Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Shangming Wang and Version 2 by Vivi Li.

As one of the most promising thermal management solutions, spray cooling has the advantages of high heat-transfer coefficient and maintaining a low temperature of the cooling surface. By summarizing the influential factors and practical applications of spray cooling, the current challenges and bottlenecks were indicated so as to prompt its potential applications in the future.

- spray cooling

- thermal management

- cooling performance

- industrial applications

1. Introduction

Electronic chips are the most important components to support the development of technology including the Internet, artificial intelligence, and supercomputers, etc. To pursue high performance and high integration, the power density of electronic chips must increase dramatically, yielding much higher heat-dissipation requirements. If heat cannot be removed in time, a local hotspot with a large temperature gradient will directly affect the performance and operational reliability of the equipment. Recent studies [1] have indicated that about 55% of electronic equipment failure is related to high temperatures. Meanwhile, once the temperature exceeds 75 °C, the failure rate of chips exhibits an exponential increase [2]. Therefore, long-time stable and reliable operation of high-performance chips requires a high-efficiency thermal management strategy to remove high-heat flux and maintain a device’s temperature below its limits.

Today, electronic chips can produce heat fluxes as high as 10–100 W/cm2 [3]. In next-generation electronic systems, the typical heat flux can even exceed 1000 W/cm2 [4][5][4,5]. However, the cooling capacity of the conventional heat-dissipation methods (air cooling, microchannel, semiconductor cooling, and heat pipes, etc.) has been demonstrated to be less than 100 W/cm2 [6][7][6,7], which cannot meet the increasingly stringent chip-cooling requirements. One solution to the aforementioned cooling dilemma is the spray-cooling technique, owing to its advantages such as high heat removal capability with a small amount of working fluid consumption, precise temperature control, and relatively good temperature homogeneity. For instance, spray cooling using water as a working fluid has demonstrated a strong ability to remove heat fluxes as high as 1000 W/cm2 [8][9][8,9]. Thus, spray cooling has been considered as a desirable cooling strategy for high-power electronic devices and has been intensively discussed in recent years.

In spray-cooling systems, the liquid working medium is rapidly atomized into small droplets through the nozzle, which impinges and accumulates on the targeted cooling surface to form a liquid film. Single-phase or two-phase heat transfer occurs to dissipate heat by both sensible and latent heat. In the single-phase regime, it is widely accepted that forced convection caused by droplet impingement and film flow is the dominant mechanism. By contrast, spray-cooling heat transfer in two-phase regimes is extremely complicated since forced convection, liquid film evaporation, surface nucleation, and secondary nucleation are all involved, and there is still no convincing consensus formed so far on the spray-cooling heat-transfer mechanisms.

2. Heat-Transfer Mechanism and Influence Factors of Spray Cooling

2.1. Influence of Spray Parameters on Heat-Transfer Performance

Spray parameters, such as flow rate of the working fluid, nozzle type, nozzle-to-surface distance, pressure in the spray chamber, and so on, must have a significant effect on the size, impact velocity, temperature, and spatial distribution of liquid droplets formed after atomization, changing the dynamics and thermodynamics of spray droplets and finally affecting the heat transfer between the liquid film and the hot surface [10][11][14,15]. Therefore, the spray parameters are the most important determinants of the heat-transfer performance of spray cooling.2.1.1. Nozzle Type

There exist a large variety of nozzles, which directly determine the atomization characteristics and post-atomization spray behavior. The pressure-atomizing nozzles are the most widely applied in spray cooling, which can be classified into gas-assisted nozzles, pressure swirl nozzles, and straight-tube nozzles. Researchers have adopted a different view of the impact of the atomizer-type nozzles on spray cooling. Hsieh and Tsai [10][14] studied the CHF of spray cooling using different types of nozzles. The results revealed that nozzle diameter has no perceptible effect on the CHF, whereas it can strongly affect the utilization of working fluid. Employing R134a as the working fluid, Martínez-Galván et al. [12][16] obtained similar spray parameters as well as similar heat-transfer performance and film thickness with different internal geometries of atomizing nozzles, which is consistent with the observation of Hsieh and Tsai [10][14]. Nevertheless, Rashad et al. [13][17] obtained different results for the effect of geometric configurations of the pressure-swirl atomizers on the spray cone angle, Sauter mean diameter (SMD), and other spray characteristics. It was shown that an appropriate geometric ratio of the atomizer can enhance the atomization, while a large increase may lead to more frictional losses and poor atomization. At present, straight-tube nozzles are commonly used in cryogen spray cooling (CSC). Zhou et al. [14][15][18,19] designed a cylindrical expansion chambered nozzle for CSC applications in laser dermatology, yielding a more concentrated spray and better cooling efficiency than those achieved using a straight-tube nozzle.2.1.2. Flow Rate

