Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by In Jung Kim and Version 2 by Conner Chen.

Nonconventional yeasts (NCYs) have several advantages over S. cerevisiae from an industrial viewpoint. S. cerevisiae is often directed toward ethanol synthesis (due to its Crabtree-positive effect), restricting product diversification. In contrast, NCYs may have desired metabolic pathways, enabling product profile expansion. The ability to resist various stresses is additional key benefit in industrial bioprocesses.

- nonconventional yeast

- genome editing

- metabolic engineering

1. Introduction

Petroleum-derived chemical production has detrimental effects on the environment and exhibits industrial noncompatibility associated with cost-effectiveness due to multiple labor-intensive processes [1]. To overcome this problem, biotransformation using microorganisms can be considered an alternative approach [1][2][1,2], which has the advantage of rapid growth rate and easy cultivation of microorganisms under laboratory conditions [3]. In particular, eukaryotic yeasts represent robust microbial cell factories owing to their simple structure and ability to grow on various substrates, as well as the relatively simple gene editing techniques used to manipulate their genomes [4].

Saccharomyces cerevisiae is the most widely used eukaryotic platform in bioprocesses [5][6][5,6]. S. cerevisiae has long been a model organism for fundamental biological research and industrial applications because of its ease of handling and safety as a generally recognized as safe (GRAS) strain [7]. Moreover, its genetics are well understood, and tools for manipulating it are well established; thus, numerous specialized strains and plasmids are available. However, as a Crabtree-positive organism, the carbon flux in S. cerevisiae is mainly directed toward the ethanol fermentation pathway. This preference for ethanol production often limits its utilization as a host when nonethanol products are to be synthesized. Therefore, other suitable yeasts, known as nonconventional yeasts (NCY), should be considered as alternative hosts.

Approximately 1500 NCY species have been identified to date [8], each of which exhibits unique genetics, physiology, and characteristics. They often have excellent potential for industrial uses that are not feasible with S. cerevisiae. Thus, NCY can be considered as promising eukaryotic hosts alternative to S. cerevisiae to overcome or improve its limitations. Specifically, NCYs that are Crabtree-negative can diversify the profile of industrially useful products. In addition, a much higher capacity of NCYs for pentose phosphate pathway relative to S. cerevisiae is also advantageous feature when synthesizing products using NCYs as the cell factory by increasing the available pool of cofactors and precursors [9]. Moreover, a high tolerance against multiple stress factors, such as heat, low pH, and salt, can extend yeasts’ utility. Advancements in genetic and metabolic engineering technologies will facilitate NCY-based scaled-up bioprocesses [8][10][8,10].

Despite their beneficial traits, genetic information and manipulation tools for many NCYs are lacking compared with those for S. cerevisiae [11]. As most organisms have not been thoroughly analyzed for safety and lack genome sequencing data with the limited information on the exact gene loci and protein functions, it is challenging to develop and apply suitable gene editing tools, together with establishing transformation protocols and selectable marker genes [11].

The clustered regularly interspaced short palindromic repeats (CRISPR)-associated protein (Cas) system is an adaptive immune system of bacteria and archaea that protects them from invasion by foreign genetic elements [12]. As a gene editing tool, the CRISPR-Cas system is based on a simple single guide RNA (sgRNA)/DNA hybrid that recognizes specific target DNA, providing a simple-to-design methodology, which has more sophisticated, accurate, and cheaper gene editing capabilities compared with traditional methods like zinc finger nucleases (ZFNs) and transcription activator-like effector nucleases (TALENs) [13]. Thus, this revolutionary CRISPR-Cas9 system has been applied to various yeast strains, such as S. cerevisiae, Pichia pastoris, Kluyveromyces marxianus, and Yarrowia lipolytica; among these, most studies have been conducted on S. cerevisiae [14][15][14,15]. Although numerous studies have reported the CRISPR-guided metabolic engineering of S. cerevisiae, only few studies have explored the applicability of this system in NCYs [16]. To achieve commercial scale bioproduction using NCYs as cell factories, it is necessary to develop highly efficient and convenient engineered strains [10][17][10,17].

2. Industrial Value of NCYs

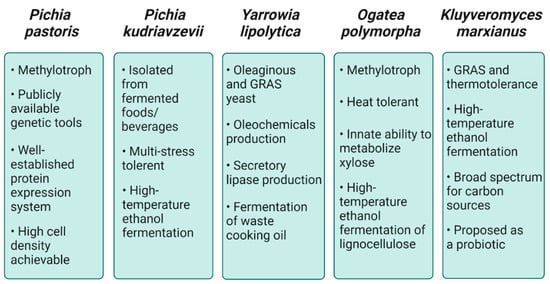

NCYs have several advantages over S. cerevisiae from an industrial viewpoint [18]. S. cerevisiae is often directed toward ethanol synthesis (due to its Crabtree-positive effect), restricting product diversification. In contrast, NCYs may have desired metabolic pathways, enabling product profile expansion. The ability to resist various stresses is a key benefit in industrial bioprocesses. For example, ethanol production from lignocellulose can be enhanced by developing alternative microbial platforms that are highly resistant to inhibitors. NCYs often exhibit strong resistance to various stresses, such as heat, acid, and high sugar concentrations, as environmental adaptations. Another key advantage of NCYs is their ability to utilize a wide range of carbon sources [8][19][8,19]. Additionally, many NCYs can exist in both haploid and diploid types like S. cerevisiae, and sexual reproduction is possible. Therefore, NCY strains with a desired ploidy can be developed through mating depending on the purpose. For example, diploid P. pastoris strains having a higher stability than its haploid form were constructed through a well-designed mating process for production of proteins [20], or various auxotrophic K. marxianus libraries were constructed using mating and dissection [21]. In this section, the industrial potentials of five promising NCYs are described (Figure 1).

Figure 1.

Properties and industrial values of promising NCYs.