L.; Stanzione, M.; Temussi, F. Removal of Low Molecular Weight Phenols from Olive Oil Mill Wastewater Using Microalgae. Biotechnol. Lett. 2003, 25, 1657–1659.

More