Miscanthus × giganteus, the giant miscanthus, is a sterile hybrid of Miscanthus sinensis and Miscanthus sacchariflorus. It is a perennial grass with bamboo-like stems that can grow to heights of more than 4 metres (13 ft) in one season (from the third season onwards). Just like Pennisetum purpureum, Arundo donax and Saccharum ravennae, it is also called elephant grass. Miscanthus × giganteus' perennial nature, its ability to grow on marginal land, its water efficiency, non-invasiveness, low fertilizer needs, significant carbon sequestration and high yield have sparked a lot of interest among researchers, with some arguing that it has "ideal" energy crop properties. Some argue that it can provide negative emissions, while others highlight its water cleaning and soil enhancing qualities. There are practical and economic challenges related to its use in the existing, fossil based combustion infrastructure, however. Torrefaction and other fuel upgrading techniques are being explored as countermeasures to this problem.

- perennial grass

- high yield

- economic challenges

1. Use Areas

Miscanthus × giganteus is mainly used as raw material for solid biofuels. It can be burned directly, or processed further into pellets or briquettes. It can also be used as raw material for liquid biofuels or biogas.

Alternatively, it is possible to use miscanthus as a building material, and as insulation.[1] Materials produced from miscanthus include fiberboards, composite miscanthus/wood particleboards, and blocks. It can be used as raw material for pulp and fibers as well as molded products such as eco-friendly disposable plates, cups, cartons, etc. Miscanthus has a pulp yield of 70–80% compared to dry weight, due to the high holocellulose content. The pulp can be processed further into methylcellulose and used as a food additive and in many industrial applications. Miscanthus fiber provides raw material for reinforcement of biocomposite or synthetic materials. In agriculture, miscanthus straw is used in soil mulching to retain soil moisture, inhibit weed growth, and prevent erosion. Further, miscanthus' high carbon to nitrogen ratio makes it inhospitable to many microbes, creating a clean bedding for poultry, cattle, pigs, horses, and companion animals. Miscanthus used as horse bedding can be combined with making organic fertilizer.[2] Miscanthus can be used as a healthy fiber source in pet food.[3]

2. Life Cycle

2.1. Propagation

Miscanthus × giganteus is propagated by cutting the rhizomes (its below-ground stems) into small pieces, and then re-planting those pieces 10 cm (4 in) below ground. One hectare (2.5 acres) of miscanthus rhizomes, cut into pieces, can be used to plant 10–30 hectares of new miscanthus fields (multiplication factor 10–30).[4] Rhizome propagation is a labor-intensive way of planting new crops, but only happens once during a crop's lifetime. New and cheaper propagation techniques is underway, which seem to increase the multiplication factor from 10–30 to 1000–2000.[5][6] A halving of the cost is predicted.[7]

2.2. Management

A limited amount of herbicide should only be applied at the beginning of the first two seasons; after the second year the dense canopy and the mulch formed by dead leaves effectively reduces weed growth.[8] Other pesticides are not needed.[9] Because of miscanthus' high nitrogen use efficiency,[10] fertilizer is also usually not needed.[11] Mulch film, on the other hand, helps both M. x giganteus and various seed based hybrids to grow faster and taller, with a larger number of stems per plant, effectively reducing the establishment phase from three years to two.[12] The reason seems to be that this plastic film keeps the humidity in the topsoil and increases the temperature.[13]

2.3. Yield

Miscanthus is close to the theoretical maximum efficiency at turning solar radiation into biomass,[14] and its water use efficiency is among the highest of any crop.[15] It has twice the water use efficiency of its fellow C4 plant maize, twice the efficiency as the C3 energy crop willow (Salix viminalis), and four times the efficiency as the C3 plant wheat.[16] This combined efficiency makes miscanthus fields energy dense. Since miscanthus has an energy content of 18 GJ per dry tonne, the typical UK dry yield (winter harvest) of 11–14 tonnes per hectare produce 200–250 gigajoules of energy per hectare per year in that particular region. This compares favorably to maize (98 GJ), oil seed rape (25 GJ), and wheat/sugar beet (7–15 GJ),[17] underlining the differences between first and second generation bioenergy crops. In the USA, M. x giganteus has been shown to yield two times more than switchgrass.[18]

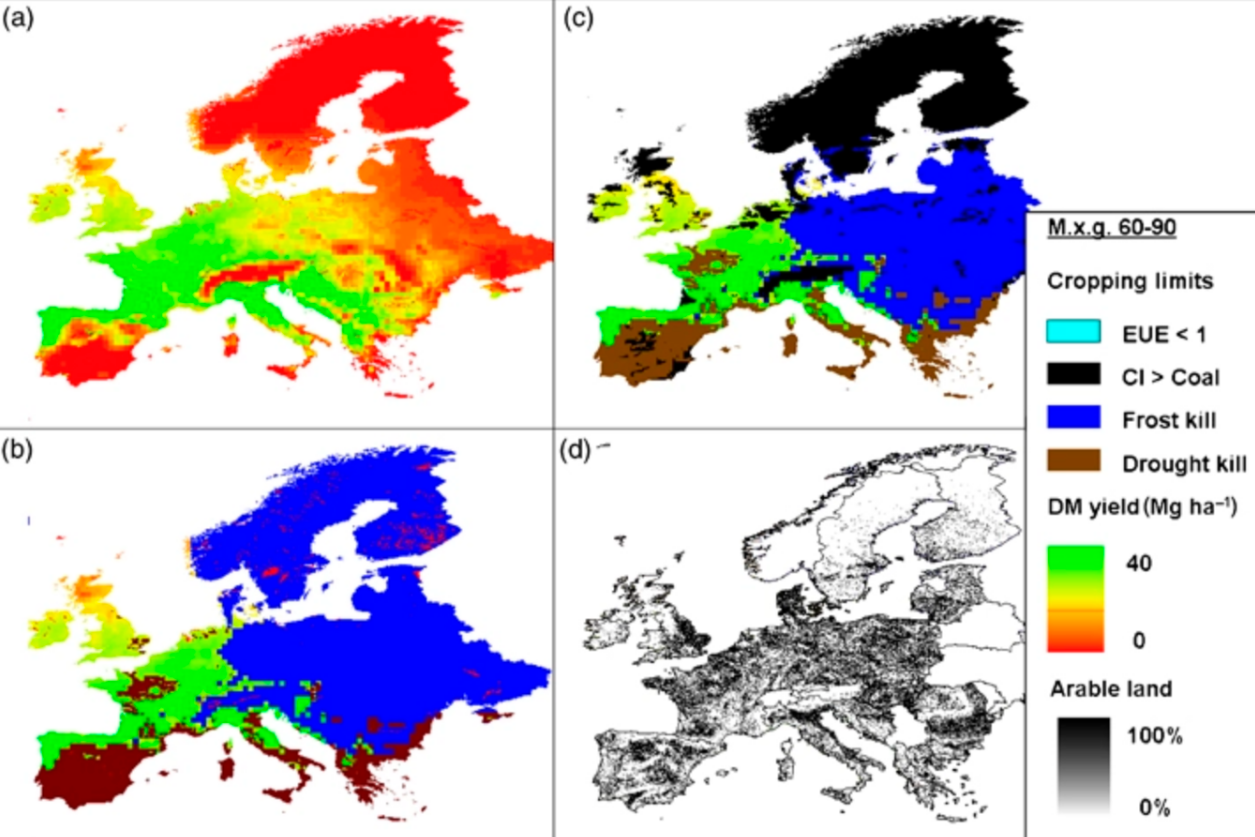

Hastings et al. note that "[f]ield trials have shown that for many locations in Europe M. x giganteus has the largest energy yield of all potential bioenergy crops in terms of net MJ ha −1 [megajoule per hectare], and the highest energy‐use efficiency (EUE), in terms of the energy cost of production, due to its relatively high yields and low inputs [...]".[19] The main competitors yield wise is willow and poplar, grown at short rotation coppice (SRC) or short rotation forestry (SRF) plantations. In the northern parts of Europe, willow and poplar approach and sometimes exceed miscanthus winter yields in the same location.[20] FAO (Food and Agriculture Organization of the United Nations) estimate that forest plantation yields range from 1 to 25 m3 "green" (non-dried) wood per hectare per year globally, equivalent to 0.4–12.2 dry tonnes per hectare per year. Russian pine have the lowest yield (0.4–2 tonnes, or 1–5 m3), while eucalyptus in Argentina, Brazil, Chile and Uruguay, and poplar in France/Italy, have the highest (7.8–12.2 tonnes for eucalyptus and 2.7–8.4 tonnes for poplar.)[21] For natural temperate mixed forests, Vaclav Smil estimates somewhat lower average sustainable yields (NAI: Net Annual Increment); 1.5–2 dry tonnes per hectare (2–2,5 m3 per hectare, ranging from 0.9 m3 in Greece to 6 m3 in France).[22]

The miscanthus peak yield is reached at the end of summer but harvest is typically delayed until winter or early spring. Yield is roughly 33% lower at this point because of leaves drop, but the combustion quality is higher. Delayed harvest also allows nitrogen to move back into the rhizome for use by the plant in the following growing season.[23]

In Europe the peak (autumn) dry mass yield has been measured to 10–40 tonnes per hectare per year (4–16 tonnes per acre per year), depending on location, with a mean peak dry mass yield of 22 tonnes.[24] Yields are highest in southern Europe; Roncucci et al. quote dry mass yields of 25–30 tonnes generally for that area under rainfed conditions. With irrigation, trials in Portugal yielded 36 tonnes, Italy 34–38 tonnes, and Greece 38–44 tonnes.[25] Trials in Illinois, USA, yielded 10–15 tonnes per acre (25–37 t/ha). Like in Europe, yields increase as you move south. In general, Vaclav Smil estimates roughly a doubling of net primary production (NPP) of biomass in the tropics compared to the temperate regions of the world.[26] For Micanthus x giganteus specifically, there are no scientific trials available yet regarding yields in the tropics, but other elephant grass types (different napier variants) have been shown to yield up to 80 tonnes per hectare,[27][28][29] and commercial napier grass developers advertise yields of around 100 dry tonnes per hectare per year, provided there is an adequate amount of rain or irrigation available (100 mm per month).[30][31]

Yield – arable land

File:Miscanthus Pflanzen und Ernte.ogv Felten et al. found a mean winter/spring yield of 15 tonnes per hectare per year (6.1 tonnes per acre per year) during a 16-year trial on arable land in Germany.[32] McCalmont et al. estimate a mean UK yield of 10–15 tonnes if harvested in the spring,[33] while Hastings et al. estimate a "pessimistic" UK mean yield of 10.5 tonnes.[34] Nsanganwimana et al. summarize several trials, and give these numbers:

- Austria: Autumn harvest 17–30. Winter harvest 22.

