Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Vivi Li and Version 1 by Jinhao Meng.

With the widespread use of Lithium-ion (Li-ion) batteries in Electric Vehicles (EVs), Hybrid EVs and Renewable Energy Systems (RESs), much attention has been given to Battery Management System (BMSs). By monitoring the terminal voltage, current and temperature, BMS can evaluate the status of the Li-ion batteries and manage the operation of cells in a battery pack, which is fundamental for the high efficiency operation of EVs and smart grids. Battery capacity estimation is one of the key functions in the BMS, and battery capacity indicates the maximum storage capability of a battery which is essential for the battery State-of-Charge (SOC) estimation and lifespan management.

- lithium-ion battery

- battery management system

- capacity estimation

- electric vehicle

- battery degradation

1. Introduction

On the background of energy crisis and global warming, applications such as renewable energy systems and new energy vehicles (Electric Vehicles (EVs) and Hybrid EVs) have become a necessary way of saving energy and decreasing carbon emission [1,2][1][2]. As the key component in the power supply of the EVs and Renewable Energy Systems(RESs) [3,4[3][4][5],5], the energy management of the battery pack directly affects its performance in various operation conditions [6,7][6][7]. Due to its high energy density, long service life, no memory effect, etc. [8[8][9],9], the Lithium-ion (Li-ion) battery has become a first choice for EVs and RESs [10]. For example, lithium iron phosphate (LFP) has a 90~140 Wh/kg energy density and up to 2000 life cycles, which usually consists of LiFePO4 cathode and graphite anode. In addition, Li-ion battery chemistries also include lithium Nickel Manganese Cobalt oxide (NMC) and lithium Nickel Cobalt Aluminum oxide (NCA) with a higher energy density (140~250 Wh/kg) [11]. Recently, battery manufacturers have also developed new products with relatively superior performance, such as the blade battery (LFP) from BYD which has good thermal safety characteristics through nail penetration tests [12]. Thanks to its excellent properties, the scope of Li-ion batteries has also expanded to various areas like robots, Automated Guided Vehicles (AGVs) and consumer electronics. Especially, with the concept of low carbon, Li-ion batteries will play an important role in the future. According to Research and Markets research data in Statista [13], the global lithium-ion battery scales to about 185 GWh in 2020, and the market is expected to grow to 950 GWh in 2026 as shown in Figure 1.

Figure 1.

Global battery demand 2020–2026.

A typical structure of the Battery Energy Storage System (BESS) is illustrated in Figure 2, which mainly includes battery cells, Battery Management System (BMS), Power Conversion System (PCS), etc. Among all the components, BMS is responsible for the safety operation of the cells in the BESS. The functions of BMS include state estimation, voltage/temperature monitoring and fault diagnosis and warning. One key parameter here is the battery capacity representing the maximum Ah throughput at present. In essence, the battery capacity is the number and energy of the electrons inside the electrodes [14,15][14][15]. One consensus is that the Li-ion battery capacity will fade with battery degradation, which could be influenced by numerous external factors in operation conditions. Although the degradation of Li-ion battery can be briefly divided into two modes: Loss of Active Materials in electrodes (LAM), and Loss of Lithium Inventory (LLI), it is difficult to distinguish the aging modes in reality. However, the capacity of an Li-ion battery is critical for the energy management decision marking of BMS. For example, the battery State of Charge (SOC) represents current energy left, which is a ratio of the present Ah amount to its capacity [16]. It is impossible to obtain an accurate SOC without knowing the battery capacity. Once a precise SOC is received, BMS can choose when to charge or discharge each cell. In order to avoid the overuse of the Li-ion battery, its capacity should also be clearly defined. Otherwise, safety hazards, such as failure and thermal runaway [17[17][18],18], may exist when the Li-ion battery reaches its End-Of-Life (EOL) [19]. Capacity is also a fundamental index for the secondary use of the Li-ion battery [20,21][20][21]. In general, the battery capacity is especially important for the lifespan management of the cells by BMS [22,23][22][23].

Figure 2.

Structure of the battery energy storage system.

Battery capacity is usually regarded as the indicator of its lifespan, and it is believed to reach its EOL once the battery capacity reaches 80% of its initial value [24]. An accurate capacity can improve the accuracy of SOC estimation, thus enabling the users to perform charging operations and battery maintenance prompt. A slightly changed capacity will gradual deteriorate the battery’s electrical and thermal characteristics and further lead to other severe safety issues [25]. However, a series of barriers hinder an accurately measurement of the Li-ion battery’s capacity. One primary fact is the capacity of Li-ion battery is related to current rate and temperature [26,27][26][27] considering the effect of electrode kinetics. Then, it is easy to understand that the Li-ion battery’s capacity greatly influences the working conditions of the battery pack, which increase the difficulties of obtaining an accurate battery capacity. Another critical factor is the limitation from BMS, the computing power of the microprocessor is limited due to the cost [28]. It can be deduced that onboard implementable battery capacity estimation algorithms are still needed for most EV applications [29,30][29][30]. One expectation is that the fast development of Internet-of-Things (IoT) and artificial intelligence can improve the capacity estimation techniques for BMS [31,32][31][32].

2. Li-Ion Battery Degradation Mechanism Analysis

An Li-ion battery mainly contains the lithium metal oxide as the cathode, and graphite as the anode material at present. A separator exists between the two electrodes for insulation, which only allows the pass of Li-ions, and the electrons can only exchange through external circuits. Additionally, an electrolyte is also needed to assist the transfer of Li-ion. Thus, it is clear that the Li-ions exchange from the electrodes during battery charging and discharging [37][33]. For EVs, the reduction of the battery capacity results in less energy available, which directly reflects the performance degradation of the battery pack. The capacity loss of the battery is a non-linear process containing complex aging mechanism. However, the aging mechanism of batteries cannot be precisely described, especially for the decay rules of cycle life. To conveniently analyze the battery degradation, recent research usually divides the battery aging into two main forms: calendar aging and cycling aging [38,39,40,41][34][35][36][37].

