In the last two decades, food scientists (engineers) have attempted to develop new technologies that can improve the detection of insect infestation in fruits and vegetables under postharvest conditions using a multitude of non-destructive technologies. While consumers’ expectations for higher nutritive and sensorial value of fresh produce has increased over time, they have also become more critical on using insecticides or synthetic chemicals to preserve food quality from insects’ attacks or enhance the quality attributes of minimally processed fresh produce. In addition, the increasingly stringent quarantine measures by regulatory agencies for commercial import–export of fresh produce needs more reliable technologies for quickly detecting insect infestation in fruits and vegetables before their commercialization. For these reasons, the food industry investigates alternative and non-destructive means to improve food quality. Several studies have been conducted on the development of rapid, accurate, and reliable insect infestation monitoring systems to replace invasive and subjective methods that are often inefficient. There are still major limitations to the effective in-field, as well as postharvest on-line, monitoring applications. The future of non-destructive testing will be enhanced by the current trend in IoT, big data science, and machine learning analysis.

- Insect infestation

- Non-destructive testing

- Machine learning

- Fruits and Vegetables

- Hyperspectral imaging

1. Introduction or History

In recent years, there has been significant growth in the consumption of fruits and vegetables, which can be attributed to several factors, among which is increased awareness of their health benefits [1]. Consumers, especially the “Generation Z” (post-millennial with ages between 11 and 23 years) that constitute about 32% of the US population, are more cognizant of what they eat and many of them tend to eat healthy, often preferring organic foods [2]. The easy access to information through smart devices has also increased the understanding of consumers on what they eat, and many more people, beyond the younger generations, are tending toward more natural, minimally processed, and organic food. This demand is driving the trend for high-quality, consistent, and safe products at a reasonable price [3]. The agricultural production sector and the food industry as well as the safety agencies are saddled with the responsibility to meet these increasing demands for produce with low-toxicity pesticides. In order to be efficient in meeting quality and demand, there is a need to replace destructive and off-line conventional quality assessment methods with rapid, non-invasive, environmentally friendly, and accurate methods for quality assessment and safety assurance [4].

Insects cause enormous damage to fruits and vegetables each year, leading to major production and economic losses in the agricultural production and food industry worldwide. Insect pests are considered to be responsible for approximately 10–20% of yield losses in major crops worldwide, and even far more in developing countries, reaching about 50% of annual horticultural production in Africa, which is a $22.5 billion industry [5]. The havoc caused by insect pests in trans-border trade, with increased global trade network, is enormous. The detection of these insect pests before they get into the supply chain is still a major challenge for the industry. The US loses about $40 billion yearly because of these organisms of quarantine concern [6,7][6][7]. On the other hand, insect pests such as budworms are hard to control [8]. Insect feeding often cryptically occurs within fruits and vegetables without showing an obvious external symptom until they are nearly fully rotten. This is the case of the codling moth (Cydia pomonella, Lepidoptera: Tortricidae), one of the most devastating pests in apples. This insect has four main stages in its life cycle, egg, larva, pupa, and adult moth [9]. The larval phase is its most devastating phase when it feeds on the flesh and pulp of fruits it was laid on. When the point of entry is the calyx, the damage is difficult to detect with the subjective method of assessment common in most apple processing plants and this is why non-destructive detection becomes important [9,10][9][10]. Early detection when eggs are laid on the surface of the produce is also very important.

In order to prevent the economic and ecological losses from alien insect pests, increasingly stringent quarantine measures are being put in place by governments. As an example, Fruits and Vegetables Import Requirements (FAVIR) of the US government require preclearance of horticultural consignments in the exporting countries as well as inspections at the ports of arrival for any live larva or pupa of quarantine pests. In general, a biometrically designed statistical sampling is applied to conduct phytosanitary physical inspections against any quarantine-significant insect in fruits and vegetable commodities. In 2017, around 194 million pounds of fresh fruits and vegetables were inspected and cleared for shipment to the United States [11]. Based on the United States Department of Agriculture (USDA) report about the US plant inspection stations in 2017, the inspection of plant materials is mostly conducted physically, along with some modern technologies such as digital imaging, X-ray and molecular detection tools for low-volume plants, plant cuttings, and seeds. As a result, automatic, fast, and reliable noninvasive methods of detection are needed to monitor quarantine pest existence and the internal quality of the fruits and vegetables in high-volume shipments [12].

