Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Camila Xu and Version 1 by Jawed Qureshi.

With strict legislation on landfill and other environmental limits, recycling, reusing, and repurposing FRP composites will be at the forefront of sustainable waste management strategies in the future. This preseaperrch presents a review of FRP waste disposal methods, with a focus on waste minimisation and reuse. The methods include waste minimisation, reuse/repurpose, recycling, incineration and landfill. The main recycling routes consist of mechanical, thermal and chemical recycling. Discarding FRP waste in a sustainable manner presents a major challenge in a circular economy. Waste prevention or reuse of FPR composite waste is the way forward to tackle this challenge.

- FRP Recycling

- glass fibre

- carbon fibre

- FRP waste

- waste management

- circular economy

- sustainability

- net-zero carbon

1. Introduction

The construction sector produces about a third of global carbon emissions. Sustainable technologies and materials are needed to support the transition to net-zero carbon emissions through an energy-efficient and resilient building and construction sector [1]. Fibre reinforced polymer (FRPs) composites are eco-friendly materials with a lower carbon footprint than traditional materials, such as concrete, steel, masonry, and timber. FRPs have been used in various industries ranging from construction, aerospace, automotive, marine, and electronics to the wind energy sector. The key reasons for the growth of FRPs include their excellent mechanical properties, lightweight, mouldability, and corrosion resistance. With the growing use of FRP materials in the building and construction industry, recycling FRP waste materials is becoming a major environmental challenge. Sustainable tools and methods should be used for the effective disposal of FRP waste.

Fibre reinforced polymer (FRP) composite materials contain fibres placed in a resin matrix. Fibres provide strength and stiffness, and the resin acts as a binder for fibres. Generally, synthetic or man-made fibres are used in FRP composite parts. These include carbon, glass, and aramid fibres [2][3][4]. Currently, semi-natural basalt fibres made from basalt rock are undergoing experimentation for structural applications [5][6][7][8][9]. Academic research is available on natural fibres, such as hemp, sisal, flax, and bamboo fibres. However, commercial FRP products using natural fibres do not exist yet [5][9][10][11][12]. Thermoset resins, such as polyester, vinylester, or epoxy, are commonly used. Thermoplastic resins, though not widely used in structural engineering, also exist, primarily for use in aerospace engineering. Thermoset resins have cross-linked molecules; once set, they cannot be remoulded. It is hard to recycle thermoset-based FRP composites without the deterioration of the recovered fibres or resin [13]. Thermoplastic resins can be moulded, remoulded, and reshaped into any form due to their weak molecular bonds. They can be easily recycled and reprocessed [2][3][14][15][16]. As per the European Composites Industry Association (EuCia), in 2020, more than 90% of all FRPs materials were glass FRP composites [17]. The nature of the FRP composite industry controls the use of a particular resin. About 2/3 of all resins are thermoset, and 1/3 are thermoplastic [18]. Both glass fibres and thermoset resin are difficult to recycle.

