Wine and beer are the most appreciated and consumed beverages in the world. This success is mainly due to their characteristic taste, smell, and aroma, which can delight consumer’s palates. These olfactory characteristics are produced from specific classes of volatile compounds called “volatile odor-active compounds” linked to different factors such as age and production. Given the vast market of drinking beverages, the characterization of these odor compounds is increasingly important. However, the chemical complexity of these beverages has led the scientific community to develop several analytical techniques for extracting and quantifying these molecules. Even though the recent “green-oriented” trend is directed towards direct preparation-free procedures, for some class of analytes a conventional step like derivatization is unavoidable.

- derivatization

- sample preparation

- volatile odor-active compounds

- odor

- aroma

- flavor

- wine

- beer

- green analytical chemistry

1. Introduction

2. Derivatization of VOAs in Wine and Beer Analysis

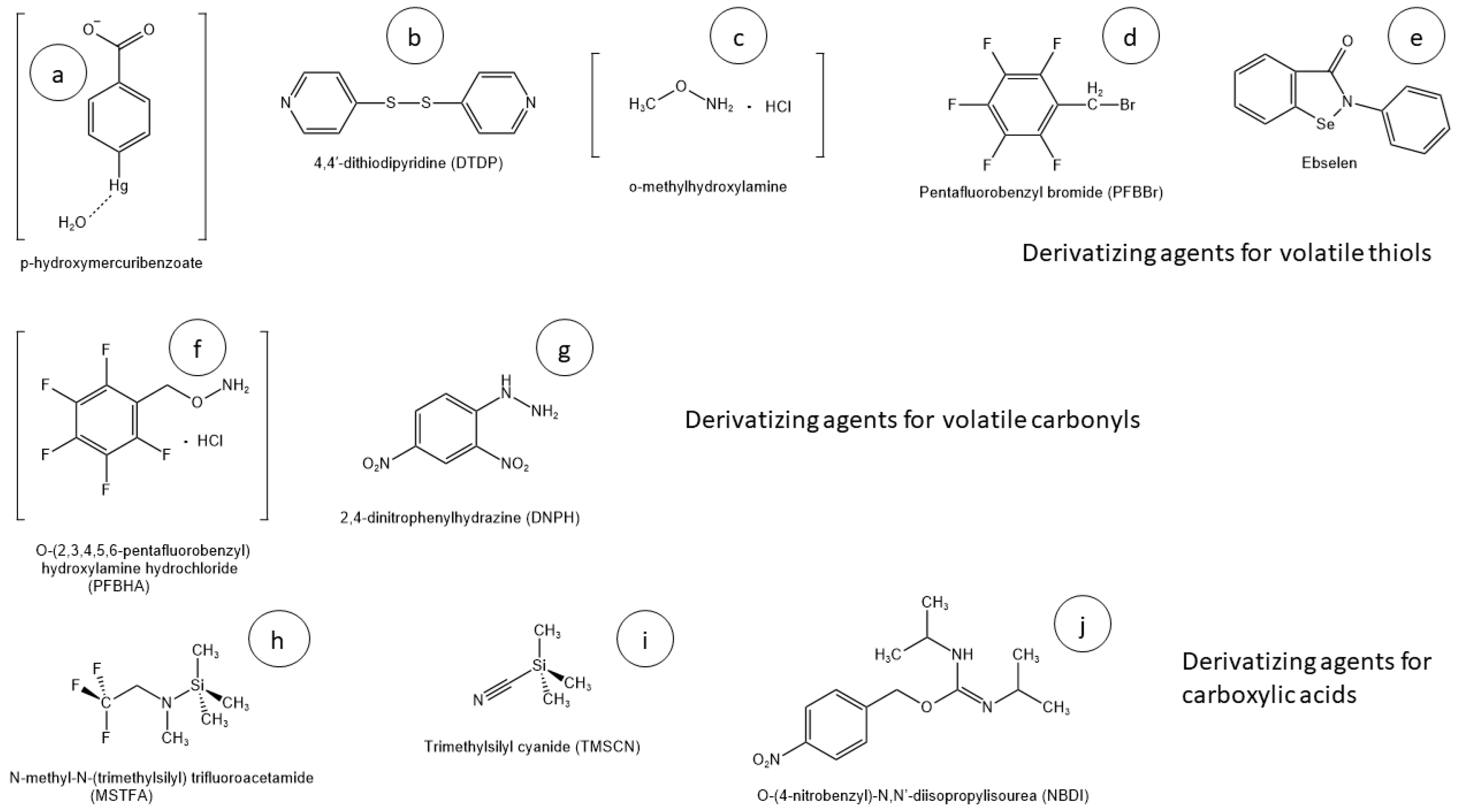

Most VOAs in wine and beer can be extracted and analyzed as they are, so derivatization concerns only a restricted pool of molecules. It must be highlighted that the need for derivatization is not only class-dependent but also structure-dependent. There are analytes belonging to the same group that could require or not require derivatization, depending on the olfactory threshold and volatility. To date, the most frequently derivatized VOAs are thiols, carboxylic acids, carbonyls, and some other extra compounds with particular characteristics. Early derivatization procedures involved transition metals or hazardous substances with consequent environmental and safety issues. The current approaches discussed below are based on organic or organometallic agents (Figure 1) with increased selectivity, yields, and reduced drawbacks.