The rapid advancement in electronic technology and data analytics with greater computing power, along with their increased application in the agricultural field, have introduced new methods for non-destructive quality assessment of fruits and vegetables. A range of techniques have been reported for non-destructive detection of insect infestation such as near-infrared (NIR) spectroscopy [13,14,15,16][13][14][15][16], acoustic methods—sound/noise/vibration [17[17][18][19],18,19], imaging—visible light sensing [20], hyperspectral imaging [3[3][21],21], nuclear magnetic resonance [22], X-ray [23[23][24],24], volatile emission, and others [25,26,27,28][25][26][27][28]. With these new applications of technology in agricultural processing as well as the multiplicity of investigations all over the world, up-to-date reviews are needed as an orientation over technological applications in agriculture and food science. There are currently few reference papers reviewing some of the state-of-the-art works in non-destructive quality assessment of fruits and vegetables. Particularly, no review is available focusing on recent postharvest non-destructive methods for the detection of insect infestation in fruits and vegetables. Thus, this paper reviews all known techniques used for postharvest non-destructive detection of internal insect infestation in fruits and vegetables: their basic principles of operation are explained, the merits, as well as the limitations of each method are profiled, several examples of applications are presented, and challenges and opportunities for the future are discussed.

2. Applications and classification

2.1. Spectroscopic Techniques

Spectroscopy methods provide operational information about the chemical and physical characteristics of fruits and vegetables by obtaining reflectance, transmittance, absorbance, or scattering of polychromatic or monochromatic radiation from the surface of the sample in the ultraviolet (UV), visible (Vis), and NIR regions of the electromagnetic spectrum. But, the application of NIR region (780 to 2500 nm) is particularly compelling because it is sensitive to overtones and combinations of chemical bonds such as C–H, O–H, and N–H, which are abundantly present in foods. Moreover, NIR spectroscopy has the capacity of measuring multiple quality attributes of foods simultaneously [28]. Some researchers have proven the high potential of NIR spectroscopy for the detection of insects or insect damage in food commodities, such as blueberries [14], cherries [31][29], figs [32][30], green soybeans [33][31], jujubes [16], chestnuts [34][32], and other foods [25,26,27,35][25][26][27][33].

2.2. Visible Light Sensing

In the last four decades, machine vision systems have been extensively investigated to replace the human role in several agricultural applications, including sorting, detecting defects and diseases, and characterizing other quality attributes of agricultural products [38,39]. Visible light sensors at a wavelength from 380 to 750 nm falls in the range that is generally used for detecting external or surface features [8].

MIA: multivariate image analysis; BDA: Bayesian discriminant analysis; LDA: Linear discriminant analysis; ROSA: region-oriented segmentation algorithm; DF: discriminant function; RGB—Red, Green and Blue color spaces; NA—not applicable.

Table 1. Studies on detection of insect infestations in fruits and vegetables using visible color cameras.

2.3 Hyperspectral Imaging Systems

| Sensor Type | Crop | Insect Type | Machine Learning Technique | Classification Results | Reference |

|---|---|---|---|---|---|

| RGB camera | Citrus | Scale insect (Coccoidea) | MIA | 92.8% | [34] |

| RGB camera | Citrus | Thrips (Thysanoptera), Scales, and Medfly (Ceratitis capitata) egg | BDA | 73–86% | [35] |

| RGB camera | Citrus | Medfly | BDA | NA | [36] |

| RGB camera | Citrus | Thrips, Scales, and Medfly egg | ROSA | 93.4–100% | [37] |

| RGB camera | Citrus | Thrips, Scales, and Medfly egg | LDA | 43.2–78.1% | [38] |