The published literature reveals that flow rate is the most influential factor on the performance of spray cooling [16][17][20,21], while its mechanism has not been fully revealed. Estes and Mudawar [18][22] found that high flow rate reduced the cooling efficiency and an obvious transition between single- and two-phase heat transfer was not be observed, i.e., high flow rate is not necessarily beneficial to spray cooling. Nevertheless, the increase of flow rate has positive effects on the surface heat flux, but the cooling efficiency consequently decreases [16][19][20][21][22][13,20,23,24,25]. At low flow rates, few droplets impact the hot surface, and thinner liquid film will promote evaporation and ultimately lead to a high cooling efficiency. At high flow rates, however, more spray droplets impact the target surface and a thicker liquid film will reduce the evaporation rate of the liquid film. Furthermore, thicker liquid film is easier be wash off the cooling surface without sufficient heat transfer. Therefore, the cooling efficiency decreases with the increase of flow rate. In the vacuum-flashing spray-cooling systems, Cheng et al. [23][26] and Fu et al. [24][27] claimed that the increase of flow rate can enhance heat transfer because of the increase of droplet velocity and the scouring of liquid film on the surface. Nevertheless, Cheng et al. [25][28] showed that surface temperature non-uniformity becomes more pronounced with the increase of flow rate. As a result, there is an optimal spray flow rate value to balance the heat transfer and the consumption of working fluid [26][29]. For the pressure-atomizing nozzles, increasing the spray flow rate is usually achieved by the improvement of the inlet pressure, which affects the cooling performance of spray in at least two aspects: velocity and particle size of the droplet. On the one hand, increasing the inlet pressure helps to accelerate the working fluid, which strengthens the impingement of the droplet on the liquid film, and finally enhances the droplet–wall convection heat transfer [27][28][30,31]. On the other hand, higher inlet pressure results in the decrease of the droplet size, which contributes to liquid film evaporation [29][32]. At lower surface temperatures, increasing the nozzle inlet pressure can improve the uniformity of the heated surface temperature and attain a higher cooling rate [29][32]. However, droplet speeds as high as 50–60 m/s will lead to a higher temperature of the heating surface, since most droplets splash directly from the heating surface and the amount of liquid involved in heat transfer is reduced [30][33]. In any case, it is necessary to improve the energy efficiency and economic benefit of spray cooling through reasonable flow distribution and optimization strategies in the future.2.1.3. Spray Distance and Spurt Duration

Spray distance (nozzle-to-surface distance) and spurt duration are the most easily adjusted parameters in spray-cooling systems. Aguilar et al. [31][32][34,35] conducted a series of experiments to investigate the influence of spray exit-to-target distance and spurt duration on the surface heat flux and temperature. It was found that the spray distance is more conducive to enhancing surface cooling than the spurt duration [33][36]. Up to now, there has been limited literature discussing the effects of spurt duration on spray-cooling performance. Tian et al. [34][37] investigated the effect of spurt duration on the transient cooling performance in an open-loop pulsed spray-cooling system, and found that the moderate spurt duration (Δt = 30 s) can provide relatively high cooling efficiency and a large surface temperature drop. Hsieh and Tsai [10][14] found that the spray distance has a significant effect on the CHF for a variety of nozzles. Furthermore, the smaller the spray distance, the higher the CHF. However, more recent research demonstrated that the best cooling capacity of spray cooling is achieved at an optimal nozzle-to-surface distance. Through a theoretical study, Tian et al. [35][38] determined that the optimal spray distances for R32, R404A, and R134a were 22.5, 43.1, and 66.0 mm, respectively. Some researchers believe that with regard to the effect of nozzle-to-surface distance, maximum CHF can be achieved when the spray completely covers the heat-exchange surface [22][36][25,39]. However, some others discovered that the optimal spray distance corresponding to the strongest heat dissipation capacity is smaller than that achieved when fully cover the heating surface [37][40]. The experimental research of Zhou et al. [38][39][41,42] showed that the determination of the optimal spray distance also needs to consider the spray-back pressure. Moreover, they revealed the coupling effect of spray distance and nozzle diameter on the surface heat-transfer performance of cryogen spray cooling [40][43]. Sarmadian et al. [41][42][44,45] observed the significant influence of spray distance on the CHF in presence of vibration, and this effect depended on the vibration range. The abovementioned results suggest that the spray distance is associated with spray coverage area, impinging energy and droplet flux. Due to the different experimental conditions, the most suitable nozzle-to-surface distances obtained from each experiment are incomparable. Thus, more in-depth research is still needed.2.1.4. Spray Angle

