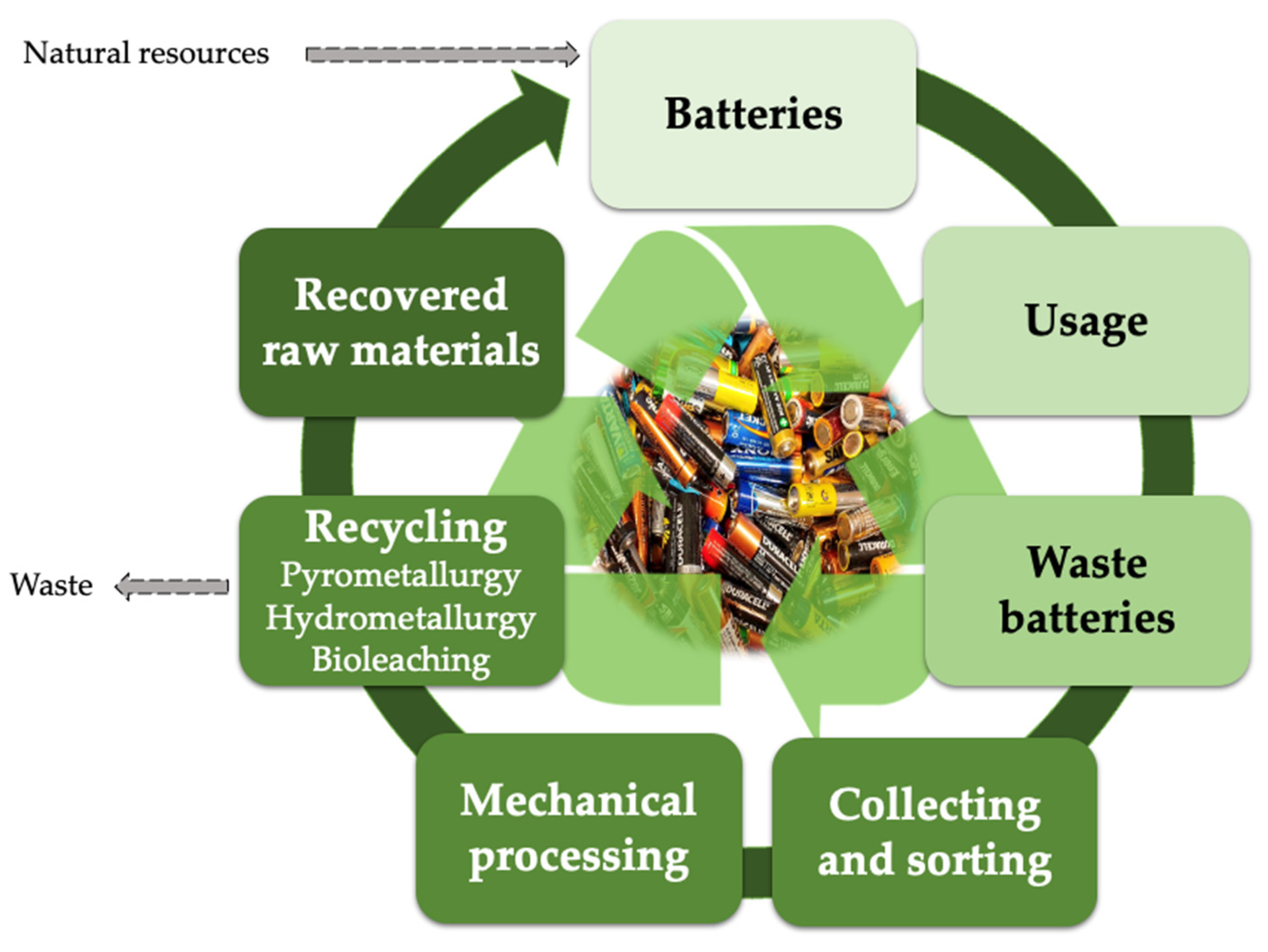

The rapid growth of battery production and usage will cause waste and disposal-related issues as these batteries reach end-of-life. Moreover, it also causes the depletion of natural mineral resources. Thus, effective battery reuse and recycling procedures are highly important because they contain metals of critical importance. The recycling of batteries causes the return of valuable materials, including lead, lithium, nickel, cadmium, and copper, back to the value chain, partially easing the need to extract new resources. Moreover, recovering metals from batteries reduces the burden on landfills, the burden on the environment, and the negative impact on human health. The critical material’s recirculation also leads to a reduction of the ecological CO2 footprint, which is connected with battery cell production and may provide CO2-neutral battery cell production. Improper battery waste disposal causes harmful effects on human and animal health, as well as the environment, as they contain a huge number of heavy metals. These waste compounds contaminate water, soil, and vegetation.

