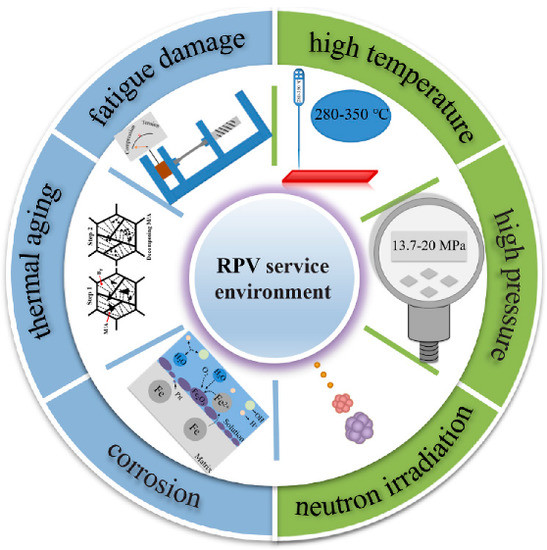

The nuclear reactor pressure vessel is an important component of a nuclear power plant. It has been used in harsh environments such as high temperature, high pressure, neutron irradiation, thermal aging, corrosion and fatigue for a long time, which puts forward higher standards for the performance requirements for nuclear pressure vessel steel.

- nuclear reactor pressure vessels

- microstructure evolution

- mechanical properties

- irradiation

- corrosion

- thermal aging

- fatigue properties

1. Background

2. Development of Steel for Nuclear Pressure Vessels

|

Materials |

|---|

|

Elements |

C |

Grade 1 Si |

Grade 2 Mn |

Cr |

Ni |

Mo |

|

|---|---|---|---|---|---|---|---|

Grade 3 | Grade 4N |

Grade 5 |

Grade 6 |

||||

|

A212B |

≤0.30 |

0.15–0.30 |

0.85–1.20 |

||||

|

C (max) |

0.35 |

0.27 |

|

Reactor Type |

Flux, m−2·s−1 (E > 1 MeV) |

Lifetime * Fluence, m−2 (E > 1 MeV) |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