When spray impinges on the surface vertically, liquid accumulated on the heating surface may hinder heat transfer. To increase the heat transfer in this zone, inclined spray can be used. Most related studies about spray angle (between the spray axis relative to the normal direction of the heating surface) have shown that the cooling performance gradually increases with the spray angle up and sharply decreases after attaining an optimum angle [43][44][45][46][46,47,48,49]. Compared with vertical spray, inclined spray reduces the area of the stagnation zone, which is beneficial to remove the excess liquid on the cooling surface and improve the heat-transfer ability [46][47][49,50]. However, some researchers believe that inclined spray could increase CHF, but results in the deterioration of the surface temperature non-uniformity [48][51]. Therefore, the enhancement effect of inclined spray on the spray-cooling performance is controversial.2.2. Properties of the Working Fluid on Heat-Transfer Performance

2.2.1. Coolant Used in Spray Cooling

The importance of the physical properties of the working fluid on the heat transfer of spray cooling has been widely recognized [49][50][52,53]. The most widely used working fluids of spray cooling for the heat dissipation of electronics can be classified into two types: non-dielectric and dielectric liquids [51][54]. In most cases, non-dielectric liquids are aqueous coolants, for example, pure water [22][25], methanol [52][55], ethylene glycol (EG) water solution [53][56], n-Propanol-water [54][57], NaCl solution [55][58], propylene glycol [56][59], and ethanol–water solution [57][60], which exhibit high specific heat, high thermal conductivity, and low viscosity. Among these coolants, water has attracted widespread attention in spray cooling for electronics due to its distinct advantages such as low cost, non-flammability, being easily available, possessing a high latent heat of vaporization, and being pollution-free. The highest value of CHF for water spray cooling in the published literature depends upon spray systems and experimental conditions. For instance, the CHF value reached 500 W/cm2, which was reported by Lin and Ponnappan [52][55], 638 W/cm2 by Mudawar and Valentine [58][61], and 945.7 W/cm2 by Chen et al. [59][62]. Pais et al. [60][63] found that the maximum CHF could reach up to 1200 W/cm2 by using an air-water atomizing nozzle. Nevertheless, due to the relatively high boiling point, heat transfer of water spray cooling in the practical application of electronics is in the single-phase cooling mode and the surface temperatures of electronics are all above 80 °C [61][64]. Moreover, water cannot directly contact electronic devices because of its poor electrical insulation properties. A specialized cold plate is required for heat removal, which increases the complexity of the spray-cooling system, reduces the heat-transfer capacity, and limits its application in the thermal management of high-power electronics [62][65]. A high boiling point and superior physical characteristics make water the first choice for a single-phase coolant [63][66], and dielectric liquids are the first choice for two-phase boiling heat transfer [64][67]. Typical dielectric liquids include Aromatics, Silicones, Fluorocarbons, and Aliphatics-based fluids, characterized by low density, low boiling point, non-reactivity, non-corrosivity, as well as good chemical and thermal stability [51][65][54,68]. Lin and Ponnappan [52][55] obtained a CHF of spray cooling up to 90 W/cm2 by fluorocarbon fluids (FC-87/FC-72) with a working temperature of 25 °C. Visaria and Mudawar [66][69] achieved a high CHF of 349 W/cm2 by FC-77 with a target surface temperature of 129.4 °C. Hou et al. [67][70] established a closed-loop R22 (boiling point of −40.8 °C at 1 atm) spray cooling system which can handle heat fluxes as high as 276.1 W/cm2 with 26.8 °C cooling surface temperature at the nozzle-inlet pressure of 0.8 MPa. Later, Chen et al. [68][71] compared the cooling performance of R134a (boiling point of −26.1 °C at 1 atm) and R22. The maximum CHF of R134a spray reached 117.2 W/cm2 with 46 °C target surface temperature, while those of R22 were 276.1 W/cm2 and 26.8 °C target surface temperature, respectively. The result demonstrated the heat-transfer characteristics of R22 spray cooling are better than those of R134a spray cooling under the same experimental conditions. Additionally, under low heat flux, R22 spray cooling is still expected to be completely replaced by R134a. Unfortunately, compared with the zero ozone depression potential (ODP) of R134a, R22 (ODP of 0.055) will deplete the ozone layer, leading to the greenhouse effect. Meanwhile, R134a is simple to react with water and in the closed-loop spray cooling systems, and the corrosive chemicals generated will damage the metal. Therefore, the abovementioned reasons limit the application of R22 and R134a in electronic spray cooling. Zhou et al. [50][69][53,72] conducted a comparative experimental study on the heat-transfer dynamics of transient spray cooling with different cryogens (R134a, R407C, and R404A). On an epoxy resin block, R404A produces the best cooling capacity, namely the highest heat flux and lowest surface temperature, which means R404A could be a substitute for R134a. Subsequently, considering the need for environmental protection and energy-saving, Lin et al. of the same group [62][65], using a zero-ODP coolant and R410A (boiling point of −51 °C at 1 atm) as the spray fluid, achieved the CHF of 264 W/cm2 while maintaining a target surface temperature lower than 30 °C.2.2.2. Soluble Additives