- battery waste

- waste management

- artificial intelligence

- genetic programming

1. Artificial Intelligence in Battery Production and Monitoring

2. Artificial Intelligence in Waste Management, Including Battery Waste Management Systems

3. Artificial Intelligence in the Waste Sorting

4. Artificial Intelligence in Battery Waste Recycling

References

- Duffner, F.; Mauler, L.; Wentker, M.; Leker, J.; Winter, M. Large-scale automotive battery cell manufacturing: Analyzing strategic and operational effects on manufacturing costs. Int. J. Prod. Econ. 2021, 232, 107982.

- Lombardo, T.; Duquesnoy, M.; El-Bouysidy, H.; Arén, F.; Gallo-Bueno, A.; Jørgensen, P.B.; Bhowmik, A.; Demortière, A.; Ayerbe, E.; Alcaide, F.; et al. Artificial Intelligence Applied to Battery Research: Hype or Reality? Chem. Rev. 2022, 122, 10899–10969.

- Chemali, E.; Kollmeyer, P.J.; Preindl, M.; Emadi, A.J. State-of-charge estimation of Li-ion batteries using deep neural networks: A machine learning approach. J. Power Sources 2018, 400, 242–255.

- Girijaprasanna, T.; Dhanamjayulu, C. A Review on Different State of Battery Charge Estimation Techniques and Management Systems for EV Applications. Electronics 2022, 11, 1795.

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391.

- Tan, S.W.; Huang, S.W.; Hsieh, Y.Z.; Lin, S.S. The Estimation Life Cycle of Lithium-Ion Battery Based on Deep Learning Network and Genetic Algorithm. Energies 2021, 14, 4423.

- Cunha, R.P.; Lombardo, T.; Primo, E.N.; Franco, A.A. Artificial Intelligence Investigation of NMC Cathode Manufacturing Parameters Interdependencies. Batter. Supercaps 2020, 3, 60–67.

- He, W.; Williard, N.; Chen, C.; Pecht, M. State of charge estimation for Li-ion batteries using neural network modeling and unscented Kalman filter-based error cancellation. Int. J. Electr. Power Energy Syst. 2014, 62, 783–791.

- Salkind, A.J.; Fennie, C.; Singh, P.; Atwater, T.; Reisner, D.E. Determination of state-of charge and state-of-health of batteries by fuzzy logic methodology. J. Power Sources 1999, 80, 293–300.

- Zheng, Y.; Lu, L.; Han, X.; Li, J.; Ouyang, M. LiFePO4 battery pack capacity estimation for electric vehicles based on charging cell voltage curve transformation. J. Power Sources 2013, 226, 33–41.

- Xu, J.; Cao, B.; Chen, Z.; Zou, Z. An online state of charge estimation method with reduced prior battery testing information. Int. J. Electr. Power Energy Syst. 2014, 63, 178–184.

- Wu, X.; Mi, L.; Tan, W.; Qin, J.L.; Na Zhao, M. State of Charge (SOC) Estimation of Ni-MH Battery Based on Least Square Support Vector Machines. Adv. Mater. Res. 2011, 211–212, 1204–1209.

- How, D.N.; Hannan, M.; Lipu, M.H.; Sahari, K.S.; Ker, P.J.; Muttaqi, K.M. State-of-charge estimation of li-ion battery in electric vehicles: A deep neural network approach. IEEE Trans. Ind. Appl. 2020, 56, 5565–5574.

- Song, X.; Yang, F.; Wang, D.; Tsui, K.L. Combined CNN-LSTM Network for State-of-Charge Estimation of Lithium-Ion Batteries. IEEE Access 2019, 7, 88894–88902.