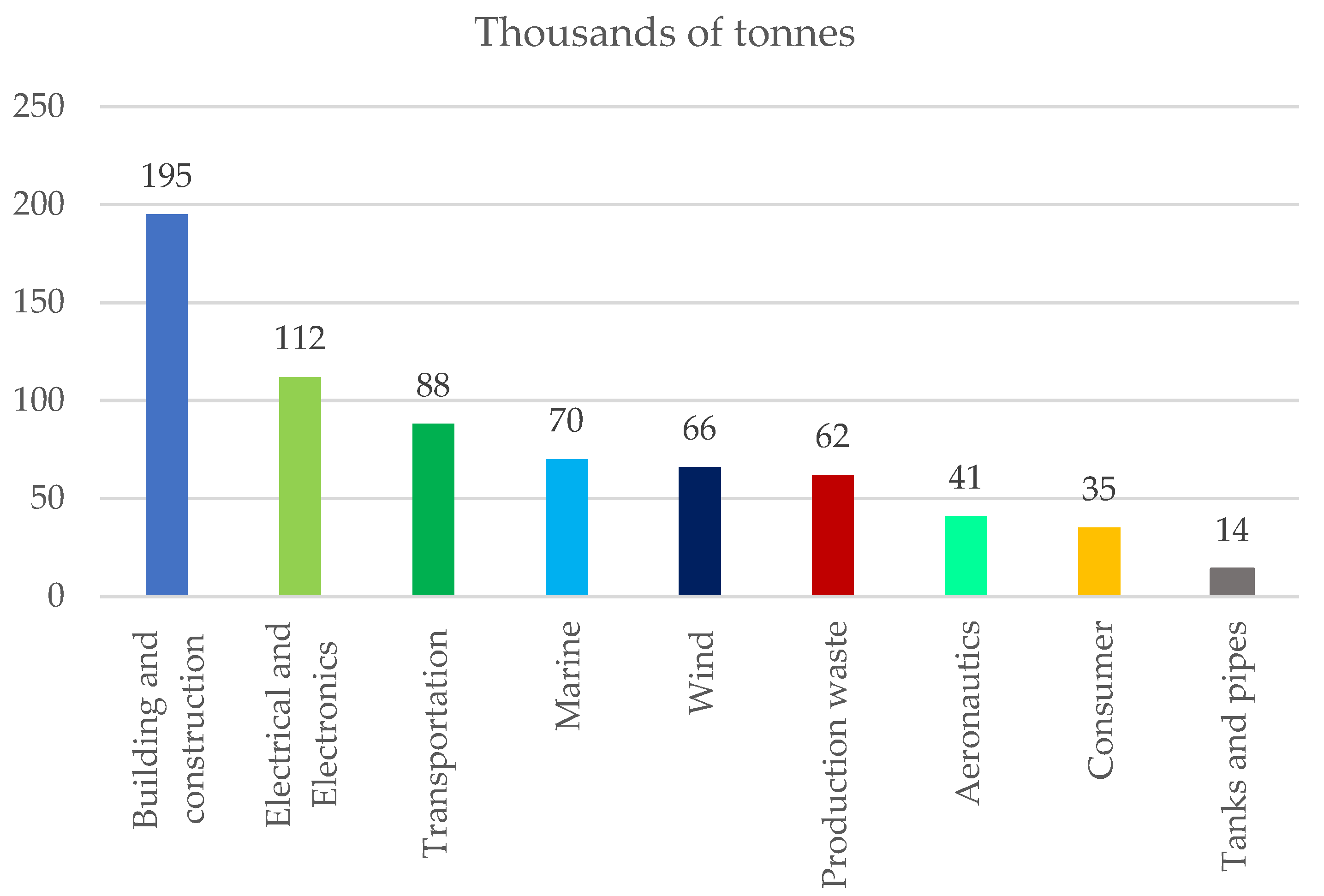

By 2026, the global market for fibre reinforced polymer composites is expected to reach USD 375 billion, from USD 228 billion in 2019, with a compound annual growth rate of 7.3% [19]. FRP composites have applications in more than 15 industries, with an estimated production value of USD 100 billion and a volume of 12.1 million tonnes in 2021. The major growth will be in the construction, transportation, wind energy, aerospace, electrical, and electronics sectors [20]. The main challenges for the FRP industry in the future will be related to the handling and recycling of FRPs while meeting environmental limits and governmental legislation. In a circular economy, a closed-loop cradle-to-cradle approach is needed to turn the FRP composite waste into a valuable resource [19][21]. The waste is generated during production and end-of-life use. The estimated volume of FRP composite waste generated by various industries is shown in Figure 1. Construction is the largest contributor to FRP waste. To address this issue, a proper waste management hierarchy is needed, which is presented in the next section. The global market share and the size of FRP waste are estimated by market research organisations and should be used with caution. Different organisations provide different values. The reseauthorcher found no independent published journal papers to verify the claims made.

The growing demand for FRP composites in various industries has led to increased waste. This waste should be discarded in a manner that is considerate to the environment. Furthermore, governmental legislation shapes public behaviour by promoting recycling rates and minimising landfill use. The European Union Directive 2018/850 on the landfill of waste [23] limits the municipal waste to landfill to only 10% by 2035 (article 5(5) of Landfill Directive, LFD). In future, there will be more and more focus on recycling FRP composite waste. Therefore, there is a need to explore different composite waste recycling/disposal routes that are environmentally sustainable and commercially viable. Most papers are based on a single FRP recycling method, but some papers review all disposal options. The majority of research is on generic recycling methods at a small-scale while using laboratory experiments. FRP parts used in automotive, aerospace, and electrical/electronic industries are typically thin and small. Buildings, bridges, and wind turbines generally use thicker and bigger FRP components than the other FRP sectors. As per Figure 1, the building and construction sector is the major contributor to FRP waste. Recycling these large parts requires scalable recycling processes.