| Line scan cameras | Pistachio | Insect damage | DF | 74–91.8% | [39] |

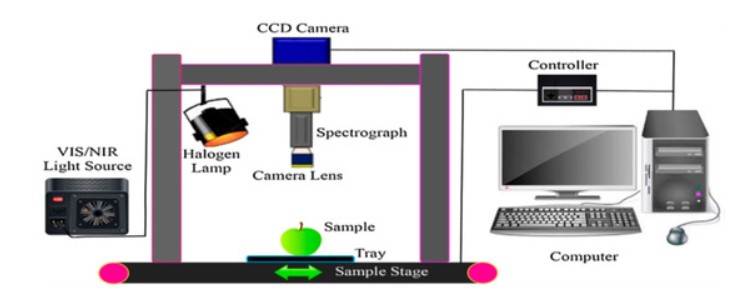

The hyperspectral imaging (HSI) technique is a relatively recent approach that is gaining extensive use in the agricultural production systems and food processing for noninvasive detection of properties and classification into quality categories. In the past decade and a half, it is among the most widely studied techniques for noninvasive monitoring of quality and ensuring the safety of fruits, vegetables, and food products [3,10,49,50,51,52,53]. The result of a sample scanning using the HSI system is a data cube (hypercube), where two (x and y) dimensions represent the spatial coordinates and the third dimension (λ) represents the wavelength coordinate [3]. The spectral responses can be related to the physical and chemical constituents of different agricultural products.

MIA: multivariate image analysis; BDA: Bayesian discriminant analysis; LDA: Linear discriminant analysis; ROSA: region-oriented segmentation algorithm; DF: discriminant function; RGB—Red, Green and Blue color spaces; NA—not applicable.

2.3. Hyperspectral Imaging Systems

2.4 X-ray Imaging

The hyperspectral imaging (HSI) technique is a relatively recent approach that is gaining extensive use in the agricultural production systems and food processing for noninvasive detection of properties and classification into quality categories. In the past decade and a half, it is among the most widely studied techniques for noninvasive monitoring of quality and ensuring the safety of fruits, vegetables, and food products [3][10][40][41][42][43][44]. The result of a sample scanning using the HSI system is a data cube (hypercube), where two (x and y) dimensions represent the spatial coordinates and the third dimension (λ) represents the wavelength coordinate [3]. The spectral responses can be related to the physical and chemical constituents of different agricultural products.

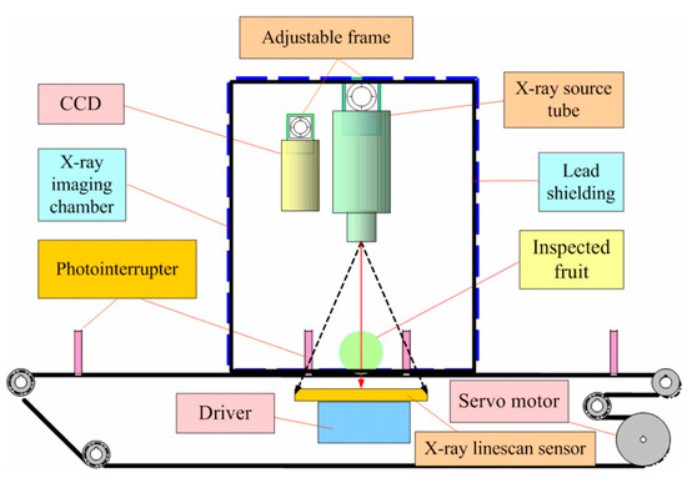

The principle of an X-ray imaging system is based on the transmission imaging technique in which an X-ray beam emitted from a source penetrates an object and attenuates based on the density variance of the object. The attenuated energy that passed through the object is detected using a photodetector, a film, or an ionization chamber on the other side. The attenuation coefficients of the object components lead to different contrast between such components [69,70,71]. Computed Tomography (CT) X-ray imaging is a more recent and advanced technique than plain X-ray technology. The latter technique solves the problem of having overlapping layers of soft tissues or complex bone structures [71]. The source and detector rotate around the object to generate an enormous number of 2-dimensional slices or images, which are used to create a 3-dimensional image called a tomogram [26,71].