- Afshar, S.; Morris, K.; Khajepour, A. State-of-Charge Estimation Using an EKF-Based Adaptive Observer. IEEE Trans. Control Syst. Technol. 2019, 27, 1907–1923.

- Li, Y.; Guo, H.; Qi, F.; Guo, Z.; Li, M. Comparative Study of the Influence of Open Circuit Voltage Tests on State of Charge Online Estimation for Lithium-Ion Batteries. IEEE Access 2020, 8, 17535–17547.

- Fan, E.; Li, L.; Wang, Z.; Lin, J.; Huang, Y.; Yao, Y.; Chen, R.; Wu, F. Sustainable Recycling Technology for Li-Ion Batteries and Beyond: Challenges and Future Prospects. Chem. Rev. 2020, 120, 7020–7063.

- Wang, B.; Zhang, G.; Wang, H.; Xuan, J.; Jiao, K. Multi-physics-resolved digital twin of proton exchange membrane fuel cells with a data-driven surrogate model. Energy AI 2020, 1, 100004.

- Hsu, C.W.; Xiong, R.; Chen, N.Y.; Li, J.; Tsou, N.T. Deep neural network battery life and voltage prediction by using data of one cycle only. Appl. Energy 2022, 306, 118134.

- Blomeke, S.; Rickert, J.; Mennenga, M.; Thiede, S.; Spengler, T.S.; Herrmann, C. Recycling 4.0—Mapping smart manufacturing solutions to remanufacturing and recycling operations. Procedia CIRP 2020, 90, 600–605.

- Garg, A.; Mou, J.; Su, S.; Gao, L. Reconfigurable battery systems: Challenges and safety solutions using intelligent system framework based on digital twins. IET Collab. Intell. Manuf. 2022, 4, 232–248.

- Cerchecci, M.; Luti, F.; Mecocci, A.; Parrino, S.; Peruzzi, G.; Pozzebon, A. A low power IoT sensor node architecture for waste management within smart cities context. Sensors 2018, 18, 1282.

- Khoa, T.A.; Phuc, C.H.; Lam, P.D.; Nhu, L.M.B.; Trong, N.M.; Phuong, N.T.H.; Dung, N.V.; Tan-Y, N.; Nguyen, H.N.; Duc, D.N.M. Waste Management System Using IoT-Based Machine Learning in University. Wirel. Commun. Mob. Comput. 2020, 2020, 6138637.

- Gutierrez, J.M.; Jensen, M.; Henius, M.; Riaz, T. Smart waste collection system based on location intelligence. Procedia Comput. Sci. 2015, 61, 120–127.

- Aziz, F.; Arof, H.; Mokhtar, N.; Mubin, M.; Abu Talip, M.S. Rotation invariant bin detection and solid waste level classification. Measurement 2015, 65, 19–28.

- Nowakowski, P.; Pamuła, T. Application of deep learning object classifier to improve e-waste collection planning Author links open overlay panel. Waste Manag. 2020, 109, 1–9.

- Hua, D.; Gao, J.; Mayo, R.; Smedley, A.; Puranik, P.; Zhan, J. Segregating Hazardous Waste Using Deep Neural Networks in Real-Time Video. In Proceedings of the 2020 10th Annual Computing and Communication Workshop and Conference (CCWC), Las Vegas, NV, USA, 6–8 January 2020; pp. 1016–1022.

- Chen, J.; Huang, S.; BalaMurugan, S.; Tamizharasi, G.S. Artificial intelligence based e-waste management for environmental planning. Environ. Impact Assess. Rev. 2021, 87, 106498.

- Han, W.; Gao, G.; Geng, J.; Li, Y.; Wang, Y. Ecological and health risks assessment and spatial distribution of residual heavy metals in the soil of an e-waste circular economy park in Tianjin, China. Chemosphere 2018, 197, 325–335.

- Ihsanullah, I.; Alam, G.; Jamal, A.; Shaik, F. Recent advances in applications of artificial intelligence in solid waste management: A review. Chemosphere 2022, 309, 136631.

