The rapid development of sensing technology has created an urgent need for chemical sensor systems that can be rationally integrated into efficient, sustainable, and wearable electronic systems. In this case, the triboelectric nanogenerator (TENG) is expected to be a major impetus to such innovation because it can not only power the sensor by scavenging mechanical energies and transforming them into electricity but also act as the chemical sensor itself due to its intrinsic sensitivity towards the chemical reaction that occurs at the triboelectric interface.

- triboelectric nanogenerator

- chemical sensor

- self-powered

1. Introduction

2. Basic Principle of TENGs

2.1. Working Mode of TENGs

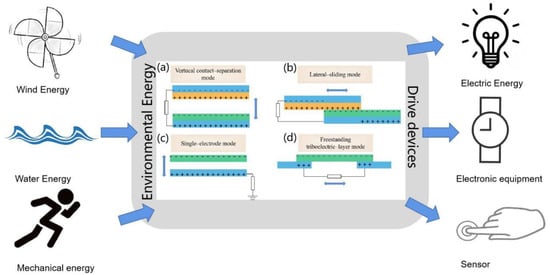

By varying the relative motion of the contact initiation layer, TENGs are generally classified into four basic operating modes: the vertical contact separation mode, the sliding mode, the single-electrode mode, and the free-standing friction layer mode [33][34]. The most typical device structure in TENGs is the vertical contact separation mode (Figure 12a), which has two electrodes—one attached to the top of the dielectric membrane and the other on the back. These two electrodes move towards each other in the vertical direction of the device, generating an electrical charge as a result of an externally applied force. The potential between the electrodes will change during contact or separation, resulting in a current output from the external circuit [35].

2.2. Working Principle

Triboelectrification is a common phenomenon that people encounter daily. While its origin is still unclear, it is widely believed that frictional electricity is caused by the overlap of electron clouds inside the material when the electrode surfaces are in contact. In this case, the energy barrier in the interior of the atom is lowered [39]. From a theoretical point of view, the charges of the two friction electrodes are equal. When no external force is applied, the two friction electrode surfaces are separated from each other, leading to the establishment of an internal potential in the device [40][41]. Additionally, in this process, the internal potential can induce the flow of carriers in the material from one electrode to the other, thus counteracting the change in electric potential caused by electrostatic induction and, finally, generating a positive current [42]. When there is an external force, the two electrodes of the TENG move toward each other, which can cause the carriers in the material to flow in opposite directions, resulting in a change in the polarity of the electric potential as well [43]. In addition, when the two friction electrodes are in contact again, this process will cycle, resulting in a periodic output with positive and negative properties [44].3. Progress of TENG-Based Chemical Sensor Systems

3.1. Chemical Sensor Powered by TENG

As a renewable energy harvesting technology, TENGs have promoted the development of self-powered sensors and portable electronic equipment to meet the growing demand for autonomy and sustainability [45]. Here, the basic principle, design strategy, and recent progress of TENGs acting as a power source in chemical sensors are illustrated.3.1.1. Basic Principle

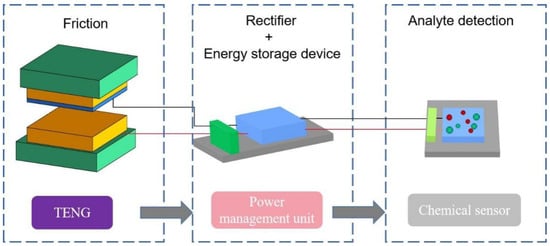

As shown in Figure 23, the TENG serves as a power source that can directly drive a chemical sensor system (CSS). In this process, the output of the TENG is processed by a power management device in the system, which typically consists of a rectifier and various types of energy storage devices. In this case, the stability of the TENG output can only affect the charging efficiency of the energy storage devices in the system and has no effect on the detection abilities of the sensor.