2.4. X-ray Imaging

2.4. X-ray Imaging

The principle of an X-ray imaging system is based on the transmission imaging technique in which an X-ray beam emitted from a source penetrates an object and attenuates based on the density variance of the object. The attenuated energy that passed through the object is detected using a photodetector, a film, or an ionization chamber on the other side. The attenuation coefficients of the object components lead to different contrast between such components [45][46][47]. Computed Tomography (CT) X-ray imaging is a more recent and advanced technique than plain X-ray technology. The latter technique solves the problem of having overlapping layers of soft tissues or complex bone structures [47]. The source and detector rotate around the object to generate an enormous number of 2-dimensional slices or images, which are used to create a 3-dimensional image called a tomogram [26][47].

2.5 Magnetic Resonance Imaging (MRI)

2.5. Magnetic Resonance Imaging (MRI)

2.5. Magnetic Resonance Imaging (MRI)

MRI is a non-ionizing imaging technique in contrast to X-ray or computed tomography (CT) imaging and was first used for medical applications. The principle of MRI is such that a high-resolution image can be obtained by a strong and uniform magnetic field applied to hydrogen nuclei that are mainly located in water [71]. The image is formed as a result of the different levels of contrast of the object tissues as a response to a vigorous magnetic field and radio frequency waves. Applications of MRI in food quality monitoring is still considerably limited mainly due to the high cost of MRI systems. Torres [87] studied the application of a low-field MRI system to detect fruit fly in peaches, with classification rates of 58% and 71% for healthy and infested fruits, respectively. Haishi et al. [86] applied a low-field MRI using a 0.2 Teslaa or T magnet field to track the presence of peach fruit moth on apple fruits by analyzing multi-slice two-dimensional (2D) images. It was shown that the detection of larvae inside the fruit is feasible using a single slice gradient echo method in 6.4 s. Whereas, the multi-slice 2D measurement provided 6 images in 2 min, and these images covered a larger image area in a short time. Although MRI technology has a promising possibility for an effective noninvasive determination of fruits and vegetable defects, several problems still arise, especially when compared to other noninvasive systems such as color vision, hyperspectral and multispectral imaging, and spectroscopic systems. Such problems include the high cost for building, running, and maintenance, and the large volume and heavy weight of the MRI systems [86,90].

MRI is a non-ionizing imaging technique in contrast to X-ray or computed tomography (CT) imaging and was first used for medical applications. The principle of MRI is such that a high-resolution image can be obtained by a strong and uniform magnetic field applied to hydrogen nuclei that are mainly located in water [47]. The image is formed as a result of the different levels of contrast of the object tissues as a response to a vigorous magnetic field and radio frequency waves. Applications of MRI in food quality monitoring is still considerably limited mainly due to the high cost of MRI systems. Torres [48] studied the application of a low-field MRI system to detect fruit fly in peaches, with classification rates of 58% and 71% for healthy and infested fruits, respectively. Haishi et al. [49] applied a low-field MRI using a 0.2 Teslaa or T magnet field to track the presence of peach fruit moth on apple fruits by analyzing multi-slice two-dimensional (2D) images. It was shown that the detection of larvae inside the fruit is feasible using a single slice gradient echo method in 6.4 s. Whereas, the multi-slice 2D measurement provided 6 images in 2 min, and these images covered a larger image area in a short time. Although MRI technology has a promising possibility for an effective noninvasive determination of fruits and vegetable defects, several problems still arise, especially when compared to other noninvasive systems such as color vision, hyperspectral and multispectral imaging, and spectroscopic systems. Such problems include the high cost for building, running, and maintenance, and the large volume and heavy weight of the MRI systems [49][50].