The novelty of this preseaperrch is that it critically reviews various FRP waste disposal routes for structural engineering applications and wind turbines. Prior research mainly focussed on the disposal of thin and small parts in other industries, such as aerospace, electrical, sports, marine, and automotive. The scope of this paperresearch is limited to a review of the disposal routes for thermoset-based glass and carbon FRPs in the construction and wind turbine industries; thermoplastic FRPs are only briefly discussed. The recycling methods for thermoplastic FRPs are no different from thermoset FRPs. The reason for using only glass and carbon fibre composites is that most FRP applications use these fibres. More than 90% of all FRP products use glass fibres, and 66% of all composites use thermoset resin. The remaining FRPs mostly employ carbon fibres. This makes it worthwhile to study the recycling of glass and carbon fibres with thermoset resin. Other synthetic fibres, such as aramid fibres, are only used in less than 1% of FRP applications [17][18].

Currently, only a small percentage of FRP composites are reused in the UK, 6% for glass fibre and 2% for carbon fibre [38]. There are two main barriers to the wide adoption of reusing and repurposing FRP composites. First is the difficulty in establishing the material properties of the decommissioned FRP part, and second is the high cost associated with reclaimed fibres, resin, and other ground FRP material. To address the first problem, non-destructive testing and structural health monitoring techniques can be used to estimate the material properties of the deconstructed part. The second problem can be solved by linking a suitable recycling route to the quality and value of the reclaimed material. For example, glass FRPs can be ground and reused in concrete or asphalt mixes; and carbon fibres can be recovered using more refined recycling processes—thermal or chemical recycling. The reclaimed carbon fibres can then be reused as a reinforcement in other FRP components.

Currently, only a small percentage of FRP composites are reused in the UK, 6% for glass fibre and 2% for carbon fibre [38]. There are two main barriers to the wide adoption of reusing and repurposing FRP composites. First is the difficulty in establishing the material properties of the decommissioned FRP part, and second is the high cost associated with reclaimed fibres, resin, and other ground FRP material. To address the first problem, non-destructive testing and structural health monitoring techniques can be used to estimate the material properties of the deconstructed part. The second problem can be solved by linking a suitable recycling route to the quality and value of the reclaimed material. For example, glass FRPs can be ground and reused in concrete or asphalt mixes; and carbon fibres can be recovered using more refined recycling processes—thermal or chemical recycling. The reclaimed carbon fibres can then be reused as a reinforcement in other FRP components.