3.1.2. Design Criteria of TENG-Based Power Source

To be used as a power supply, the design of TENGs needs to consider the following aspects. First, a direct and stable output TENG should be designed to continuously drive the sensor. Second, it is essential to increase the maximum output power and energy conversion efficiency of the device and, finally, improve the reliability performance of the device in harsh operating conditions.Power Management Approach

It knows that conventional TENGs produce a transient peak AC output when in operation, which is one of their most significant limitations; therefore, they cannot be directly used as a power source for sensors. Nowadays, there are two main methods of achieving conversion from AC power to DC power in a circuit. The first method is to connect a rectifier to the TENGs to obtain a stable, constant DC voltage, thus maintaining the daily operation of the sensor.Performance Enhancement Strategy

Although TENGs are a promising power source due to their ability to collect energy from the environment, the relatively low output power limits the broad application of TENGs. The following are several effective ways to increase the output of TENGs: firstly, increase the surface charge density of the material; subsequently, increase the area of electrode contact separation; in addition, optimizing the structural design is also a solution.Resistance to Harsh Conditions

In practical applications, self-powered chemical sensor systems based on nanogenerators always face complex operating environments such as acid, alkali, temperature, corrosive, high humidity, high salinity, and strong magnetic fields.3.1.3. TENG-Powered Chemical Sensors

TENG can be constructed from a wide range of materials with virtues such as biocompatibility, flexibility, permeability, and so on [46][47]. These features offer a foundation for the further development of CSSs that are powered by TENGs.Biosensors

Biosensors are important in healthcare and diagnostic treatments. Nevertheless, the battery life of these instruments is limited [48]. Battery replacement is not only an expensive and risky process for patients but also may be painful and inconvenient for them. Batteries are not ideal power sources for medical devices because they contain toxic chemicals [49][50]. Therefore, self-powered sensors are a promising strategy for the sustainable operation of biosensors.Gas Sensors

Recently, TENGs have been extensively utilized as a complementary power source for gas sensors, which helps the continuous operation toward the online detection of the environmental atmosphere.Ion Sensors

Ion sensors are widely used at present to either detect the environmental chemical composition or monitor physiochemical conditions. For autonomous operation, TENGs should provide the necessary electric power and complement electrochemical power sources.3.2. TENG-Based Active Chemical Sensor

3.2.1. Basic Principle

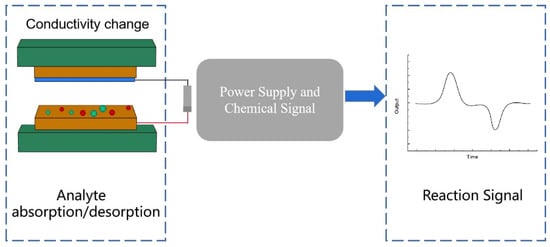

During operation, the magnitude of the electrical signals (Voc and Isc) generated by the TENG device is closely related, in some cases, even quantitatively proportional to the triboelectric charge density [51]. As frictional electricity is essentially a chemical potential difference between two electrode surfaces and as the absorption of some chemical substances and their chemical reactions at the surface affect the charge transportation and density, thus affecting the output of the TENG, it is possible to detect the absorbed target substance quantitively and develop TENG-based active chemical sensors (Figure 310). This multifunctional design reduces power consumption, simplifies the system, and, above all, enables sustainable, straightforward, and reliable sensor operation.

3.2.2. Design Criteria of TENG-Based Active Sensors

Sensitivity Improvement

Integration Optimization

In practical applications, TENGs need to be integrated with a chemical sensor and other information devices to realize the automatic analysis of collected data and provide scientific guidance.3.2.3. Applications of TENG-Based Active Chemical Sensors

TENG-based active chemical sensors have received broad attention and undergone rapid development in response to stimuli from chemical molecules or other factors, for instance, ethanol, phenol, and pH, where the output performance of the TENG and the stimulation shows a linear relationship.TENG-Based Active Biosensors

Human body physiological signals are important physiological indicators for public healthcare and health monitoring [55]. Monitoring these small but complex physiological signals in real-time with simple, convenient, economical, and accurate methods remains a challenge for healthcare devices [56][57]. As a result, new methods for analyzing these biological analytes are required.

TENG-Based Active Gas Sensors

It is essential to develop rapid and precise real-time safety monitoring systems, such as chemical gas sensors, to find gases such as alcohol, acetylene, ammonia, aniline, etc., considering the increasing worry about the security of places where people work and reside. Due to their ability to implement portable gas sensors without a separate power source, self-powered gas sensors with TENGs are drawing a lot of attention [58].The most recent progress in TENG-based self-powered active gas sensors is presented and explored in this section.