0.25 | - |

0.23 |

- |

0.23 - |

||||||||||

0.28–0.33 |

A302B |

|||||||||||||

|

Si (max) | ≤0.26 |

0.40 0.13–0.32 |

1.10–1.55 |

0.40 |

0.40 - |

0.40 - |

0.30 0.41–0.64 |

|||||||

|

WWER-440 core weld |

1.2 × 1015 |

1.1 × 1024 |

||||||||||||

|

WWER-440 maximum |

1.5 × 1015 |

1.6 × 1024 | 0.35 |

A533B |

||||||||||

|

Mn | ≤0.25 |

|||||||||||||

|

WWER-1000 |

0.40–1.05 |

0.15–0.30 |

3−4 × 1014 0.50–1.00 1.51–1.50 |

3.7 × 101.20–1.50 - |

23 0.20–0.40 0.40–0.70 |

0.20–0.40 0.45–0.60 |

||||||||

0.75–1.15 |

A508-2 |

|||||||||||||

|

Cr | ≤0.27 |

≤0.25 0.15–0.35 |

||||||||||||

|

PWR (W) | 0.25–0.45 |

0.50–0.90 |

0.25–0.45 |

≤0.25 0.50–0.90 |

0.55–0.70 |

|||||||||

1.50–2.00 | 1.50–2.00 |

0.70–1.00 |

US A508-3 |

Ni ≤0.26 |

0.15–0.40 |

1.20–1.50 |

≤0.40 ≤0.25 |

0.40–1.00 |

0.50–1.00 0.45–0.55 |

|||||

0.40–1.00 | 2.80–3.90 |

2.80–3.90 |

0.75–0.95 |

|||||||||||

4 × 1014 |

4 × 1023 |

|||||||||||||

|

PWR (B&W) |

1.2 × 1014 |

1.2 × 1023 |

20MnMoNi55 |

0.17–0.23 |

0.15–0.30 |

1.20–1.50 |

≤0.20 |

0.50–1.00 |

0.40–0.55 |

|||||

|

Mo |

||||||||||||||

|

BWR |

≤0.10 |

0.55–0.70 |

0.45–0.60 |

0.40–0.60 |

0.40–0.60 |

0.30–0.45 |

22NiMoCr37 |

≤0.20 |

0.15–0.30 |

1.20–1.40 |

≤0.40 |

0.40–1.00 |

0.40–0.55 |

|

|

16MND5 |

≤0.20 |

0.10–0.30 |

1.15–1.55 |

≤0.25 |

0.50–0.80 |

0.45–0.55 |

||||||||

|

SFVV3 |

0.15–0.22 |

0.15–0.35 |

1.40–1.50 |

0.06–0.20 |

0.70–1.00 |

0.46–0.64 |

3. Service Environment of Steel for Nuclear Pressure Vessel

4 × 10 | ||||||

13 | ||||||

4 × 10 | 22 |

|||||

Chinese A508-3 | ||||||

|

0.19 |

0.19–0.27 |

1.20–1.43 |

0.06–0.12 |

0.73–0.79 |

0.48–0.51 |

|

|

15X2HMΦA |

0.13–0.18 |

0.17–0.37 |

0.30–0.60 |

1.80–2.30 |

1.00–1.50 |

0.50–0.70 |

|

A508-4 |

≤0.23 |

≤0.40 |

0.20–0.40 |

1.50–2.0 |

2.80–3.90 |

0.40–0.60 |

4. Hot Deformation Behavior of Nuclear Pressure Vessel

RPV materials were subjected to different stages before application, such as smelting, ingot casting, forging, preheat-treatment, rough machining, quenching and tempering heat treatment, post-weld heat treatment, and delivery. Once the forging parameters were not well controlled during the forging, it was easy to cause mixed-crystal microstructures and other defects in the RPV materials, which would seriously influence the safe service performance [16,17,43]. Therefore, it was essential to study the hot deformation behavior for RPV materials.5. HMechanical Prot Deformation Behavior ofperties of Steels for Nuclear Pressure Vessel

The ASTM standard [24] specifies that nuclear pressure vessels must meet certain mechanical properties requirements after forging, as shown in Table 4. Therefore, it is very important to understand the factors influencing the mechanical properties of nuclear pressure vessel materials to improve their mechanical properties. The mechanical properties of RPV materials are affected by many factors, such as alloying elements, heat treatment parameters, carbides, grain boundaries, segregation as well as hydrogen charging environment, etc.

Table 4. The mechanical properties requirements [24].

|

Mechanical Properties |

Grades 1 and 1a |

Grades 2 Class 1 and 3 Class 1 |

Grades 2 Class 2 and 3 Class 2 |

Grades 4N Class 1 and 5 Class 1 |

Grades 4N Class 2 and 5 Class 2 |

Grades 6 Class 1 |

Grades 6 Class 2 |

|

Tensile strength, ksi [MPa] |

70–95 [485–655] |

80–105 [550–725] |

90–115 [620–795] |

105–130 [725–895] |

115–140 [795–965] |

85–110 [585–760] |

95–120 [655–825] |

|

Yield strength, min [0.2% offset], ksi [MPa] |

36 [250] |

50 [345] |

65 [450] |

85 [585] |

100 [690] |

60 [415] |

75 [515] |

|

Elongation in 2 in. or 50 mm, min, % |

20 |

18 |

16 |

18 |

16 |

20 |

18 |

|

Reduction of area, min, % |

38 |

38 |

35 |

45 |

45 |

35 |

35 |

|

Minimum average value of set of three specimens, ft·lbf [J] |

15 [20] (4.4 °C) |

30 [41] (4.4 °C) |

35 [48] (21 °C) |

35 [48] (−29 °C) |

20[27](−59 °C) |

||

|

Minimum value of one specimen, ft lbf [J] |

10[14] (4.4 °C) |

25[34] (4.4 °C) |

30[41] (21 °C) |

30[41](−29 °C) |

15[20](−59 °C) |

||

56. Irradiation Properties of Steels for Nuclear Pressure Vessel

The irradiation damage process of materials can be defined as the process that the incident particles transfer energy to the target, which leads to the redistribution of target atoms in the target. DPA (displacements per atom) is the number of times the atoms in a material leave the equilibrium position, and it is the basic unit of irradiation damage of a material [65–67]. The movement of point defects and defect clusters will occur in the process of irradiation damage [68]. The irradiation effect is the change of physical and mechanical properties caused by the movement of these defects [69]. The reactor core is wrapped inside the RPV, and its material is exposed to neutron irradiation for a long time. The microstructures will change when the nuclear pressure vessel materials are subjected to irradiation damage for a long time, such as matrix damage and impurity element segregation at grain boundaries, etc. The change of microstructures after irradiation will lead to the change of properties, such as irradiation hardness, mechanical properties and irradiation embrittlement.