2.6 Thermal Imaging

2.6. Thermal Imaging

Thermal imaging (TI) is a sensing technique that was first illustrated for military applications. Later, TI was extended to agriculture and food process monitoring [71]. A typical TI system consists of a thermal camera that has an infrared detector, a signal processing unit, and an image acquisition unit [91]. The main idea of forming a TI image is based on the difference in surface temperatures radiated by an object that is linked to the thermal energy values. Such values are translated to electrical pulses which are processed in the signal processing unit to form an image. The same image segmentation approach applied in X-ray imaging to localize the infested region of interest is applied to thermal imaging.

Thermal imaging (TI) is a sensing technique that was first illustrated for military applications. Later, TI was extended to agriculture and food process monitoring [47]. A typical TI system consists of a thermal camera that has an infrared detector, a signal processing unit, and an image acquisition unit [91]. The main idea of forming a TI image is based on the difference in surface temperatures radiated by an object that is linked to the thermal energy values. Such values are translated to electrical pulses which are processed in the signal processing unit to form an image. The same image segmentation approach applied in X-ray imaging to localize the infested region of interest is applied to thermal imaging.

3. Perspective

The significance of ineffective insect infestation detection in fruits and vegetables is broad. It lies in the reduction in the value of produce that may ensue when they enter the supply chain without detection and control, the economic losses when infestation causes a ban of produce export, spread or damage occurring to high-quality produce, and the safety issues related to consuming or processing infested produce. This paper reviewed different methods that have been explored in the last few years for non-destructive detection and classification of fruits and vegetables infested with different types of insect pests. Agricultural production is at a scale and stage where subjective assessment is insufficient to meet the scale of quality needed by the industry. The development of highly sensitive and accurate technologies for performing the role typically done by human subjects is essential for quick turnover to meet regulatory and consumer demands. Several of the technologies available have prospects and limitations. Some of the challenges include the high cost of implementation, sensitivity, accuracy, feedback time, and in some cases, safety. Techniques such as hyperspectral imaging, electronic nose, and acoustic emission are emerging as the sensors needed for artificial intelligent system deployment to address this need. HSI especially has been applied as the baseline technology in some other industries, and its potential for success in insect infestation prediction is promising, so long as the accuracy is guaranteed. A lot of these techniques require a machine learning computational approach for development and deployment. Advanced machine learning approaches like sensor data fusion and ensemble machine learning have allowed for combining the strengths of different approaches, and models for better results have shown the potential benefits of improving the models for quality assessment of fruits, vegetables, and food products [147]. Current improvement in the analytical approach of big data and feedback speed will benefit these methods and make them more amenable.

The significance of ineffective insect infestation detection in fruits and vegetables is broad. It lies in the reduction in the value of produce that may ensue when they enter the supply chain without detection and control, the economic losses when infestation causes a ban of produce export, spread or damage occurring to high-quality produce, and the safety issues related to consuming or processing infested produce. This paper reviewed different methods that have been explored in the last few years for non-destructive detection and classification of fruits and vegetables infested with different types of insect pests. Agricultural production is at a scale and stage where subjective assessment is insufficient to meet the scale of quality needed by the industry. The development of highly sensitive and accurate technologies for performing the role typically done by human subjects is essential for quick turnover to meet regulatory and consumer demands. Several of the technologies available have prospects and limitations. Some of the challenges include the high cost of implementation, sensitivity, accuracy, feedback time, and in some cases, safety. Techniques such as hyperspectral imaging, electronic nose, and acoustic emission are emerging as the sensors needed for artificial intelligent system deployment to address this need. HSI especially has been applied as the baseline technology in some other industries, and its potential for success in insect infestation prediction is promising, so long as the accuracy is guaranteed. A lot of these techniques require a machine learning computational approach for development and deployment. Advanced machine learning approaches like sensor data fusion and ensemble machine learning have allowed for combining the strengths of different approaches, and models for better results have shown the potential benefits of improving the models for quality assessment of fruits, vegetables, and food products [51]. Current improvement in the analytical approach of big data and feedback speed will benefit these methods and make them more amenable.