- Sinthiya, N.J.; Chowdhury, T.A.; Haque, A.K.M.B. Artificial Intelligence Based Smart Waste Management—A Systematic Review. In Computational Intelligence Techniques for Green Smart Cities. Green Energy and Technology; Lahby, M., Al-Fuqaha, A., Maleh, Y., Eds.; Springer: Cham, Switzerland, 2022.

- Menegaki, M.; Damigos, D. A review on current situation and challenges of construction and demolition waste management. Curr. Opin. Green Sustain. Chem. 2018, 13, 8–15.

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Uddin, A.S.; Salmiati, S.; Shahid, S. An empirical study of construction and demolition waste generation and implication of recycling. Waste Manag. 2019, 95, 10–21.

- Qu, D. Application of Artificial Intelligence in Waste Classification Management at University. In Proceedings in Adaptation, Learning and Optimization, Proceedings of the International Conference on Intelligent Vision and Computing (ICIVC 2021), Qingdao, China, 23–25 July 2021; Sharma, H., Vyas, V.K., Pandey, R.K., Prasad, M., Eds.; Springer: Cham, Switzerland, 2021; Volume 5.

- Jude, A.B.; Singh, D.; Islam, S.; Jameel, M.; Srivastava, S.; Prabha, B.; Kshirsagar, P.R. An Artificial Intelligence Based Predictive Approach for Smart Waste Management. Wirel. Pers. Commun. 2021.

- Huang, J.; Koroteevabc, D.D. Artificial intelligence for planning of energy and waste management. Sustain. Energy Technol. Assess. 2021, 47, 101426.

- Ali, T.H.; Akhund, M.A.; Memon, N.A.; Memon, A.H.; Imad, H.U.; Khahro, S.H. Application of Artifical Intelligence in Construction Waste Management. In Proceedings of the 8th International Conference on Industrial Technology and Management (ICITM) 2019, Cambridge, UK, 2–4 March 2019; pp. 50–55.

- Coskuner, G.; Jassim, M.S.; Zontul, M.; Karateke, S. Application of artificial intelligence neural network modeling to predict the generation of domestic, commercial and construction wastes. Waste Manag. Res. 2021, 39, 499–507.

- Soni, U.; Roy, A.; Verma, A.; Jain, V. Forecasting municipal solid waste generation using artificial intelligence models—A case study in India. SN Appl. Sci. 2019, 1, 162.

- Abbasi, M.; El Hanandeh, A. Forecasting municipal solid waste generation using artificial intelligence modelling approaches. Waste Manage. 2016, 56, 13–22.

- Golbaz, S.; Nabizadeh, R.; Sajadi, H.S. Comparative study of predicting hospital solid waste generation using multiple linear regression and artificial intelligence. J. Environ. Health Sci. Eng. 2019, 17, 41–51.

- Abdallaha, M.; Talib, M.A.; Feroz, S.; Nasir, Q.; Abdalla, H.; Mahfood, B. Artificial intelligence applications in solid waste management: A systematic research review. Waste Manag. 2020, 109, 231–246.

- McKinnon, D.; Fazakerley, J.; Hultermans, R. Waste Sorting Plants—Extracting Value from Waste; ISWA: Vienna, Austria, 2017.

- Abdoli, S. RFID Application in municipally solid waste management system. Int. J. Environ. Res. 2009, 3, 447–454.

- Sakr, G.E.; Mokbel, M.; Darwich, A.; Khneisser, M.N.; Hadi, A. Comparing deep learning and support vector machines for autonomous waste sorting. In Proceedings of the IEEE International Multidisciplinary Conference on Engineering Technology (IMCET) 2016, Beirut, Lebanon, 2–4 November 2016; pp. 207–212.

- Gundupalli, S.P.; Hait, S.; Thakur, A. A review on automated sorting of source-separated municipal solid waste for recycling. Waste Manag. 2017, 60, 56–74.

- Zenrobotics. Available online: https://zenrobotics.com (accessed on 19 October 2022).

- Artificial Intelligence amd Robotization in Waste Sorting Centers as an Alternative to Brown Bins. Available online: https://www.biogasworld.com/news/artificial-intelligence-robotization-waste-sorting-centers-alternative-brown-bins/ (accessed on 19 October 2022).

