Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Iris Vural Gursel and Version 2 by Sirius Huang.

To support progress towards the transition to a circular economy, the ability to measure circularity is essential. The consideration of the role biobased products can play in this transition is however still largely lacking in the development of circularity monitoring approaches. The first step in coming to a suitable monitoring framework for biobased products is to define circular economy principles.

- circular economy

- bioeconomy

- biobased products

- circularity metrics

1. Circular Economy Principles and Strategies—What to Measure?

Review of scientific and grey literature revealed that different circular economy principles and strategies have been proposed. The set of requirements provided in each source are presented in Table 1.

Table 1.

Collation of circular economy principles/strategies/requirements.

| Source | Circular Economy Principles/Strategies/Requirements |

|---|---|

| Ellen Mac Arthur Foundation [1][3] |

|

| Boyer et al. (2021) [2][29] |

|

| 3R Framework [3][24] |

|

| 4R [4][25] |

|

| Saidani et al. (2017) [5][30] |

|

| Alamerew et al. (2020) [6][31] |

|

| PBL [7][18] |

|

| Reike et al. (2018) [8][19] |

|

| Ortiz-de-Montellano and van der Meer (2022) [9][34] |

|

| Kristensen and Mosgaard (2020) [10][32] |

|

| Jerome et al. (2022) [11 |

Corona et al. (2019) [14][27] came up with a similar list of CE requirements for reviewing existing metrics including the five requirements of Elia et al. (2017) [13][26]. Additionally, they considered the effect of the circular economy on economic prosperity and social equity. Accordingly, they included three extra requirements concerning creating jobs, value added creation and increase of social wellbeing.

2. Biobased Products: Circular Economy Principles and Measurement Needs

In defining circular economy principles, additional considerations are needed looking at the role of the bioeconomy in the circular economy. The European Bioeconomy Alliance defines bioeconomy as “the biological motor of a future circular economy, which is based on optimal use of resources and the production of primary raw materials from renewably sourced feedstock” [17][35]. Navare et al. (2021) specified characteristics of biological cycles in the context of CE with focus on aspects that are not addressed by existing monitoring systems [18][36]. These are renewability, potential for cascading use of material, and closing the nutrient cycle. Additionally, Kardung et al. (2021) pointed out that two essential concepts that should be captured in monitoring the biobased economy are biorefineries and cascading use of biomass [19][37]. EEA sees cascading biomass use and recycling while preserving natural capital as core of a sustainable and circular bioeconomy [20][6]. Bos and Broeze (2020) identified four priorities for biobased product systems: 1. Maintaining soil health, with responsible exploitation of crop residues for biobased applications; 2. Circular nutrient management; 3. Replacement of fossil sources by renewables, valorization of side streams and 4. Increasing multifunctional use and recycling of biobased materials [21][38]. Additionally, Muscat et al. (2021) presented five ecological principles to guide biomass use: Safeguarding and regenerating the health of our (agro)ecosystems; Avoiding non-essential products; Prioritizing biomass streams for basic human needs (considering also cascading use); Recycling nutrients and carbon from by-products into the bio-based system; and Minimizing overall energy use and using renewable energy [22][39].

Some authors looked at the intersection of the bioeconomy and circular economy concepts. Brandão et al. (2021) defined three key interfaces between the bioeconomy and circular economy: Utilization of biomass as a resource including by-products, residues and waste, Cascading use of biomass; and Minimize use of fossil fuels (creating a more sustainable and resource-efficient world) [23][40]. Additionally, they highlighted resource-efficient valorization of biomass with biorefineries as a key part of a circular bioeconomy. Stegmann et al. (2020) identified key elements of a circular bioeconomy based on a literature review, which include resource-efficiency; biorefinery; use of wastes and residues as resource; maintaining the value of products, materials and resources for as long as possible; cascading use of biomass; and waste management (e.g., reuse, recycling) [24][15]. In another study, cascading use, utilization of waste streams, resource-efficient value chains, reuse, recycling and organic and nutrient cycling were defined as common elements of the bioeconomy and circular economy [25][12].