- Denmark: Autumn harvest 17. Winter harvest 10.

- Italy: Winter harvest 20–25.

- France: Autumn harvest 42–49. Winter harvest 30.

- Germany: Autumn harvest 17–30. Winter harvest 10–20.

- Portugal: Autumn harvest 39. Winter harvest 26–30.

- The Netherlands: Autumn harvest 25. Winter harvest 16–17.

- Spain: Winter harvest 14.

- UK: Winter harvest 11–17.[2]

Yield – marginal land

Marginal land is land with issues that limits growth, for instance low water and nutrient storage capacity, high salinity, toxic elements, poor texture, shallow soil depth, poor drainage, low fertility, or steep terrain. Depending on how the term is defined, between 1.1 and 6.7 billion hectares of marginal land exists in the world.[35] For comparison, Europe consists of roughly 1 billion hectares (10 million km2, or 3.9 million square miles), and Asia 4.5 billion hectares (45 million km2, or 17 million square miles).

Quinn et al. identified Miscanthus x giganteus as a crop that is moderately or highly tolerant of multiple environmental stressors, specifically, heat, drought, flooding, salinity (below 100 mM), and cool soil temperatures (down to −3.4 °C, or 25 °F).[36] This robustness makes it possible to establish relatively high-yielding miscanthus fields on marginal land, Nsanganwimana et al. mention wastelands, coastal areas, damp habitats, grasslands, abandoned milling sites, forest edges, streamsides, foothills and mountain slopes as viable locations.[37] Likewise, Stavridou et al. concluded that 99% of Europe's saline, marginal lands can be used for M. x giganteus plantations, with only an expected maximum yield loss of 11%.[38] Since salinity up to 200 mM does not affect roots and rhizomes, carbon sequestration carry on unaffected.[39] Lewandowski et al. found a yield loss of 36% on a marginal site limited by low temperatures (Moscow), compared to maximum yield on arable land in central Europe.

The authors also found a yield loss of 21% on a marginal site limited by drought (Turkey), compared to maximum yields on arable soil in central Europe.[40] Using yield prediction software Miscanfor, 30 days of soil dryness is the mean maximum amount of time a miscanthus crop can endure before wilting, while 60 days is the maximum before its rhizomes are killed and the crop has to be replanted.[41] In addition to adequate rainfall, soil water holding capacity is important for high yields, especially in dry periods—in fact Roncucci et al. reports approximately two times better yield for miscanthus planted in silty clay loam compared to sandy loam soil (Italy) after a relatively normal growing season precipitation wise, and approximately six times better yield after a growing season containing severe drought.[42] The authors note that in soils with poor water holding capacity, irrigation in the establishment season is important because it allows the roots to reach far deeper underground, thereby increasing the plants' ability to collect water.[43] Irrigation can also increase yield if applied during dry growing seasons (defined as 150–300 mm rainfall). The authors argue however that in soils with good water holding capacity, irrigation can potentially be avoided if rainfall exceeds 420 mm.[44] Stričević et al. make a similar point for crops in Serbia. The soil in this area is generally well wetted at the start of the growing season because of snow melt. If the roots go deep (2–3 m) and the soil has good water holding capacity, 300–400 mm rainfall during the season is enough for good yields (20–25 tonnes per hectare per year).[45] The authors note however that if there are no water constraints at all, that is, if the crops are irrigated, you can actually expect twice the yield (42 tonnes per hectare per year).[46]

Nsanganwimana et al. found that M. x giganteus grows well in soils contaminated by metals, or by industrial activities in general.[47] For instance, in one trial, it was found that M. x giganteus absorbed 52% of the lead content and 19% of the arsenic content in the soil after three months.[48] The absorption stabilizes the pollutants so they don't travel into the air (as dust), into ground water, neighbouring surface waters, or neighbouring areas used for food production.[49] If contaminated miscanthus is used as fuel, the combustion site need to install the appropriate equipment to handle this situation.[50] On the whole though, "[…] Miscanthus is [a] suitable crop for combining biomass production and ecological restoration of contaminated and marginal land."[51] Because of miscanthus' ability to be "[…] productive on lower grade agricultural land, including heavy metal contaminated and saline soils […]" Clifton-Brown et al. conclude that miscanthus can "[…] contribute to the sustainable intensification of agriculture, allowing farmers to diversify and provide biomass for an expanding market without compromising food security."[52]

Yield – comparison with other renewables

To calculate land use requirements for different kinds of energy production, it is essential to know the relevant area-specific power densities. Smil estimates that the average area-specific power densities for modern biofuels, wind, hydro and solar power production are 0.30 W/m2, 1 W/m2, 3 W/m2 and 5 W/m2, respectively (power in the form of heat for biofuels, and electricity for wind, hydro and solar).[53] The average human power consumption on ice-free land is 0.125 W/m2 (heat and electricity combined),[54] although rising to 20 W/m2 in urban and industrial areas.[55]

The reason for the low area-specific power density for biofuels is a combination of low yields and only partial utilization of the plant (for instance, ethanol is typically made from sugarcane's sugar content or corn's starch content, while biodiesel is often made from rapeseed and soybean's oil content).

Regarding ethanol production, Smil estimates that Miscanthus x giganteus fields generate 0.40 W/m2 when utilized for this purpose (yield 15 t/ha).[56] Corn fields generates 0.26 W/m2 (yield 10 t/ha).[57] In Brazil sugarcane fields typically generate 0.41 W/m2.[57] With the highest large-scale plantation yields in the industry (roughly 80 t/ha wet), sugarcane fields can generate 0.50 W/m2.[58] Winter wheat (USA) generates 0.08 W/m2 and German wheat generates 0.30 W/m2.[59] When grown for jet fuel, soybean generates 0.06 W/m2, while palm oil generates a healthier 0.65 W/m2.[58] Jathropa grown on marginal land generate 0.20 W/m2.[58] When grown for biodiesel, rapeseed generate 0.12 W/m2 (EU average).[60] In contrast to miscanthus cultivation and solid fuel production, typical liquid biofuel feedstocks and fuel production require large energy inputs. When these inputs are compensated for, power density drops further down: Rapeseed based biodiesel production in the Netherlands have the highest energy efficiency in the EU with an adjusted power density of 0.08 W/m2, while sugar beets based bioethanol produced in Spain have the lowest, at only 0.02 W/m2.[61]

Combusting solid biomass is more energy efficient than combusting liquids, as the whole plant is utilized. For instance, plantations producing solid biomass for combustion generate more than double the amount of power per square metre compared to corn fields producing for ethanol, when the yield is the same: 10 t/ha generates 0.60 W/m2 and 0.26 W/m2 respectively (without compensating for energy input).[62] For large-scale plantations with pines, acacias, poplars and willows in temperate regions, Smil estimates yields of 5–15 t/ha, equivalent to 0.30–0.90 W/m2.[63] For similarly large plantations, with eucalyptus, acacia, leucaena, pinus and dalbergia in tropical and subtropical regions, his estimate is 20–25 t/ha, equivalent to 1.20–1.50 W/m2 (a somewhat higher yield estimate than the FAO estimate above, and a yield that put these plantations' area-specific power densities inbetween the densities of wind and hydro).[63] In Brazil, the average yield for eucalyptus is 21 t/ha, but in Africa, India and Southeast Asia, typical eucalyptus yields are below 10 t/ha.[64]

Oven dry biomass in general, including wood, miscanthus[65] and napier[66] grass, have a calorific content of roughly 18 GJ/t.[67] When calculating power production per square metre, every t/ha of dry biomass yield increases a plantation's power production by 0.06 W/m2.[68] As mentioned above, Smil estimates that the world average for wind, hydro and solar power production is 1 W/m2, 3 W/m2 and 5 W/m2 respectively. In order to match these power densities, plantation yields must reach 17 t/ha, 50 t/ha and 83 t/ha for wind, hydro and solar respectively. This seems achievable based on the yield data in the preceding sections. To match the world average for biofuels (0.3 W/m2), plantations need only to produce 5 tonnes of dry mass per hectare per year.

