Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Rita Xu and Version 1 by Ali Demirci.

First-generation (1G) bioethanol is one of the most used liquid biofuels in the transport industry. It is generated by using sugar- or starch-based feedstocks, while second-generation (2G) bioethanol is generated by using lignocellulosic feedstocks. Distillers’ dried grains with solubles (DDGS) is a byproduct of first-generation bioethanol production with a current annual production of 22.6 million tons in the USA. DDGS is rich in fiber and valuable nutrients contents, which can be used to produce lignocellulolytic enzymes such as cellulases and hemicellulases for 2G bioethanol production.

- lignocellulolytic enzymes

- cellulase

- hemicellulase

- 1G + 2G

1. Introduction

The transportation industry is one of the biggest contributors to greenhouse gas emissions (GHG) in many developed countries [1,2][1][2]. Fossil fuels, mainly gasoline, are the main stimuli behind the devastating GHG emissions. The drastic impact on the environment is directly correlated with global anthropogenic activities which have resulted in an increase in the Earth’s temperature over the last five decades [3]. Another problem is energy security as fossil fuels are non-renewable on the human time scale and the need for alternative and clean energy sources is ubiquitous all around the globe. Among various proposed solutions, biofuels are one of the most prominent and most implemented solutions especially in the transport industry due to the liquid nature of bioethanol. Bioethanol is currently blended in various ratios with gasoline across the world to solve energy security and sustainability issues [1].

According to a recent report, 110 billion liters of ethanol was produced in 2019, which was expected to increase but did not due to the COVID-19 pandemic [4]. Typically, bioethanol is produced from sugar-based (sugarcane juice) or starch-based (corn grains) feedstocks [4]. The sugar-to-ethanol conversion is carried out mainly by yeast, Saccharomyces cerevisiae, which can be represented by the following chemical equation.

C6H12O6 → 2 C2H5OH + 2 CO2

However, the breakdown of starch into simple sugars is required in case of starch-based feedstocks:

(C6H10O5)n + n H2O → n C6H12O6

The two top major producers of bioethanol are the USA (56%) and Brazil (28%), which use starch-based crops (mainly corn grains), or sugar-based crops (mainly sugarcane juice) as the main feedstock for ethanol production, respectively [5]. This type of production process is known as the first-generation (1G) production process. There are several advantages of this process: the feasibility of conversion methods, the C-6 fermentation cycle, and the establishment of the industrial process. Due to these advantages, currently, more than 94% of global ethanol is in the 1G category. The 1G bioethanol production process using corn grains is comprised of several steps: milling, liquefaction, saccharification, fermentation, distillation, and drying. Each of these steps is optimized at industrial scales for the maximum possible production of ethanol [6,7][6][7]. However, various issues are still present in 1G ethanol production, such as food vs. fuel issues, the use of land and water resources, and the possible contamination of soils from distillation residues [7].