- Wilts, H.; Garcia, B.R.; Garlito, R.G.; Gómez, L.S.; Prieto, E.G. Artificial Intelligence in the Sorting of Municipal Waste as an Enabler of the Circular Economy. Resources 2021, 10, 28.

- Kshirsagar, P.R.; Kumar, N.; Almulihi, A.H.; Alassery, F.; Khan, A.I.; Islam, S.; Rothe, J.P.; Jagannadham, D.B.V.; Dekeba, K. Artificial Intelligence-Based Robotic Technique for Reusable Waste Materials. Comput. Intell. Neurosci. 2022, 2022, 2073482.

- Sousa, J.; Rebelo, A.; Cardoso, J.S. Automation of Waste Sorting with Deep Learning. In Proceedings of the XV Workshop de Visão Computacional (WVC) 2019, São Bernardo do Campo, Brazil, 9–11 September 2019; pp. 43–48.

- Wang, Z.; Li, H.; Zhang, X. Construction waste recycling robot for nails and screws: Computer vision technology and neural network approach. Autom. Constr. 2019, 97, 220–228.

- Kumar, N.M.; Mohammed, M.A.; Abdulkareem, K.H.; Damasevicius, R.; Mostafa, S.A.; Maashi, M.S.; Chopra, S.S. Artificial intelligence-based solution for sorting COVID related medical waste streams and supporting data-driven decisions for smart circular economy practice. Process Saf. Environ. Prot. 2021, 152, 482–494.

- Zhang, C.; Hu, M.; Di Maio, F.; Sprecher, B.; Yang, X.; Tukker, A. An overview of the waste hierarchy framework for analyzing the circularity in construction and demolition waste management in Europe. Sci. Total Environ. 2022, 803, 149892.

- Deshwal, D.; Sangwan, P.; Dahiya, N. Economic Analysis of Lithium Ion Battery Recycling in India. Wirel. Pers. Commun. 2022, 124, 3263–3286.

- Harper, G.; Sommerville, R.; Kendrick, E.; Driscoll, L.; Slater, P.; Stolkin, R.; Walton, A.; Christensen, P.; Heidrich, O.; Lambert, S.; et al. Recycling lithium-ion batteries from electric vehicles. Nature 2019, 575, 75–86.

- Doose, S.; Mayer, J.K.; Michalowski, P.; Kwade, A. Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations. Metals 2021, 11, 291.

- Golmohammadzadeh, R.; Faraji, F.; Jong, B.; Pozo-Gonzalo, C.; Chakraborty, P.; Banerjee. Current challenges and future opportunities toward recycling of spent lithium-ion batteries. Renew. Sust. Energ. Rev. 2022, 159, 112202.

- Heelan, J.; Gratz, E.; Zheng, Z.; Wang, Q.; Chen, M.; Apelian, D.; Wang, Y. Current and Prospective Li-Ion Battery Recycling and Recovery Processes. JOM 2016, 68, 2632–2638.

- Brückner, L.; Frank, J.; Elwert, T. Industrial Recycling of Lithium-Ion Batteries—A Critical Review of Metallurgical Process Routes. Metals 2020, 10, 1107.

- Hiskey, B. Metallurgy, Survey. In Encyclopedia of Chemical Technology; Kirk, R.E., Othmer, D.F., Eds.; Wiley: New York, NY, USA, 2003.

- Zhang, G.; He, Y.; Wang, H.; Feng, Y.; Xie, W.; Zhu, X. Application of mechanical crushing combined with pyrolysis-enhanced flotation technology to recover graphite and LiCoO2 from spent lithium-ion batteries. J. Clean. Prod. 2019, 231, 1418–1427.

- Makuza, B.; Tian, Q.; Guo, X.; Chattopadhyay, K.; Yu, D. Pyrometallurgical options for recycling spent lithium-ion batteries: A comprehensive review. J. Power Sources 2021, 491, 229622.

- Rajaeifar, M.A.; Raugei, M.; Steubing, B.; Hartwell, A.; Anderson, P.A.; Heidrich, O. Life cycle assessment of lithium-ion battery recycling using pyrometallurgical technologies. J. Ind. Ecol. 2021, 25, 1560–1571.