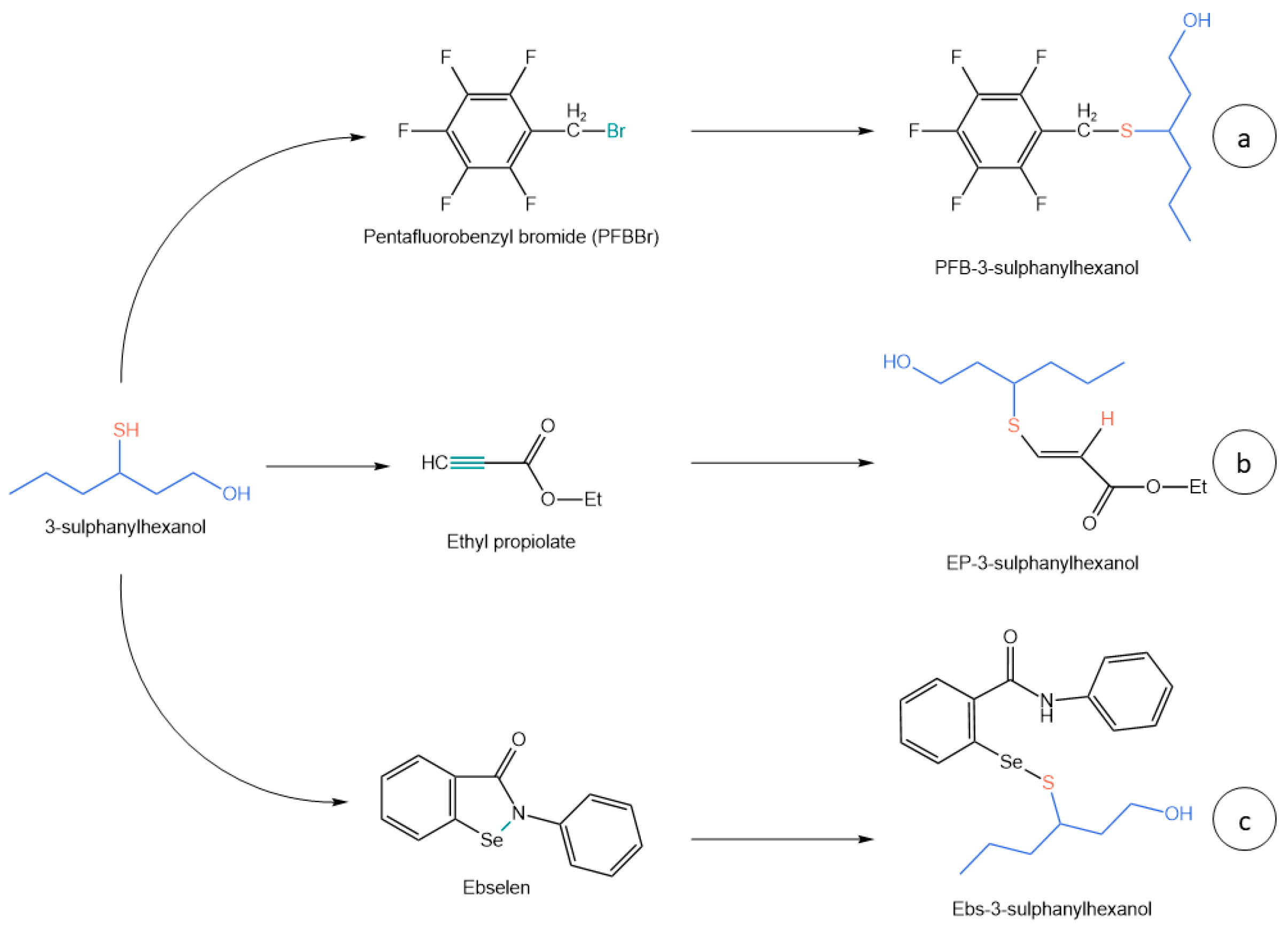

2.1. Volatile Thiols

Volatile Thiols (VTs), also known as mercaptans, are odor-active molecules functionalized with a R-SH functional group belonging to the broad category of Volatile Sulphur Compounds (VSCs). These compounds give a significant contribution to beverage aroma thanks to their broad presence and low Odor Detection Threshold (ODT) [44][14]. Despite their important contribution, VTs are present in parts per trillion (ng·L−1) levels, so an enrichment technique and a sensitive instrument are mandatory to perform analysis [44,45,46][14][15][16]. In addition, due to the Sulphur reactivity, their concentration can be affected by several reactions and equilibria that take place in the matrix [40[17][18],47], which makes derivatization unavoidable. It must be underscored that extraction parameters which are labelled as huge for other green techniques must be reconsidered for VTs due to their peculiar characteristics. Derivatizing methods had different focuses depending on the instrumental technique used. If the quantification was performed with GC, the aim was to increase volatility, whereas if it was performed with LC, the task was to increase the response of the detector. In all procedures the derivatizing agent reacted with the -SH group that, in free form, made the analyte highly reactive and unstable. Historically, thiols were known to show a strong affinity for mercury (Hg+) and silver (Ag+), so first procedures were developed using these metal ions as highly selective derivatizing agents. Curiously, the word mercaptan itself derive from the Latin forms cercurium captans, which means mercury-seizing [46][16]. Shifting to more recent times, traditional GC-based methods involve the use of metal ions or hazardous organomercurial agents like p-HMB (p-hydroxymercuribenzoate), require pH adjustment, large extraction volumes (over hundred mL), and are highly time-consuming (Figure 1a) [48][19]. Five hundred mL of wine are adjusted to pH 7 with sodium hydroxide and extracted 2 times with 100 mL of dichloromethane; the organic phase is then extracted with 20 mL of p-hydroxymercuribenzoate aqueous solution, keeping pH > 7. The resulting solution is finally purified and concentrated in a preparative column, eluted in dichloromethane again, and injected in GC-MS. The most relevant aspects of this and the following methods are reported in Table 1. This procedure is highly time-consuming and requires huge volumes of sample and hazardous solvent, with consequent production of more than 1 L of waste per sample [49][20]. However, this was the method which allowed the first instrumental studies on VTs’ occurrence in wine and, for over 10 years from its presentation, did not have any alternative [50,51,52][21][22][23]. HS-SPME methods coupled to GC-MS-based techniques were interesting due to