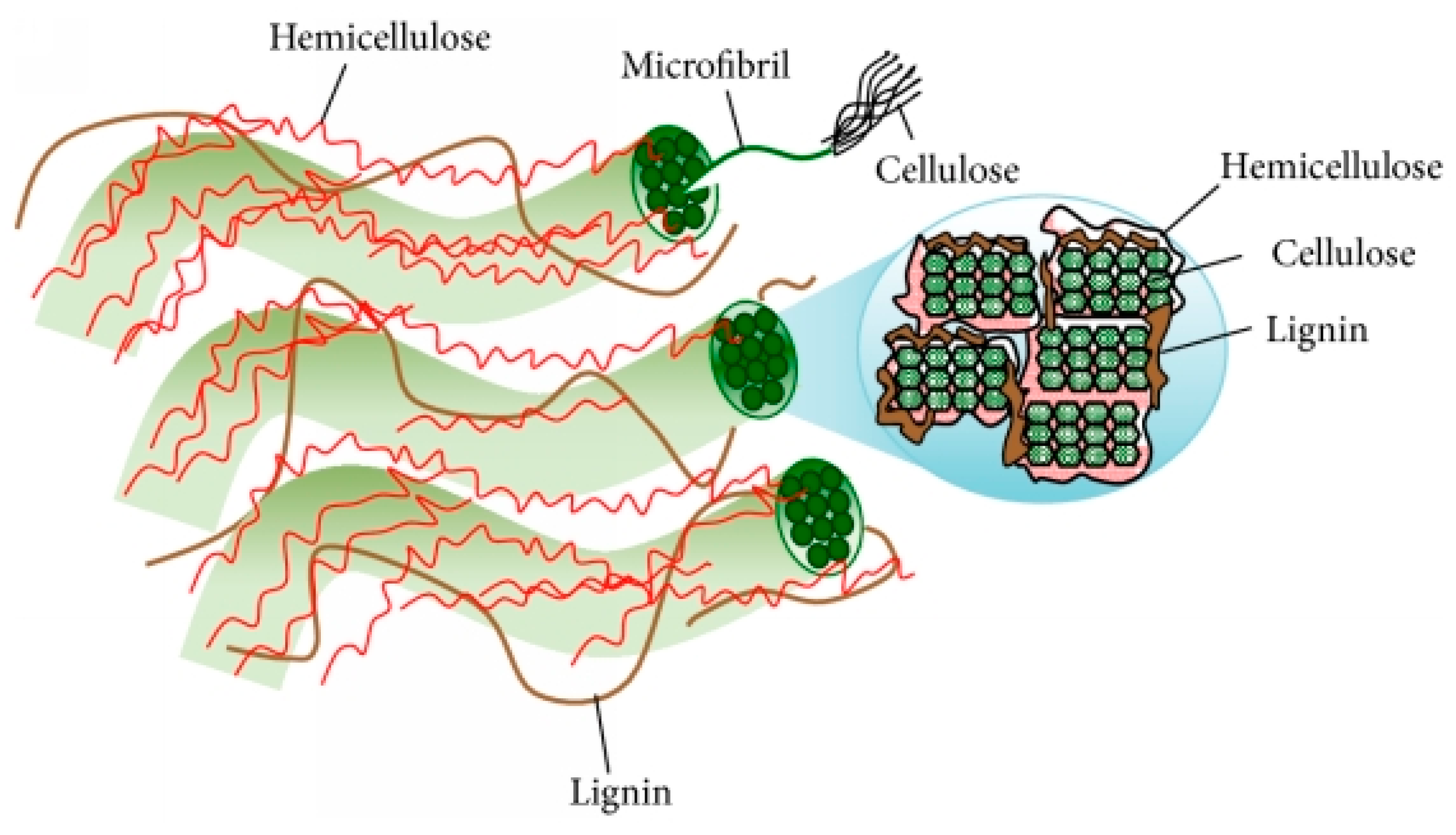

Recently, second-generation (2G) ethanol has gained research interest due to its capacity to reduce GHG emissions and the availability of more sustainable feedstock. According to a published report, while 1G ethanol can reduce GHG emissions by 39–52% as compared to gasoline, 2G ethanol can further decrease the emissions by 86% [8]. The main feedstock for 2G ethanol is lignocellulosic biomass, which is abundant and inexpensive compared to sugar- or starch-based crops, which are cultivated specifically for fuel generation. This will certainly ease the fuel vs. food concerns. Currently, the annual production of lignocellulosic biomass is 181.5 billion tons and the price is approximately 24 USD to 121 USD per ton [9]. Therefore, lignocellulosic biomass should be preferable over 1G feedstocks for bioethanol production. However, the main disadvantage of lignocellulosic biomass is its recalcitrant nature that comes from lignin, cellulose, and hemicellulose. In any given lignocellulosic biomass, the cellulose content can be 40–60%, the hemicellulose content can be 10–40%, and the lignin content can be 15–30% [10]. These three components are an integral part of a plant cell wall (Figure 1). They support and protect the plant cell as compared to starch or sugars which are the main energy sources. Therefore, the breakdown of such materials as an energy source is naturally more difficult than starch or simple sugars. The enzymes required for the breakdown are known as cellulases, hemicellulases, and lignases or lignin-modifying enzymes [11,12][11][12]. These enzymes are currently a major topic of research interest due to their underlying applications in the production of 2G biofuels [11]. However, such enzymes are currently not of industrial standards, and, in addition, they are very expensive as high loading is required. However, various feedstocks and process improvement strategies have been proposed in the literature to improve the quality and production of these enzymes.

A byproduct of starch-based bioethanol, mainly in the USA, is distillers’ dried grains with solubles (DDGS). The current global production of DDGS is around 40 million tons, with the USA as the top producer contributing to 58% of global production [13]. Currently, DDGS is used as animal feed or to a much lesser extent as fertilizer. DDGS is a corn residue after the almost complete conversion of starch into bioethanol. One-third of corn is DDGS by the 1G ethanol production process. DDGS is mainly comprised cellulose and hemicellulose fibers, proteins, and lipids. In the case of corn-based DDGS, the composite fiber content is around 33–40%, the crude protein content is 26–33%, and the fat or oil content can be around 9.1–14.1% [14]. The fiber and protein contents in DDGS make it desirable for the production of microbial products via microbial fermentations such as lignocellulolytic hydrolysis enzymes, which are required to hydrolyze cellulose and hemicellulose fibers in the fermentation media for their efficient utilization [11].