Calendar aging refers to the capacity loss during storage, which is mainly influenced by high temperature and SOC [42,43,44][38][39][40]. Five aging cases are set in [43][39] for the calendar aging of 15 Li-ion batteries for a period between 24 and 36 months. The test results clearly prove there is a non-linear battery degradation during calendar aging, and the fading rate of the Li-ion battery is accelerated by increased storage temperature and SOC. Among all the influencing factors, high storage temperature is believed to be the most critical factor for battery calendar degradation [45,46][41][42]. LLI is the main reason for calendar aging with high temperature [15].

3. Review of Capacity Estimation Methods

Considering the complexity of battery degradation, it is still challenging for the BMS to accurately predict the battery capacity onboard. Thus, researchers have made significant efforts to solve this problem. This section will brief introduces the battery capacity estimation methods in the literature. WResearchers mainly divide the methods into direct measurement methods, analysis-based methods, SOC-based methods and data-driven methods, whose principle and current processes will be detailed in the following subsection.- A.

-

Direct Measurement Method

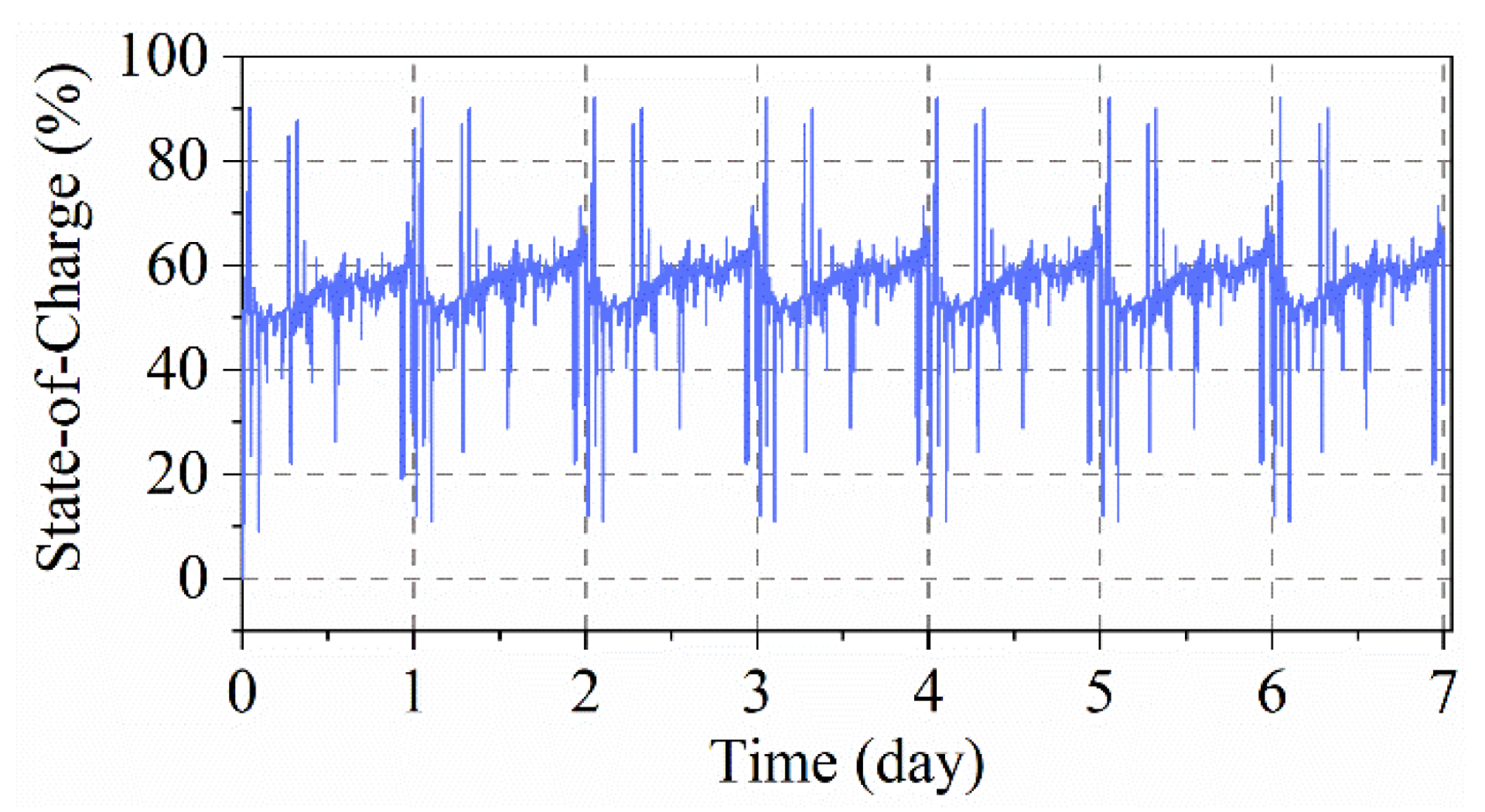

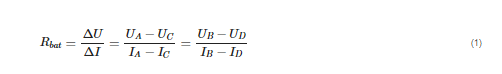

Figure 63.For convenience, an option is to measure the internal resistance to reflect the battery capacity. The battery internal resistance can be directly measured by applying a current pulse to the battery [62][48] as shown in Figure 74. Usually, the current pulse lasts a few seconds, and then the internal resistance can be calculated by the following Equation,SOC profile of BESS for the primary frequency regulation of grid.

Figure 63.For convenience, an option is to measure the internal resistance to reflect the battery capacity. The battery internal resistance can be directly measured by applying a current pulse to the battery [62][48] as shown in Figure 74. Usually, the current pulse lasts a few seconds, and then the internal resistance can be calculated by the following Equation,SOC profile of BESS for the primary frequency regulation of grid.

Figure 74.Unfortunately, the internal resistance is more related to the power fade of the battery, which does not always exhibit a linear relationship with capacity fade. The capacity degradation is related to lithium corrosion at the anode, while the power fade is related to SEI growth and LAM [63][49]. Moreover, the internal resistance measurement is also affected by C-rate, temperature and SOC, and the internal resistance is quite small in the milliohm range [43,64,65][39][50][51]. Thus, some uncertainties may exist if only internal resistance is used for calculation. Direct measurement methods are strictly performed by charging and discharging of the battery in laboratories. As for onboard BMS implementation, the practical application requires estimation methods that can be done with limited complexity. Therefore, more advanced methods are needed to estimate the battery capacity by processing the current, voltage, temperature and mechanical stress. Those existing methods include analysis-based methods, SOC-based methods and data-driven methods, which will be introduced in the following subsections.The DC internal resistance measurement for Li-ion battery.

