Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Dongdong Song and Version 2 by Catherine Yang.

Carbon capture, utilization and storage (CCUS) has been applied in many countries and has proven to be a key carbon-reduction technology for the future. China currently emits the most carbon, and prior research findings indicate the high potential of CCUS technology to support the country’s emission-reduction process. China introduced CCUS technology at the end of the 20th century and has since implemented a series of related policies.

- carbon capture

- utilization and storage (CCUS)

- policy

1. Operation Status of CCUS Project in China

In recent years, China has yet to complete megaton CCUS projects to be built in operating catches. The biggest project is the CCU demonstration project for the Shengli Oilfield, located in the Shandong Province. The carbon yield is 400,000 tons per year, and the capture of CO2 is used for the injection of oil into the field or oil displacement (EOR, enhanced oil recovery). In 2007, the CNPC Jilin Oilfield CO2-EOR Research and Demonstration project realized the industrialization of CCUS-EOR technology for the first time in China, representing a milestone CCUS project in China. Subsequently, the Shenhua Ordos new coal-to-oil CO2 capture and storage project in 2011 was China’s first test project of saline geological storage [1][21].

In general, China’s carbon capture is mainly distributed in the north, and most application scenarios are coal-fired power plants. Some high-emission chemical industries have also carried out experiments, and most of the CO2 captured by the chemical industries is used for oil displacement. There are currently two ways to reuse captured CO2 in China: CO2-enhanced petroleum exploitation technology and CO2-enhanced coalbed methane technology. Both are of great significance to China’s energy strategy and can respectively help China achieve stable oil production and improve the exploitation and utilization of coalbed methane. China’s national major technology research project, “greenhouse gases to improve recovery efficiency of resource utilization and underground storage”, has experts from China’s Ministry of Land point out that within the scope of geologic reserves, about 13 billion tons of crude oil is suitable for CO2 flooding technology and can be improved by about 15% compared to the original recovery rate; therefore, the oil production of 1.92 billion tons can be increased, and at the same time, oil fields can also sequester about 5 billion tons of CO2, so the application of CCUS technology plays a certain role in promoting China’s crude oil and mining industry [2][23].

2. Current Situation of CCUS Deployment Potential in China

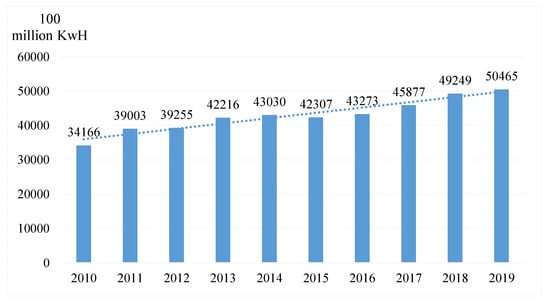

China is now the world’s largest generator of electricity, producing 25% of the global total [3][24]. However, China’s power supply remains dominated by fossil energy consumption, resulting in extraordinarily high annual CO2 emissions from its thermal power plants. These plants account for the highest proportion of China’s total annual carbon emissions. The Chinese government aims to help solve the problem, on the one hand, through the technological breakthrough of fossil energy use efficiency, as this method can reduce the consumption of fossil energy obviously in the short-term, but in the long-term, because of the limitation of technical bottlenecks, after reaching a certain value of fossil energy, use efficiency is difficult to ascend, or ascending costs will outweigh the benefits. The government has also increased public investment in renewable energy, especially clean energy, such as hydro, photovoltaic, and wind power, which have increased sharply in recent years. Consequently, the share of power generated from renewable energy sources has also increased year by year. By 2019, 17.8% of hydropower and 8.6% of wind and photovoltaics power generation in China were generated. However, with numerous studies suggesting that China will continue relying on fossil fuels for power, CCUS technology is key to achieving large-scale sustainable use of these fuels [4][25]. CO2 produced by coal-fired power plants is one of the main sources of greenhouse gases in China every year, and these emissions are characterized by large volume and concentration, which is one of the main scenarios for CCUS application. To achieve the government’s goals of carbon peak and carbon neutrality, it will be necessary to apply CCUS technology in coal-fired power plants [5][26]. The vast majority of China’s power plants are coal-fired, and with the coal-dominated energy mix unlikely to change soon, China is likely to continue building coal-fired plants to meet the pressure to reduce emissions from its growing power demand [6][27]. Although the proportion of thermal power generation in China is decreasing year by year, only accounting for about 70%, its total amount is increasing, as shown in Figure 1 [7][28].