Note however that yields need to be adjusted to compensate for the amount of moisture in the biomass (evaporating moisture in order to reach the ignition point is usually wasted energy). The moisture of biomass straw or bales varies with the surrounding air humidity and eventual pre-drying measures, while pellets have a standardized (ISO-defined) moisture content of below 10% (wood pellets)[69] and below 15% (other pellets).[70] Likewise, for wind, hydro and solar, power line transmission losses amounts to roughly 8% globally and should be accounted for.[71] If biomass is to be utilized for electricity production rather than heat production, note that yields has to be roughly tripled in order to compete with wind, hydro and solar, as the current heat to electricity conversion efficiency is only 30-40%.[72] When simply comparing area-specific power density without regard for cost, this low heat to electricity conversion efficiency effectively pushes at least solar parks out of reach of even the highest yielding biomass plantations, power density wise.[73]

2.4. Carbon Sequestration

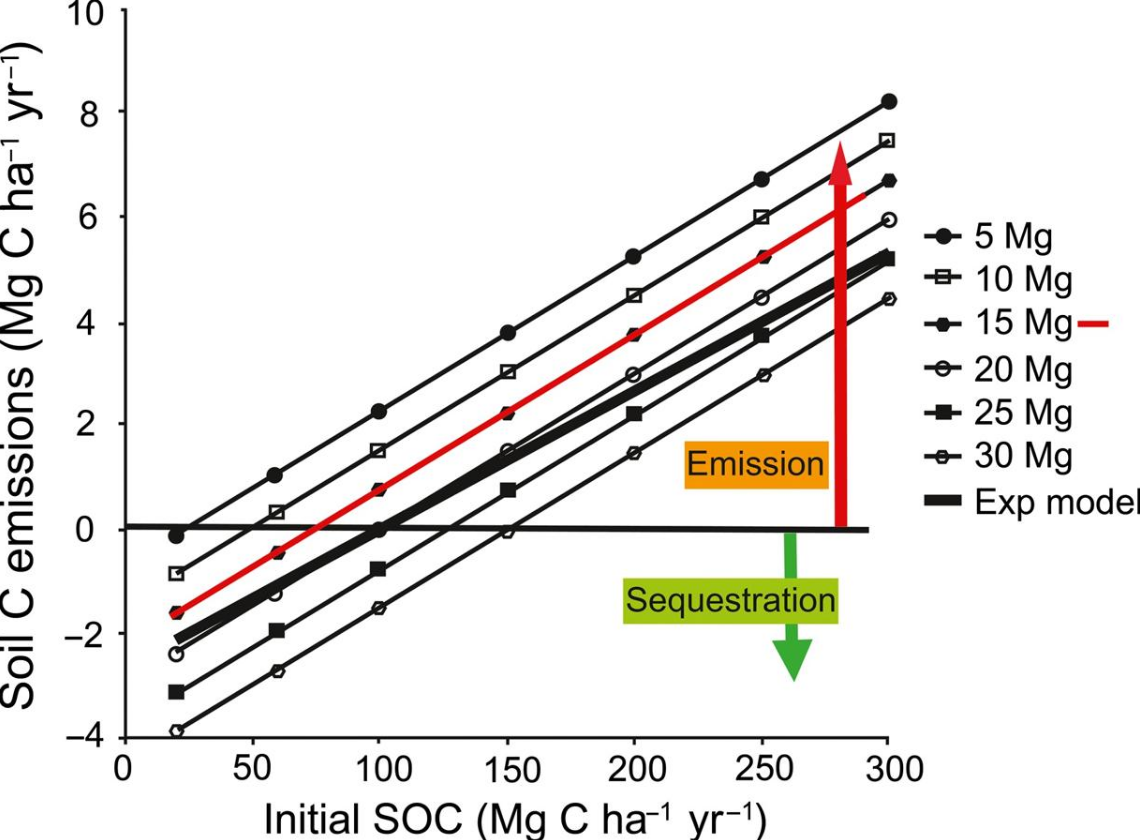

Soil carbon input/output

Plants sequester carbon through photosynthesis, a sunlight-driven process where CO2 and water are absorbed and then combined to form carbohydrates. The absorbed carbon is released back to the atmosphere as CO2 when the harvested biomass is combusted, but the belowground parts of the plant (roots and rhizomes) remain in the soil and can potentially add substantial amounts of carbon to the soil over the years. Belowground carbon does not stay below ground forever however; "[…] soil carbon is a balance between the decay of the initial soil carbon and the rate of input […]."[74][75] Plant derived soil carbon is a continuum, ranging from living biomass to humus,[76] and it decays in different stages, ranging from months (decomposable plant material; DPM) to hundreds of years (humus). The rate of decay depends on many factors, for instance plant species, soil, temperature and humidity,[77] but as long as fresh new carbon is input, a certain amount of carbon stays in the ground—in fact Poeplau et al. did not find any "[…] indication of decreasing SOC [soil organic carbon ] accumulation with age of the plantation indicating no SOC saturation within 15–20 years."[78] Harris et al. estimate 30–50 years of SOC change following a land use change between annual and perennial crops before a new SOC equilibrium is reached.[79] The amount of carbon in the ground under miscanthus fields is thus seen to increase during the entire life of the crop, albeit with a slow start because of the initial tilling (plowing, digging) and the relatively low amounts of carbon input in the establishment phase.[80][81] (Tilling induces soil aeration, which stimulates the soil microbe populations to decompose the available carbon, producing CO2.[82]) Felten et al. argue that high proportions of pre- and direct-harvest residues (e.g. dead leaves), direct humus accumulation, the well-developed and deep-reaching root system, the low decomposition rates of plant residues due to a high C:N ratio (carbon to nitrogen ratio), and the absence of tillage and subsequently less soil aeration are the reasons for the high carbon sequestration rates.[83]

Net annual carbon accumulation

A number of studies try to quantify the net amount of miscanthus-induced below-ground carbon accumulation each year, after decay is accounted for, in various locations and under various circumstances.

Dondini et al. found 32 tonnes more carbon per hectare (13 tonnes per acre) under a 14 year old miscanthus field than in the control site, suggesting a combined (C3 plus C4) mean carbon accumulation rate of 2.29 tonnes per hectare per year (1 tonne per acre per year), or 38% of total harvested carbon per year.[84] Likewise, Milner et al. suggest a mean carbon accumulation rate for the whole of the UK of 2.28 tonnes per hectare per year (also 38% of total harvested carbon per year), given that some unprofitable land (0.4% of total) is excluded.[85] Nakajima et al. found an accumulation rate of 1.96 (± 0.82) tonnes per hectare per year below a university test site in Sapporo, Japan (0.79 per acre), equivalent to 16% of total harvested carbon per year. The test was shorter though, only 6 years.[86] Hansen et al. found an accumulation rate of 0.97 tonne per hectare per year (0.39 tonnes per acre per year) over 16 years under a test site in Hornum, Denmark, equivalent to 28% of total harvested carbon per year.[87] McCalmont et al. compared a number of individual European reports, and found accumulation rates ranging from 0.42 to 3.8 tonnes per hectare per year,[88] with a mean accumulation rate of 1.84 tonne (0.74 tonnes per acre per year),[89] or 25% of total harvested carbon per year.[90]

2.5. Transport and Combustion Challenges

Overview

Biomass in general, including miscanthus, have different properties compared to coal, for instance when it comes to handling and transport, grinding, and combustion.[92] This makes sharing the same logistics, grinding and combustion infrastructure difficult. Often new biomass handling facilities have to be built instead, which increases cost.[93] Together with the relatively high cost of feedstock, this often leads to the well-known situation where biomass projects have to receive subsidies to be economically viable.[94] A number of fuel upgrading technologies are currently being explored, however, that make biomass more compatible with the existing infrastructure. The most mature of these is torrefaction, basically an advanced roasting technique which—when combined with pelleting or briquetting—significantly influences handling and transport properties, grindability and combustion efficiency.

Energy density and transport costs

Miscanthus chips have a bulk density of only 50–130 kg/m3,[95] bales 120–160 kg/m3,[96] while pellets and briquettes have a bulk density of 500 and 600 kg/m3 respectively.[97] Torrefaction works hand in hand with this trend towards a denser and therefore cheaper to transport product, specifically by increasing the product’s energy density. Torrefaction removes (by gasification) the parts of the biomass that has the lowest energy content, while the parts with the highest energy content remain. That is, approximately 30% of the biomass is converted to gas during the torrefaction process (and potentially used to power the process), while 70% remains, usually in the form of compacted pellets or briquettes. This solid product contains approximately 85% of the original biomass energy however.[98] Basically the mass part has shrunk more than the energy part, and the consequence is that the calorific value of torrefied biomass increases significantly, to the extent that it can compete with energy dense coals used for electricity generation (steam/thermal coals). Vaclav Smil states that the energy density of the most common steam coals today is 22–26 GJ/t.[99]

The higher energy density means lower transport costs, and a decrease in transport-related GHG emittance.[100] The IEA (International Energy Agency) has calculated energy and GHG costs for regular and torrefied pellets/briquettes. When making pellets and shipping them from Indonesia to Japan, a minimum of 6.7% energy savings or 14% GHG savings is expected when switching from regular to torrefied. This number increases to 10.3% energy savings and 33% GHG savings when making and shipping minimum 50mm briquettes instead of pellets (briquette production requires less energy).[101] The longer the route, the bigger the savings. The relatively short supply route from Russia to the UK equals energy savings of 1.8%, while the longer supply route from southeast USA to the Amsterdam-Rotterdam-Antwerp (ARA) area is 7.1%. From southwest Canada to ARA 10.6%, southwest USA to Japan 11%, and Brazil to Japan 11.7% (all these savings are for pellets only.)[102]

Water absorption and transport costs

Torrefaction also converts the biomass from a hydrophilic (water absorbing) to a hydrophobic (water repelling) state. Water repelling briquettes can be transported and stored outside, which simplifies the logistics operation and decreases cost.[103] All biological activity is stopped, reducing the risk of fire and stopping biological decomposition like rotting.[100]

Uniformity and customization

Generally, torrefaction is seen as a gateway for converting a range of very diverse feedstocks into a uniform and therefore easier to deal with fuel.[100] The fuel's parameters can be changed to meet customers demands, for instance type of feedstock, torrefaction degree, geometrical form, durability, water resistance, and ash composition.[104] The possibility to use different types of feedstock improves the fuel's availability and supply reliability.[100]

Grindability

Unprocessed M. x giganteus has strong fibers, making grinding into equally sized, very small particles (below 75 µm / 0.075 mm) difficult to achieve. Coal chunks are typically ground to that size because such small, even particles combust stabler and more efficient.[105][106] While coal has a score on the Hardgrove Grindability Index (HGI) of 30–100 (higher numbers mean it is easier to grind), unprocessed miscanthus has a score of 0.[107] During torrefaction however, "[…] the hemi-cellulose fraction which is responsible for the fibrous nature of biomass is degraded, thereby improving its grindability."[108] Bridgeman et al. measured a HGI of 79 for torrefied miscanthus,[109] while the IEA estimates a HGI of 23–53 for torrefied biomass in general.[110] UK coal scores between 40 and 60 on the HGI scale.[111] The IEA estimates an 80–90% drop in energy use required to grind biomass that has been torrefied.[112]

