Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Edith Flora Joel and Version 2 by Vivi Li.

Graphene-oxide-based metal hybrids (GM) are used for the rapid and efficient reduction and removal of toxic adulterants in the environment. The exceptionally high specific surface area, versatile surface chemistry, and exceptional customization efficiency of graphene oxide nanosheets combined with the adaptable chemistry of metal nanoparticles enable the formation of GM hybrid nanocomposites. However, little is known about the architecture of GM nanocomposite engineering, interaction mechanisms, and environmental compatibility.

- graphene oxide

- metallic nanoparticles

- gas capture

- water purification

- environmental

- radionuclides

1. Introduction

The extraordinary optical, mechanical, electrical, and temperature characteristics of graphene make it a unique material. Recently, graphene-based nanostructures have attracted significant attention. Graphene is a honeycomb-shaped bilayer (2D) sheet of carbon particles. Other graphene structures, such as graphene oxide (GO) and reduced graphene oxide (rGO), are also being explored because of their wide range of applications in sensors, energy capacity, water sanitization, optoelectronics, and other fields. Therefore, it is important to understand the difference between GO and rGO. Graphene oxide is synthetically modified graphene. Shedding and oxidation are used to synthesize GO, which is associated with a significant adjustment of the basal plane in its structure. The monolayer GO films had a high oxygen content. The carbon/oxygen ratio of GO is often below 3:1 and close to 2:1.

Numerous investigations on the environmental applications of GO–metal-based hybrids have been published in the last decade, but the literature is replete with contradictory reports of their performance. These deviations are due in part to the highly variable nature of the synthesis methods of GM hybrid materials. The surface chemistry, lateral size, and crystalline structure of GM hybrids are predominantly dependent on the synthesis methods. Similarly, the pore size distribution and interlayer spacing can also be affected by the synthesis methods. Furthermore, half-breeds of GO/rGO with metal/metal oxide nanostructures had synergistic attributes [1].

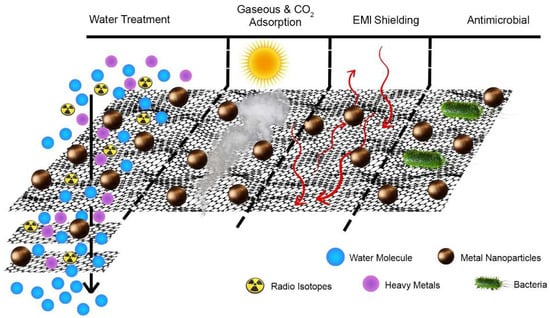

ResearchWers critically review recent advances in the ecological application of GM hybrids. Most GM hybrids fabricated for water treatment are 2D and 3D materials, typically GO–metal composites, membranes, or three-dimensional matrices, in addition to a polymer. The main objective of this entryreview is to highlight the link between the material properties of GM hybrids and their environmental performance. Graphene has high carrier mobility, outstanding mechanical strength and flexibility, high thermal conductivity, a large specific surface area, and excellent electrical conductivity [2]. Figure 1 shows the graphical illustration of GM hybrids in various environmental applications.

Figure 1. Schematic illustration of graphene oxide hybrids for environmental applications in water purification, gaseous CO2 adsorption, electromagnetic shielding, and antimicrobial elimination.