TENG-Based Active Ion Sensors

Chemical ion sensors are commonly used in sectors to detect inorganic, organic, and biological ions, particularly ions in liquids such as H+, Hg2+, Cu2+, Pb2+, and so on. With high selectivity, great sensitivity, and a wide sensing range, self-powered TENG-based active ion sensors are able to detect various types of substances. The ions in the detection target can be identified by the friction layer surface of the TENG or the outside dopant material [59][60]. The following typical examples demonstrate these applications and advances.Other Active Sensors

Aside from TENG-based activity sensors, as discussed above, there is a solid–liquid interface-based TENG that can detect organic compounds in solution [61][62], such as ethanol and acetone in solution. The sensing mechanism is the same as that of gas detection; the effect of different molecules or concentrations on the friction layer will cause the performance of the TENG to change. The detection method is similar to the case of ion sensors; TENG-based chemical sensors detect target molecules in a solution by dropping the solution onto the surface of a frictional electric material and observing its reaction with the counter electrode after the surface of that material has dried, enabling the analysis of the solution.4. Conclusions

TENG-based CSSs not only demonstrate the sensitive detection of physiological activity, gases, and ions but may also achieve independent, continuous, and reliable operation by scavenging mechanical energy from nature or biology. Although this TENG-based sensor system has achieved significant progress through the design strategy of TENG-based active sensors, it is still not systematic and comprehensive enough. The challenges that TENG-based power sources face are relatively simple; the enhancement of output performance is always the prime target, which can be effectively promoted by improved power management, material selection, and structure design. For TENG-based active sensors, the main starting point is the adsorption or chemical reaction of specific targets at the triboelectric interface, whose reliability is susceptible to environmental conditions and the TENG’s own signal interference. Nevertheless, in both cases, the coupling of different material properties can bring new insights into the design of TENG-based CSSs with higher performance, thus innovating their applications in a wide range of multidisciplinary areas, such as disease diagnosis, environmental monitoring, and the defense industry.

References

- Yogeswaran, U.; Chen, S. A review on the electrochemical sensors and biosensors composed of nanowires as sensing material. Sensors 2008, 8, 290–313.

- Dong, X.; Yan, X.; Li, M.; Liu, H.; Li, J.; Wang, L.; Wang, K.; Lu, X.; Wang, S.; He, B. Ultrasensitive detection of chloramphenicol using electrochemical aptamer sensor: A mini review. Electrochem. Commun. 2020, 120, 106835.

- Gan, X.; Zhao, H. Understanding signal amplification strategies of nanostructured electrochemical sensors for environmental pollutants. Curr. Opin. Electrochem. 2019, 17, 56–64.

- Wijesinghe, M.S.; Batchelder, K.; Wickramasinghe, D.; Oh, J.; Chow, K. Battery-powered distance-based electrochemical sensor using a longitudinally-oriented silver band electrode. Sens. Actuators B Chem. 2020, 308, 127684.

- Brett, C.M.A.; Oliveira-Brett, A.M. Electrochemical sensing in solution—Origins, applications and future perspectives. J. Solid State Electrochem. 2011, 15, 1487–1494.

- Yan, L.; Mi, Y.; Lu, Y.; Qin, Q.; Wang, X.; Meng, J.; Liu, F.; Wang, N.; Cao, X. Weaved piezoresistive triboelectric nanogenerator for human motion monitoring and gesture recognition. Nano Energy 2022, 96, 107135.

- Downs, A.M.; Gerson, J.; Hossain, M.N.; Ploense, K.; Pham, M.; Kraatz, H.; Kippin, T.; Plaxco, K.W. Nanoporous gold for the miniaturization of in vivo electrochemical aptamer-based sensors. ACS Sens. 2021, 6, 2299–2306.

- Li, M.; Zhou, P.; Wang, X.; Wen, Y.; Xu, L.; Hu, J.; Huang, Z.; Li, M. Development of a simple disposable laser-induced porous graphene flexible electrode for portable wireless intelligent votammetric nanosensing of salicylic acid in agro-products. Comput. Electron. Agric. 2021, 191, 106502.