The relatively easy grinding of torrefied miscanthus makes a cost-effective conversion to fine particles possible, which subsequently makes efficient combustion with a stable flame possible. Ndibe et al. found that the level of unburnt carbon "[…] decreased with the introduction of torrefied biomass", and that the torrefied biomass flames "[…] were stable during 50% cofiring and for the 100% case as a result of sufficient fuel particle fineness."[113]

Chlorine and corrosion

Raw miscanthus biomass has a relatively high chlorine amount, which is problematic in a combustion scenario because, as Ren et al. explains, the "[…] likelihood of corrosion depends significantly on the content of chlorine in the fuel […]."[114] Likewise, Johansen et al. state that "[…] the release of Cl-associated [chlorine-associated] species during combustion is the main cause of the induced active corrosion in the grate combustion of biomass."[115] Chlorine in different forms, in particular combined with potassium as potassium chloride, condensates on relatively cooler surfaces inside the boiler and creates a corrosive deposit layer. The corrosion damages the boiler, and in addition the physical deposit layer itself reduce heat transfer efficiency, most critically inside the heat exchange mechanism.[116] Chlorine and potassium also lowers the ash melting point considerably compared to coal. Melted ash, known as slag or clinker, sticks to the bottom of the boiler, and increase maintenance costs.[117][118]

In order to reduce chlorine (and moisture) content, M. x giganteus is usually harvested dry, in early spring, but this late harvest practice is still not enough of a countermeasure to achieve corrosion-free combustion.[119]

However, the chlorine amount in miscanthus reduces by approximately 95% when it is torrefied at 350 degrees Celsius.[120] Chlorine release during the torrefaction process itself is more manageable than chlorine release during combustion, because "[…] the prevailing temperatures during the former process are below the melting and vaporization temperatures of the alkali salts of chlorine, thus minimizing their risks of slagging, fouling and corrosion in furnaces."[121]

For potassium, Kambo et al. found a 30% reduction for torrefied miscanthus.[122] However, potassium is dependent on chlorine to form potassium chloride; with a low level of chlorine, the potassium chloride deposits reduce proportionally.[123]

Conclusion

Li et al. conclude that the "[…] process of torrefaction transforms the chemical and physical properties of raw biomass into those similar to coal, which enables utilization with high substitution ratios of biomass in existing coal-fired boilers without any major modifications."[124] Likewise, Bridgeman et al. state that since torrefaction removes moisture, creates a grindable, hydrophobic and solid product with an increased energy density, torrefied fuel no longer requires "[…] separate handling facilities when co-fired with coal in existing power stations."[92] Smith et al. makes a similar point in regard to hydrothermal carbonization, sometimes called "wet" torrefaction.[125]

Ribeiro et al. note that "[…] torrefaction is a more complex process than initially anticipated" and state that "[…] torrefaction of biomass is still an experimental technology […]."[126] Michael Wild, president of the International Biomass Torrefaction Council, stated in 2015 that the torrefaction sector is "[…] in its optimisation phase […]", i.e. it is maturing. He mentions process integration, energy and mass efficiency, mechanical compression and product quality as the variables most important to master at this point in the sector's development.[104]

3. Environmental Impacts

3.1. GHG Savings

Yield and soil carbon content

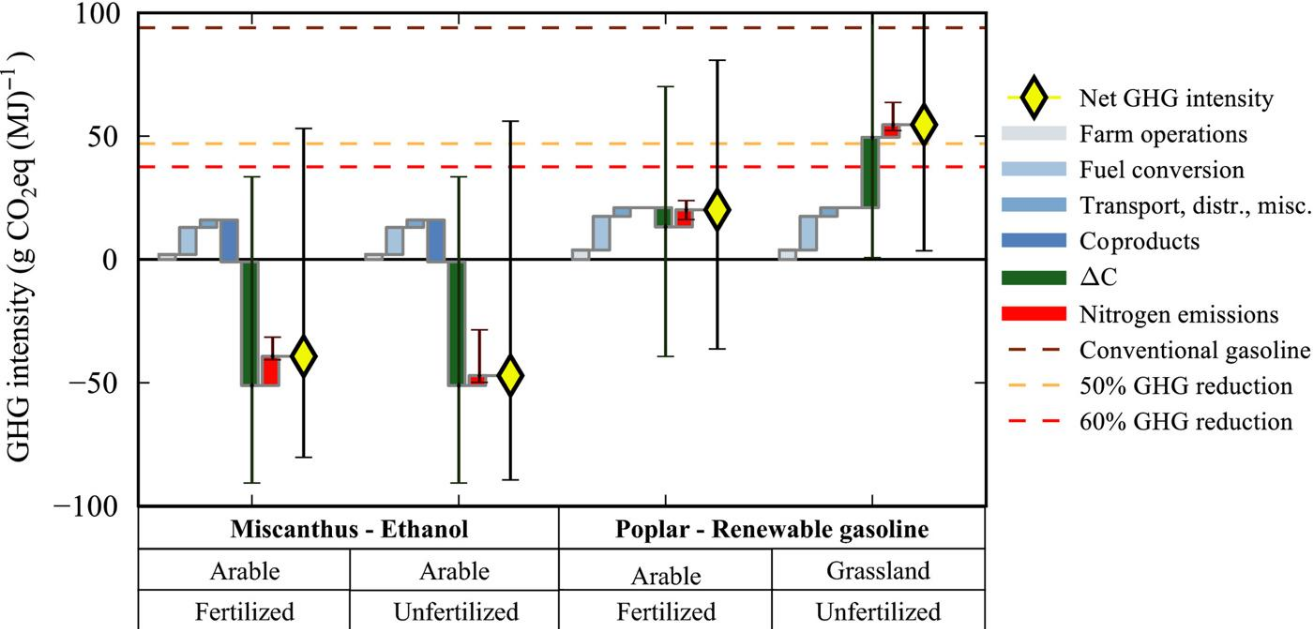

The amount of carbon sequestrated and the amount of GHG (greenhouse gases) emitted determine if the total GHG life cycle cost of a bio-energy project is positive, neutral or negative. Specifically, a GHG/carbon negative life cycle is possible if the total below-ground carbon accumulation more than compensates for the above-ground total life-cycle GHG emissions. Whitaker et al. estimate that for Miscanthus x giganteus carbon neutrality and even negativity is within reach. The authors argue that a miscanthus crop with a yield of 10 tonnes per hectare per year sequesters so much carbon that the crop more than compensates for both farm operations emissions and transport emissions. The chart on the right displays two CO2 negative miscanthus production pathways, represented in gram CO2-equivalents per megajoule. The green bars represents soil carbon change, the yellow diamonds represent mean values.[127]

Emmerling et al. make the same point for miscanthus in Germany (yield 15 t/ha/yr, carbon sequestration 1.1 t/ha/yr): "Miscanthus is one of the very few crops worldwide that reaches true CO2 neutrality and may function as a CO2 sink. [...] Related to the combustion of fuel oil, the direct and indirect greenhouse gas emissions can be reduced by a minimum of 96% through the combustion of Miscanthus straw (emissions: 0.08 kg CO2‐eq MJ−1 (fuel oil) vs. 0.0032 kg CO2‐eq MJ−1 (Miscanthus straw)). Due to the C‐sequestration during Miscanthus growth, this results in a CO2‐eq mitigation potential of 117%".[128]

One should note that successful sequestration is dependent on planting sites, as the best soils for sequestration are those that are currently low in carbon. The varied results displayed in the chart highlights this fact.[129] Milner et al. argue that for the UK, successful sequestration is expected for arable land over most of England and Wales, with unsuccessful sequestration expected in parts of Scotland, due to already carbon rich soils (existing woodland). Also, for Scotland, the relatively lower yields in this colder climate makes CO2 negativity harder to achieve. Soils already rich in carbon include peatland and mature forest. Milner et al. further argue that the most successful carbon sequestration in the UK takes place below improved grassland.[130] However, Harris et al. notes that since the carbon content of grasslands vary considerably, so does the success rate of land use changes from grasslands to perennial.[131] The bottom graphic displays the estimated yield necessary to achieve CO2 negativity for different levels of existing soil carbon saturation.

The perennial rather than annual nature of miscanthus crops implies that the significant below-ground carbon accumulation each year is allowed to continue undisturbed. No annual plowing or digging means no increased carbon oxidation and no stimulation of the microbe populations in the soil, and therefore no accelerated carbon-to-CO2 conversion happening in the soil every spring.

Savings comparison

Fundamentally, the below-ground carbon accumulation works as a GHG mitigation tool because it removes carbon from the above-ground carbon circulation (the circulation from plant to atmosphere and back into plant.) The above-ground circulation is driven by photosynthesis and combustion—first, the miscanthus fields absorb CO2 and assimilates it as carbon in its tissue both above and below ground. When the above-ground carbon is harvested and then burned, the CO2 molecule is formed yet again and released back into the atmosphere. However, an equivalent amount of CO2 (and possibly more, if the biomass is expanding) is absorbed back by next season's growth, and the cycle repeats. This above-ground cycle has the potential to be carbon neutral, but of course the human involvement in operating and guiding the above-ground CO2 circulation means additional energy input, often coming from fossil sources. If the fossil energy spent on the operation is high compared to the amount of produced energy, the total CO2 footprint (CO2 emissions from operation plus plant burning, minus carbon sequestration) can approach, match or even exceed the CO2 footprint originating from burning fossil fuels exclusively, as has been shown to be the case for several first-generation biofuel projects.[132][133][134] Transport fuels might be worse than solid fuels in this regard.[135]

The problem can be dealt with both from the perspective of increasing the amount of carbon that is moved below ground (see Carbon sequestration, above), and from the perspective of decreasing fossil fuel input to the above-ground operation. If enough carbon is moved below ground, it can compensate for the total lifecycle emissions of a particular biofuel. Further, if the above-ground emissions decreases, less below-ground carbon storage is needed for the biofuel to become CO2 neutral or negative. To sum up, a GHG negative life cycle is possible if the below-ground carbon accumulation more than compensates for the above-ground lifecycle GHG emissions.