2. Environmental Applications of Graphene Oxide

2.1. Water Purification

2.1.1. Removal of Heavy Metals

The toxicity of heavy metals in the environment, such as Pb, Ca, Cu, Zn, Cr, Hg, Ni, Li, Fe, As, and Cd, induces toxicity to the ecosystem. Graphene oxide and its composites are beneficial for the removal of organic pollutants and microbes from contaminated waters because of their large surface area and high catalytic efficiency. Consequently, the literature reports that the adsorption process is one of the most effective methods to remove heavy metals from the complex water matrix of the other methods available [3][15]. Heavy metal adsorption by graphene oxide nanocomposites involves physical adsorption [4][16], chemical adsorption, and electrostatic interaction [5][17]. The interaction of graphene oxide with heavy metals usually occurs through precipitation, ion exchange, and surface complexation. Ununiform active sites on the evacuated surface of GO promote calcium ion adsorption from hard underground water [6][18]. The selectivity of graphene oxide for heavy metals in a complex matrix composed of dissolved organic matter and other contaminants was investigated by Jun et al. [7][19]. Negatively charged ion-chelating functional groups in GO induce nanocomposites based on graphene oxide, ideal for the removal of heavy metals, such as Cr (VI), Cu (II), Pb (II), and Cd (II), by chemical adsorption from the water matrix, as confirmed by the Langmuir model [8][20]. For the adequate removal of the heavy metals of greatest environmental concern in complex matrices, the limitations of graphene oxide, such as low sorption selectivity and difficulty in solid–liquid separation, can be improved by doping with metal nanoparticles. As an example, to enhance the selectivity of the heavy metal adsorption of Pb (II), graphene oxide hydrated manganese oxide nanocomposites (HMO@GO) were investigated [9][21]. Silver nanoparticles were produced on the GO sheets via the chemical reduction of Ag+ ions on the GO surface. The fabricated Ag-GO was used as an adsorbent for malachite green (MG) and ethyl violet (EV) dyes, catalyst, and antibacterial agent by Hina et al. [10][22]. The functionalization of graphene oxide surfaces with more oxygen functional groups increased the adsorption capacity. Usually, oxygen functional groups are preferred for the removal of heavy metals because the negative surface charge of graphene oxide along with the negative surface charge of oxygen functional groups can aid in the efficient adsorption of positively charged heavy metals.

The use of magnetic materials in solid-phase extraction has received considerable attention considering the advantages arising from the inherent characteristics of magnetic particles. The choice of an appropriate magnetic adsorbent material dominates the selectivity and sensitivity of the method through hydrophobic interactions and hydrogen bonding. For example, Zahra et al. fabricated a reusable double-charged ionic liquid-modified magnetic graphene oxide (DIL-MGO) and applied it to the separation and preconcentration of Pb (II), Cd (II), Ni (II), Cu (II), and Cr (III). In addition to the higher adsorption efficiency, this compound (DIL-MGO) was also tested for the reclamation of these metals, which can add value to the reusability of the material [11][23]. Yue et al. synthesized self-propelled tubular motors containing an outer layer of graphene oxide and an inner layer of platinum as a catalyst that works under the influence of a magnetic field to remove lead from microchannels [12][24]. Subsequently, oxygen-rich functional groups allow graphene oxide to perform a secondary functionalization of GO for the preparation of hybrid nanomaterials. The formation of oxygen-containing functional groups in GO and its subsequent influence on its structure play a significant role in the adsorption and co-adsorption of polar and non-polar organics in fluid arrangements.

The higher adsorption sites in hybrids, achieved by suppressing particle aggregation and lowering the size of copper nanoparticles, explain the superior removal capabilities compared to bare particles [13][25]. Moreover, the structure of GO plays a significant role in providing access to active sites for the adsorption and regeneration of heavy metals. For example, Archana et al. [14][26] grafted NiO crystals onto graphene oxide sheets by hydrothermal treatment. The surface morphology of GO-NiO showed a substantial amount of space and surface wrinkles in a functionalized three-dimensional structure, resulting in greater accessibility to the active sites for the chemisorption of Pb (II) and Cd (II). The removal of selenium by water-dispersible magnetic graphene oxide nanocomposites was explored by You et al., 2014 [15][27].