Figure 74.Unfortunately, the internal resistance is more related to the power fade of the battery, which does not always exhibit a linear relationship with capacity fade. The capacity degradation is related to lithium corrosion at the anode, while the power fade is related to SEI growth and LAM [63][49]. Moreover, the internal resistance measurement is also affected by C-rate, temperature and SOC, and the internal resistance is quite small in the milliohm range [43,64,65][39][50][51]. Thus, some uncertainties may exist if only internal resistance is used for calculation. Direct measurement methods are strictly performed by charging and discharging of the battery in laboratories. As for onboard BMS implementation, the practical application requires estimation methods that can be done with limited complexity. Therefore, more advanced methods are needed to estimate the battery capacity by processing the current, voltage, temperature and mechanical stress. Those existing methods include analysis-based methods, SOC-based methods and data-driven methods, which will be introduced in the following subsections.The DC internal resistance measurement for Li-ion battery.- B.

-

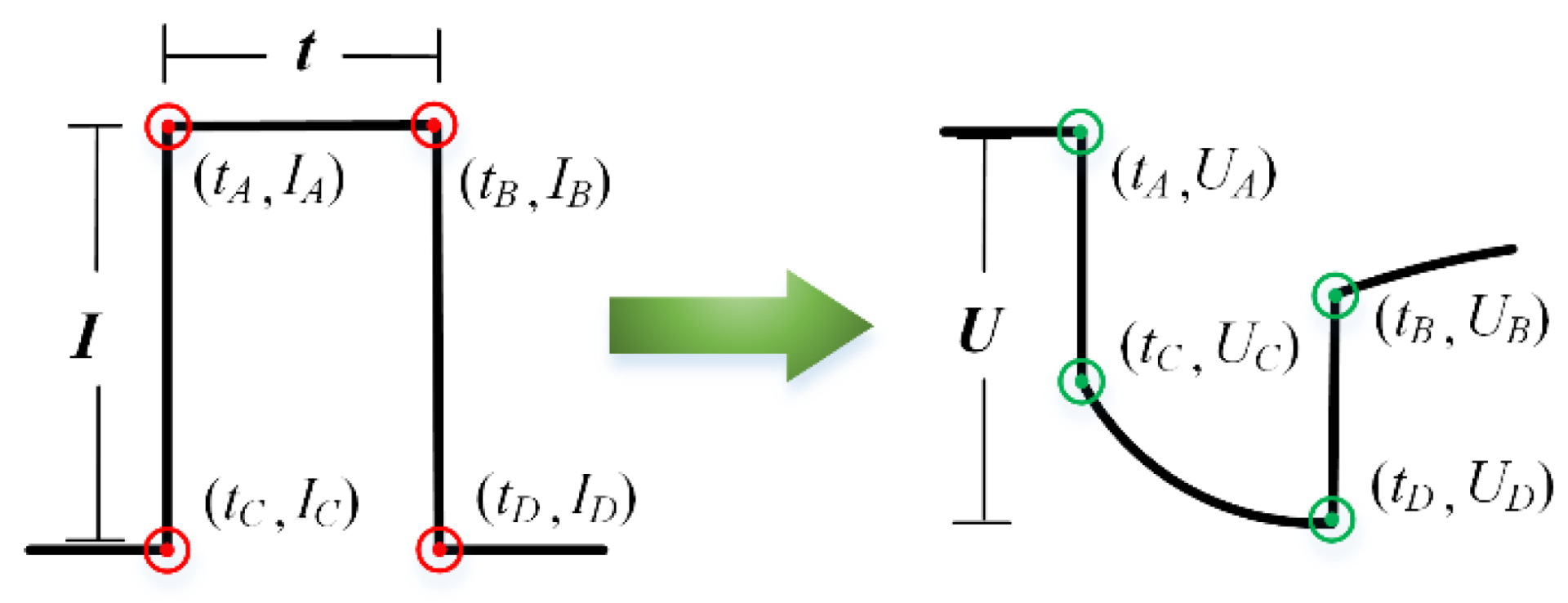

Analysis-Based Methods

where Qpresent denotes the current capacity and Qinitial is the nominal capacity. Thus, wresearchers will not distinguish capacity estimation and SOH estimation in the following explanations.

where Qpresent denotes the current capacity and Qinitial is the nominal capacity. Thus, wresearchers will not distinguish capacity estimation and SOH estimation in the following explanations.

Figure 85.Schematic of analysis-based method.

Figure 85.Schematic of analysis-based method.- C.

-

SOC-based method

Figure 116.SOC-based method.

Figure 116.SOC-based method.- D.