the high automation, avoided use of solvents, and the requirement of less than 20 mL of sample. Pentafluorobenzyl bromide (PFBBr) was successfully used as a derivatizing agent because, despite its toxicity, its selectivity and reaction efficiency require just a low amount of reagent, minimizing possible safety drawbacks (Figure 1d) [53][24]. PFBBr has a bromide atom bound to a benzylic primary carbon that perfectly matches with the requirements of nucleophilic substitution; in this case, the thiolic -SH acts as the nucleophile and replaces the Br leaving group, giving a more volatile and less polar product that better fits for gas chromatography (Figure 2a) [54][25].| Article | Year | Matrix | Ext. Volume | Ext. Technique | Der. Agent | Instrumentation | Pro & Cons |

|---|---|---|---|---|---|---|---|

| [48][19] | 2003 | White wine | 500 mL | LLE + N2 concentration + preparative column | p-HMB | GC-EI-MS | + 5000 concentration factors − 100 mL of hazardous solvent |

| [53][24] | 2006 | White wine | 20 mL | HS-SPME with on-fiber derivatization | PFBBr | GC-NCI-MS | + Solvent-free − Time-consuming derivatizing process |

| [55][26] | 2007 | White wine | 6 mL | LLE with benzene | PFBBr | GC-NCI-MS | + No equipment required − Time-consuming, hazardous solvent |

| [54][25] | 2008 | White wine | 20 mL | SPE and SIDA | PFBBr | GC-NCI-MS | + Good performance − Disposable cartridge, use of solvents |

| [56][27] | 2014 | White wine | 3 mL | HS-SPME with in-situ derivatization | o-methyl-hydroxylamine hydrochloride | GC-EI-MS/MS | + Low LOD, high automation, low sample volume − Only 4-MSP |

| [57][28] | 2015 | Beer, hops, wort | 10 mL | SBSE-PDMS with in-situ derivatization | Ethyl propiolate | GC-EI-MS/MS + GC-EI-QTof | + Low LODs, many analytes, solvent-free, safe reagents − Instrumentation complexity |

| [58][29] | 2015 | White wine | 20 mL | SPE with Bond-Elut C18, and SIDA | DTDP | LC-MS/MS | + Relevant VTs, accuracy − Disposable cartridge |

| [59][30] | 2018 | Wine (all) | 20 mL | SPE with Bond-Elut C18, and SIDA | DTDP | LC-HRMS | + Enantiomer analysis − Disposable cartridge |

| [60][31] | 2018 | Red wine | 20 mL | SPE with Supelclean ENVI-18 | DTDP | GC-MS/MS | + Greener chromatography − Disposable cartridge, complexity |

| [61][32] | 2015 | Wine, beer | 20 mL | LLE with 4 mL of CH2Cl2 | Ebselen | LC-HRMS | + No equipment required, flexibility, performance − CH2Cl2, time-consuming |

| [62][33] | 2018 | White wine | 35 mL | LLE with ethanol | Ebselen | LC-HRMS | + No equipment required, safe solvent − high sample volume, filtration |

| [63][34] | 2017 | White wine | 100 mL | SPE, 20 mg Li-Chrolut EN | Ebselen | LC-HRMS | + Minimized cartridge, accuracy − High sample volume |

| [39][35] | 2022 | White wine | 35 mL | Micro LLE + 0.22 µm filtration | Ebselen | LC-MS/MS | + Performance, reduced volumes − Low automatability |