2. FRP Waste Disposal Routes

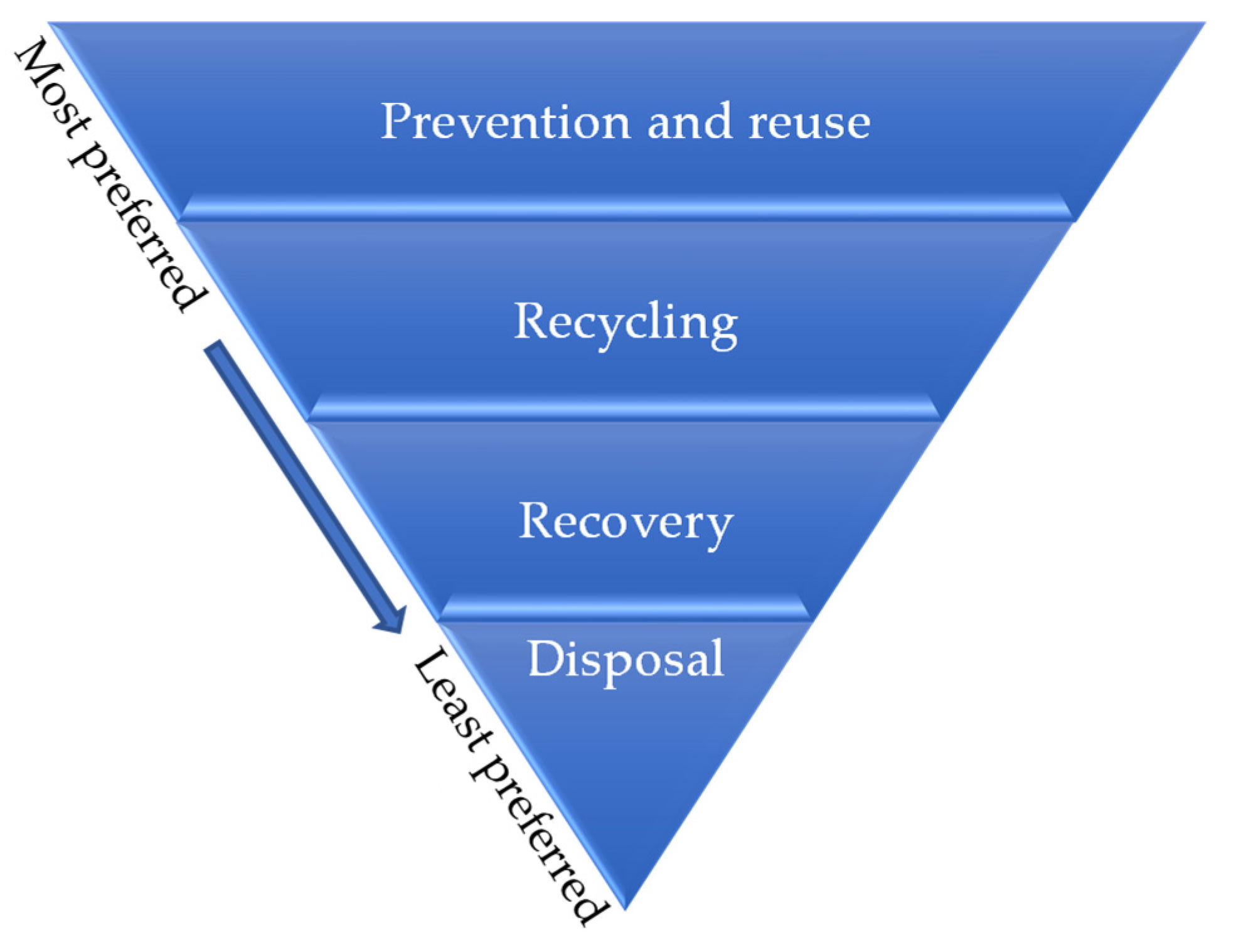

As per the four-tiered waste management hierarchy developed by The European Union’s 2008/98/EC directive [24], as shown in Figure 2, the waste should be minimised to preserve valuable space in landfills. In order of preference, FRP waste disposal options are minimisation/prevention, reuse/repurpose, recycling, incineration with or without energy recovery, and dumping in a landfill [25][26]. The main focus is on either the minimisation or prevention of waste, followed by reuse, recycling, recovery, and disposal. It is essential to recycle, reuse, and repurpose FRP composite waste generated from production, usage, or end-of-life scrap. FRP waste material negatively impacts the local environment by contaminating the soil, air, and groundwater. It can spread infectious diseases as well [16]. Landfill and incineration are not recycling methods. The incineration route still leaves behind 50% of the waste material as ash, which still needs to be landfilled [27].3. Waste Prevention and Reuse

FRP waste should be minimised as much as possible. The waste from production processes can be reduced by using automatic manufacturing methods. The end-of-life waste can be minimised by considering sustainable disposal routes at the conceptual design stage of the FRP composite part. Reusing and repurposing composite parts after their service lives should be the next preferred step in a sustainable waste management hierarchy.3.1. Waste Minimisation or Prevention

The most eco-friendly option for waste disposal is to minimise waste. The production and manufacturing of FRP members and parts generate a considerable amount of waste. As much as 40% waste can be generated from the production of FRP parts [28]. FRP manufacturing techniques must be improved to reduce production waste. Most automatic methods, such as pultrusion and filament winding, are efficient and have limited production waste. The FRP waste generated from various manufacturing methods includes defective items, outdated moulds, trial runs, off-cuts, spray trimmings, trimming from vacuum infusion, trimming dust, and off-cuts [29]. FRP production waste (scrap) produced in highly efficient automatic processes, such as pultrusion, is in the range of 2–5%. In comparison, it can increase to 15% when using manual methods such as a hand layup. CFRP pre-preg scrap in aerospace production can reach as much as 40% [30]. The average FRP manufacturing waste or process waste/scrap is estimated to be 10% of the production volume [15]. Most FRP production waste, as seen in Figure 3, ends up in a landfill. Dumping this waste in a landfill may not be the best sustainable waste disposal solution, as there are now strict laws in some European countries for landfilling. Moreover, the space available in landfill sites may be limited in some countries. FRP waste comes from production, usage, and end-of-life deconstruction. Production waste can be reduced by reviewing the manufacturing process and identifying the most efficient one. Most automatic processes result in less waste than manual methods. In construction, automatic processes can be used for structural profiles. However, free-form geometry may be required in bridge components, where manual methods are more suitable. Manual methods, such as pre-pregs and resin transfer moulding, dominate the FRP composite aerospace industry. Some automated hand-layups are also used in aerospace, but complete process automation is not feasible. Scrap pre-pregs can also be used as construction tiles. Trim allowances, normally 25–50 mm, can be reduced to minimise pre-preg scrap. Nesting composite parts for efficient material use in pre-pregs can also reduce waste.3.2. Reuse or Repurpose