For first generation bio-energy crops, the greenhouse gas footprints were often large, but second generation bio-energy crops like miscanthus reduces its CO2 footprint drastically. Hastings et al. found that miscanthus crops "[…] almost always has a smaller environmental footprint than first generation annual bioenergy ones [...]."[136] A large meta-study of 138 individual studies, done by Harris et al., revealed that second generation perennial grasses (miscanthus and switchgrass) planted on arable land on average store five times more carbon in the ground than short rotation coppice or short rotation forestry plantations (poplar and willow).[137] Compared to fossil fuels, the GHG savings are large—even without considering carbon sequestration, miscanthus fuel has a GHG cost of 0.4–1.6 grams CO2-equivalents per megajoule, compared to 33 grams for coal, 22 for liquefied natural gas, 16 for North Sea gas, and 4 for wood chips imported to Britain from the USA.[138]

Confirming the above numbers, McCalmont et al. found that the mean energy input/output ratios for miscanthus is 10 times better than for annual crops, while GHG costs are 20-30 times better than for fossil fuels.[139] For instance, miscanthus chips for heating saved 22.3 tonnes of CO2 emissions per hectare per year in the UK (9 tonnes per acre), while maize for heating and power saved 6.3 (2.5 per acre). Rapeseed for biodiesel saved only 3.2 (1.3 per acre).[140] Lewandowski et al. found that each hectare (2.47 acres) of Central European arable land planted with miscanthus can reduce the atmospheric CO2 level with up to 30.6 tonnes per year, save 429 GJ of fossil energy used each year, with 78 euros earned per tonne reduced CO2 (2387 euros earned per hectare per year)—given that the biomass is produced and used locally (within 500 km / 310 miles).[141] For miscanthus planted on marginal land limited by cold temperatures (Moscow), the reduction in atmospheric CO2 is estimated to be 19.2 tonnes per hectare per year (7.7 tonnes per acre), with fossil energy savings of 273 GJ per hectare per year (110 GJ per acre). For marginal land limited by drought (Turkey), the atmospheric CO2 level can potentially be reduced with 24 tonnes per hectare per year (9.7 tonnes per acre), with fossil energy savings of 338 GJ per hectare per year (137 tonnes per acre).[142] Based on similar numbers, Poeplau and Don expect miscanthus plantations to grow large in Europe in the coming decades.[143] Whitaker et al. state that after some discussion, there is now (2018) consensus in the scientific community that "[…] the GHG balance of perennial bioenergy crop cultivation will often be favourable […]", also when considering the implicit direct and indirect land use changes.[144]

3.2. Biodiversity

Below ground, Felten and Emmerling found that the number of earthworm species per square meter was 5.1 for miscanthus, 3 for maize, and 6.4 for fallow (totally unattended land), and state that "[…] it was clearly found that land-use intensity was the dominant regressor for earthworm abundance and total number of species." Because the extensive leaf litter on the ground helps the soil to stay moist, and also protect from predators, they conclude that "[…] Miscanthus had quite positive effects on earthworm communities […]" and recommend that "[…] Miscanthus may facilitate a diverse earthworm community even in intensive agricultural landscapes."[145][146]

Nsanganwimana et al. found that the bacterial activity of certain bacteria belonging to the proteobacteria group almost doubles in the presence of M. x giganteus root exudates.[48]

Above ground, Lewandowski et al. found that young miscanthus stands sustain high plant species diversity, but as the miscanthus stands mature, the canopy closes, and less sunlight reach the competing weeds. In this situation it gets harder for the weeds to survive. After canopy closure, Lewandowski et al. found 16 different weed species per 25 m2 plot. The dense canopy works as protection for other life-forms though; Lewandowski et al. notes that "[…] Miscanthus stands are usually reported to support farm biodiversity, providing habitat for birds, insects, and small mammals […]."[147] Supporting this view, Caslin et al. argue that the flora below the canopy provides food for butterflies, other insects and their predators, and 40 species of birds.[148]

Both Haughton et al.[149] and Bellamy et al. found that the miscanthus overwinter vegetative structure provided an important cover and habitat resource, with high levels of diversity in comparison with annual crops. This effect was particularly evident for beetles, flies, and birds, with breeding skylarks and lapwings being recorded in the crop itself. The miscanthus crop offers a different ecological niche for each season—the authors attribute this to the continually evolving structural heterogeneity of a miscanthus crop, with different species finding shelter at different times during its development—woodland birds found shelter in the winter and farmland birds in the summer. For birds, 0.92 breeding pairs species per hectare (0.37 per acre) was found in the miscanthus field, compared to 0.28 (0.11) in the wheat field. The authors note that due to the high carbon to nitrogen ratio, it is in the field's margins and interspersed woodlands that the majority of the food resources are to be found. Miscanthus fields work as barriers against chemical leaching into these key habitats however.[150]

Caslin et al. further argue that miscanthus crops provides better biodiversity than cereal crops, with three times as many spiders and earthworms as cereal.[151] Brown hare, stoat, mice, vole, shrew, fox and rabbit are some of the species that are observed in miscanthus crops. The crop act as both a nesting habitat and a wildlife corridor connecting different habitats.[152]

3.3. Water Quality

McCalmont et al. claim that miscanthus fields leads to significantly improved water quality because of significantly less nitrate leaching.[153] Likewise, Whitaker et al. claim that there is drastically reduced nitrate leaching from miscanthus fields compared to the typical maize/soy rotation because of low or zero fertilizer requirements, the continuous presence of a plant root sink for nitrogen, and the efficient internal recycling of nutrients by perennial grass species. For instance, a recent meta-study concluded that miscanthus had nine times less subsurface loss of nitrate compared to maize or maize grown in rotation with soya bean.[154]

3.4. Soil Quality

The fibrous, extensive miscanthus rooting system and the lack of tillage disturbance improves infiltration, hydraulic conductivity and water storage compared to annual row crops, and results in the porous and low bulk density soil typical under perennial grasses, with water holding capabilities expected to increase by 100–150 mm.[155] Nsanganwimana et al. argue that miscanthus improves carbon input to the soil, and promote microorganism activity and diversity, which are important for soil particle aggregation and rehabilitation processes. On a former fly ash deposit site, with alkaline pH, nutrient deficiency, and little water-holding capacity, a miscanthus crop was successfully established—in the sense that the roots and rhizomes grew quite well, supporting and enhancing nitrification processes, although the above-ground dry weight yield was low because of the conditions. The authors argue that M. x giganteus' ability to improve soil quality even on contaminated land is a useful feature especially in a situation where organic amendments can be added. For instance, there is a great potential to increase yield on contaminated marginal land low in nutrients by fertilizing it with nutrient-rich sewage sludge or wastewater. The authors claim that this practice offer the three-fold advantage of improving soil productivity, increasing biomass yields, and reducing costs for treatment and disposal of sewage sludge in line with the specific legislation in each country.[8]

3.5. Invasiveness

Miscanthus × giganteus parents on both sides, M. sinensis and M. sacchariflorus, are both potentially invasive species, because they both produce viable seeds. M. x giganteus does not produce viable seeds however, and Nsanganwimana et al. claim that "[...] there has been no report on the threat of invasion due to rhizome growth extension from long-term commercial plantations to neighbouring arable land."[51]

3.6. Summary

There seem to be agreement in the scientific community that a shift from annual to perennial crops have environmental benefits. For instance, Lewandowski et al. conclude that analyses "[...] of the environmental impacts of miscanthus cultivation on a range of factors, including greenhouse gas mitigation, show that the benefits outweigh the costs in most cases."[156] McCalmont et al. argue that although there is room for more research, "[...] clear indications of environmental sustainability do emerge."[157] In addition to the GHG mitigation potential, miscanthus' "[…] perennial nature and belowground biomass improves soil structure, increases water-holding capacity (up by 100–150 mm), and reduces run-off and erosion. Overwinter ripening increases landscape structural resources for wildlife. Reduced management intensity promotes earthworm diversity and abundance although poor litter palatability may reduce individual biomass. Chemical leaching into field boundaries is lower than comparable agriculture, improving soil and water habitat quality."[158] Milner et al. argue that a change from first generation to second generation energy crops like miscanthus is environmentally beneficial because of improved farm-scale biodiversity, predation and a net positive GHG mitigation effect. The benefits are primarily a consequence of low inputs and the longer management cycles associated with second generation (2G) crops.[159] The authors identifies 293247 hectares of arable land and grassland in the UK (equivalent to 1.3% of the total land area) where both the economical and environmental consequences of planting miscanthus is seen as positive.[160] Whitaker et al. argue that if land use tensions are mitigated, reasonable yields obtained, and low carbon soils targeted, there are many cases where low-input perennial crops like miscanthus "[...] can provide significant GHG savings compared to fossil fuel alternatives [...]."[161] In contrast to annual crops, miscanthus have low nitrogen input requirements, low GHG emissions, sequesters soil carbon due to reduced tillage, and can be economically viable on marginal land.[162] The authors agree that in recent years, "[...] a more nuanced understanding of the environmental benefits and risks of bioenergy has emerged, and it has become clear that perennial bioenergy crops have far greater potential to deliver significant GHG savings than the conventional crops currently being grown for biofuel production around the world (e.g. corn, palm oil and oilseed rape)."[163] The authors conclude that "[...] the direct impacts of dedicated perennial bioenergy crops on soil carbon and N2O are increasingly well understood, and are often consistent with significant lifecycle GHG mitigation from bioenergy relative to conventional energy sources."[164]

4. Practical Farming Considerations

For practical farming advice, see Iowa State University's "Giant Miscanthus Establishment" PDF.[165] See also the best practice manual jointly developed by Teagasc (the agriculture and food development authority in Ireland) and AFBI (the Agri-Food and Biosciences Institute, also Ireland).[166]

References

- Lewandowski et al. argue that the "[...] fossil-energy savings are highest where miscanthus biomass is used as construction material (our analysis uses the example of insulation material)." Lewandowski et al. 2016, p. 20.