2.2. Volatile Carbonyls

Volatile carbonyl compounds (VCCs) are fundamental components in the flavor of all fermented beverages. Because of their low odor perception threshold, these molecules are responsible for a strong olfactory impact even at low concentrations [69,70][41][42]. VCCs, both aldehydes and ketones, originate as products of Maillard reactions, Strecker degradation, aldol condensation, and lipid oxidation [71][43] but also from biological processes like alcoholic fermentation. Because of that, these molecules are among the most relevant VOAs in fermented beverages [33,72][44][45]. A content of VCCs slightly above the olfactory threshold is related to aromatic and pleasant nuances of vanilla, caramel, butter, honey, potato, orange, lemon, violets, cider, and plum [19,73,74,75,76,77,78,79,80][46][47][48][49][50][51][52][53][54]. Conversely, higher concentrations are associated with oxidation, which is a long-standing undesired problem responsible for aroma defects [81,82,83][55][56][57]. From the analytical point of view, VCCs’ quantification is affected by two main issues. First, thanks to the presence of a functional group suitable for receiving the hydrogen bond, these molecules are among the most hydrophilic VOAs [83][57]. In addition, the average concentration in principally fermented beverages is comprised between hundreds of ng·L−1 and a few µg·L−1, so the amount in the vapors is significantly low [19][46]. Most current methods were based on heterogeneous extraction (SPE or SPME) and GC-MS quantification [20][58]. For what concerns SPE, Mayr et al. developed a GC-MS/MS quantitation method for 18 carbonyl compounds based on O-(2,3,4,5,6-pentafluorobenzyl) hydroxylamine hydrochloride (PFBHA) derivatization on cartridge [84][59]. PFBHA is an efficient and selective agent that reacts with carbonyl function through a nucleophile addiction, giving an oxime-like product (Figure 1f) [41][60]. Even though this method showed high performance in terms of sensitivity and linearity, the SPE procedure was expensive, time-consuming, and scarcely automatable, in contrast to the rules of green analytical chemistry [85][61]. To overcome these limits, many other methods were based on the Head Space Solid Phase Micro Extraction technique (HS-SPME). This straightforward strategy does not involve any preliminary manual operation and combines high productivity and satisfactory performance [86][62]. HS-SPME methods were purposed with PFBHA on-fiber derivatization [87][63] and in-solution derivatization [88[64][65],89], both with satisfactory results but different simplicity of execution. Similar methods were also used to perform carbonyl quantitation in beers [68][40]. On-fiber derivatization (OFD) was applied for the determination of staling 15 aldehydes in wort and beer samples using PFBHA and GC-EI-MS/MS [90][66]. This procedure demonstrated an improved sensitivity over a broad calibration range (0.01–1000 µg·L−1) and reduced matrix effects resulting from overlapping PFBHA-oximes (PFBOs). Extensive validation through linearity assessment (R2 > 0.99), LOD/LOQ, precision (RSD < 9.2%), and recovery (80–118%) was provided to support the protocol. The procedure is very simple; 3 mL of decarbonized beer, 1 g NaCl, and 10 min at 50 °C of fiber exposure previously soaked with the derivatizing agent. A preliminary version of this method was presented some years before by Schmarr et al. for the determination of many VCCs in wine; in this case, a wider range of analytes was analyzed comprising alkanals, €-2-alkenals, (E,E)-2,4-alkadienals, and others, including S-containing ketones [87][63]. This procedure required 10 mL of untreated sample and 20 min of following head-space extraction at 40 °C.2.3. Carboxylic Acids

Carboxylic acids (or fatty acids) are hydrocarbons functionalized with a carboxyl group whose presence in fermented beverages originates from raw materials (mostly from the firm tissues of fruits) and, especially, during alcoholic fermentation [94][67]. Due to the strong hydrophilic interactions established by the carboxyl group with the matrix, most of them are non-volatile and odorless [95][68]. Despite that, some short-chain carboxylic acids are volatile enough to move into the vapors and to cause olfactory activity. As it happens for many VOAs, carboxylic acids are identified with desired flavors for some products like sour beers [96][69], whereas with a higher concentration, they are related to unpleasant acrid and repulsive nuances [97][70]. Conventional fatty acid quantitation was performed with an extraction followed by derivatization to methyl esters and GC-MS analysis [98][71]; in this case, the extraction was performed using methanol, which also had the function of a derivatizing agent for thorough esterification in acid conditions [99][72]. This method, which was developed over 30 years ago and is still in use, was affected by the simultaneous transesterification between methanol and ethyl esters present in the samples; this issue determined an increased amount of free fatty acids and a non-representative measurement of other VOAs. Gallart et al. presented an alternative procedure based on methylation for a precise quantitation of free fatty acids, spanning from C6 to C18 [100][73]; these are key compounds for wines and beers, since C6 (caproic acid), C8 (caprylic acid), and C10 (capric acid) are important VOAs because of their flavors of rancid cheese and goat-like flavors, which are unpleasant already at a high concentration. In this upgraded protocol, the extraction was performed in triplicate using hexane (5 mL), the sum of aliquots was then centrifuged and concentrated to 1 mL under a nitrogen stream, and finally 1 mL of derivatizing solution (sulfuric acid (3%) in methanol) was injected and allowed to react for 3 h at room temperature. This procedure was more complex but made the quantitation of free fatty acids feasible and precise. In more recent times, silylation of the carboxyl function was implemented as a selective derivatization strategy for the analysis of free carboxylic acids. This procedure was used in many other matrices before and only in the last ten years was extended to beverages [101][74]. Silylation proceeds via bimolecular nucleophilic substitution (SN2) on the silicon atom (electrophile) where the carboxyl group acts as the nucleophile that replaces a part of the derivatizing reagent (leaving group). The aim of this process is to hide the hydrophilic carboxyl function and to simultaneously lower the polarity and increase the volatility [102][75]. Browsing published literature within all developed reactants for silylation purposes, only two of them were used in beverages. Zhang et al. optimized a method based on the use of [N-methyl-N-(trimethylsilyl) trifluoroacetamide] MSTFA, the application field of which was the metabolomics of plant leaves (Figure 1h) [103][76]. The authors implemented a lyophilization (10 h at room temperature) prior to sample drying, dissolution in methoxyamine hydrochloride (20 mg·L−1 in pyridine), silylation with MSTFA for 30 min at 37 °C, and a final filtration. This method demonstrated a significant efficiency and good versatility (amines and monosaccharides were also simultaneously derivatized).References