-

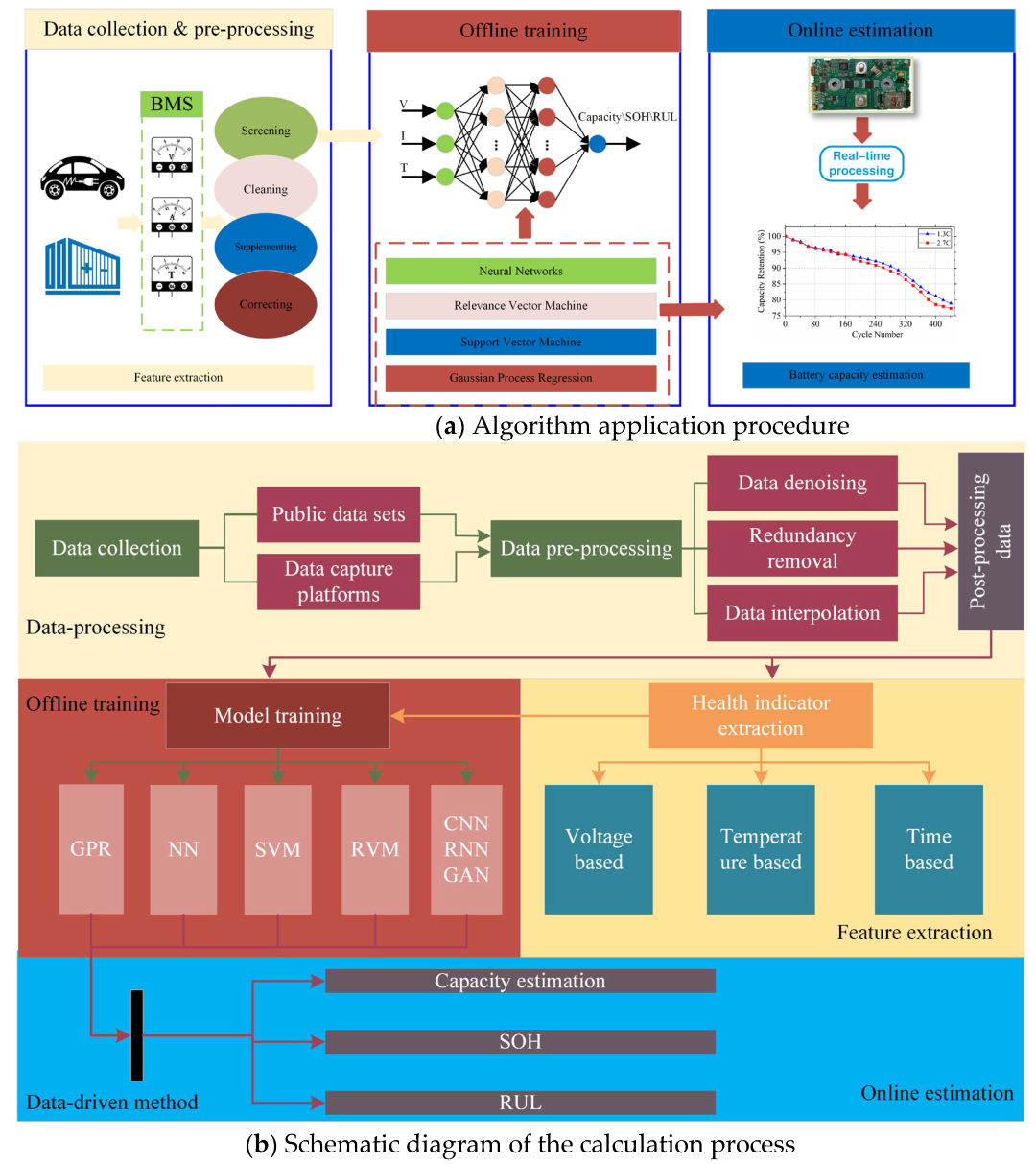

Data-driven methodWith the fast development of IoT and artificial intelligence, the daily operation measurement of the battery system is easy to be recorded to a cloud platform which could be further used for cloud to edge estimation. The data-driven approach is characterized by a reliance on a large amount of dataset to make decisions and does not require a specific battery model. In a data-driven approach, a model can be used to map the data as long as a sufficiently representative sample is available, without the need to pre-determine a definitive model in advance. In the case of batteries, the operation measurement that wresearchers can collect may contain aging information. The degree of aging can be reflected by certain characteristics during the charging and discharging process, and the data-driven approach constructs an approximate model to match the true aging situation with this information. Figure 15a is a schematic diagram of the data-driven approach application procedure, which mainly includes three processes: data collection & preprocessing, offline training and online estimation. The main purpose of data collection is measuring the voltage, current and temperature during the operation of the battery pack. Then, the data-driven model can be trained offline with high computing power processor, and the trained model is later implemented in a BMS for online estimation. In this type of method, the keys lie in the processing of the data, the extraction of key features and model training, the main data stream of those processes is shown in Figure 157b.

Figure 157.The basic process of the data-driven approach.The existing data-driven method is introduced in the following subsections.Neural Network (NN): The basic NN is a three-layer structure network including an input layer, hidden layer and output layer. The input layer neuron can be regarded as extracting capacity-related features [153][53]. It is critical to choose a suitable indicator. Refs. [154,155][54][55] use NN to investigate the battery capacity. From the perspective of feature extraction, the former uses discharge voltage, while the latter adds also the temperature effects. The weight coefficients from the input layer to the hidden layer or from the hidden layer to the output layer need to be obtained after training a large number of samples [105][56]. Ref. [156][57] chooses to train a generalized regression NN with the battery’s constant current charging time to estimate SOH. The instantaneous discharging voltage drop and the amount of Ah-throughout for a certain depth of discharge are captured as features. Ref. [157][58] uses the Broad Learning System (BLS) to process historical capacity data and generate feature nodes as the input layer of the neural network. This method does not require an in-depth study of the battery aging mechanism, but it also requires at least 25% of the historical capacity data.Support Vector Machine (SVM): Support Vector Machine (SVM) is another technique. The core is to divide the data set in a hyperplane [158,159][59][60] so that the geometric interval between each data point can be maximized in the hyperplane. It can be transformed into an objective function under constraints to solve the optimization problem. Ref. [160][61] studies the relationship between the electrolyte concentration and voltage with the battery capacity. The non-linear relationship is then fitted by SVM. A Least Squares Support Vector Machine (LSSVM) is used in [161][62], with charging voltage, discharging current, temperature, and cycle times as inputs, and the residual sum of squares error is selected as the cost function to calculate the capacity retention rate. Ref. [162][63] uses Particle Swarm Optimization (PSO) to find the suitable hyper-parameters for the SVM kernel function and trains the impedance values as the features to complete the battery SOH estimation.Bayesian learning method: Bayesian methods solve the posterior information with assumed prior probabilities to infer the unknown parameters [163][64]. There are a variety of data-driven methods that use their associated theory, such as the Relevance Vector Machine (RVM), which provides an output of posterior probabilities based on a Bayesian approach. Compared to SVM, it eliminates the need for model selection, but it often requires more training time. The literature uses empirical modal decomposition for battery capacity data, and sets up a multi-start prediction matrix to train RVM. It reduces the stochastic uncertainty associated with the starting point of a single prediction and parameter settings. GPR is derived from the Bayesian framework [164][65], and uses the Gaussian process prior knowledge to perform regression analysis on the data. Ref. [165][66] uses voltage segments in short periods during constant current operation as the input of GPR for capacity estimation. The non-parametric regression properties of the GPR technique allow the estimation to be adapted to the complexity of the data.Deep learning method: Deep learning utilizes multiple hidden layers in the network [32], which can reflect more complex mapping between the features and battery health. Methods, such as Convolutional Neural Network (CNN) [166[67][68],167], Recurrent Neural Network (RNN) [168,169][69][70] and Long Short-Term Memory (LSTM) [170,171][71][72] have been used for battery SOH estimation recently, and have shown promising performance in estimation accuracy. Ref. [167][68] takes advantage of CNN and Transformers for accurate SOH estimation of Li-ion batteries, which utilizes the attention mechanism to extract more important features from the original measurement. A differential evolution grey wolf optimizer is used in [171][72] to tune the hyperparameters of LSTM for an accurate battery health estimation. A hybrid of gate recurrent unit and CNN is shown to estimate the Li-ion battery SOH in [172][73], which utilizes voltage, current and temperature as the input of the network.The implementation of data-driven methods relies on the validity of the data and a complex training process. The advantage is that the model can be adapted to the data through training, but this also means that a large sampling and training dataset is required to achieve an accurate estimation.