- Nsanganwimana et al. 2014, p. 125.

- Lackowski 2019.

- "Producing rhizomes for propagation in the United Kingdom climate takes at least two growing season, this entails clearing the production ground of weeds, plowing in spring and tilling the ground to a fine seed bed like tilth before planting the rhizomes with a potato type planter. [...] In the spring following the second growth year, the rhizomes are harvested using a modified potato harvester, hand or semi-automatically sorted and cut into viable pieces, 20–40 g. [...] One ha of rhizomes produces enough material to plant 10–30 ha of crop with the same modified potato type planter. Lower quality rhizomes, tested by sprouting tests, would require 80–90 g rhizomes (private communication, M. Mos)." Hastings et al. 2017, pp. 5–6.

- "Our work is showing, depending on the hybrid type, one ha (hectare) of seed production can produce enough seed for ∼1000–2000 ha of planting, depending on parental combinations, two orders of magnitude greater than rhizome propagation. [...] [A]n 85–95% establishment rate is achieved." Hastings et al. 2017, p. 6.

- "Seeds are sown by machine and raised in the greenhouse (Figure 3A) before being planted out in the field (Figure 3B). It is anticipated that seed-based establishment methods will prove most effective for the scaling up of miscanthus production because they have the following advantages: · With increasing market demand, large quantities can easily be provided, once seed production has been well developed · Short growing period for plantlets: Only 8–10 weeks from seed to final product (plugs) · Plug production is energy efficient (no need for refrigerators) · Low establishment costs" Lewandowski et al. 2016, p. 15.

- "Results show that new hybrid seed propagation significantly reduces establishment cost to below £900 ha−1 [...]. The breakeven yield was calculated to be 6 Mg [Mg/megagram equals metric ton] DM [dry matter] ha−1 y−1 [hectare per year], which is about half average United Kingdom yield for Mxg; with newer seeded hybrids reaching 16 Mg DM ha−1 in second year United Kingdom trials. These combined improvements will significantly increase crop profitability. The trade-offs between costs of production for the preparation of different feedstock formats show that bales are the best option for direct firing with the lowest transport costs (£0.04 Mg−1 km−1) and easy on-farm storage. However, if pelleted fuel is required then chip harvesting is more economic. [...] The specific cost of rhizome and plug planting are similar as they are relatively labor intensive whereas seed drilling, is predicted to halve the cost." Hastings et al. 2017, pp. 1, 8.

- Nsanganwimana et al. 2014, p. 130.

- McCalmont et al. 2017, p. 503.

- "C4 species characteristically demonstrate improved efficiency in nitrogen (N) and water-use [28,29]. Specifically, C4 species can show N-use efficiencies twice those of C3 species." Anderson et al. 2014, p. 73.

- "Nitrogen fertilizer is unnecessary and can be detrimental to sustainability, unless planted into low fertility soils where early establishment will benefit from additions of around 50 kg N ha−1. [...] N2O emissions can be five times lower under unfertilized Miscanthus than annual crops, and up to 100 times lower than intensive pasture land. Inappropriate nitrogen fertilizer additions can result in significant increases in N2O emission from Miscanthus plantations, exceeding IPCC emission factors although these are still offset by potential fossil fuel replacement." McCalmont et al. 2017, p. 503.

- "Plastic mulch film reduced establishment time, improving crop economics. [...] The mulch film trial in Aberystwyth showed a significant (P < 0.05) difference between establishment rates for varying plant densities with the cumulative first 2-year mean yield almost doubling under film as shown in Table 3. Using film adds £100 per ha and 220 kg CO2 eq. C ha−1, to the cost of establishment. The effect of this increase is to reduce the establishment period of the crop by 1 year in Aberystwyth environmental conditions, similar reduction in establishment times were observed at the other trial sites and also in Ireland (O’Loughlin et al., 2017). [...] With mulch film agronomy the latest seeded hybrids establish far more quickly with significantly higher early yields (years 1 and 2) compared to commercial Mxg in the United Kingdom delivering a breakeven return on investment at least a year earlier." Hastings et al. 2017, pp. 1, 9, 14–15.

- "The planting of seed-derived plugs proved to be most successful method for miscanthus establishment on marginal soils. Covering the plants with a plastic film accelerates their growth. The film keeps the humidity in the topsoil and increases the temperature. This is beneficial for the plants, especially on light soils with a higher risk for drought stress and in cool temperatures." Lewandowski et al. 2016, p. 14.

- "Crop productivity is determined as the product of total solar radiation incident on an area of land, and the efficiencies of interception, conversion and partitioning of that sunlight energy into plant biomass. [...] Beale and Long demonstrated in field trials in southeastern England that εc,a was 0.050–0.060, 39% above the maximum value observed in C3 species. Furthermore, when εc is calculated in terms of total (i.e., above-ground and below-ground) M. x giganteus biomass production (εc,t), it reaches 0.078, which approaches theoretical maximum of 0.1. Studies performed in the midwestern USA by Heaton et al. reported a similar efficiency of intercepted PAR (0.075)." Anderson et al. 2014, p. 73.

- "Water‐use efficiency is among the highest of any crop, in the range of 7.8–9.2 g DM (kg H2O)−1. - Overall, water demand will increase due to high biomass productivity and increased evapotranspiration at the canopy level (e.g. ET up from wheat by 100–120 mm yr−1). - Improved soil structures mean greater water‐holding capacity (e.g. up by 100–150 mm), although soils may still be drier in drought years. - Reduced run‐off in wetter years, aiding flood mitigation and reducing soil erosion. - Drainage water quality is improved, and nitrate leaching is significantly lower than arable (e.g. 1.5–6.6 kg N ha−1 yr−1 [for] Miscanthus, 34.2–45.9 [for] maize/soya bean)." McCalmont et al. 2017, p. 504.

- "Beale et al. (1999) compared their results to the water‐use efficiency of a C3 biomass crop, Salix viminalis, reported in Lindroth et al. (1994) and Lindroth & Cienciala (1996), and suggest that WUE for Miscanthus could be around twice that of this willow species. Clifton‐Brown & Lewondowski (2000) reported figures from 11.5 to 14.2 g total (above‐ and belowground) DM (kg H2O)−1 for various Miscanthus genotypes in pot trials, and this compares to figures calculated by Ehdaie & Waines (1993) with seven wheat cultivars who found WUE between 2.67 and 3.95 g total DM (kg H2O)−1. Converting these Miscanthus values to dry matter biomass per hectare of cropland would see ratios of biomass to water use in the range of to 78–92 kg DM ha−1 (mm H2O)−1. Richter et al. (2008) modelled harvestable yield potentials for Miscanthus from 14 UK field trials and found soil water available to plants was the most significant factor in yield prediction, and they calculated a DM yield to soil available water ratio at 55 kg DM ha−1 (mm H2O)−1, while just 13 kg DM ha−1 was produced for each 1 mm of incoming precipitation, likely related to the high level of canopy interception and evaporation. Even by C4 standards these efficiencies are high, as seen in comparisons to field measurements averaging 27.5 ± 0.4 kg aboveground DM ha−1 (mm H2O)−1 for maize (Tolk et al., 1998)." McCalmont et al. 2017, p. 501.

- "In terms of energy production intensity, Miscanthus biomass produces more net energy per hectare than other bioenergy crops at around 200 GJ ha−1 yr−1, especially arable [maize for biogas 98, oil seed rape for biodiesel 25, wheat and sugar beet ethanol 7–15 (Hastings et al., 2012)]. Felten et al. (2013) calculated similar figures, reporting 254 GJ ha−1 yr−1 for Miscanthus." McCalmont et al. 2017, p. 493.

- Heaton, Hartzler & Barnhart 2010, p. 2.

- Hastings et al. 2009a, p. 180.

- SRF yield for willow and poplar in the UK lies in the range of 10–12 tonnes dry matter per hectare per year according to Proe, Griffiths & Craig 2002, pp. 322–323. In a willow yield meta study Fabio et al. quote willow trials in Sweden yielding 8, 13 and 14 tonnes. In the UK, the authors quote two willow trials, both yielding 10 tonnes, and one trial in Ireland yielding 8-10 tonnes. See Fabio & Smart 2018 table 1 and 2, page 551 and 552. The willow yield datapoints (location not given) in Figure 2, p. 554 show a mean yield of approximately 6–7 tonnes per hectare per year. In table 3, page 557, 6 studies is quoted, with a mean yield of 10 tonnes per hectare per year. Aylott et al. collected data from 49 test sites for willow and poplar in the UK, and conclude: "Field trial results shown that observed SRC yield varied significantly between genotype and rotation (Table 1). The highest yields were recorded in willow over the two rotations, with the 16 genotypes averaging 9.0 odt [oven dry tonne] ha−1 yr−1 compared with 6.3 odt ha−1 yr−1 for the poplar genotypes. The highest‐yielding parental line was the Swedish S. vimanlis × S. schwerinii, which displayed consistently high yields over both rotations and a high resistance to rust. This parent line included the highest‐yielding single genotype, Tora, with an average yield across both rotations of 11.3 odt ha−1 yr−1." Aylott et al. 2008, p. 363. Modelling for the future, Aust et al. estimate a mean yield of 14 tonnes for SRC willow and poplar produced on arable land in Germany, see Aust et al., p. 529. It should be noted that willow and poplar need fertilizer to achieve these yields, Fabio et al. reports 92–400 kg nitrogen per hectare per year for the yields reported in their article. See Fabio & Smart 2018, pp. 551–552. Hastings et al. used computer modelling software to estimate miscanthus, willow and poplar yields for Great Britain, and concluded with mean yields in the narrow range 8.1 to 10.6 dry tonnes per hectare per year for all these plants, with miscanthus taking the middle position. Miscanthus had the highest yield in the warmer southwest, and adjusting the computer model for the expected warmer climate in 2050 made miscanthus the top yielding crop for a larger area: "As the climate warms through the time‐slices, there is a yield increase and thus a larger area where Miscanthus is the highest yielder of the feed‐stocks considered." Hastings et al. 2014, pp. 108, 119.