In Figure 1, it is clear that China had a steadily rising trend of thermal power electricity for nearly a decade. The Chinese government plans to realize the goal of carbon peak in 2030. The economy is still in the next 10 years projected to pursue sustained growth, the demand for electricity is still growing, and China’s power-generating capacity in the next period of time will continue to rise. In 2020, energy consumption will account for about 85% of China’s total CO2 emissions and 70% of its total greenhouse gas emissions [8][29]. Wei et al. analyzed the carbon-emission-reduction potential of CCUS affiliated with the National Energy Group (formerly Shenhua) through the screening method of coal-fired power plants, the screening method of CO2 geological storage sites, the technical and economic evaluation method of the whole process of CCUS, and the source and sink matching method. More than 60% of the 72,720 MW units of the former Shenhua Coal-Fired Power Plant have the basic conditions for CCUS transformation [9][30]. Fan et al. found that 30 out of 441 Chinese counties have CCUS and emission-reduction potential, with a total of 99.01 million tons/year, and the total emission-reduction of CCUS in the top five provinces—Hebei, Xinjiang, Tianjin, Jiangsu, and Anhui—accounted for 83.9%. These and other provinces can serve as demonstrations for the deployment of CCUS projects in the near future [10][31].

3. Technical Cost Analysis of CCUS in China

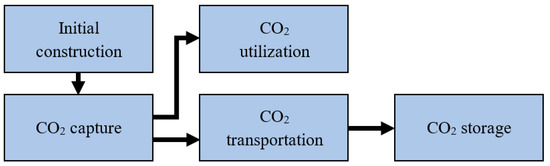

The main cost elements of CCUS are for initial construction, capture, transportation, and storage, as shown in Figure 2. The initial construction cost of a CCUS project is particularly high. Currently, the costs of deploying equipment with a 90% carbon capture rate in 400 and 800 MW power stations are about USD 70 million and USD 150 million, respectively [11][32].

Figure 2.

Cost elements of CCUS.

After the project becomes operational, the main costs relate to capturing, transportation, and storage. As of 2020, the capture cost is the highest, reaching 300 CNY/ton of CO2, while the transportation and storage costs are 1 CNY/ton and 60 CNY/ton, respectively. The cost of carbon capture is forecast to drop to 220 CNY/ton by 2035 and to 135 CNY/ton by 2050, while transportation and storage costs are predicted to drop, respectively, to 0.6 CNY/ton and 40 CNY/ton by 2035 and to 0.45 CNY/ton and 30 CNY/ton by 2050 [12][33]. Fan et al. used the learning curve model and cost optimization model to study the total cost of commercializing CCUS in China and the transformation potential of CCUS in national and provincial coal-fired power plants. Their results indicate that advancing the commercialization of CCUS to 2030 can greatly reduce the risk of technology lock-in by increasing the CCUS renovation potential to 431.1–499.90 GW at an estimated cost of USD 54.3 billion [13][34].

In the short to medium term, CCUS cost is the biggest barrier. In the long term, however, CCUS is very cost-effective compared to other mitigation options. The range of cost estimates is wide, depending on the type of process, separation technology, CO2 transfer technology, and storage location [14][35]. Compared with the other three costs, the capture cost is most influenced by technology. Accordingly, most CCUS research worldwide focuses chiefly on the technical requirements for reducing the cost of carbon capture. This cost still exceeds the benefits under the current Chinese government subsidy, which is a major impediment to introducing CCUS technology in China.

4. Public Perception of CCUS in China

The public’s understanding of CCUS will affect their acceptance of and support for the technology. One obstacle to further deploying CCUS is low public perception and support [15][36]. Liu et al. developed a behavioral model to predict public acceptance of CCUS using the ABC (affect, behavior, and cognition) model based on attitude analysis. Their findings suggest that public cognition has a significant impact on public acceptance and that perceived gain has a higher indirect impact than perceived risk [16][37]. Using articles on CCUS technology collected from national, provincial, and municipal newspapers in China, Jiang et al. performed a qualitative and quantitative content analysis to study how CCUS knowledge is transmitted and the media’s attitude toward this knowledge. They also compared CCUS marketing content in domestic and foreign newspapers. Their findings suggest that current news coverage of CCUS in China is insufficient due to technical misunderstandings and lack of comprehensiveness [17][38]. From the point of current research achievements, the Chinese government on CCUS propaganda dynamics is weak. The Chinese media also ignore detailed reports of CCUS technology, and the lack of details of the whole process of CCUS propaganda means that the public understanding of CCUS is vague. The public will realize more about the technical macroscopic problems, such as the macroeconomic policy concept, rather than micro information, such as technical processes and project presentations.