- Yao, Y.; Zhu, M.; Zhao, Z.; Tong, B.; Fan, Y.; Hua, Z. Hydrometallurgical Processes for Recycling Spent Lithium-Ion Batteries: A Critical Review. ACS Sustainable Chem. Eng. 2018, 6, 13611–13627.

- Shin, S.M.; Kim, N.H.; Sohn, J.S.; Yang, D.H.; Kim, Y.H. Development of a metal recovery process from Li-ion battery wastes. Hydrometallurgy 2005, 79, 172–181.

- Peng, C.; Hamuyuni, J.; Wilson, B.P.; Lundström, M. Selective reductive leaching of cobalt and lithium from industrially crushed waste Li-ion batteries in sulfuric acid system. Waste Manag. 2018, 76, 582–590.

- Fan, X.; Song, C.; Lu, X.; Shi, Y.; Yang, S.; Zheng, F.; Huang, Y.; Liu, K.; Wang, H.; Li, Q. Separation and recovery of valuable metals from spent lithium-ion batteries via concentrated sulfuric acid leaching and regeneration of LiNi1/3Co1/3Mn1/3O2. J. Alloys Compd. 2021, 863, 158775.

- Choi, J.W.; Cho, C.W.; Yun, Y.S. Organic acid-based linear free energy relationship models for green leaching of strategic metals from spent lithium-ion batteries and improvement of leaching performance. J. Hazard. Mater. 2022, 423, 127214.

- Sidiq, A.L.; Floweri, O.; Karunawan, J.; Abdillah, O.B.; Santosa, S.P.; Iskandar, F. NCM cathode active materials reproduced from end-of-life Li-ion batteries using a simple and green hydrometallurgical recycling process. Mater. Res. Bull. 2022, 153, 111901.

- Roy, J.J.; Srinivasan, M.; Cao, B. Bioleaching as an Eco-Friendly Approach for Metal Recovery from Spent NMC-Based Lithium-Ion Batteries at a High Pulp Density. ACS Sustain. Chem. Eng. 2021, 9, 3060–3069.

- Horeh, N.B.; Mousavi, S.M.; Shojaosadati, S.A. Bioleaching of valuable metals from spent lithium-ion mobile phone batteries using Aspergillus niger. J. Power Sources 2016, 320, 257–266.

- Xin, Y.; Guo, X.; Chen, S.; Wang, J.; Wu, F.; Xin, B. Bioleaching of valuable metals Li, Co, Ni and Mn from spent electric vehicle Li-ion batteries for the purpose of recovery. J. Clean. Prod. 2016, 116, 249–258.

- Roy, J.J.; Cao, B.; Madhavi, S. A review on the recycling of spent lithium-ion batteries (LIBs) by the bioleaching approach. Chemosphere 2021, 282, 130944.

- Ozdemir, M.E.; Ali, Z.; Subeshan, B.; Asmatulu, E. Applying machine learning approach in recycling. J. Mater. Cycles Waste Manag. 2021, 23, 855–871.

- Priyadarshini, J.; Elangovan, M.; Mahdal, M.; Jayasudha, M. Machine-Learning-Assisted Prediction of Maximum Metal Recovery from Spent Zinc–Manganese Batteries. Processes 2022, 10, 1034.

- Garg, A.; Yun, L.; Gao, L.; Putungan, D.B. Development of Recycling Strategy for Large Stacked Systems: Experimental and Machine Learning Approach to Form Reuse Battery Packs for Secondary Applications. J. Clean. Prod. 2020, 275, 124152.

- Zhou, Z.; Duan, B.; Kang, Y.; Shang, Y.; Cui, N.; Chang, L.; Zhang, C. An efficient screening method for retired lithium-ion batteries based on support vector machine. J. Clean. Prod. 2020, 67, 121882.

- Chen, H.; Shen, J. A degradation-based sorting method for lithium-ion battery reuse. PLoS ONE 2017, 12, e0185922.

- Senthilselvi, A.; Sellam, V.; Alahmari, S.A.; Rajeyyagari, S. Accuracy enhancement in mobile phone recycling process using machine learning technique and MEPH process. Environ. Technol. Innov. 2020, 20, 101137.