Polymers and plastics are crucial materials in many sectors of our economy, due to their numerous advantages. They also have some disadvantages, among the most important are problems with the recycling and disposal of used plastics. The recovery of waste plastics is increasing every year, but over 27% of plastics are landfilled. The rest is recycled, where, unfortunately, incineration is still the most common management method. From an economic perspective, waste management methods that lead to added-value products are most preferred—as in the case of material and chemical recycling. Since chemical recycling can be used for difficult wastes (poorly selected, contaminated), it seems to be the most effective way of managing these materials. Moreover, as a result this of kind of recycling, it is possible to obtain commercially valuable products, such as fractions for fuel composition and monomers for the reproduction of polymers.

- plastic waste

- liquefaction

- fuels

- quality standards

1. Introduction

2. Plastic Waste Management

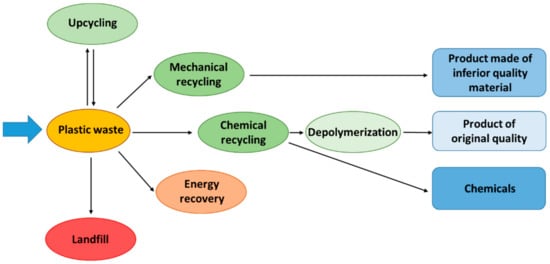

The problem with the management of plastics waste is already global, but the situation is improving every year. This is evidenced, inter alia, by the annual data published in the report of the Plastics Europe Foundation, which indicates that, in the European Union in 2020, compared to 2006, recycling of plastic waste increased by almost 118%, energy recovery through incineration increased by 77% and the amount of waste sent to landfills decreased by over 46% [10][11]. In 2020, over 29 million tonnes of post-consumer plastic waste were collected in European Union countries. Unfortunately, as much as 23.4% of them went to landfills, and only 34.6% was subjected to typical recycling. A total of 42% of collected waste was utilized through energy recovery through incineration (energy recycling) [10][11]. This form of recycling (in accordance with the principle of waste management hierarchy [11][17]) should only be used as a last resort for waste that is not suitable for other forms of recycling, such as depolymerization, material or chemical recycling. Sadly, the above data show that waste incineration is the most common and dominant form of PW management, which unfortunately leads to the complete elimination of plastic material from the economy and makes it impossible to use this material in any other way. In addition, large amounts of harmful and toxic compounds are generated during incineration [12][18]. The still relatively low level of PW recycling (depolymerization, material and chemical recycling) results from the complexity of the processing methods, significant energy demand or/and unsatisfactory quality of the obtained products. The best method for managing plastics is their depolymerization to monomers (input ingredients for the production of plastics). However, this method is applicable, with good efficiency, to a few, selected polymers (polyethylene terephthalate, polymethyl methacrylate, polystyrene) [13][14][15][19,20,21]. In addition, the raw material must be clean and free from any additives of other materials. Unfortunately, this method cannot be applied to polyolefins, which accounts for approximately 70–76% of the waste plastic stream [16][22]. In the case of polyolefins, the best method for their management is material (mechanical) recycling to regranulate. This method is considered the most environmentally friendly due to the low value of CO2 emissions compared to other methods [17][23], but it is not free from drawbacks. The feedstock for processing must be very well selected and clean, and unfortunately the material loses quality with each subsequent processing cycle. In addition, the use of different types of plastics on various parts of packaging (e.g., labels, caps, packaging) and the use of additives and fillers for plastics make it difficult to recycle and recover individual groups of materials and reduce the quality of the obtained final products [18][19][24,25]. Post-industrial plastics (such as cuttings and trimmings from production, runners from injection moulding or granulation residues) are best-suited for such recycling because they have a known and homogeneous composition and contain few impurities [20][21][26,27]. Regarding post-consumer PW, which is a complex mixture of different plastics and other materials, a sorting process should be carried out to obtain separate components should. Selected components, depending on their quality, can be mechanically recycled (for example, into outdoor furniture, flower pots, elements of terraces), directed to chemical recycling or sent to incineration [22][28]. However, due to the difficulty of completely separating the individual materials and contaminations of post-consumer waste, chemical recycling methods seem to be the most appropriate for their management [23][29]. Figure 1 shows a schematic diagram of the main directions of plastic waste management.