Figure 157.The basic process of the data-driven approach.The existing data-driven method is introduced in the following subsections.Neural Network (NN): The basic NN is a three-layer structure network including an input layer, hidden layer and output layer. The input layer neuron can be regarded as extracting capacity-related features [153][53]. It is critical to choose a suitable indicator. Refs. [154,155][54][55] use NN to investigate the battery capacity. From the perspective of feature extraction, the former uses discharge voltage, while the latter adds also the temperature effects. The weight coefficients from the input layer to the hidden layer or from the hidden layer to the output layer need to be obtained after training a large number of samples [105][56]. Ref. [156][57] chooses to train a generalized regression NN with the battery’s constant current charging time to estimate SOH. The instantaneous discharging voltage drop and the amount of Ah-throughout for a certain depth of discharge are captured as features. Ref. [157][58] uses the Broad Learning System (BLS) to process historical capacity data and generate feature nodes as the input layer of the neural network. This method does not require an in-depth study of the battery aging mechanism, but it also requires at least 25% of the historical capacity data.Support Vector Machine (SVM): Support Vector Machine (SVM) is another technique. The core is to divide the data set in a hyperplane [158,159][59][60] so that the geometric interval between each data point can be maximized in the hyperplane. It can be transformed into an objective function under constraints to solve the optimization problem. Ref. [160][61] studies the relationship between the electrolyte concentration and voltage with the battery capacity. The non-linear relationship is then fitted by SVM. A Least Squares Support Vector Machine (LSSVM) is used in [161][62], with charging voltage, discharging current, temperature, and cycle times as inputs, and the residual sum of squares error is selected as the cost function to calculate the capacity retention rate. Ref. [162][63] uses Particle Swarm Optimization (PSO) to find the suitable hyper-parameters for the SVM kernel function and trains the impedance values as the features to complete the battery SOH estimation.Bayesian learning method: Bayesian methods solve the posterior information with assumed prior probabilities to infer the unknown parameters [163][64]. There are a variety of data-driven methods that use their associated theory, such as the Relevance Vector Machine (RVM), which provides an output of posterior probabilities based on a Bayesian approach. Compared to SVM, it eliminates the need for model selection, but it often requires more training time. The literature uses empirical modal decomposition for battery capacity data, and sets up a multi-start prediction matrix to train RVM. It reduces the stochastic uncertainty associated with the starting point of a single prediction and parameter settings. GPR is derived from the Bayesian framework [164][65], and uses the Gaussian process prior knowledge to perform regression analysis on the data. Ref. [165][66] uses voltage segments in short periods during constant current operation as the input of GPR for capacity estimation. The non-parametric regression properties of the GPR technique allow the estimation to be adapted to the complexity of the data.Deep learning method: Deep learning utilizes multiple hidden layers in the network [32], which can reflect more complex mapping between the features and battery health. Methods, such as Convolutional Neural Network (CNN) [166[67][68],167], Recurrent Neural Network (RNN) [168,169][69][70] and Long Short-Term Memory (LSTM) [170,171][71][72] have been used for battery SOH estimation recently, and have shown promising performance in estimation accuracy. Ref. [167][68] takes advantage of CNN and Transformers for accurate SOH estimation of Li-ion batteries, which utilizes the attention mechanism to extract more important features from the original measurement. A differential evolution grey wolf optimizer is used in [171][72] to tune the hyperparameters of LSTM for an accurate battery health estimation. A hybrid of gate recurrent unit and CNN is shown to estimate the Li-ion battery SOH in [172][73], which utilizes voltage, current and temperature as the input of the network.The implementation of data-driven methods relies on the validity of the data and a complex training process. The advantage is that the model can be adapted to the data through training, but this also means that a large sampling and training dataset is required to achieve an accurate estimation.

References

- Tang, C.Y.; Chen, P.T.; Jheng, J.H. Bidirectional Power Flow Control and Hybrid Charging Strategies for Three-Phase PV Power and Energy Storage Systems. IEEE Trans. Power Electron. 2021, 36, 12710–12720.

- Ku, T.T.; Li, C.S. Implementation of Battery Energy Storage System for an Island Microgrid with High PV Penetration. IEEE Trans. Ind. Appl. 2021, 57, 3416–3424.

- Matthew, T.L.; Suthar, B.; Northrop, P.W.C.; De, S.; Santhanagopalan, S.; Subramanian, V.R. Battery Energy Storage System (BESS) and Battery Management System (BMS) for Grid-Scale Applications. Proc. IEEE 2014, 102, 1014–1030.

- Bharatee, A.; Ray, P.K.; Ghosh, A. A Power Management Scheme for Grid-Connected PV Integrated with Hybrid Energy Storage System. J. Mod. Power Syst. Clean Energy 2022, 10, 954–963.