- Ibáñez, E.; Cifuentes, A. Green extraction techniques 2015. TrAC Trends Anal. Chem. 2015, 71, 1.

- Özay, H.; Çakır, A.; Ecevit, M.C. Retronasal Olfaction Test Methods: A Systematic Review. Balk. Med. J. 2019, 36, 49–59.

- Morrin, M.; Tepper, B.J. Multisensory marketing: Effects of environmental aroma cues on perception, appetite, and consumption of foods and drinks. Curr. Opin. Food Sci. 2021, 40, 204–210.

- Martins, R.O.; de Araújo, G.L.; de Freitas, C.S.; Silva, A.R.; Simas, R.C.; Vaz, B.G.; Chaves, A.R. Miniaturized sample preparation techniques and ambient mass spectrometry as approaches for food residue analysis. J. Chromatogr. A 2021, 1640, 461949.

- Soares Maciel, E.V.; de Toffoli, A.L.; Lanças, F.M. Recent trends in sorption-based sample preparation and liquid chromatography techniques for food analysis. Electrophoresis 2018, 39, 1582–1596.

- Van Opstaele, F.; De Causmaecker, B.; Aerts, G.; De Cooman, L. Characterization of Novel Varietal Floral Hop Aromas by Headspace Solid Phase Microextraction and Gas Chromatography–Mass Spectrometry/Olfactometry. J. Agric. Food Chem. 2012, 60, 12270–12281.

- Karlsson, P.B. World Wine Production in 2021: Almost Record Low, France Drops to Third Place. Forbes 2021. Available online: https://www.forbes.com/sites/karlsson/2021/12/30/wine-production-in-the-world-in-2020-a-detailed-look/?sh=108ee1e364a0 (accessed on 20 September 2022).

- Statista. Wine Market Revenue Worldwide from 2012 to 2025 (in Million U.S. Dollars). 2021. Available online: https://www.statista.com/statistics/922403/global-wine-market-size/ (accessed on 20 September 2022).

- Association, B. No Title 2022. Available online: https://www.brewersassociation.org/statistics-and-data/national-beer-stats/ (accessed on 20 September 2022).

- Lyu, J.; Chen, S.; Nie, Y.; Xu, Y.; Tang, K. Aroma release during wine consumption: Factors and analytical approaches. Food Chem. 2020, 346, 128957.

- Castro-Vázquez, L.; Alañón, M.E.; Calvo, E.; Cejudo, M.J.; Díaz-Maroto, M.C.; Pérez-Coello, M.S. Volatile compounds as markers of ageing in Tempranillo red wines from La Mancha D.O. stored in oak wood barrels. J. Chromatogr. A 2011, 1218, 4910–4917.

- Andujar-Ortiz, I.; Moreno-Arribas, M.V.; Martín-Álvarez, P.J.; Pozo-Bayón, M.A. Analytical performance of three commonly used extraction methods for the gas chromatography–mass spectrometry analysis of wine volatile compounds. J. Chromatogr. A 2009, 1216, 7351–7357.

- Davis, P.M.; Qian, M.C. Effect of Ethanol on the Adsorption of Volatile Sulfur Compounds on Solid Phase Micro-Extraction Fiber Coatings and the Implication for Analysis in Wine. Molecules 2019, 24, 3392.

- McGorrin, R.J. The Significance of Volatile Sulfur Compounds in Food Flavors. ACS Symp. Ser. 2011, 1068, 3–31.

- Hart, R.S.; Jolly, N.P.; Ndimba, B.K. Characterisation of hybrid yeasts for the production of varietal Sauvignon blanc wine—A review. J. Microbiol. Methods 2019, 165, 105699.

- Chen, L.; Capone, D.L.; Jeffery, D.W. Analysis of Potent Odour-Active Volatile Thiols in Foods and Beverages with a Focus on Wine. Molecules 2019, 24, 2472.

- Liem-Nguyen, V.; Bouchet, S.; Björn, E. Determination of Sub-Nanomolar Levels of Low Molecular Mass Thiols in Natural Waters by Liquid Chromatography Tandem Mass Spectrometry after Derivatization with p-(Hydroxymercuri) Benzoate and Online Preconcentration. Anal. Chem. 2014, 87, 1089–1096.

- Petri, L.; Ábrányi-Balogh, P.; Varga, P.R.; Imre, T.; Keserű, G.M. Comparative reactivity analysis of small-molecule thiol surrogates. Bioorganic Med. Chem. 2020, 28, 115357.