Reusing and repurposing FRP parts at the end of their service life should be the next priority if the waste cannot be prevented or minimised. Reusing means using the FRP parts after their end-of-life in the same industry in which the components were once used. Repurposing relates to reusing FRP parts at the end of their service for a different application, generally lower in value than the original application [31]. Deconstruction and reuse must be kept in mind when designing, constructing, and using FRP structures for intended future reuse. For example, FRP structures using bolted joints can be demounted at the end of their service life and can be reused. However, it might be challenging to re-calculate the strength and material properties of the reused pultruded FRP parts. This also depends on the type of FRP structure. FRP profiles are challenging to reuse, whereas FRP domes can be easily reused or repurposed. On the other hand, adhesively bonded joints are difficult to deconstruct and reuse at the end of their lives. Many FRP products are specifically designed and constructed for a particular application with no intention of recovery or reuse after their usage. These applications include façade panels, FRP swimming pools, and pipes. However, FRP domes, chimneys, and clock towers can potentially be reused or repurposed. Structural profiles, such as I, W, channel, angle, and tubular sections, may be difficult to reuse, as the extent of deterioration and creep effects cannot be reliably determined. Equally, it is hard to assess the load-carrying capacity and material properties without prior knowledge of the fibre layup of the decommissioned composite part. Pultruded FRP profiles produced for one application are generally not suitable for reuse in other applications [29]. Glass FRP wind turbine blades can be repurposed into structural beams or columns. Repurposing is defined as remanufacturing and redesigning wind blades at the end of their service life and reusing them as structural elements in new structures, such as sound barriers, transmission poles, bridges, sea walls, and shelters [32]. A footbridge made from decommissioned wind turbine blades was installed in 2022 in Cork, Ireland, as shown in Figure 4. The bridge is 5 m long and 3.5 m wide and is supported on concrete abutments. The main girders are from two GFRP wind turbine blades. The joints, transverse beams and decks use structural steel. Wind turbine blades are designed for a service life of 20–25 years. Regardless of their condition, they are decommissioned at the end of life. Glass FRPs are very difficult to recycle. Repurposing these blades to new structural applications minimises the waste in a landfill [33]. Wind turbine blades are also proposed to be used in electric transmission towers [34][35][36], as seen in Figure 5. Wind turbine blades have also been employed in secondary applications, such as playgrounds and bus shelters in The Netherlands [37].

Figure 4. Re-Wind Network’s first footbridge in Cork, Ireland, constructed from decommissioned wind turbine blades in January 2022: (a) Front view of the blade bridge; (b) Side view of the footbridge, Photo Credit: Re-Wind Network [32].

References

- United Nations Environment Programme. Towards a Zero-Emission, Efficient, and Resilient Buildings and Construction Sector—Global Status Report 2017; The United Nations Environment Programme: Nairobi, Kenya, 2017; ISBN 978-92-807-3686-1.

- Qureshi, J. A Review of Fibre Reinforced Polymer Structures. Fibers 2022, 10, 27.

- Bank, L.C. Composites for Construction—Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006.

- Assadi-Langroudi, A.; O’Kelly, B.C.; Barreto, D.; Cotecchia, F.; Dicks, H.; Ekinci, A.; Garcia, F.E.; Harbottle, M.; Tagarelli, V.; Jefferson, I.; et al. Recent Advances in Nature-Inspired Solutions for Ground Engineering (NiSE). Int. J. Geosynth. Gr. Eng. 2021, 8, 3.