- Wan, T.; Tao, Y.; Qiu, J.; Lai, S. Data-Driven Hierarchical Optimal Allocation of Battery Energy Storage System. IEEE Trans. Sustain. Energy 2021, 12, 2097–2109.

- Rezvanizaniani, S.M.; Liu, Z.; Chen, Y.; Lee, J. Review and Recent Advances in Battery Health Monitoring and Prognostics Technologies for Electric Vehicle (EV) Safety and Mobility. J. Power Sources 2014, 256, 110–124.

- Wang, J.; Kang, L.; Liu, Y. Optimal Scheduling for Electric Bus Fleets Based on Dynamic Programming Approach by Considering Battery Capacity Fade. Renew. Sustain. Energy Rev. 2020, 130, 109978.

- Zhuang, W.; Lu, S.; Lu, H. Progress in Materials for Lithium-Ion Power Batteries. In Proceedings of the 2014 International Conference on Intelligent Green Building and Smart Grid (IGBSG), Taipei, Taiwan, 23–25 April 2014.

- Weiss, H.; Winkler, T.; Ziegerhofer, H. Large Lithium-Ion Battery-Powered Electric Vehicles—From Idea to Reality. In Proceedings of the 2018 ELEKTRO, Mikulov, Czech Republic, 21–23 May 2018; pp. 1–5.

- Hannan, M.A.; Hoque, M.M.; Hussain, A.; Yusof, Y.; Ker, P.J. State-of-the-Art and Energy Management System of Lithium-Ion Batteries in Electric Vehicle Applications: Issues and Recommendations. IEEE Access 2018, 6, 19362–19378.

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The Lithium-Ion Battery: State of the Art and Future Perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308.

- BYD Blade Battery: Everything You Should Know. Available online: https://topelectricsuv.com/news/byd/byd-blade-battery-update/ (accessed on 1 October 2022).

- Statista Projected Global Battery Demand from 2020 to 2030, by Application (in Gigawatt Hours). Available online: https://www.statista.com/statistics/ (accessed on 1 October 2022).

- Plett, G.L. Battery Management Systems, Volume II: Equivalent-Circuit Methods; Artech House: Norwood, MA, USA, 2020; Volume II, ISBN 9781630810276.

- Wang, L.; Qiu, J.; Wang, X.; Chen, L.; Cao, G.; Wang, J.; Zhang, H.; He, X. Insights for Understanding Multiscale Degradation of LiFePO4 Cathodes. eScience 2022, 2, 125–137.

- Meng, J.; Luo, G.; Ricco, M.; Swierczynski, M.; Stroe, D.-I.; Teodorescu, R. Overview of Lithium-Ion Battery Modeling Methods for State-of-Charge Estimation in Electrical Vehicles. Appl. Sci. 2018, 8, 659.

- Feng, X.; Ren, D.; He, X.; Ouyang, M. Mitigating Thermal Runaway of Lithium-Ion Batteries. Joule 2020, 4, 743–770.

- Feng, X.; Ouyang, M.; Liu, X.; Lu, L.; Xia, Y.; He, X. Thermal Runaway Mechanism of Lithium Ion Battery for Electric Vehicles: A Review. Energy Storage Mater. 2018, 10, 246–267.

- Monden, Y.; Mizutani, M.; Yamazaki, S.; Kobayashi, T. Charging and Discharging Control of a Hybrid Battery Energy Storage System Using Different Battery Types in Order to Avoid Degradation. In Proceedings of the 2021 IEEE International Future Energy Electronics Conference (IFEEC), Taipei, Taiwan, 16–19 November 2021; pp. 1–6.

- Zhao, Y.; Pohl, O.; Bhatt, A.I.; Collis, G.E.; Mahon, P.J.; Rüther, T.; Hollenkamp, A.F. A Review on Battery Market Trends, Second-Life Reuse, and Recycling. Sustain. Chem. 2021, 2, 167–205.

- Martinez-Laserna, E.; Gandiaga, I.; Sarasketa-Zabala, E.; Badeda, J.; Stroe, D.I.; Swierczynski, M.; Goikoetxea, A. Battery Second Life: Hype, Hope or Reality? A Critical Review of the State of the Art. Renew. Sustain. Energy Rev. 2018, 93, 701–718.

- Dai, H.; Jiang, B.; Hu, X.; Lin, X.; Wei, X.; Pecht, M. Advanced Battery Management Strategies for a Sustainable Energy Future: Multilayer Design Concepts and Research Trends. Renew. Sustain. Energy Rev. 2021, 138, 110480.

- Hossain Lipu, M.S.; Hannan, M.A.; Karim, T.F.; Hussain, A.; Saad, M.H.M.; Ayob, A.; Miah, M.S.; Indra Mahlia, T.M. Intelligent Algorithms and Control Strategies for Battery Management System in Electric Vehicles: Progress, Challenges and Future Outlook. J. Clean. Prod. 2021, 292, 126044.

- Schuster, S.F.; Bach, T.; Fleder, E.; Müller, J.; Brand, M.; Sextl, G.; Jossen, A. Nonlinear Aging Characteristics of Lithium-Ion Cells under Different Operational Conditions. J. Energy Storage 2015, 1, 44–53.

- Deyab, M.A.; Mohsen, Q. Improved Battery Capacity and Cycle Life in Iron-Air Batteries with Ionic Liquid. Renew. Sustain. Energy Rev. 2021, 139, 110729.

- Stroe, D.; Świerczyński, M.; Stan, A.; Teodorescu, R.; Andreasen, S.J. Accelerated Lifetime Testing Methodology for Lifetime Estimation of Lithium-Ion Batteries Used in Augmented Wind Power Plants. IEEE Trans. Ind. Appl. 2014, 50, 4006–4017.

- Meng, J.; Cai, L.; Stroe, D.-I.; Ma, J.; Luo, G.; Teodorescu, R. An Optimized Ensemble Learning Framework for Lithium-Ion Battery State of Health Estimation in Energy Storage System. Energy 2020, 206, 118140.

- Lu, L.; Han, X.; Li, J.; Hua, J.; Ouyang, M. A Review on the Key Issues for Lithium-Ion Battery Management in Electric Vehicles. J. Power Sources 2013, 226, 272–288.