- Tominaga, T.; Darriet, P.; Dubourdieu, D. Identification de l’acetate de 3-mercaptohexanol, compose a forte odeur de buis, intervenant dans l’arome des vins de Sauvignon. Vitis 1996, 35, 207–210.

- Tominaga, T.; Murat, A.M.-L.; Dubourdieu, D. Development of a Method for Analyzing the Volatile Thiols Involved in the Characteristic Aroma of Wines Made from Vitis vinifera L. Cv. Sauvignon Blanc. J. Agric. Food Chem. 1998, 46, 1044–1048.

- Tominaga, T.; Masneuf, I.; Dubourdieu, D. Powerful Aromatic Volatile Thiols in Wines Made from Several Vitis Vinifera Grape Varieties and Their Releasing Mechanism; ACS Publications: Washington, DC, USA, 2003; pp. 314–337.

- Vermeulen, C.; Bailly, S.; Collin, S. Occurrence of polyfunctional thiols in fresh and aged lager beers. Dev. Food Sci. 2006, 43, 245–248.

- Tominaga, T.; Guimbertau, G.; Dubourdieu, D. Role of Certain Volatile Thiols in the Bouquet of Aged Champagne Wines. J. Agric. Food Chem. 2003, 51, 1016–1020.

- Mateo-Vivaracho, L.; Ferreira, V.; Cacho, J. Automated analysis of 2-methyl-3-furanthiol and 3-mercaptohexyl acetate at ngL−1 level by headspace solid-phase microextracion with on-fibre derivatisation and gas chromatography–negative chemical ionization mass spectrometric determination. J. Chromatogr. A 2006, 1121, 1–9.

- Mateo-Vivaracho, L.; Cacho, J.; Ferreira, V. Improved solid-phase extraction procedure for the isolation and in-sorbent pentafluorobenzyl alkylation of polyfunctional mercaptans: Optimized procedure and analytical applications. J. Chromatogr. A 2008, 1185, 9–18.

- Mateo-Vivaracho, L.; Cacho, J.; Ferreira, V. Quantitative determination of wine polyfunctional mercaptans at nanogram per liter level by gas chromatography–negative ion mass spectrometric analysis of their pentafluorobenzyl derivatives. J. Chromatogr. A 2007, 1146, 242–250.

- Dagan, L.; Reillon, F.; Roland, A.; Schneider, R. Development of a routine analysis of 4-mercapto-4-methylpentan-2-one in wine by stable isotope dilution assay and mass tandem spectrometry. Anal. Chim. Acta 2014, 821, 48–53.

- Ochiai, N.; Sasamoto, K.; Kishimoto, T. Development of a Method for the Quantitation of Three Thiols in Beer, Hop, and Wort Samples by Stir Bar Sorptive Extraction with in Situ Derivatization and Thermal Desorption–Gas Chromatography–Tandem Mass Spectrometry. J. Agric. Food Chem. 2015, 63, 6698–6706.

- Capone, D.L.; Ristic, R.; Pardon, K.H.; Jeffery, D.W. Simple Quantitative Determination of Potent Thiols at Ultratrace Levels in Wine by Derivatization and High-Performance Liquid Chromatography–Tandem Mass Spectrometry (HPLC-MS/MS) Analysis. Anal. Chem. 2015, 87, 1226–1231.

- Chen, L.; Capone, D.L.; Jeffery, D.W. Chiral analysis of 3-sulfanylhexan-1-ol and 3-sulfanylhexyl acetate in wine by high-performance liquid chromatography–tandem mass spectrometry. Anal. Chim. Acta 2018, 998, 83–92.

- Mafata, M.; Stander, M.A.; Thomachot, B.; Buica, A. Measuring Thiols in Single Cultivar South African Red Wines Using 4,4-Dithiodipyridine (DTDP) Derivatization and Ultraperformance Convergence Chromatography-Tandem Mass Spectrometry. Foods 2018, 7, 138.

- Vichi, S.; Cortés-Francisco, N.; Caixach, J. Analysis of volatile thiols in alcoholic beverages by simultaneous derivatization/extraction and liquid chromatography-high resolution mass spectrometry. Food Chem. 2015, 175, 401–408.

- Román, T.; Tonidandel, T.; Larcher, R.; Celotti, E.; Nicolini, G. Importance of polyfunctional thiols on semi-industrial Gewürztraminer wines and the correlation to technological treatments. Eur. Food Res. Technol. 2017, 244, 379–386.

- Lv, Z.; You, J.; Lu, S.; Sun, W.; Ji, Z.; Sun, Z.; Song, C.; Chen, G.; Li, G.; Hu, N.; et al. Sensitive determination of thiols in wine samples by a stable isotope-coded derivatization reagent d0/d4-acridone-10-ethyl-N-maleimide coupled with high-performance liquid chromatography-electrospray ionization-tandem mass spectrometry analysis. J. Chromatogr. A 2017, 1491, 98–107.

- Carlin, S.; Piergiovanni, M.; Pittari, E.; Lisanti, M.T.; Moio, L.; Piombino, P.; Marangon, M.; Curioni, A.; Rolle, L.; Segade, S.R.; et al. The contribution of varietal thiols in the diverse aroma of Italian monovarietal white wines. Food Res. Int. 2022, 157, 111404.