- Sánchez Del Río, J.; Yusuf, A.; Ao, X.; Olaizola, I.A.; López-Puertas, L.U.; Ballesteros, M.Y.; Giannetti, R.; Martínez, V.; Jiménez, J.L.; Monge, J.B.B.; et al. High-resolution tengs for earthquakes ground motion detection. Nano Energy 2022, 102, 107666.

- Zhang, C.; Bu, T.; Zhao, J.; Liu, G.; Yang, H.; Wang, Z.L. Tribotronics for active mechanosensation and self-powered microsystems. Adv. Funct. Mater. 2019, 29, 1808114.

- Nemčeková, K.; Labuda, J. Advanced materials-integrated electrochemical sensors as promising medical diagnostics tools: A review. Mater. Sci. Eng. C 2021, 120, 111751.

- Li, G.; Wen, D. Wearable biochemical sensors for human health monitoring: Sensing materials and manufacturing technologies. J. Mat. Chem. B 2020, 8, 3423–3436.

- Yu, Y.; Nyein, H.Y.Y.; Gao, W.; Javey, A. Flexible electrochemical bioelectronics: The rise of in situ bioanalysis. Adv. Mater. 2020, 32, 1902083.

- Jeerapan, I.; Poorahong, S. Review—Flexible and stretchable electrochemical sensing systems: Materials, energy sources, and integrations. J. Electrochem. Soc. 2020, 167, 37573.

- Dai, C.; Hu, L.; Jin, X.; Chen, H.; Zhang, X.; Zhang, S.; Song, L.; Ma, H.; Xu, M.; Zhao, Y.; et al. A cascade battery: Coupling two sequential electrochemical reactions in a single battery. Adv. Mater. 2021, 33, 2105480.

- Jiang, G.; Li, F.; Wang, H.; Wu, M.; Qi, S.; Liu, X.; Yang, S.; Ma, J. Perspective on high-concentration electrolytes for lithium metal batteries. Small Struct. 2021, 2, 2000122.

- Aller Pellitero, M.; Del Campo, F.J. Electrochromic sensors: Innovative devices enabled by spectroelectrochemical methods. Curr. Opin. Electrochem. 2019, 15, 66–72.

- Zhou, L.; Liu, D.; Liu, L.; He, L.; Cao, X.; Wang, J.; Wang, Z.L. Recent advances in self-powered electrochemical systems. Research 2021, 2021, 4673028.

- Liang, J.; Mondal, A.K.; Wang, D.; Iacopi, F. Graphene-based planar microsupercapacitors: Recent advances and future challenges. Adv. Mater. Technol. 2019, 4, 1800200.

- Parrilla, M.; De Wael, K. Wearable self-powered electrochemical devices for continuous health management. Adv. Funct. Mater. 2021, 31, 2107042.

- Kim, D.W.; Lee, J.H.; Kim, J.K.; Jeong, U. Material aspects of triboelectric energy generation and sensors. NPG Asia Mater. 2020, 12, 6.

- Wang, K.; Li, J. Electricity generation from the interaction of liquid–solid interface: A review. J. Mater. Chem. A 2021, 9, 8870–8895.

- Tan, G.; Ohta, M.; Kanatzidis, M.G. Thermoelectric power generation: From new materials to devices. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2019, 377, 20180450.

- Shafranjuk, S.E. Converting heat to electricity by a graphene stripe with heavy chiral fermions. Eur. Phys. J. B 2014, 87, 99.

- Zoui, M.A.; Bentouba, S.; Stocholm, J.G.; Bourouis, M. A review on thermoelectric generators: Progress and applications. Energies 2020, 13, 3606.

- Pilli, S.K.; Summers, K.; Chidambaram, D. Photoelectrochemical generation of hydrogen and electricity from hydrazine hydrate using bivo4 electrodes. Phys. Chem. Chem. Phys. 2015, 17, 13851–13859.

- Zhong, M.; Shi, J.; Xiong, F.; Zhang, W.; Li, C. Enhancement of photoelectrochemical activity of nanocrystalline cds photoanode by surface modification with tio2 for hydrogen production and electricity generation. Sol. Energy 2012, 86, 756–763.