- For yield estimates see FAO's "The global outlook for future wood supply from forest plantations", section 2.7.2 – 2.7.3. Scot's pine, native to Europe and northern Asia, weighs 390 kg/m3 oven dry (moisture content 0%). The oven dry weight of eucalyptus species commonly grown in plantations in South America is 487 kg/m3 (average of Lyptus, Rose Gum and Deglupta). The average weight of poplar species commonly grown in plantations in Europe is 335 kg/m3 (average of White Poplar and Black Poplar. http://www.fao.org/3/X8423E/X8423E08.htm#TopOfPage

- Smil 2008, p. 75-76.

- Miscanthus yield software Miscanfor calculates a yield decline of 33% between autumn peak and winter harvest. See Hastings et al. 2009, p. 186. This calculation is confirmed by Roncucci et al. which found a dry mass yield decrease of 32–38% for their test crops when harvest was delayed until winter. See Roncucci et al. 2015, p. 1002. Clifton-Brown et al. found a mean yield reduction of 0.3% per day in the period between peak autumn yield and winter harvest, see Clifton‐Brown, Breuer & Jones 2007, p. 2305.

- "The majority of the literature reporting dry biomass yield for M. x giganteus originates from European studies. Ceiling peak biomass yields in established stands of M. x giganteus have approached 40 t dry matter (DM) ha−1 in some European locations, although it may take 3–5 years to achieve these ceiling yields. Across Europe, harvestable yields of up to 25 t DM ha−1 from established stands of M. x giganteus have been reported in areas between central Germany and southern Italy, while peak yields in central and northern Europe have ranged between 10–25 t DM ha−1, and in excess of 30 t DM ha−1 in southern Europe. A quantitative review of established M. x giganteus stands across Europe reported a mean peak biomass yield of 22 t DM ha−1, averaged across N rates and precipitation levels." Anderson et al. 2014, p. 79.

- Roncucci et al. 2015, p. 1004.

- Smil 2015, p. 81.

- Zhang et al. measured a bana grass (napier variant) yield of 74 tonnes per hectare per year with light fertilisation and 1000 mm rainfall. Zhang et al. 2010, pp. 96, 98.

- Hoshino et al. measured a napier yield of 75.6 tonnes per hectare per year the second year of growth under heavy fertilisation and with rainfall level 1000 mm annually. Hoshino, Ono & Sirikiratayanond 1979, pp. 310, 311, 315.

- Vicente-Chandler et al. found that heavily fertilized napiergrass produced 75,661 pounds of dry matter per acre per year when cut at 90-day intervals, equivalent to 84.8 tonnes per hectare per year. Vicente-Chandler, Silva & Figarella 1959, p. 202.

- "The total water requirements are approximately 100 mm (4 inches) per month rainfall equivalent. [...] The yield of Giant King Grass depends on the time between harvests. For example, a six-month harvest of tall Giant King Grass, one can expect to obtain 80 or more US tons per acre (180 metric tons per hectare) of fresh grass at approximately 70-75% moisture. For two harvests per year, double these figures." Viaspace 2020.

- Mackay quotes yields of 360 wet tonnes per hectare per year, but does not quantify moisture content. Mackay 2020.

- "From the second year of Miscanthus planting, crops were annually harvested on the verge of shoot in late March or the beginning of April. Mean Miscanthus yield was 15 Mg dry mass (d.m.) ha−1 y−1, which remained nearly constant from the fourth year of establishment." Felten & Emmerling 2012, p. 662.

- McCalmont et al. 2017, p. 497.

- "The yields used in the calculation of GHG emissions and crop economics this study used mean yields of 12–14 Mg ha−1 y−1 that have been observed from Mxg from current commercial plantings observed in the United Kingdom (private communication, M. Mos). We have assumed a logistic yield increase for establishment year yields and a linear decline in yield after 15 years Lesur et al. (2013). Inter-annual yield variation, due to weather conditions, as observed in long term trials (Clifton-Brown et al., 2007) and modeled Miscanthus yields for the United Kingdom, using weather data from 2000 to 2009 (Harris et al., 2014) using the MiscanFor model (Hastings et al., 2009, 2013) indicates that the weather related standard deviation of inter-annual yield variation in the United Kingdom is of the order 2.1 Mg ha−1 y−1 for a mean yield of 10.5 Mg ha−1 y−1 for the whole of the United Kingdom. The modeled yields are generally pessimistic as they calculate rain-fed yields and do not account for ground water support that is available in many United Kingdom arable farms." Hastings et al. 2017, p. 4.

- "The Asia-Pacific Economic Cooperation (APEC) estimates that marginal lands make up approximately 400 million hectares across Asia, the Pacific Islands, Australia, and North America. Other estimates put the global marginal land area anywhere from 1100 to 6650 million hectares, depending on the parameters used to describe marginal (e.g., "non-favored agricultural land", "abandoned or degraded cropland", or arid, forested, grassland, shrubland, or savanna habitats). The potential area available in the USA for cellulosic biomass crops and low-input, high-diversity native perennial mixtures ranges from 43 to 123 million hectares. The differences in these estimates reflect the inconsistencies in the usage of the term "marginal land", despite its common use in the bioenergy industry and literature. Marginal lands are often described as degraded lands that are unfit for food production and/or of some ambiguously poor quality and are often termed unproductive. Unproductive soils are characterized by unfavorable chemical and/or physical properties that limit plant growth and yield, including low water and nutrient storage capacity, high salinity, toxic elements, and poor texture. Further difficulties encountered in marginal landscapes include shallow soil depth due to erosion, poor drainage, low fertility, steep terrain, and unfavorable climate. Despite the poor quality of marginal land and the potential problems it could present for its production, biomass is unlikely to be grown on high-quality land that is economically viable for traditional crops." Quinn et al. 2015, pp. 1–2.

- roots > shoots in order of increasing sensitivity (rhizomes least sensitive). Plants grown from larger rhizomes initially were less sensitive. [p. 8]. [...] The lethal temperature at which 50 % (LT50) of Miscanthus × giganteus rhizomes were killed was −3.4 °C, which can be problematic especially during first winter. [...] Miscanthus × giganteus shows unusual cold tolerance for a C4 species. [p. 10] [...] Because C4 and CAM species have inherent mechanisms to resist heat stress, it makes sense to consider biomass crops with these photosynthetic pathways (see Table 5) [page 11]. [...] Our literature review has revealed several "all purpose" biomass crops that are moderately or highly tolerant of multiple environmental stressors (Table 6). For example, Andropogon gerardii, Eucalyptus spp., Miscanthus spp., Panicum virgatum, Pinus spp., Populus spp., Robinia pseudoacacia, and Spartina pectinata were shown to be moderately or highly tolerant of four or more stress types [p. 14]." Quinn et al. 2015, pp. 4, 5, 8, 10, 11, 14. " id="ref_36">It takes 30 days with a mean temperature of below −3.4 °C before the soil temperature fall to below −3.4 °C. See Hastings et al. 2009b, p. 184. Quinn et al. state that "[m]iscanthus × giganteus leaf area and yield reduced under drought stress, but water availability does not affect shoot production or plant height at the beginning of the growing season. [p. 4]. [...] Miscanthus × giganteus biomass and rhizome viability unaffected by flooding [p. 5]. [...] Salinity above 100 mM affected Miscanthus × giganteus growth, with rhizomes > roots > shoots in order of increasing sensitivity (rhizomes least sensitive). Plants grown from larger rhizomes initially were less sensitive. [p. 8]. [...] The lethal temperature at which 50 % (LT50) of Miscanthus × giganteus rhizomes were killed was −3.4 °C, which can be problematic especially during first winter. [...] Miscanthus × giganteus shows unusual cold tolerance for a C4 species. [p. 10] [...] Because C4 and CAM species have inherent mechanisms to resist heat stress, it makes sense to consider biomass crops with these photosynthetic pathways (see Table 5) [page 11]. [...] Our literature review has revealed several "all purpose" biomass crops that are moderately or highly tolerant of multiple environmental stressors (Table 6). For example, Andropogon gerardii, Eucalyptus spp., Miscanthus spp., Panicum virgatum, Pinus spp., Populus spp., Robinia pseudoacacia, and Spartina pectinata were shown to be moderately or highly tolerant of four or more stress types [p. 14]." Quinn et al. 2015, pp. 4, 5, 8, 10, 11, 14.

- Nsanganwimana et al. 2014, p. 124.

- "Most saline soils covering 539 567 km2 in the European geographical area can be used to grow Miscanthus with up to an estimated 11% reduction in yield; a further 2717 km2 can be used with an estimated 28% reduction in yield, and only, 3607 km2 will produce a yield reduction greater that 50%." Stavridou et al. 2017, p. 99.

- "Rhizome D.W. [dry weight] and the ratios of root/rhizome and below‐/above‐ground D.W. were not affected by increased salinity, and only, the root D.W. was significantly reduced at the highest salt concentration (22.4 dS m−1 NaCl) (Table 1). Płażek et al. (2014) showed a similar response in M. × giganteus, with reduction only in roots D.W. at 200 mm NaCl and no changes in rhizomes D.W. below 200 mm NaCl. This ability of perennial grasses to maintain below‐ground biomass under stress conditions could preserve sufficient reserves for the following growing season (Karp & Shield, 2008); while this may be physiologically relevant for transitory stresses like drought, it remains to be seen how this response affects year on year yield under the accumulative stress effect of salinity." Stavridou et al. 2017, p. 100.