2.2. Adsorption Equilibrium Parameters of Uranium Ions

The adsorption capacity increases with increasing temperature, mainly because the rate of diffusion, both internal and external, increases with increasing temperature. Uranium is an actinide element that is widely used in most nuclear reactors and is an important contributor to nuclear waste. The surface functional groups of GO-based nanoparticles are primarily responsible for their strong uranium adsorption. Because of the variety of functional groups on GO-based nanomaterials, the effect of different functional groups on uranium adsorption is unknown. Here, rwesearchers attempt to correlate the adsorption parameters of materials with the adsorption of uranium. In general, sorption parameters provide information on the mechanisms involved in the adsorption process. Thermodynamic parameters, such as the Gibbs free energy change (ΔG), enthalpy change (ΔH), and the entropy change (ΔS), were calculated from temperature-dependent sorption data. The sorption of radionuclides onto GO-based materials is an endothermic and spontaneous process. The sorption of uranium on GO is influenced by the solution conditions, ionic strength, experimental conditions, pH, and temperature. Because of the thermodynamic parameters at different concentrations of the GO adsorbate and the U adsorbent, finding a correlation between entropy and enthalpy is not reasonable. In general, enthalpy–entropy compensation is present only when ∆G0 is constant. Changes in Gibbs free energy and entropy were estimated based on temperature-dependent equilibrium constants.2.3. CO