References

- Padayachee, A.; Day, L.; Howell, K.; Gidley, M.J. Complexity and health functionality of plant cell wall fibers from fruits and vegetables. J. Crit. Rev. Food Sci. 2017, 57, 59–81.

- Gherini, A. Gen-Z Is About to Outnumber Millennials. Here’s How That Will Affect the Business World. Available online: https://www.inc.com/anne-gherini/gen-z-is-about-to-outnumber-millennials-heres-how-that-will-affect-business-world.html (accessed on 22 August 2018).

- Lu, Y.; Huang, Y.; Lu, R. Innovative Hyperspectral Imaging-Based Techniques for Quality Evaluation of Fruits and Vegetables: A Review. Appl. Sci. 2017, 7, 189.

- Suktanarak, S.; Teerachaichayut, S. Non-destructive quality assessment of hens’ eggs using hyperspectral images. J. Food Eng. 2017, 215, 97–103.

- Badii, K.; Billah, M.; Afreh-Nuamah, K.; Obeng-Ofori, D.; Nyarko, G. Review of the pest status, economic impact and management of fruit-infesting flies (Diptera: Tephritidae) in Africa. Afr. J. Agric. Res. 2015, 10, 1488–1498.

- Pimentel, D.; Zuniga, R.; Morrison, D. Update on the environmental and economic costs associated with alien-invasive species in the United States. Ecol. Econ. 2005, 52, 273–288.

- Gulati, P.; Weier, S.A.; Santra, D.; Subbiah, J.; Rose, D.J. Effects of feed moisture and extruder screw speed and temperature on physical characteristics and antioxidant activity of extruded proso millet (P Anicum Miliaceum) flour. Int. J. Food Sci. 2016, 51, 114–122.

- Liu, H.; Lee, S.-H.; Chahl, J.S. A review of recent sensing technologies to detect invertebrates on crops. Precis. Agric. 2017, 18, 635–666.

- Greenwood, P. American Horticultural Society Pests & Diseases: Pests and Diseases; Dorling Kindersley: London, UK, 2000.

- Rady, A.; Ekramirad, N.; Adedeji, A.; Li, M.; Alimardani, R. Hyperspectral imaging for detection of codling moth infestation in GoldRush apples. Postharvest Biol. Technol. 2017, 129, 37–44.

- USDA Annual Report. Available online: https://www.aphis.usda.gov/publications/plant_health/report-ppq-2017.pdf (accessed on 10 May 2018).

- USDA Annual Report. Available online: https://www.aphis.usda.gov/publications/plant_health/report-ppq-2016.pdf (accessed on 10 March 2017).

- Moscetti, R.; Haff, R.P.; Stella, E.; Contini, M.; Monarca, D.; Cecchini, M.; Massantini, R. Feasibility of NIR spectroscopy to detect olive fruit infested by Bactrocera oleae. Postharvest Biol. Technol. 2015, 99, 58–62.

- Peshlov, B.N.; Dowell, F.E.; Drummond, F.A.; Donahue, D.W. Comparison of three near infrared spectrophotometers for infestation detection in wild blueberries using multivariate calibration models. J. Near Infrared Spectrosc. 2009, 17, 203–212.

- Saranwong, S.; Haff, R.P.; Thanapase, W.; Janhiran, A.; Kasemsumran, S.; Kawano, S. A feasibility study using simplified near infrared imaging to detect fruit fly larvae in intact fruit. J. Near Infrared Spectrosc. 2011, 19, 55–60.

- Wang, J.; Nakano, K.; Ohashi, S.; Takizawa, K.; He, J. Comparison of different modes of visible and near-infrared spectroscopy for detecting internal insect infestation in jujubes. J. Food Eng. 2010, 101, 78–84.

- Li, M.; Ekramirad, N.; Rady, A.M.; Adedeji, A. Application of Acoustic Emission and Machine Learning to Detect Codling Moth Infested Apples. Trans. ASABE (Am. Soc. Agric. Biol. Eng.) 2018, 61.