- "The highest biomass yields as well as the highest GHG- and fossil-energy savings potentials (up to 30.6 t CO2eq/ha*a [CO2 equivalents per hectare per year] and 429 GJ/ha*a [gigajoule per hectare per year], respectively) can be achieved on non-marginal sites in Central Europe. On marginal sites limited by cold (Moscow/Russia) or drought (Adana/Turkey) savings of up to 19.2 t CO2eq/ha*a and 273 GJ/ha*a (Moscow) and 24.0 t CO2eq/ha*a and 338 GJ/ha*a (Adana) can be achieved." Lewandowski et al. 2016, p. 19.

- "Shoot death means that in a given year, there will be limited yield but a recovery the following year. Rhizome kill means that the crop needs to be replanted. [...] For drought conditions, we calculate the time below the wilting point: if this exceeds 30 days, then the shoot is killed for that year, if it exceeds 60 days for M. × giganteus the rhizome is killed and the crop destroyed. This was based upon a growing chamber water stress experiment with M. × giganteus (Clifton‐Brown and Hastings, unpublished data). This is extended to 60 and 120 days for M. sinensis." Hastings et al. 2009b, p. 161.

- "In the second year of growth (2011) crops growing in SiC [silty-clay-loam] soil showed a significantly higher aboveground dry yield (Table S1) compared to crops growing in SL [sandy loam] soil (19.1 vs. 10.9 Mg ha−1) (Fig. 2a). [...] General trends in biomass productivity were amplified in the third growing year (2012), when miscanthus growing in SL soil was severely influenced by the summer drought which led to premature aboveground senescence, leaf loss and inhibition of flowering. Hence, averaged over the three harvest dates, dry biomass yield in the SL soil was one order of magnitude lower than in the SiC soil (24.6 vs. 3.9 Mg ha−1). [...] The results obtained in our experiments confirmed the importance of water availability in determining satisfactory miscanthus yields in a Mediterranean environment. In fact, miscanthus plantations in soils characterized by a poor water holding capacity (i.e. SL soil) were severely affected after three growing years, with harvestable dry yields lower than 5 Mg ha−1. [...] Roncucci et al. 2015, pp. 1001, 1004. Stričević et al. make a similar point, adding root depth to the equation: "Water availability for Miscanthus depended equally on precipitation and accumulated soil moisture, such that yields were generally a reflection of root depth and soil characteristics. For example, the yields recorded at Ralja were lower than those achieved at Zemun because of the restrictive soil layer in the former case [at 1.1 m] and the inability of Miscanthus to develop deeper roots. The importance of soil and root depth for the simulation of plant production has been corroborated by other researchers (Raes et al., 2009)." See Stričević et al. 2015, pp. 1205.

- Stričević et al. make a contrasting point however: "Each year Miscanthus increased its above‐ground biomass and root depth [...]. In the first 2 years Miscanthus formed rhizomes and root growth was slow. In the third year, there was enough moisture in the more fertile surface layer of soil, such that root depth was smaller than expected. The next 3 years were dry, so in search for water the roots considerably increased their depth (up to 2.3 m), which was consistent with data collected from other experiments (Neukirchen et al., 1999; Riche & Christian, 2001)." See Stričević et al. 2015, pp. 1207.

- 420 mm), while a 58% increase in aboveground dry yield was observed in irrigated miscanthus at the site with a lower precipitation (around 313 mm). Finally, in our experimental site, Ercoli et al. (1999), when comparing the effect of irrigation and nitrogen fertilization on miscanthus yield, observed an increase in about 20% (+4.5 Mg ha−1) in irrigated vs. rainfed plots harvested in autumn. This is consistent with our results: when precipitation during the growing season was rather low (~164 mm) and similar to that reported by Ercoli et al. (1999) (~173 mm), plots receiving irrigation increased their dry yield by around 15% compared to rainfed plots. Conversely, in 2012 when precipitation was much greater (~400 mm) miscanthus under ET0 and ET75 yielded nearly the same." Roncucci et al. 2015, pp. 1005–1006,. " id="ref_44">"Mantineo et al. (2009) stated how irrigation in the first 3 years after the establishment affected miscanthus belowground growth and size, and the same authors found good aboveground yields during the fourth and fifth years (around 27 and 18 Mg ha−1) when no irrigation was given. These findings are corroborated by Mann et al. (2013b) who investigated the root system dynamics of miscanthus in response to rainfed and irrigated conditions, and highlighted no roots development below a depth of 1.2 m under rainfed conditions, while given supplemental irrigation during the establishment, miscanthus was able to develop roots 3 m down. Therefore, miscanthus growth patterns in sandy‐loam soil (Experiment 1) highlighted the importance of supplying irrigation water also during the years following the establishment. However, in soils characterized by a good water holding capacity (Experiment 2), revealed that irrigation water had no influence on crop productivity. Previous studies conducted in the Mediterranean (central and southern Italy) comparing irrigated and rainfed miscanthus crops gave ambiguous results. In fact, in southern Italy, two‐ and three‐year old crops responded to irrigation only when water supply exceeded 440 mm (Cosentino et al., 2007) or when precipitation during the growing season was rather limited (around 400 mm) (Mantineo et al., 2009). The importance of precipitation for miscanthus grown in Mediterranean was confirmed by Petrini et al. (1996) who compared rainfed and irrigated miscanthus in two different locations in central Italy. In 2‐year old crops no differences in the aboveground yield were recorded at the site with a higher precipitation (>420 mm), while a 58% increase in aboveground dry yield was observed in irrigated miscanthus at the site with a lower precipitation (around 313 mm). Finally, in our experimental site, Ercoli et al. (1999), when comparing the effect of irrigation and nitrogen fertilization on miscanthus yield, observed an increase in about 20% (+4.5 Mg ha−1) in irrigated vs. rainfed plots harvested in autumn. This is consistent with our results: when precipitation during the growing season was rather low (~164 mm) and similar to that reported by Ercoli et al. (1999) (~173 mm), plots receiving irrigation increased their dry yield by around 15% compared to rainfed plots. Conversely, in 2012 when precipitation was much greater (~400 mm) miscanthus under ET0 and ET75 yielded nearly the same." Roncucci et al. 2015, pp. 1005–1006,.

- Stričević et al. 2015, pp. 1204–1205. However, in table 2, page 1208, the stated rainfall levels for the 20–25 tonne yields is even lower; 220, 220 and 217 mm. It is unclear why the authors went for the 300-400 mm estimation instead of 220 mm.

- This yield is a result of a computer simulation, it is not an actual measured yield. The authors used FAO's freely available yield prediction software AquaCrop to calculate yield under optimal conditions: "Although Miscanthus generally achieves high yields even when its water supply is low, it responds very well to irrigation, increasing biomass yield by as much as 100% (Cosentino et al., 2007). In Serbia's ecological circumstances, Miscanthus had enough water during the first 3 years of research, but it was under water stress over short periods in the fourth, fifth, and sixth years. To check whether the model generated realistic biomass levels when the water supply was nonlimiting, the file called 'Generation of irrigation schedule' was used and the option 'Replenish when 80% readily available water depleted' was selected. As such, if irrigation is applied, the dates of irrigation and amounts of water need to be entered so that they are accounted for in the water balance. In the present example, instead of entering the dates of irrigation and amounts of water, the model determined how much water was needed and when, to achieve potential yields. The same input data with the addition of irrigation water generated a yield of 42 Mg ha−1, which matched those recorded in Greece and Italy under irrigation and constraint free‐conditions, in similar climatic circumstances and with similar crop densities (Cosentino et al., 2007; Danalatos et al., 2007)." See Stričević et al. 2015, pp. 1206–1207. http://www.fao.org/aquacrop/en/

- Nsanganwimana et al. 2014, p. 126.

- Nsanganwimana et al. 2014, p. 128.

- "Miscanthus grown on contaminated soils can contain higher shoot TE [trace elements; metals and metalloids] concentrations, but the TF [translocation factor], which is for the most part less than 1, indicates that root-to-shoot TE transfer is minimized (Table 3). The combination of this trait with low BCF [bio concentration factor] and higher TE concentrations in roots than in shoots demonstrates the capacity to contain TE in soils. Owing to the perennial growth and its ability to stabilize TE and degrade some organic pollutants, Miscanthus could potentially limit pollutant transfer into different environmental compartments by reducing (1) pollutant leaching from the root zone and groundwater contamination, (2) pollutant run-off (water erosion) and surface water contamination, (3) dust emission into the atmosphere due to wind erosion and seasonal soil tillage, and (4) pollutant transfer into plant AG [above ground] parts and thus transfer into food chains. Therefore, as non-food crops, Miscanthus forms a potential resource for phytomanagement of contaminated areas, with the option of TE phytostabilization and/or organic pollutant degradation, hence the opportunity to reduce both human and environmental risks." Nsanganwimana et al. 2014, p. 129.

- Nsanganwimana et al. 2014, p. 129.

- Nsanganwimana et al. 2014, p. 131.

- Clifton-Brown et al. 2017, p. 2.

- Smil 2015, p. 211, box 7.1.

- Smil 2015, p. 170.

- Smil 2015, p. 2095 (kindle location).

- Smil 2015, p. 91.

- Smil 2015, p. 89.

- Smil 2015, p. 227.

- Smil 2015, p. 228.

- Smil 2015, p. 90.

- Smil 2015, p. 229.

- Smil 2015, pp. 80, 89.

- Smil 2015, p. 85.

- Smil 2015, p. 86.

- Schwarz 1993, p. 413.

- Flores et al. 2012, p. 831.

- Ghose 2011, p. 263.

- Cf. Smil's estimate of 0.60 W/m2 for the 10 t/ha yield above. The calculation is: Yield (t/ha) multiplied with energy content (GJ/t) divided by seconds in a year (31 556 926) multiplied with the number of square metres in one hectare (10 000).

- "The raw material for wood pellets is woody biomass in accordance with Table 1 of ISO 17225‑1. Pellets are usually manufactured in a die, with total moisture content usually less than 10 % of their mass on wet basis." ISO (International Organization for Standardization) 2014a.