2. The Main Differences in 1G and 2G Bioethanol Production

Bioethanol production processes are of many kinds, but the main principle is the conversion of simple sugars such as glucose into ethanol via fermentation. The main difference between first-generation (1G) and second-generation (2G) biofuel is the level of sustainability in terms of source material or feedstock. The feedstock for 1G ethanol production is mostly pure sugar- or starch-based feedstock [16]. For example, the USA, which is the top producer of bioethanol in the world, uses corn grain as the main feedstock for ethanol production. On the other hand, Brazil, which is the second-largest bioethanol producer uses sugarcane. Currently, 1G bioethanol is the most common type of ethanol in the world with an approximate annual production of 110 billion liters [16]. In the United States, the current production of corn ethanol is approximately 54% of the total global production [16].

During 1G bioethanol production with corn grains, one-third of corn grains are converted into ethanol while the other two-thirds are converted into carbon dioxide and solid residues known as DDGS. Approximately 5% of the glucose is converted into yeast cells which are extracted into thin stillage and approximately 15–30% of the thin stillage is recycled back into the bioethanol production process while the rest is mixed into DDGS after drying [14,17][14][17]. However, there are other parts of corn crops that are wasted or turned into low agriculture products such as corn stover [18]. The main issue with 1G ethanol production is sustainability in terms of making more ethanol from all of the parts of the crops and not just from the grains. On the other hand, the feedstock for the 2G ethanol is lignocellulosic biomass including but not limited to inedible parts of the plants, wood waste, straw, grasses, etc. All such feedstocks are either a waste product or a byproduct of upstream agricultural processes.

The feedstock, however, alone does not characterize all the differences between the two processes. The type and severity of the pretreatment method for the breakdown of the complex polysaccharides into simple sugars for their further conversion into ethanol is also a necessary step in both 1G and 2G production processes. In the 1G bioethanol production process, the pretreatment is characterized by the process of liquefaction. In the liquefaction step, the ground corn grains are mixed with water and kept at 85 °C for one to two hours [16]. In the case of 2G ethanol production with lignocellulosic feedstock, the pretreatment methods are more severe and are carried out at temperatures higher than 100 °C (Table 1). These main differences between the two pretreatment steps drastically impact the economics and carbon footprint differences in the two processes.

Table 1. Main differences between 1G and 2G bioethanol productions.

| Parameter | 1G | 2G | Advantage of 1G over 2G or Vice-Versa | References |

|---|---|---|---|---|

| Feedstock | Sugar or starch based: corn, wheat, sugarcane, beet, etc. | Lignocellulosic biomass: inedible parts of the plant, straw, wood, and sawdust, etc. | Sugar- or starch-based feedstocks are easy to breakdown into simple monosaccharides which are then easily fermented into ethanol. | [19] |

| Pretreatment | Liquefaction | Dilute acid, steam, AFEX, etc. | Liquefaction requires low to medium process conditions as compared to lignocellulosic pretreatment strategies. | [2,3][2][3] |

| Enzymatic hydrolysis | Saccharification with amylases and glucoamylases | Lignocellulolytic process with cellulases and hemicellulases | Saccharification has high conversion yield as compared to the cellulose and hemicellulose hydrolysis | [16] |

| Cost of feedstock | 40–70% | 30% | 2G is advantageous as the feedstock is inexpensive. | [16] |

| Pretreatment cost | Low | High | 1G is advantageous as low capital investment is needed. | [16] |

| Reduction in GHG emissions | 39–52% | 86% | 2G ethanol is more sustainable as compared to 1G ethanol. | [1] |

| Food vs. fuel issue | Yes | No | 2G ethanol is advantageous over 1G for food security. | [20] |