- Ke, K.; Chung, C. High-performance al/pdms teng with novel complex morphology of two-height microneedles array for high-sensitivity force-sensor and self-powered application. Small 2020, 16, 2001209.

- Huang, C.; Chen, G.; Nashalian, A.; Chen, J. Advances in self-powered chemical sensing via a triboelectric nanogenerator. Nanoscale 2021, 13, 2065–2081.

- Chen, J.; Wang, Z.L. Reviving vibration energy harvesting and self-powered sensing by a triboelectric nanogenerator. Joule 2017, 1, 480–521.

- Fan, F.; Tian, Z.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy 2012, 1, 328–334.

- Cao, X.; Jie, Y.; Wang, N.; Wang, Z.L. Triboelectric nanogenerators driven self-powered electrochemical processes for energy and environmental science. Adv. Energy Mater. 2016, 6, 1600665.

- Niu, S.; Wang, Z.L. Theoretical systems of triboelectric nanogenerators. Nano Energy 2015, 14, 161–192.

- Kim, W.; Kim, D.; Tcho, I.; Kim, J.; Kim, M.; Choi, Y. Triboelectric nanogenerator: Structure, mechanism, and applications. ACS Nano 2021, 15, 258–287.

- Yang, W.; Chen, J.; Zhu, G.; Yang, J.; Bai, P.; Su, Y.; Jing, Q.; Cao, X.; Wang, Z.L. Harvesting energy from the natural vibration of human walking. ACS Nano 2013, 7, 11317–11324.

- Wang, S.; Lin, L.; Xie, Y.; Jing, Q.; Niu, S.; Wang, Z.L. Sliding-triboelectric nanogenerators based on in-plane charge-separation mechanism. Nano Lett. 2013, 13, 2226–2233.

- Sun, H.; Zhao, Y.; Jiao, S.; Wang, C.; Jia, Y.; Dai, K.; Zheng, G.; Liu, C.; Wan, P.; Shen, C. Environment tolerant conductive nanocomposite organohydrogels as flexible strain sensors and power sources for sustainable electronics. Adv. Funct. Mater. 2021, 31, 2101696.

- Wang, S.; Xie, Y.; Niu, S.; Lin, L.; Wang, Z.L. Freestanding triboelectric-layer-based nanogenerators for harvesting energy from a moving object or human motion in contact and non-contact modes. Adv. Mater. 2014, 26, 2818–2824.

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ. Sci. 2015, 8, 2250–2282.

- Pan, S.; Zhang, Z. Fundamental theories and basic principles of triboelectric effect: A review. Friction 2019, 7, 2–17.

- Wang, Z.L. Triboelectric nanogenerators as new energy technology for self-powered systems and as active mechanical and chemical sensors. ACS Nano 2013, 7, 9533–9557.

- Wang, Z.L. From contact electrification to triboelectric nanogenerators. Rep. Prog. Phys. 2021, 84, 96502.

- Zhao, Z.; Zhou, L.; Li, S.; Liu, D.; Li, Y.; Gao, Y.; Liu, Y.; Dai, Y.; Wang, J.; Wang, Z.L. Selection rules of triboelectric materials for direct-current triboelectric nanogenerator. Nat. Commun. 2021, 12, 4686.

- Dharmasena, R.D.I.G.; Cronin, H.M.; Dorey, R.A.; Silva, S.R.P. Direct current contact-mode triboelectric nanogenerators via systematic phase shifting. Nano Energy 2020, 75, 104887.

- Zhang, R.; Xia, R.; Cao, X.; Wang, N. Nutshell powder-based green triboelectric nanogenerator for wind energy harvesting. Adv. Mater. Interfaces 2022, 9, 2200293.

- Kim, J.; Lee, J.; Go, T.W.; Rajabi-Abhari, A.; Mahato, M.; Park, J.Y.; Lee, H.; Oh, I. Skin-attachable and biofriendly chitosan-diatom triboelectric nanogenerator. Nano Energy 2020, 75, 104904.

- Wang, R.; Mu, L.; Bao, Y.; Lin, H.; Ji, T.; Shi, Y.; Zhu, J.; Wu, W. Holistically engineered polymer–polymer and polymer–ion interactions in biocompatible polyvinyl alcohol blends for high-performance triboelectric devices in self-powered wearable cardiovascular monitorings. Adv. Mater. 2020, 32, 2002878.