- Fiore, V.; Scalici, T.; Di Bella, G.; Valenza, A. A Review on Basalt Fibre and Its Composites. Compos. Part B Eng. 2015, 74, 74–94.

- Abdelkerim, D.S.E.; Wang, X.; Ibrahim, H.A.; Wu, Z. Static and Fatigue Behavior of Pultruded FRP Multi-Bolted Joints with Basalt FRP and Hybrid Steel-FRP Bolts. Compos. Struct. 2019, 220, 324–337.

- Abdelkerim, D.S.E.; Wang, X.; Ibrahim, H.A.; Wu, Z. Effect of Connection Techniques on the Static and Fatigue Performance of Pultruded Basalt FRP Multibolted Joints. J. Compos. Constr. 2020, 24, 04020046.

- Gopu, G.N.; Sofi, A.; Brahmareddy, C.; Sairaman, G. Experimental Investigation of Tensile, Compression, Shear and Flexural Behaviour of Basalt Fibre and Glass Fibre Reinforced Polymer Bars. Mater. Today Proc. 2022, 64, 1122–1128.

- Mugahed Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.-C. Properties and Applications of FRP in Strengthening RC Structures: A Review. Structures 2018, 16, 208–238.

- Correia, J.R. Fibre reinforced Polymer (FRP) Composites. In Materials for Construction and Civil Engineering, Science, Processing, and Design; Goncalves, M.C., Margarido, F., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 501–556. ISBN 978-3-319-08235-6.

- Task Group 5.1. FRP Reinforcement in RC Structures; Technical Report CEB-FIP fib bulletin 40; International Federation for Structural Concrete (fib): Lausanne, Switzerland, 2007; ISBN 978-2-88394-080-2.

- Vinay, S.S.; Sanjay, M.R.; Siengchin, S.; Venkatesh, C.V. Basalt Fiber Reinforced Polymer Composites Filled with Nano Fillers: A Short Review. Mater. Today Proc. 2022, 52, 2460–2466.

- Utekar, S.; V K, S.; More, N.; Rao, A. Comprehensive Study of Recycling of Thermosetting Polymer Composites—Driving Force, Challenges and Methods. Compos. Part B Eng. 2021, 207, 108596.

- Correia, J.R.; Bai, Y.; Keller, T. A Review of the Fire Behaviour of Pultruded GFRP Structural Profiles for Civil Engineering Applications. Compos. Struct. 2015, 127, 267–287.

- Bank, L.C.; Yazdanbakhsh, A. Reuse of Glass Thermoset FRP Composites in the Construction Industry—A Growing Opportunity. In Proceedings of the 7th International Conference on FRP Composites in Civil Engineering, CICE 2014, Vancouver, BC, Canada, 20–22 August 2014; El-Hacha, R., Ed.; International Institute for FRP in Construction: Vancouver, BC, Canada, 2014.

- Gharde, S.; Kandasubramanian, B. Mechanothermal and Chemical Recycling Methodologies for the Fibre Reinforced Plastic (FRP). Environ. Technol. Innov. 2019, 14, 100311.

- Witten, E.; Mathes, V. The Market for Glass Fibre Reinforced Plastics (GRP) in 2020, Report; European Composites Industry Association (EuCIA): Brussels, Belgium, 2020.

- EURECOMP. Final Summary Report EURECOMP Recycling Thermoset Composites of the SST. Available online: https://cordis.europa.eu/project/id/218609/reporting (accessed on 30 November 2022).

- Research and Markets. Fiber Reinforced Polymer (FRP) Composites Market—Forecasts from 2021 to 2026. Available online: https://www.researchandmarkets.com/reports/5547603/fiber-reinforced-polymer-frp-composites-market?utm_source=GNOM&utm_medium=PressRelease&utm_code=q88slz&utm_campaign=1679794+-+Worldwide+Fiber+Reinforced+Polymer+Composites+Industry+to+2026+-+by+Type%2C+En (accessed on 30 November 2022).

- JEC Observer Overview of the Global Composites Market, 2021–2026. Available online: https://www.jeccomposites.com/press/jec-observerbroverview-of-the-globalbrcomposites-market-2021-2026-eco/ (accessed on 30 November 2022).