67. Corrosion Properties of Steels for Nuclear Pressure Vessel

Theoretically, nuclear pressure vessel materials are rarely in direct contact with corrosive solutions due to the austenitic stainless surfacing on the inner wall of nuclear pressure vessels. However, the actual operation experience of global nuclear power plants shows that the serious corrosion behavior of RPV materials caused by the leakage of boric acid water in the primary circuit is common [27,77]. Therefore, the research on the corrosion resistance of nuclear pressure vessels needs to be given more attention in order to ensure the safe service.

78. Study on Thermal Aging of Steel for Nuclear Pressure Vessel

Thermal aging refers to a phenomenon that the microstructure of material will change under high temperature environment for a long time, and then lead to changes in the properties. Long term service of RPV materials in high temperature environment can easily cause thermal aging embrittlement. The thermal aging embrittlement of low-alloy steel is closely related to thermal aging time and temperature.

8. Fatigue Properties of Steels for Nuclear Pressure Vessel

Fatigue damage accompanied the whole service cycle of RPV, and it mainly includes two influencing factors: Material factors and environmental factors, also known as internal and external factors [84–90]. The essential characteristic of materials was that internal factors affected the fatigue properties, which had a decisive effect on fatigue crack initiation, cyclic hardening/softening and fatigue life. The results of some literature showed that the chemical composition, microstructures and inclusions have great influence on the fatigue properties of materials [42,56,85,91,92]. Environmental factors were the external factor that affected the fatigue properties. The influencing factor of environment on the fatigue properties of RPVs materials mainly included service environment, loading environment and natural environment, among which service environment and loading environment were common influencing factors [87,93–97]. Service environment included service temperature, pressure, water environment, dissolved hydrogen/oxygen and pH value, and so on. Loading environment included loading frequency, loading wave, stress ratio, stress amplitude, strain amplitude as well as the strain rate, and so on.

9. Fatigue Properties of Steels for Nuclear Pressure Vessel

Fatigue damage accompanied the whole service cycle of RPV, and it mainly includes two influencing factors: Material factors and environmental factors, also known as internal and external factors [84–90]. The essential characteristic of materials was that internal factors affected the fatigue properties, which had a decisive effect on fatigue crack initiation, cyclic hardening/softening and fatigue life. The results of some literature showed that the chemical composition, microstructures and inclusions have great influence on the fatigue properties of materials [42,56,85,91,92]. Environmental factors were the external factor that affected the fatigue properties. The influencing factor of environment on the fatigue properties of RPVs materials mainly included service environment, loading environment and natural environment, among which service environment and loading environment were common influencing factors [87,93–97]. Service environment included service temperature, pressure, water environment, dissolved hydrogen/oxygen and pH value, and so on. Loading environment included loading frequency, loading wave, stress ratio, stress amplitude, strain amplitude as well as the strain rate, and so on.

10. Conclusions and Outlook

nuclear pressure vessels had been used in harsh environments such as neutron irradiation, corrosion, high temperature thermal aging and fatigue damage for a long time, which would deteriorate the properties of RPV materials. Nuclear pressure vessel materials exposed to neutron irradiation for a long time would cause matrix damage, dislocation loops and impurity element segregation, resulted in irradiation hardening and irradiation embrittlement. Although stainless steel was overlaid on the inner wall of the nuclear pressure vessel to prevent corrosion of its materials, long-term service might lead to damage of stainless steel and leakage of potential leakage sources, which would lead to directly contact between the RPV materials and boric acid corrosion solution, and then cause the occurrence of corrosion behavior. Long-term service at high temperature would cause thermal aging behavior of RPV materials, which would lead to microstructure decomposition or carbides coarsening. The thermal aging behavior mainly caused the increase of the ductile–brittle transition temperature and deteriorated the impact properties of materials. Finally, fatigue damage also accompanied the whole service process of nuclear pressure vessels. The influence factors of fatigue included microstructure evolution, second phase, service environment, corrosion environment and strain rate, etc. The fine second phase could hinder the propagation of fatigue cracks, while the coarsening second phase would become the source of crack initiation. In addition, corrosion fatigue would significantly decrease the fatigue life of materials compared with fatigue in air.

At present, the research on the nuclear pressure vessel is mostly the influence of a single factor, such as radiation, corrosion and fatigue. However, the service environment of nuclear pressure vessels is very complex, and the influence of single factor on the performance is far from the real service conditions, so the research results are insufficient and unscientific for the safety application of RPV materials. Therefore, in order to ensure their safe service in the later period of service, the collaborative mechanism of multiple service environments on nuclear pressure vessel materials should be focused on studied in future work.