- Liljedahl, L.; Abbott, J. Changes in Sonic Resonance of ‘Delicious’ and ‘Golden Delicious’ Apples Undergoing Accelerated Ripening. Trans. ASAE 1994, 37, 907–912.

- Mankin, R.W.; Hagstrum, D.W.; Smith, M.T.; Roda, A.L.; Kairo, M.T.K. Perspective and Promise: A Century of Insect Acoustic Detection and Monitoring. Am. Entomol. 2011, 57, 30–44.

- Blasco, J.; Munera, S.; Aleixos, N.; Cubero, S.; Molto, E. Machine Vision-Based Measurement Systems for Fruit and Vegetable Quality Control in Postharvest. In Measurement, Modeling and Automation in Advanced Food Processing; Springer: Cham, Switzerland, 2017; pp. 71–91.

- Cen, H.; Lu, R.; Ariana, D.P.; Mendoza, F. Hyperspectral Imaging-Based Classification and Wavebands Selection for Internal Defect Detection of Pickling Cucumbers. Food Bioprocess Technol. 2013, 7, 1689–1700.

- Zhang, L.; McCarthy, M.J. Assessment of pomegranate postharvest quality using nuclear magnetic resonance. Postharvest Biol. Technol. 2013, 77, 59–66.

- Chuang, C.-L.; Ouyang, C.-S.; Lin, T.-T.; Yang, M.-M.; Yang, E.-C.; Huang, T.-W.; Kuei, C.-F.; Luke, A.; Jiang, J.-A. Automatic X-ray quarantine scanner and pest infestation detector for agricultural products. Computers 2011, 77, 41–59.

- Haff, R.P.; Toyofuku, N. X-ray detection of defects and contaminants in the food industry. Sens. Instrum. Food Qual. Saf. 2008, 2, 262–273.

- Burns, D.A.; Ciurczak, E.W. Handbook of Near-Infrared Analysis; CRC Press: Boca Raton, FL, USA, 2007.

- Nicolaï, B.M.; Defraeye, T.; De Ketelaere, B.; Herremans, E.; Hertog, M.L.; Saeys, W.; Torricelli, A.; Vandendriessche, T.; Verboven, P. Nondestructive measurement of fruit and vegetable quality. Annu. Rev. Food Sci. Technol. 2014, 5, 285–312.

- Rajendran, S. Detection of insect infestation in stored foods. Adv. Food Nutr. Res. 2005, 49, 163–232.

- Sun, D.-W. Hyperspectral Imaging for Food Quality Analysis and Control; Elsevier: Amsterdam, The Netherlands, 2010.

- Xing, J.; Guyer, D.; Ariana, D.; Lu, R. Determining optimal wavebands using genetic algorithm for detection of internal insect infestation in tart cherry. Sens. Instrum. Food Qual. Saf. 2008, 2, 161–167.

- Burks, C.; Dowell, F.; Xie, F. Measuring fig quality using near-infrared spectroscopy. J. Stored Prod. Res. 2000, 36, 289–296.

- Sirisomboon, P.; Hashimoto, Y.; Tanaka, M. Study on non-destructive evaluation methods for defect pods for green soybean processing by near-infrared spectroscopy. J. Food Eng. 2009, 93, 502–512.

- Moscetti, R.; Haff, R.P.; Saranwong, S.; Monarca, D.; Cecchini, M.; Massantini, R. Nondestructive detection of insect infested chestnuts based on NIR spectroscopy. Postharvest Biol. Technol. 2014, 87, 88–94.

- Singh, C.B.; Jayas, D.S.; Paliwal, J.; White, N.D. Identification of insect-damaged wheat kernels using short-wave near-infrared hyperspectral and digital colour imaging. Comput. Electron. Agric. 2010, 73, 118–125.

- López-García, F.; Andreu-García, G.; Blasco, J.; Aleixos, N.; Valiente, J.-M. Automatic detection of skin defects in citrus fruits using a multivariate image analysis approach. Comput. Electron. Agric. 2010, 71, 189–197.