The third main difference between 1G and 2G ethanol production is enzymatic hydrolysis. Enzymes such as amylases and glucoamylases are added to break down the long starch chains into glucose molecules, which are ready for further fermentation in the 1G ethanol production process. This enzyme hydrolysis step is carried out at 95–107 °C [14]. The enzymes for lignocellulosic hydrolysis and breakdown are known as lignocellulolytic enzymes and the two main contributors are cellulases and hemicellulases. The hydrolysis step is carried out at a temperature similar to that of the 1G ethanol production process. However, the main differences between the two enzymatic processes are the degree of hydrolysis and the cost of the enzymes. It has been confirmed in many studies that the cost of the enzymes is one of the major bottlenecks in the production of 2G ethanol, and the lower hydrolytic quality of cellulases and hemicellulases than amylases and glucoamylases is another barrier. In addition, the lignin removal step is required which is carried out with the help of different pretreatment methods such as acid hydrolysis or alkaline soaking. In acid hydrolysis, the lignin is dissolved along with hemicellulose fractions and thus lignocellulosic biomass with low lignin content can be treated with such methods. On the other hand, in the alkaline pretreatment methods, the lignin structure is altered and lignin needs to be removed from the pretreated slurries [21]. In addition, such pretreatments also generate toxic byproducts such as furfural, hydroxymethylfurfural, phenols, and organic acids which negatively affect the action of cellulases and hemicellulases [22]. The improvement of such enzymes towards low cost and higher quality is extremely necessary for the commercialization of the 2G ethanol production process [11].

Therefore, the cost of the two production processes plays an important role in the commercialization of bioethanol production at industrial scales. The need for effective pretreatment methods requires high capital investment in the case of the 2G bioethanol production process. This leads to the high cost of lignocellulosic ethanol. The current cost of 1G ethanol from sugar- or starch-based feedstocks is approximately 43% lower than that of 2G ethanol [1]. In another study conducted in the year 2000, it was reported that 2G ethanol can be 60% more expensive than 1G ethanol [23]. Therefore, the cost efficacy of the 1G bioethanol production is one of the main reasons it is currently the only type of commercial bioethanol in the world. The corn ethanol production process in the United States has been optimized through several strategies such as simultaneous saccharification and fermentation [16].

Another and perhaps the most crucial difference between 1G and 2G ethanol production processes is the GHG emissions of the two processes. 1G ethanol was commercialized because it shows lower GHG emissions than gasoline or other conventional fossil-based fuels. In some studies, it was shown that 1G ethanol reduces GHG emissions by 39–52% as compared to gasoline [8]. However, the land use for sugar or starch-based crops for the whole purpose of bioethanol production has raised several concerns related to food security [20]. In addition, the transport of such crops to the site of ethanol production also raises some sustainability issues. On the other hand, bioethanol from lignocellulosic biomass can cause lower GHG emissions than 1G ethanol. Some studies suggest the reduction in GHG emissions from using 2G bioethanol can be as much as 86% lower than gasoline [1].

Even though both 1G and 2G bioethanol production processes are similar to each other, they have very distinctive differences that impact the overall sustainability and cost of industrialization. 2G bioethanol is more sustainable and fed by lignocellulosic feedstocks, which makes it ideal for commercialization. However, the recalcitrant nature of the lignocellulosic biomass makes it difficult for biochemical conversion. Therefore, high capital investment and severe pretreatment methods are needed. This main disadvantage is the reason for 1G ethanol being preferable, and currently, more than 99% of bioethanol is produced through 1G bioethanol production. However, the 1G ethanol production process can be further optimized by integrating the 1G and 2G ethanol production processes at the same biorefinery via strategies such as on-site lignocellulolytic enzyme production.

References

- Aui, A.; Wang, Y.; Mba-Wright, M. Evaluating the economic feasibility of cellulosic ethanol: A meta-analysis of techno-economic analysis studies. Renew. Sustain. Energy Rev. 2021, 145, 111098.

- Miklautsch, P.; Woschank, M. A framework of measures to mitigate greenhouse gas emissions in freight transport: Systematic literature review from a Manufacturer’s perspective. J. Clean. Prod. 2022, 366, 132883.

- Edenhofer, O.; Pichs-Madruga, R.; Sokona, Y.; Agrawala, S.; Bashmakov, I.A.; Blanco, G.; Broome, J.; Bruckner, T.; Brunner, S.; Bustamante, M. Summary for policymakers. In Climate Change 2014: Mitigation of Climate Change; Cambridge University Press: Cambridge, UK, 2014.

- Hoang, T.-D.; Nghiem, N. Recent developments and current status of commercial production of fuel ethanol. Fermentation 2021, 7, 314.

- Raj, T.; Chandrasekhar, K.; Naresh Kumar, A.; Rajesh Banu, J.; Yoon, J.-J.; Kant Bhatia, S.; Yang, Y.-H.; Varjani, S.; Kim, S.-H. Recent advances in commercial biorefineries for lignocellulosic ethanol production: Current status, challenges and future perspectives. Bioresour. Technol. 2022, 344, 126292.