- Yu, Y.; Nassar, J.; Xu, C.; Min, J.; Yang, Y.; Dai, A.; Doshi, R.; Huang, A.; Song, Y.; Gehlhar, R.; et al. Biofuel-powered soft electronic skin with multiplexed and wireless sensing for human-machine interfaces. Sci. Robot. 2020, 5, z7946.

- Sun, J.; Li, J.; Zhou, T.; Yang, K.; Wei, S.; Tang, N.; Dang, N.; Li, H.; Qiu, X.; Chen, L. Toxicity, a serious concern of thermal runaway from commercial li-ion battery. Nano Energy 2016, 27, 313–319.

- Larsson, F.; Andersson, P.; Blomqvist, P.; Mellander, B. Toxic fluoride gas emissions from lithium-ion battery fires. Sci. Rep. 2017, 7, 10018.

- Lai, M.; Du, B.; Guo, H.; Xi, Y.; Yang, H.; Hu, C.; Wang, J.; Wang, Z.L. Enhancing the output charge density of teng via building longitudinal paths of electrostatic charges in the contacting layers. ACS Appl. Mater. Interfaces 2018, 10, 2158–2165.

- Gong, H.; Xu, Z.; Yang, Y.; Xu, Q.; Li, X.; Cheng, X.; Huang, Y.; Zhang, F.; Zhao, J.; Li, S.; et al. Transparent, stretchable and degradable protein electronic skin for biomechanical energy scavenging and wireless sensing. Biosens. Bioelectron. 2020, 169, 112567.

- Fu, X.P.; Bu, T.Z.; Xi, F.B.; Cheng, T.H.; Zhang, C.; Wang, Z.L. Embedded triboelectric active sensors for real-time pneumatic monitoring. ACS Appl. Mater. Interfaces 2017, 9, 32352–32358.

- Xiang, H.; Yang, J.; Cao, X.; Wang, N. Flexible and highly sensitive triboelectric nanogenerator with magnetic nanocomposites for cultural heritage conservation and human motion monitoring. Nano Energy 2022, 101, 107570.

- Meng, K.; Xiao, X.; Wei, W.; Chen, G.; Nashalian, A.; Shen, S.; Xiao, X.; Chen, J. Wearable pressure sensors for pulse wave monitoring. Adv. Mater. 2022, 34, 2109357.

- Gao, W.; Ota, H.; Kiriya, D.; Takei, K.; Javey, A. Flexible electronics toward wearable sensing. Acc. Chem. Res. 2019, 52, 523–533.

- Yang, J.C.; Mun, J.; Kwon, S.Y.; Park, S.; Bao, Z.; Park, S. Electronic skin: Recent progress and future prospects for skin-attachable devices for health monitoring, robotics, and prosthetics. Adv. Mater. 2019, 31, 1904765.

- Wang, D.; Zhang, D.; Yang, Y.; Mi, Q.; Zhang, J.; Yu, L. Multifunctional latex/polytetrafluoroethylene-based triboelectric nanogenerator for self-powered organ-like mxene/metal–organic framework-derived cuo nanohybrid ammonia sensor. ACS Nano 2021, 15, 2911–2919.

- Wu, L.; Huang, C.; Emery, B.P.; Sedgwick, A.C.; Bull, S.D.; He, X.; Tian, H.; Yoon, J.; Sessler, J.L.; James, T.D. Förster resonance energy transfer (fret)-based small-molecule sensors and imaging agents. Chem. Soc. Rev. 2020, 49, 5110–5139.

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514.

- Shen, F.; Zhang, D.; Zhang, Q.; Li, Z.; Guo, H.; Gong, Y.; Peng, Y. Influence of temperature difference on performance of solid-liquid triboelectric nanogenerators. Nano Energy 2022, 99, 107431.

- Chung, J.; Cho, H.; Yong, H.; Heo, D.; Rim, Y.S.; Lee, S. Versatile surface for solid–solid/liquid–solid triboelectric nanogenerator based on fluorocarbon liquid infused surfaces. Sci. Technol. Adv. Mater. 2020, 21, 139–146.