Recently, researchers have been inclined to improve cooling performance by modifying coolant properties, which refers to the method of adding nanoparticles (NPs) [70][71][72][73,74,75], surfactants [73][74][76,77], dissolving salts [75][78], water-soluble polymers [76][77][79,80], and other additives to the pure working fluid to change its surface tension and other characteristics. The most widely applied surfactants are cetyltrimethylammonium bromide (CTAB) as cationic, sodium dodecyl sulfate (SDS) as anionic, and polyoxyethylene (20) sorbitan monolaurate (Tween 20) as non-ionic additives. Qiao and Chandra [73][76] explored the heat-transfer enhancement by addition of the surfactant (SDS) to water spray. Through the visualization of spray cooling on the test surface, it was found that adding surfactant can accelerate the bubble nucleation and foaming of droplets, thus enhancing the boiling heat transfer. In air-atomized spray cooling, CHF may be attributed to the insufficient liquid supply caused by droplet entrainment, splashing, and expulsion from nucleate bubbles [78][81]. Thus, Jia and Qiu [79][82] found that the addition of surfactant decreases the atomized droplet diameter and the liquid film thickness, which leads to larger stable CHF and lower superheat.2.2.3. Nanofluids Adopted in Spray Cooling

The physical properties of the working fluid can be changed by adding a small amount of nanoparticles (NPs), showing its potential in the improvement of the cooling performance for electronics [80][90]. Hsieh et al. [81][82][91,92] dispersed seven different types of nanofluids (Ag, Al, Al2O3, Fe3O4, SiO2, TiO2, and MWCNTs) in deionized water, and the average HTC as well as the associated CHF were improved significantly. Among the various nanofluids tested, Al2O3 with an average dimension of 5–30 nm and volume fraction of 0.1% showed the maximum CHF of 375 W/cm2. In this case, it only took less than 8 s to reduce the heater surface temperature from 400 °C to 160 °C. Malý et al. [83][93] checked the effect of NPs concentration of Al2O3, ZnO, CuO, and FeCl·4H2O on the spray cooling of a targeted surface using a pressure-swirl atomizer. It was found that the addition of nanoparticles with high thermal conductivity had no significant effects on the atomization mechanisms, but was beneficial to improving the dynamic viscosity of the resulting nanofluid, resulting in a slight decrease in the diameter of the atomized droplets and the spray-cone angle. Chang et al. [84][94] investigated the comprehensive influence of spray-spurt duration and NP concentrations on the surface wettability and spray-cooling performance. In a given spurt duration, the surface wettability increased with the increase of NPs added. Moreover, for the nanofluids with NP concentrations of 0.001 and 0.05 vol%, respectively, the surface wettability and cooling performance both increased with increasing spray spurt duration. In 2016, Tiara et al. [85][95] reported that addition of surfactants into nanoparticle suspensions is advantageous for improving the stability and uniformity distribution of nanofluids. Meanwhile, surfactant additives also help to change the surface properties and thermo-physical properties of nanofluids, such as viscosity and thermal conductivity [86][87][96,97]. Bandaru et al. [88][89][98,99] conducted a series of