3. Pyrolysis

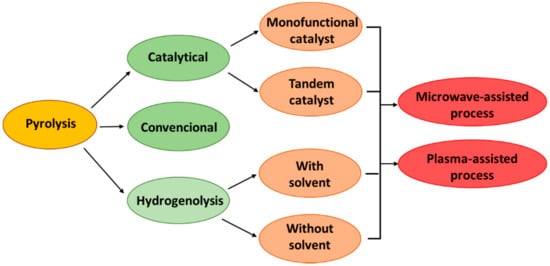

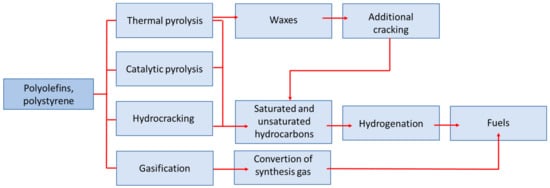

One of the methods of converting waste plastics to hydrocarbon fractions is pyrolysis. This enables the transformation of high-molecular compounds, such as waste plastics, into compounds with much shorter carbon chains. It is considered a promising method for the conversion of addition polymers such as polyethylene and polypropylene (polyolefins) [25][26][31,32]. It offers the opportunity to recycle this polyolefin stream, which cannot be economically managed in conventional mechanical recycling, thus avoiding their incineration and the generation of hazardous substances such as dioxins and furans [27][28][33,34]. The pyrolysis oil (a mixture of waxes and a liquid fraction) obtained as a result of pyrolysis can be used as a substitute for heavy fuel oil or undergo further processing, e.g., in the petrochemical industry [29][30][35,36]. Furthermore, as shown in Reference [31][37], large-scale pyrolysis is economically viable. For example, in the case of an investment in installation that processes 100,000 kg/h of waste plastics, income is generated within the first year and has a positive net present value. The advantage of pyrolysis is that pre-segregated, mixed and contaminated plastic waste with both organic and inorganic material can be subjected to this process [32][33][38,39]. The pyrolysis process is based on the thermochemical decomposition of various materials of organic and synthetic origin at elevated temperatures and in an oxygen-free atmosphere. Typically, the process is carried out at temperatures in the range of 500–800 °C and, in the case of plastics, it follows four types of mechanism: end-chain scission or depolymerization, random-chain scission, chain stripping and cross-linking [34][40]. The main products of the pyrolysis process are pyrolysis oil, gaseous products and the solid fraction (char). On average, depending on the technology used, 45–50% of the oil fraction, 35–40% of the gaseous fraction and 10–20% of char is obtained in the process [35][41]. It was generally found that with the increase of the process temperature, the yield of the liquid fraction increases, while the yield of the solid fraction decreases [36][42]. However, for selected plastics (e.g., for PE over catalyst), it is possible to obtain a liquid fraction in an amount exceeding even 90% [37][38][43,44]. The high propensity of plastics to generate significant amounts of oil fraction during pyrolysis is the result of high volatile matter and low ash content in relation to other materials (e.g., biomass). These two parameters are the key factors influencing the pyrolysis oil yield [39][45]. Due to the process conditions (vapor residence time in the reactor, temperature, raw material heating rate), pyrolysis is divided into three types [40][41][46,47]:-

Slow pyrolysis—process temperature from 350 °C to 550 °C, heating rate from 1 to 10 °C/min, extended steam residence time, where char is the main product’s first bullet;

-

Fast pyrolysis—the process temperature usually ranges from 500 °C to 700 °C, the raw material heating rate is above 100 °C/min, and the vapor residence time is usually within a few seconds; the main product is the liquid fraction, and in the case of polyolefin, pyrolysis also waxes;

-

Flash pyrolysis—the process temperature usually exceeds 700 °C, the heating rate of the raw material >200 °C/s, and the vapor residence time is in the millisecond range.

|

Type of Reactor |

Type of Feedstock Materials |

|||

|---|---|---|---|---|

|

Type of Reactor | References | |||

Advantages |

Disadvantages |

|||

|

Batch reactor |

||||

|

Batch reactor |

PS, PE, PP and PET |

| ||

|

HDPE |

[25] | ||

|

Semi-batch reactor | [31] |

|||

|

|

Plastic medical wastes |

[60 | |

|

Fixed-bed reactor | ][65] |

|||

|

|

Semi-batch reactor |

PS, HDPE, LDPE, PP |

|

|

Fluidized-bed reactor |

| |||

|

PE |

|||

|

Rotary kiln reactor | ||||

|

|

Polyolefin |

[ | |

|

Stirred tank reactor | ||||

|

|

Continuous reactor |

Plastic waste from landfill |

|

|

Conical spouted bed reactor |

| |||

|

HDPE |

|||

|

Fixed bed reactor |

PP, HDPE, LDPE |

|||

|

HDPE |

||||

|

Fluidized bed reactor |

LDPE |

|||

|

PP, PE |

||||

|

PE |

||||

|

CSBR |

HDPE, LDPE, PP |

|||

|

HDPE, LDPE, PP, PS, PET, PMMA |

||||

|

PE |