- Niphadkar, S.; Bagade, P.; Ahmed, S. Bioethanol production: Insight into past, present and future perspectives. Biofuels 2018, 9, 229–238.

- Bertrand, E.; Vandenberghe, L.P.S.; Soccol, C.R.; Sigoillot, J.-C.; Faulds, C. First generation bioethanol. In Green Fuels Technology; Springer: Berlin/Heidelberg, Germany, 2016; pp. 175–212.

- Wang, M.; Wu, M.; Huo, H. Life-cycle energy and greenhouse gas emission impacts of different corn ethanol plant types. Environ. Res. Lett. 2007, 2, 24001.

- Qaisar, K.; Nawaz, A.; Akram, F.; Mukhtar, H.; Zohu, X.; Xu, Y.; Mumtaz, M.W.; Rashid, U.; Ghani, W.A.W.A.K.; Choong, T.S.Y. Advances in valorization of lignocellulosic biomass towards energy generation. Catalysts 2021, 11, 309.

- Wu, X.; Luo, N.; Xie, S.; Zhang, H.; Zhang, Q.; Wang, F.; Wang, Y. Photocatalytic transformations of lignocellulosic biomass into chemicals. Chem. Soc. Rev. 2020, 49, 6198–6223.

- Iram, A.; Cekmecelioglu, D.; Demirci, A. Ideal Feedstock and Fermentation Process Improvements for the Production of Lignocellulolytic Enzymes. Processes 2021, 9, 38.

- Iram, A.; Berenjian, A.; Demirci, A. A review on the utilization of lignin as a fermentation substrate to produce lignin-modifying enzymes and other value-added products. Molecules 2021, 26, 2960.

- Fan, W.; Sun, X.; Cui, G.; Li, Q.; Xu, Y.; Wang, L.; Li, X.; Hu, B.; Chi, Z. A strategy of co-fermentation of distillers dried grains with solubles (DDGS) and lignocellulosic feedstocks as swine feed. Crit. Rev. Biotechnol. 2022, 1–15.

- Iram, A.; Cekmecelioglu, D.; Demirci, A. Distillers’ Dried Grains with Solubles (DDGS) and its Potential as the Fermentation Feedstock. Appl. Microbiol. Biotechnol. 2020, 104, 6115–6128.

- Lee, H.V.; Hamid, S.B.A.; Zain, S.K. Conversion of lignocellulosic biomass to nanocellulose: Structure and chemical process. Sci. World J. 2014, 2014, 631013.

- Susmozas, A.; Martín-Sampedro, R.; Ibarra, D.; Eugenio, M.E.; Iglesias, R.; Manzanares, P.; Moreno, A.D. Process strategies for the transition of 1G to advanced bioethanol production. Processes 2020, 8, 1310.

- Kwiatkowski, J.R.; McAloon, A.J.; Taylor, F.; Johnston, D.B. Modeling the process and costs of fuel ethanol production by the corn dry-grind process. Ind. Crops Prod. 2006, 23, 288–296.

- Guo, Y.; Liu, G.; Ning, Y.; Li, X.; Hu, S.; Zhao, J.; Qu, Y. Production of cellulosic ethanol and value-added products from corn fiber. Bioresour. Bioprocess. 2022, 9, 1–18.

- Gurunath, R.B.; Gobinath, R.; Giridhar, P.V. Bioethanol Production from Lignocellulosic Biomass: Past, Present and Future Trends. Res. J. Biotechnol. 2022, 17, 10.

- Kumar, B.; Bhardwaj, N.; Agrawal, K.; Verma, P. Bioethanol production: Generation-based comparative status measurements. In Biofuel Production Technologies: Critical Analysis for Sustainability; Springer: Berlin/Heidelberg, Germany, 2020; pp. 155–201.

- Badiei, M.; Asim, N.; Jahim, J.M.; Sopian, K. Comparison of chemical pretreatment methods for cellulosic biomass. APCBEE Procedia 2014, 9, 170–174.

- Kim, J.S.; Lee, Y.Y.; Kim, T.H. A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour. Technol. 2016, 199, 42–48.

- McAloon, A.; Taylor, F.; Yee, W.; Ibsen, K.; Wooley, R. Determining the Cost of Producing Ethanol from Corn Starch and Lignocellulosic Feedstocks; National Renewable Energy Lab.(NREL): Golden, CO, USA, 2000.

More