- Blasco, J.; Aleixos, N.; Gómez-Sanchis, J.; Moltó, E. Recognition and classification of external skin damage in citrus fruits using multispectral data and morphological features. Biosyst. Eng. 2009, 103, 137–145.

- Blasco, J.; Cubero, S.; Moltó, E. Quality evaluation of citrus fruits. In Computer Vision Technology for Food Quality Evaluation; Elsevier: Amsterdam, The Netherlands, 2016; pp. 305–325.

- Blasco, J.; Aleixos, N.; Moltó, E. Computer vision detection of peel defects in citrus by means of a region oriented segmentation algorithm. J. Food Eng. 2007, 81, 535–543.

- Blasco, J.; Aleixos, N.; Gómez, J.; Moltó, E. Citrus sorting by identification of the most common defects using multispectral computer vision. J. Food Eng. 2007, 83, 384–393.

- Pearson, T.; Doster, M.; Michailides, T. Automated detection of pistachio defects by machine vision. Appl. Eng. Agric. 2001, 17, 729.

- Del Fiore, A.; Reverberi, M.; Ricelli, A.; Pinzari, F.; Serranti, S.; Fabbri, A.; Bonifazi, G.; Fanelli, C. Early detection of toxigenic fungi on maize by hyperspectral imaging analysis. Int. J. Food Microbiol. 2010, 144, 64–71.

- Ekramirad, N.; Adedeji, A.A.; Alimardani, R. A review of non-destructive methods for detection of insect infestation in fruits and vegetables. Innov. Food Res. 2016, 2, 6–12.

- Lorente, D.; Aleixos, N.; Gómez-Sanchís, J.; Cubero, S.; García-Navarrete, O.; Blasco, J. Recent Advances and Applications of Hyperspectral Imaging for Fruit and Vegetable Quality Assessment. Food Bioprocess Technol. 2011, 5, 1121–1142.

- Pu, Y.Y.; Feng, Y.Z.; Sun, D.W. Recent progress of hyperspectral imaging on quality and safety inspection of fruits and vegetables: A review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 176–188.

- Rady, A.; Adedeji, A. Assessing different processed meats for adulterants using visible-near-infrared spectroscopy. Meat Sci. 2018, 136, 59–67.

- Adedeji, A.A.; Ngadi, M.O. 3-D Imaging of Deep-Fat Fried Chicken Nuggets Breading Coating Using X-Ray Micro-CT. Food Process Eng. 2009, 5.

- Adedeji, A. Microstructural characterization of deep-fat fried breaded chicken nuggets using X-ray micro-computed tomography. Food Process Eng. 2011, 34.

- Ammari, H. An Introduction to Mathematics of Emerging Biomedical Imaging; Springer: Berlin/Heidelberg, Germany, 2008; Volume 62.

- Torres, M.T.R. Transmisión Optica e Imagen en Visible e Infrarrojo en Frutas. Ensayo de Equipos Comerciales. Ph.D. Thesis, Universidad Politécnica de Madrid, Madrid, Spain, 2008.

- Haishi, T.; Koizumi, H.; Arai, T.; Koizumi, M.; Kano, H. Rapid detection of infestation of apple fruits by the peach fruit moth, Carposina sasakii Matsumura, larvae using a 0.2-T dedicated magnetic resonance imaging apparatus. Appl. Magn. Reson. 2011, 41, 1.

- Torres, I.D.A. Estudio, Aplicación y Propuesta de Automatización del Procesamiento de Imágenes Por Resonancia Magnética Para la Evaluación y Detección de Defectos Internos de Calidad en Cítricos y Melocotones. Ph.D. Thesis, Universitat Politècnica de València, Valencia, Spain, 2006.

- Rady, A.; Giaretta, A.; Akinbode, A.; Ruwaya, M.; Dev, S. Pretreatment and freezing rate effect on physical, microstructural, and nutritional properties of fried sweet potato. Trans. ASABE 2019, 62, 45–59.