experiments on the effect of dispersant type on heat-transfer enhancement of air-atomized spray cooling. The dispersants used include SDS, CTAB, Tween 20, and polymer surfactant polyvinylpyrrolidone (PVP). In comparison with the nanofluid without the surfactant, water-Al2O3 nanofluid with the surfactant could enhance the cooling rate significantly via the improvement of thermal conductivity. Among the dispersing agents used, the addition of non-ionic surfactant exhibited the best augmentation of boiling heat transfer. Thereafter, the same group [90][91][92][100,101,102] synthesized a brand new nanofluid by using a co-precipitation technique, through with Cu–Zn–Al LDH nanofluid was utilized as a coolant to experimentally study the effect of molar ratios of Cu and Al, and dispersant type on the thermo-physical properties, stability, and heat-exchange performance of LDH nanofluid during pressure atomized spray. The maximum value of cooling rate and average heat flux for SDS-aided Cu–Zn–Al LDH nanofluid could reach 174.8 °C/s and 170 W/cm2. In contrast with water-based cooling, its cooling rate and average heat flux increased by 30.7% and 14.2%, respectively.2.3. Surface Modification

Surface modification is a universal strategy for each spray-cooling system regardless of the nozzle type and working coolant, usually in conjunction with other enhancement methods. Considering the significance of liquid film in spray-cooling mechanisms, this section categorizes cooling surfaces as macrostructures (mm) and microstructures (μm and nm), according to the thickness of liquid film in 10–1000 μm [6]. The complexity of spray cooling makes it difficult to explain the enhancement mechanism of surface modification. Principally, it can be summarized as the increase of heat-transfer area, improved wettability, flow optimization, and more active nucleation sites. As for macro-scale modified surfaces, working fluid flows in a larger area with more intense turbulence. Normally, well-designed macro-scale surfaces perform better than ordinary fin surfaces with same heat-transfer area due to the facilitated liquid drainage and improved contact between the surface and coolant. Therefore, spray-cooling performance is improved in both single-phase and two-phase cooling modes, which means low- and high-heat flux stages. Researchers usually utilize their novel spray-cooling systems to study the influence of macro-structures. Yu et al. [93][114] developed a liquid nitrogen spray-cooling system with a low heat-transfer surface temperature. The straight-grooved surfaces with different groove depths were employed to obtain the optimal sample. Salman et al. [94][115] fabricated a surface with circular and radial grooves, which overcomes the shortcomings of fluid confinement by straight-pins. Zhou et al. [95][116] prepared a novel pyramid enhanced surface by the electrical discharge machining (EDM) method, which had a larger area and better flow pattern. Nevertheless, macro-modification does not always show effects. Wang et al. [96][117] indicated 0.5 × 0.5 × 0.2 mm fins in 0.5 mm-distance structures will decrease spray-cooling performance, with superfluous wettability and a useless outspread area. Surface-modification strategies are crucial for the further development of high-efficiency spray cooling.2.4. System and Environmental Parameters