- Naqvi, S.R.; Prabhakara, H.M.; Bramer, E.A.; Dierkes, W.; Akkerman, R.; Brem, G. A Critical Review on Recycling of End-of-Life Carbon Fibre/Glass Fibre Reinforced Composites Waste Using Pyrolysis towards a Circular Economy. Resour. Conserv. Recycl. 2018, 136, 118–129.

- Gonçalves, R.M.; Martinho, A.; Oliveira, J.P. Recycling of Reinforced Glass Fibers Waste: Current Status. Materials 2022, 15, 1596.

- European Commission. Directive (EU) 2018/850 of the European Parliament and of the Council of 30 May 2018 Amending Directive 1999/31/EC on the Landfill of Waste. Off. J. Eur. Union 2018, L 150, 100–108.

- Gharfalkar, M.; Court, R.; Campbell, C.; Ali, Z.; Hillier, G. Analysis of Waste Hierarchy in the European Waste Directive 2008/98/EC. Waste Manag. 2015, 39, 305–313.

- Halliwell, S. FRPs—The Environmental Agenda. Adv. Struct. Eng. 2010, 13, 783–791.

- EPA Waste Management Hierarchy. Available online: https://www.epa.gov/smm/sustainable-materials-management-non-hazardous-materials-and-waste-management-hierarchy (accessed on 5 December 2022).

- Jacob, A. Composites Can Be Recycled. Reinf. Plast. 2011, 55, 45–46.

- Yazdanbakhsh, A.; Bank, L.C. A Critical Review of Research on Reuse of Mechanically Recycled FRP Production and End-of-Life Waste for Construction. Polymers 2014, 6, 1810–1826.

- Conroy, A.; Halliwell, S.; Reynolds, T. Composite Recycling in the Construction Industry. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1216–1222.

- Potter, K.; Ward, C. In-Process Composite Recycling in the Aerospace Industry. In Management, Recycling and Reuse of Waste Composites; Goodship, V., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2010; pp. 458–494. ISBN 978-1-84569-462-3.

- Fraile, D.; Walsh, C. Accelerating Wind Turbine Blade Circularity; Report; WindEurope–Cefic-EuCIA: Brussels, Belgium, 2020.

- Re-Wind Network Repurposing Wind Blades, Driving Innovation in Wind Farm Decommissioning. Available online: https://www.re-wind.info/ (accessed on 28 September 2022).

- Bank, L.C.; Gentry, T.R.; Al-Haddad, T.; Alshannaq, A.; Zhang, Z.; Bermek, M.; Henao, Y.; McDonald, A.; Li, S.; Poff, A.; et al. Case Studies of Repurposing FRP Wind Blades for Second-Life New Infrastructure. In Proceedings of the Eighth International Conference on Structural Engineering, Mechanics and Computation (SEMC 2022), Cape Town, South Africa, 5–7 September 2022; Zingoni, A., Ed.; CRC Press, 2022; pp. 1441–1446.

- Alshannaq, A.A.; Bank, L.C.; Scott, D.W.; Gentry, R. A Decommissioned Wind Blade as a Second-Life Construction Material for a Transmission Pole. Constr. Mater. 2021, 1, 95–104.

- Alshannaq, A.A.; Bank, L.C.; Scott, D.W.; Gentry, T.R. Structural Analysis of a Wind Turbine Blade Repurposed as an Electrical Transmission Pole. J. Compos. Constr. 2021, 25, 04021023.

- Al-Haddad, T.; Alshannaq, A.A.; Bank, L.C.; Bermek, M.; Gentry, R.; Henao-Barragan, Y.; Li, S.; Poff, A.; Respert, J.; Woodham, C. Strategies for Redesigning High Performance FRP Wind Blades as Future Electrical Infrastructure. In Proceedings of the ARCC-EAAE 2022—RESILIENT CITY: Physical, Social, and Economic Perspectives, International conference hosted by Florida International University, Miami, FL, USA, 2–5 March 2022; Jarrett, C., Sharag-Eldin, A., Eds.; Architectural Research Centers Consortium, Inc.: San Antonio, TX, USA, 2022.

- Mishnaevsky, L. Sustainable End-of-Life Management of Wind Turbine Blades: Overview of Current and Coming Solutions. Materials 2021, 14, 1124.

- Mohamed Sultan, A.A.; Mativenga, P.T. Sustainable Location Identification Decision Protocol (SuLIDeP) for Determining the Location of Recycling Centres in a Circular Economy. J. Clean. Prod. 2019, 223, 508–521.

More