- Xu, K.; Zhang, Y.; Tang, B.; Laskin, J.; Roach, P.J.; Chen, H. Study of Highly Selective and Efficient Thiol Derivatization Using Selenium Reagents by Mass Spectrometry. Anal. Chem. 2010, 82, 6926–6932.

- Sarma, B.K.; Mugesh, G. Glutathione Peroxidase (GPx)-like Antioxidant Activity of the Organoselenium Drug Ebselen: Unexpected Complications with Thiol Exchange Reactions. J. Am. Chem. Soc. 2005, 127, 11477–11485.

- Vichi, S.; Cortés-Francisco, N.; Caixach, J. Determination of volatile thiols in lipid matrix by simultaneous derivatization/extraction and liquid chromatography–high resolution mass spectrometric analysis. Application to virgin olive oil. J. Chromatogr. A 2013, 1318, 180–188.

- Vichi, S.; Jerí, Y.; Cortés-Francisco, N.; Palacios, O.; Caixach, J. Determination of volatile thiols in roasted coffee by derivatization and liquid chromatography–high resolution mass spectrometric analysis. Food Res. Int. 2014, 64, 610–617.

- Moreira, N.; Meireles, S.; Brandão, T.; de Pinho, P.G. Optimization of the HS-SPME–GC–IT/MS method using a central composite design for volatile carbonyl compounds determination in beers. Talanta 2013, 117, 523–531.

- Luo, Y.; Kong, L.; Xue, R.; Wang, W.; Xia, X. Bitterness in alcoholic beverages: The profiles of perception, constituents, and contributors. Trends Food Sci. Technol. 2020, 96, 222–232.

- Vanderhaegen, B.; Neven, H.; Verachtert, H.; Derdelinckx, G. The chemistry of beer aging—A critical review. Food Chem. 2006, 95, 357–381.

- Oliveira, C.M.; Ferreira, A.C.S.; De Freitas, V.; Silva, A.M. Oxidation mechanisms occurring in wines. Food Res. Int. 2011, 44, 1115–1126.

- Garde-Cerdán, T.; Ancín-Azpilicueta, C. Review of quality factors on wine ageing in oak barrels. Trends Food Sci. Technol. 2006, 17, 438–447.

- Escudero, A.; Hernández-Orte, P.; Cacho, J.; Ferreira, V. Clues about the Role of Methional As Character Impact Odorant of Some Oxidized Wines. J. Agric. Food Chem. 2000, 48, 4268–4272.

- Polášková, P.; Herszage, J.; Ebeler, S.E. Wine flavor: Chemistry in a glass. Chem. Soc. Rev. 2008, 37, 2478–2489.

- Bueno, M.; Marrufo-Curtido, A.; Carrascon, V.; Fernandez-Zurbano, P.; Escudero, A.; Ferreira, V. Formation and Accumulation of Acetaldehyde and Strecker Aldehydes during Red Wine Oxidation. Front. Chem. 2018, 6, 20.

- Ugliano, M. Oxygen Contribution to Wine Aroma Evolution during Bottle Aging. J. Agric. Food Chem. 2013, 61, 6125–6136.

- Ferreira, A.C.S.; Barbe, J.-C.; Bertrand, A. 3-Hydroxy-4,5-dimethyl-2(5H)-furanone: A Key Odorant of the Typical Aroma of Oxidative Aged Port Wine. J. Agric. Food Chem. 2003, 51, 4356–4363.

- Escudero, A.; Asensio, E.; Cacho, J.; Ferreira, V. Sensory and chemical changes of young white wines stored under oxygen. An assessment of the role played by aldehydes and some other important odorants. Food Chem. 2002, 77, 325–331.

- Escudero, A.; Cacho, J.; Ferreira, V. Isolation and identification of odorants generated in wine during its oxidation: A gas chromatography-olfactometric study. Eur. Food Res. Technol. 2000, 211, 105–110.

- Bartowsky, E.J.; Henschke, P.A. The ‘buttery’ attribute of wine—Diacetyl—Desirability, spoilage and beyond. Int. J. Food Microbiol. 2004, 96, 235–252.

- Gabrielli, M.; Fracassetti, D.; Romanini, E.; Colangelo, D.; Tirelli, A.; Lambri, M. Oxygen-induced faults in bottled white wine: A review of technological and chemical characteristics. Food Chem. 2020, 348, 128922.

- Li, H.; Guo, A.; Wang, H. Mechanisms of oxidative browning of wine. Food Chem. 2008, 108, 1–13.

- Alañón, M.E.; Pérez-Coello, M.S.; Marina, M.L. Wine science in the metabolomics era. TrAC Trends Anal. Chem. 2015, 74, 1–20.

- Jackowetz, J.; de Orduña, R.M. Survey of SO2 binding carbonyls in 237 red and white table wines. Food Control 2013, 32, 687–692.

- Mayr, C.M.; Capone, D.L.; Pardon, K.H.; Black, C.A.; Pomeroy, D.; Francis, I.L. Quantitative Analysis by GC-MS/MS of 18 Aroma Compounds Related to Oxidative Off-Flavor in Wines. J. Agric. Food Chem. 2015, 63, 3394–3401.