- Xiong, R.; Zhang, Y.; Wang, J.; He, H.; Peng, S.; Pecht, M. Lithium-Ion Battery Health Prognosis Based on a Real Battery Management System Used in Electric Vehicles. IEEE Trans. Veh. Technol. 2019, 68, 4110–4121.

- Farmann, A.; Waag, W.; Marongiu, A.; Sauer, D.U. Critical Review of On-Board Capacity Estimation Techniques for Lithium-Ion Batteries in Electric and Hybrid Electric Vehicles. J. Power Sources 2015, 281, 114–130.

- Cai, L.; Meng, J.; Stroe, D.-I.; Luo, G.; Teodorescu, R. An Evolutionary Framework for Lithium-Ion Battery State of Health Estimation. J. Power Sources 2019, 412, 615–622.

- Sui, X.; He, S.; Vilsen, S.B.; Meng, J.; Teodorescu, R.; Stroe, D.I. A Review of Non-Probabilistic Machine Learning-Based State of Health Estimation Techniques for Lithium-Ion Battery. Appl. Energy 2021, 300, 117346.

- Xiong, R.; Pan, Y.; Shen, W.; Li, H.; Sun, F. Lithium-Ion Battery Aging Mechanisms and Diagnosis Method for Automotive Applications: Recent Advances and Perspectives. Renew. Sustain. Energy Rev. 2020, 131, 110048.

- Corno, M.; Pozzato, G. Active Adaptive Battery Aging Management for Electric Vehicles. IEEE Trans. Veh. Technol. 2020, 69, 258–269.

- Shi, M.; Shi, X.; Li, Z.; Wang, X. Study on the Aging Characteristics of Li-Ion Battery Based on the Electro-Thermal and Aging Joint Simulation Platform. In Proceedings of the 2020 IEEE/IAS Industrial and Commercial Power System Asia (I&CPS Asia), Weihai, China, 13–15 July 2020; pp. 257–261.

- Meyer, C.; Bockholt, H.; Haselrieder, W.; Kwade, A. Characterization of the Calendering Process for Compaction of Electrodes for Lithium-Ion Batteries. J. Mater. Process. Technol. 2017, 249, 172–178.

- Schreiner, D.; Klinger, A.; Reinhart, G. Modeling of the Calendering Process for Lithium-Ion Batteries with DEM Simulation. Procedia CIRP 2020, 93, 149–155.

- Mocera, F.; Soma, A.; Clerici, D. Study of Aging Mechanisms in Lithium-Ion Batteries for Working Vehicle Applications. In Proceedings of the 2020 Fifteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte-Carlo, Monaco, 10–12 September 2020.

- Stroe, D.I.; Swierczynski, M.; Kær, S.K.; Teodorescu, R. Degradation Behavior of Lithium-Ion Batteries During Calendar Ageing—The Case of the Internal Resistance Increase. Proc. IEEE Trans. Ind. Appl. 2018, 54, 517–525.

- Dufek, E.J.; Tanim, T.R.; Chen, B.-R. Sangwook Kim Battery Calendar Aging and Machine Learning. Joule 2022, 6, 1363–1367.

- Dubarry, M.; Liaw, B.Y.; Chen, M.-S.; Chyan, S.-S.; Han, K.-C.; Sie, W.-T.; Wu, S.-H. Identifying Battery Aging Mechanisms in Large Format Li Ion Cells. J. Power Sources 2011, 196, 3420–3425.

- Mendoza-Hernandez, O.S.; Hosono, E.; Asakura, D.; Matsuda, H.; Shironita, S.; Umeda, M.; Sone, Y. Impact of Calendar Degradation on the Performance of LiFePO4—Graphite Li-Ion Cells during Charge-Discharge Cycling at −5 °C. J. Electrochem. Soc. 2019, 166, A3525–A3530.

- Sataloff, R.T.; Johns, M.M.; Kost, K.M. Fundamentals and Applications of Lithium-Ion Batteries in Electric Drive Vehicles. In Geriatric Otolaryngology; Thieme Medical Publishers: New York, NY, USA, 2015; ISBN 9781626239777.

- IEC-62660-2; Secondary Lithium-Ion Cells for the Propulsion of Electric Road Vehicles—Part 2: Reliability and Abuse Testing 2018. International Electrotechnical Commission: Geneva, Switzerland, 2018.

- ISO 12405-3; ISO Electrically Propelled Road Vehicles—Test Specification for Lithium-Ion Traction Battery Packs and Systems—Part 3: Safety Performance Requirements. ISO: Geneva, Switzerland, 2018.

- IEEE Std 450-2020 (Revision IEEE Std 450-2010); IEEE Recommended Practice for Maintenance, Testing, and Replacement of Vented Lead-Acid Batteries for Stationary Applications. IEEE: New York, NY, USA, 2021; pp. 1–71.

- Meng, J.; Cai, L.; Stroe, D.-I.; Luo, G.; Sui, X.; Teodorescu, R. Lithium-Ion Battery State-of-Health Estimation in Electric Vehicle Using Optimized Partial Charging Voltage Profiles. Energy 2019, 185, 1054–1062.

- Meng, J.; Cai, L.; Luo, G.; Stroe, D.-I.; Teodorescu, R. Lithium-Ion Battery State of Health Estimation with Short-Term Current Pulse Test and Support Vector Machine. Microelectron. Reliab. 2018, 88–90, 1216–1220.

- Belt, J.R.; Ho, C.D.; Motloch, C.G.; Miller, T.J.; Duong, T.Q. A Capacity and Power Fade Study of Li-Ion Cells during Life Cycle Testing. J. Power Sources 2003, 123, 241–246.

- Wen, A.; Meng, J.; Peng, J.; Cai, L.; Xiao, Q. Online Parameter Identification of the Lithium-Ion Battery with Refined Instrumental Variable Estimation. Complexity 2020, 2020, 8854618.

- Du, X.; Meng, J.; Zhang, Y.; Huang, X.; Wang, S.; Liu, P.; Liu, T. An Information Appraisal Procedure: Endows Reliable Online Parameter Identification to Lithium-Ion Battery Model. IEEE Trans. Ind. Electron. 2022, 69, 5889–5899.