2

Capture

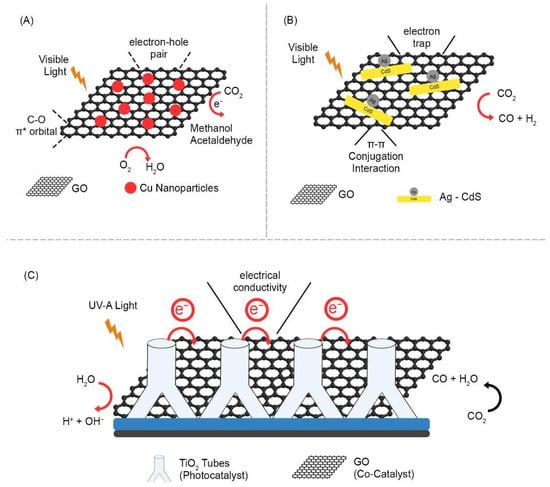

Graphene oxide can effectively remove gaseous contaminants in a manner similar to that of contaminant removal from water. Graphene oxide has been previously investigated for its potential in CO2 capture and its electrochemical, thermal, or photocatalytic reduction to CO. The resulting CO, CH3OH, CH2O, HCOOH, and C3H8O were used as precursors for fuel and chemicals. Like the removal of impurities from water, GO can remove gaseous contaminants. Graphene-based materials are known for their potential in CO2 capture and their electrochemical or photocatalytic reduction to CO. Under powerful adsorption/desorption conditions, rGO can be used as an adsorbent for volatile organic compounds (at ppm levels) [16][17][73,74]. The adsorption capacity of graphene oxide is increased with increasing temperature, pressure, interlayer distance, and the addition of nitrogen compounds. As a most striking example, nitrogen-doped reduced graphene oxide (NRGO) exhibited the highest specificity for CO2, with 3.81295232 (g·g−1 ) maximum specific absorbance of 3.81295232 g·g−1 and a specific surface area of 9916.88239 m2/g [18][75]. The performance of graphene oxide can be improved by decorating it with catalytic nanomaterials [19][76]. Moreover, to improve the governing factors influencing the removal efficiency, surface chemistry can be improved by decorating the GO surface with reactive nanomaterials. Several metals and metal oxides exhibit excellent bandgap, electrical conductivity, and stability under experimental conditions. CO2 capture can be greatly influenced by catalyst, catalyst carrier, and integration strategies. Different nanoparticles with catalytic properties can be used for CO2 capture, such as copper [20][77]. The photocatalytic reduction of CO2 requires several electron transfers and can produce a wide range of products depending on the precise reaction pathway adopted and the number of electrons transferred, which determine the final oxidation state of the carbon atom. The photocatalytic reduction of CO2 can be achieved using various metal composites. Graphene has shown potential as an effective electron acceptor and transporter for photocatalytic CO2 reduction and reduces photogenerated charge carrier recombination. A study demonstrated the photocatalytic reduction of CO2 in methanol (CH3OH) and methane (CH4) using silver chromate (Ag2CrO4) nanoparticles as photosensitizers and graphene oxide (GO) as cocatalysts. They concluded that, as a cocatalyst, GO assisted in charge transfer and improved CO2 adsorption and catalytic sites [21][78]. TiO2 and its photocatalytic ability to reduce CO2 have been extensively studied. Due to its extensive 3.2 eV band gap and excellent efficient photoactivity, high stability, and low cost, graphene oxide can be used for excellent CO2 reduction [22][79]. A vertically aligned TiO2 nanostructure-wrapped GO/rGO layer were used for the photocatalytic reduction of CO2 to CO. The unique morphology with graphene oxide as a cocatalyst combined with TiO2 as a photocatalyst resulted in a maximum CO yield of 1348 μmol/g (Figure 25C) [23][80]. Indrajit et al. synthesized GO-Cu nanocomposites via a one-pot microwave process. The compound developed has a strong interaction between copper nanoparticles and graphene oxide, which helps to produce higher CO2 of approximately 6.84 μmol/gcat−1h−1 for the reduction of photocatalytic CO2 under visible-light irradiation [24][81] (Figure 25A). Solvothermal methods and subsequent photochemical deposition have been used to successfully create Ag-RGO-CdS nanocomposites. Zezhou et al. implemented Ag-RGO-CdS for the catalytic conversion of CO2 to CO in a photocatalytic system with TEOA as a hole scavenger. As a result, 1.0 wt.%-Ag3.0 wt% RGO-CdS presents the highest photocatalytic performance of 1.61 μmol/h in comparison with bare CdS nanorods (0.21 μmol/h) (Figure 25B) [25][82]. Deerattrakul et al. synthesized Cu-Zn/reduced graphene oxide (rGO) catalysts by incipient wetness impregnation and estimated the hydrogenation of CO2 to methanol using a fixed-bed tubular stainless-steel reactor. As a result, 424 mgMeOH gcat−1h−1 of methanol was obtained at 250 °C with a loading content of 10 wt% Cu-Zn metals on rGO [26][83]. In general, a catalytic system requires an additional sacrificial donor for the photoreduction of CO2, resulting in efficient fuel generation from CO2. To overcome this, Tingting et al. synthesized nitrogen-doped graphene (Gr–CuC) for CO2 in methanol under visible-light irradiation [27][84].

Figure 25.

Mechanism of CO

2

reduction in GO metal hybrids: (

) Cu [81]; (

) Ag-Cds [82]; (

C

) TiO

[80].

Similarly, to minimize the overpotential of CO2 reduction, electrocatalysts are needed in the catalytic process known as electrocatalysis, which involves reactions of oxidation and reduction by the direct transfer of electrons. The electrocatalytic CO2 reduction reaction (CO2RR) is an inner-sphere process in which adsorption and bond rearrangement, as well as reaction intermediates, take place inside the inner Helmholtz region (IHR). Several studies have been conducted to develop graphene oxide–metal hybrids with increased CO2 reduction activity. Additionally, it was discovered that the rGO and CO2 molecules interact via a π–π conjugation, which is crucial for facilitating adsorption and activating CO2 molecules on the catalytic surface. Zhirong et al. synthesized porous In2O3 nanobelt-reduced graphene oxide (rGO) catalysts. To better understand the CO2 reduction mechanism, DFT calculations were performed and compared with the experimental results. The results revealed that In2O3–rGO reduced CO2 electroreduction by improving electrical conductivity and stabilizing the key intermediate HCOO–* [28][85]. Strong metal support contacts primarily contribute to improved electrochemical CO2 reduction activity by improving interfacial electron transfer ability, according to experimental kinetic data. Zhang et.al., used rGO supported gold nanoparticles for electro catalytic reduction of CO2 [29][86]. A lone pair of nitrogen electrons interacts with transition metal complexes to form composite materials [30][87].