- Román, S.M.-S.; Rubio-Bretón, P.; Pérez-Álvarez, E.P.; Garde-Cerdán, T. Advancement in analytical techniques for the extraction of grape and wine volatile compounds. Food Res. Int. 2020, 137, 109712.

- Aly, A.A.; Górecki, T. Green Approaches to Sample Preparation Based on Extraction Techniques. Molecules 2020, 25, 1719.

- Ferreira, V.; Culleré, L.; Loscos, N.; Cacho, J. Critical aspects of the determination of pentafluorobenzyl derivatives of aldehydes by gas chromatography with electron-capture or mass spectrometric detection: Validation of an optimized strategy for the determination of oxygen-related odor-active aldehydes in wine. J. Chromatogr. A 2006, 1122, 255–265.

- Olivero, S.J.P.; Trujillo, J.P.P. A New Method for the Determination of Carbonyl Compounds in Wines by Headspace Solid-Phase Microextraction Coupled to Gas Chromatography−Ion Trap Mass Spectrometry. J. Agric. Food Chem. 2010, 58, 12976–12985.

- Schmarr, H.-G.; Potouridis, T.; Ganß, S.; Sang, W.; Köpp, B.; Bokuz, U.; Fischer, U. Analysis of carbonyl compounds via headspace solid-phase microextraction with on-fiber derivatization and gas chromatographic–ion trap tandem mass spectrometric determination of their O-(2,3,4,5,6-pentafluorobenzyl)oxime derivatives. Anal. Chim. Acta 2008, 617, 119–131.

- Moreira, N.; Araújo, A.M.; Rogerson, F.; Vasconcelos, I.; De Freitas, V.; de Pinho, P.G. Development and optimization of a HS-SPME-GC-MS methodology to quantify volatile carbonyl compounds in Port wines. Food Chem. 2019, 270, 518–526.

- Bueno, M.; Zapata, J.; Ferreira, V. Simultaneous determination of free and bonded forms of odor-active carbonyls in wine using a headspace solid phase microextraction strategy. J. Chromatogr. A 2014, 1369, 33–42.

- Dennenlöhr, J.; Thörner, S.; Maxminer, J.; Rettberg, N. Analysis of Selected Staling Aldehydes in Wort and Beer by GC-EI-MS/MS Using HS-SPME with On-Fiber Derivatization. J. Am. Soc. Brew. Chem. 2020, 78, 284–298.

- Hernandes, K.C.; Souza-Silva, E.A.; Assumpção, C.F.; Zini, C.A.; Welke, J.E. Validation of an analytical method using HS-SPME-GC/MS-SIM to assess the exposure risk to carbonyl compounds and furan derivatives through beer consumption. Food Addit. Contam. Part A 2019, 36, 1808–1821.

- Di Gianvito, P.; Englezos, V.; Rantsiou, K.; Cocolin, L. Bioprotection strategies in winemaking. Int. J. Food Microbiol. 2022, 364, 109532.

- Schreier, P.; Jennings, W.G. Flavor composition of wines: A review. Crit. Rev. Food Sci. Nutr. 1979, 12, 59–111.

- Thompson Witrick, K.; Duncan, S.E.; Hurley, K.E.; O’Keefe, S.F. Acid and Volatiles of Commercially-Available Lambic Beers. Beverages 2017, 3, 51.

- Tieman, D.; Zeigler, M.; Schmelz, E.; Taylor, M.G.; Rushing, S.; Jones, J.B.; Klee, H.J. Functional analysis of a tomato salicylic acid methyl transferase and its role in synthesis of the flavor volatile methyl salicylate. Plant J. 2010, 62, 113–123.

- Troton, D.; Charpentier, M. Evolution of the lipid contents of Champagne wine during the second fermentation of Saccharomyces cerevisiae. Am. J. Enol. Vitic. 1989, 40, 175–182.

- Wang, X.; Xu, X.; Wang, Q.; Huang, Z.; He, J.; Qiu, T. Fatty Acid Methyl Ester Synthesis through Transesterification of Palm Oil with Methanol in Microchannels: Flow Pattern and Reaction Kinetics. Energy Fuels 2020, 34, 3628–3639.

- Gallart, M.; Francioli, S.; Viu-Marco, A.; López-Tamames, E.; Buxaderas, S. Determination of free fatty acids and their ethyl esters in musts and wines. J. Chromatogr. A 1997, 776, 283–291.

- Fiehn, O.; Kopka, J.; Trethewey, R.N.; Willmitzer, L. Identification of Uncommon Plant Metabolites Based on Calculation of Elemental Compositions Using Gas Chromatography and Quadrupole Mass Spectrometry. Anal. Chem. 2000, 72, 3573–3580.

- Borden, S.A.; Damer, H.N.; Krogh, E.T.; Gill, C.G. Direct quantitation and characterization of fatty acids in salmon tissue by condensed phase membrane introduction mass spectrometry (CP-MIMS) using a modified donor phase. Anal. Bioanal. Chem. 2018, 411, 291–303.

- Gullberg, J.; Jonsson, P.; Nordström, A.; Sjöström, M.; Moritz, T. Design of experiments: An efficient strategy to identify factors influencing extraction and derivatization of Arabidopsis thaliana samples in metabolomic studies with gas chromatography/mass spectrometry. Anal. Biochem. 2004, 331, 283–295.