- Xiong, R.; Sun, F.; He, H. Model-Based Health Condition Monitoring Method for Multi-Cell Series-Connected Battery Pack. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 27–29 June 2016; pp. 1–5.

- Zhao, F.; Li, P.; Li, Y.; Li, Y. The Li-Ion Battery State of Charge Prediction of Electric Vehicle Using Deep Neural Network. In Proceedings of the 2019 Chinese Control and Decision Conference (CCDC), Nanchang, China, 3–5 June 2019; pp. 773–777.

- Chen, C.-R.; Huang, K.-H. The Estimation of the Capacity of Lead-Acid Storage Battery Using Artificial Neural Networks. In Proceedings of the 2006 IEEE International Conference on Systems, Man and Cybernetics, Taipei, Taiwan, 8–11 October 2006; pp. 1575–1579.

- Sarvi, M.; Adeli, S. A Neural Network Method for Estimation of Battery Available Capacity. In Proceedings of the 45th International Universities Power Engineering Conference UPEC, Cardiff, UK, 31 August–3 September 2010; pp. 28–32.

- Khan, N.; Ullah, F.U.M.; Afnan; Ullah, A.; Lee, M.Y.; Baik, S.W. Batteries State of Health Estimation via Efficient Neural Networks with Multiple Channel Charging Profiles. IEEE Access 2021, 9, 7797–7813.

- Zhou, J.; He, Z.; Gao, M.; Liu, Y. Battery State of Health Estimation Using the Generalized Regression Neural Network. In Proceedings of the 2015 8th International Congress on Image and Signal Processing (CISP), Shenyang, China, 14–16 October 2015; pp. 1396–1400.

- Zhao, S.; Zhang, C.; Wang, Y. Lithium-Ion Battery Capacity and Remaining Useful Life Prediction Using Board Learning System and Long Short-Term Memory Neural Network. J. Energy Storage 2022, 52, 104901.

- Lei, X.; Chan, C.C.; Liu, K.; Ma, L. Pruning LS-SVM Based Battery Model for Electric Vehicles. In Proceedings of the Third International Conference on Natural Computation (ICNC 2007), Haikou, China, 24–27 August 2007; Volume 3, pp. 333–337.

- Yan, Q. SOC Prediction of Power Battery Based on SVM. In Proceedings of the 2020 Chinese Control and Decision Conference (CCDC), Hefei, China, 22–24 August 2020; pp. 2425–2429.

- Zhao, M.; Chen, Y.; Luo, B.; Zhong, L.; Xing, R.L. Research of Battery Capacity Fiber On-Line Intelligent Testing Technology Based on SVM. In Proceedings of the 2008 7th World Congress on Intelligent Control and Automation, Chongqing, China, 25–27 June 2008; pp. 3067–3070.

- Chu, L.; Zhou, F.; Guo, J. Investigation of Cycle Life of Li-Ion Power Battery Pack Based on LV-SVM. In Proceedings of the 2011 International Conference on Mechatronic Science, Electric Engineering and Computer (MEC), Jilin, China, 19–22 August 2011; pp. 1602–1605.

- Xie, J.; Li, W.; Hu, Y. Aviation Lead-Acid Battery State-of-Health Assessment Using PSO-SVM Technique. In Proceedings of the 2014 IEEE 5th International Conference on Software Engineering and Service Science, Beijing, China, 27–29 June 2014; pp. 344–347.

- He, Z.; Gao, M.; Ma, G.; Liu, Y.; Chen, S. Online State-of-Health Estimation of Lithium-Ion Batteries Using Dynamic Bayesian Networks. J. Power Sources 2014, 267, 576–583.

- Liu, K.; Shang, Y.; Ouyang, Q.; Widanage, W.D. A Data-Driven Approach with Uncertainty Quantification for Predicting Future Capacities and Remaining Useful Life of Lithium-Ion Battery. IEEE Trans. Ind. Electron. 2021, 68, 3170–3180.

- Richardson, R.R.; Birkl, C.R.; Osborne, M.A.; Howey, D.A. Gaussian Process Regression for in Situ Capacity Estimation of Lithium-Ion Batteries. IEEE Trans. Ind. Informatics 2019, 15, 127–138.

- Sun, S.; Sun, J.; Wang, Z.; Zhou, Z.; Cai, W. Prediction of Battery SOH by CNN-BiLSTM Network Fused with Attention Mechanism. Energies 2022, 15, 4428.

- Gu, X.; See, K.W.; Li, P.; Shan, K.; Wang, Y.; Zhao, L.; Lim, K.C.; Zhang, N. A Novel State-of-Health Estimation for the Lithium-Ion Battery Using a Convolutional Neural Network and Transformer Model. Energy 2022, 262, 125501.

- You, G.-W.; Park, S.; Oh, D. Diagnosis of Electric Vehicle Batteries Using Recurrent Neural Networks. IEEE Trans. Ind. Electron. 2017, 64, 4885–4893.

- Raman, M.; Champa, V.; Prema, V. State of Health Estimation of Lithium Ion Batteries Using Recurrent Neural Network and Its Variants. In Proceedings of the 2021 IEEE International Conference on Electronics, Computing and Communication Technologies (CONECCT), Bangalore, India, 9–11 July 2021; pp. 1–6.

- Zhang, J.; Hou, J.; Zhang, Z. Online State-of-Health Estimation for the Lithium-Ion Battery Based on An LSTM Neural Network with Attention Mechanism. In Proceedings of the 2020 Chinese Control and Decision Conference (CCDC), Hefei, China, 22–24 August 2020; pp. 1334–1339.

- Ma, Y.; Shan, C.; Gao, J.; Chen, H. A Novel Method for State of Health Estimation of Lithium-Ion Batteries Based on Improved LSTM and Health Indicators Extraction. Energy 2022, 251, 123973.

- Fan, Y.; Xiao, F.; Li, C.; Yang, G.; Tang, X. A Novel Deep Learning Framework for State of Health Estimation of Lithium-Ion Battery. J. Energy Storage 2020, 32, 101741.

More