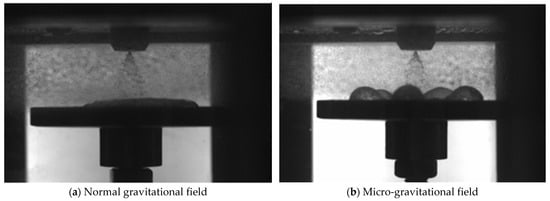

Besides the factors mentioned above, system and environmental parameters can also have non-negligible effects on spray-cooling systems, such as non-condensable gas, gravity, etc. Puterbaugh et al. [97][131] and Elston et al. [98][132] controlled the amount of air dissolved in FC-72 by changing the total pressure of the spray system, and then studied the effect of the non-condensing gas on spray-cooling heat transfer. Their results showed that the presence of air changes the system pressure, but has a minimal effect on the cooling performance of the spray system. Lin and Ponnappan [52][55] experimentally investigated the cooling ability of water spray, methanol, and FC-87, and obtained the CHF of 500 W/cm2, 490 W/cm2, and 90 W/cm2. More importantly, their results showed the effect of non-condensable gas on heat-transfer performance. Such gas yields finer droplets and thinner films formed on the cooling surface, and the air flow replaces the evaporating vapor on the surface to reduce its partial pressure, thereby strengthening the surface evaporation. As a result, the CHF is increased, but the spray-cooling curve shifts to a higher wall temperature. Horacek et al. [99][133] also studied the influence of non-condensable gas content in the coolant on the spray-cooling heat-transfer mechanisms and obtained similar conclusions. However, Liu et al. [100][134] used PF-5060 and FC-3284 as working fluids in a closed spray system to further study the effect of air. Theis study showed that the surface temperature will increase and spray-cooling efficiency will decrease with the increase of air volume fraction (from 0.06 to 0.65) at the same heat flux. In addition, the secondary nucleation induced by air may weaken the effect of total chamber pressure on the heat transfer of spray cooling. Liang and Mudawar [101][135] pointed out that the presence of non-condensable gas will make the design of the spray system more complicated after summarizing the previous research work. To ouresearchers' knowledge, the negatives owing to the non-condensable gas outweigh the positives. Even worse, the presence of non-condensable gas can damage the compressor or pump, which is detrimental to the long-term and stable operation of the system. In the design and work of spray systems, therefore, attention should be paid to removing impure gas [102][136]. Spray cooling is recognized as the most promising next-generation thermal management technology, and its application in the aerospace field is another research focus [103][137]. Therefore, it is of profound significance to explore the effect of gravity on spray systems. In the early stage, Golliher et al. [104][138] constructed a visual spray-cooling system and used the NASA elevator to change the gravity field. They successfully visualized spray flow on the cooling surface under different gravitational fields, as shown in Figure 12. Different from the normal gravity, the surface tension would dominate the heat transfer and flow regime change during the spray-cooling process in the micro-gravitational field. Ohta et al. [105][139] conducted a nuclear boiling experiment by parabolic flight under 0.01 times gravity. Their results revealed that microgravity makes it more difficult for bubbles to escape from the liquid film in the nucleate boiling stage, which leads to the deterioration of heat-transfer performance. Buoyancy is the main driving force for bubble separation under normal gravity, but it is difficult to produce buoyancy under microgravity [106][140]. Tatiana et al. [107][141] used visual image-processing technology to study the liquid film produced by the spray impact on heated targets. From their results, it was found that the average thickness of the liquid film on the cooling surface would increase in microgravity environment, which weakens the system cooling performance. By contrast, Elston et al. [108][142] tested the FC-72 spray system in different gravity fields and found that the heat-transfer performance under microgravity was the best, which is contrary to Tatiana’s conclusion. Kato et al. [106][140] also used gravity-reducing aircraft to control the gravity between 0.01 g and 2 g, and studied the spray cooling characteristics of different working fluids in this range. Their results demonstrated that when taking CFC-113 as the working fluid, CHF decreases by about 10% at 0.01 g relative to 1 g of gravity. When taking water as the working fluid, however, CHF increases by about 15%. It can be seen that the research on the effect of gravity on the cooling performance of spray system is still inconclusive, and the conclusions obtained from different experiments are quite different, or even opposite. The authors believe that the main reason is that the duration of the microgravity field generated by either the lift or the parabolic flight is only a few seconds during the experiment, which causes an inability to effectively study the heat-transfer and flow characteristics of the spray. In future work, the effect of gravity may be better understood and explained if the rate of bubble formation and detachment on the cooling surface is taken as the penetrating point of the study.