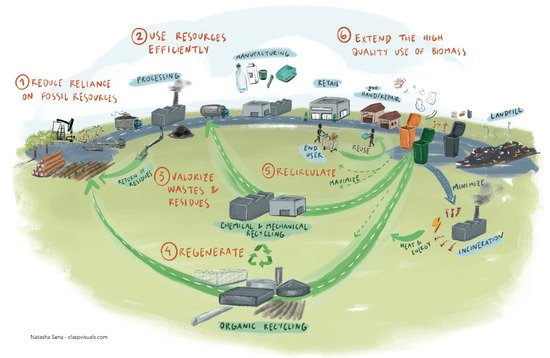

It can be seen that some key aspects are repeated specific to use of biomass towards a circular bioeconomy. First is the role of biobased products in reducing reliance on fossil resources. Biomass provides renewable carbon to the economy and can replace fossil carbon [26][13], thereby any virgin feedstock input demand in the circular economy can be supplied in a renewable way. The second key aspect is using resources efficiently where the role of biorefining is highlighted. Biorefining allows processing of biomass into a spectrum of products and is seen as a major enabling strategy of the circular economy [27][42]. Then, the third key aspect is the valorization of residues and wastes. A biobased economy allows utilization of biological residues and wastes from variety of sources and can bring these products into the circular economy [28][14]. As was also included in the CE principles defined by Ellen Mac Arthur Foundation, regeneration of natural systems is a key consideration, which is about closing the carbon and nutrient cycles in the biosphere [29][43]. This fourth key aspect of regeneration incorporates returning of nutrients and organic matter from residual and waste streams back to soil. Recycling and lifetime extension strategies are equally valid for biobased products, therefore the fifth and sixth key aspects are “recirculate” and “extend the high-quality use of biomass”. One integral consideration here is the possibility of cascading use of biomass, defined as the strategy to use “the biomass as long, often and efficiently as possible for materials and only to recover energy from them at the end of the product life cycle” [30][44].

Accordingly, six circular economy principles for biobased products were derived as included in Table 2 and illustrated in Figure 13. The description of each principle is provided below.

Figure 13. Illustration of a biobased product system and the defined circular economy principles (source: Authors’ own elaboration visualized by Natasha Sena).

Table 2.

Circular economy principles and what needs to be measured for monitoring circularity of biobased products.

| Circular Economy Principles: | What Needs to Be Measured: |

|---|---|

|

|

| ] | |

| [ | |

| 33 | |

| ] | |

| |

|

|

| Moraga et al. (2019) [12][28] |

|

| Elia et al. (2017) [13][26] |

|

| Corona et al. (2019) [14][27] |

|

Several ladders, or R-frameworks, position the CE strategies. All R frameworks have a hierarchy as they are ordered from high priority towards low priority in the order of high to low level of circularity. The R framework was developed at first as a 3R framework (Reduce, Reuse, Recycle) [3][24]. It evolved into a 4R framework with the inclusion of Recover as the fourth R, in accordance with the European Union’s Waste Framework Directive considering incineration of materials with energy recovery [4][25]. While these have been well accepted and applied, there has recently been emphasis on more nuanced hierarchies reaching up to 10 Rs [8][19]. Saidani et al. (2017) ranked the different circularity loops from the most inner-loop to the most outer-loop according to the Ellen MacArthur Foundation’s circular economy model grouped into four categories (Maintain/Prolong, Reuse/Redistribute, Refurbish/Remanufacture, Recycle) [15][22]. PBL’s circularity ladder includes 10 Rs [7][18]. They are grouped into three categories of “smarter product use and manufacture” (R0–R2), “extend lifespan of product and its parts” (R3–R7) and “useful application of materials” (R8–R9). Therefore, the focus is on functionality first, then on preserving products and their parts and after that on recycling materials and energy recovery. Review of Reike et al. (2018) of R frameworks revealed not only varying numbers of Rs used in different studies (ranging from 3 to 10 Rs) as well as varying conceptualizations of each principle [8][19]. Accordingly, they synthesized the most common perspectives into a single systemic typology composed of 10 Rs, which they refer to as value retention options. It has almost the same list of principles as PBL (there is no rethink at level 2; instead, there is a re-mine at level 10), similarly distinguishing between short, medium and long loops. The term value retention was recently also used by Ortiz-de-Montellano and van der Meer (2022) where they considered eight value retention stages with Redesign placed at first [9][34].

CE requirements were included in several review papers that evaluated existing circularity metrics. Moraga et al. (2019) [12][28] defined six CE strategies inspired by PBL’s circularity ladder [7][18] to classify indicators. The first five strategies acknowledge preservation (of function, product, product’s components, material and embodied energy), and the last strategy considers the measurement of the linear economy as a reference scenario. Elia et al. (2017) [13][26] considered five requirements that were deduced from an European Environmental Agency report [16][17]. All the circular economy strategies aim to bring about reduction in resource use, which is captured in the first requirement. The third requirement links to recycling materials and fifth requirement links to the lifespan extension strategies of products (R3-R7 of PBL). The second and fourth are not explicitly covered in the above strategies. The second requirement considers the effect of the circular economy on environment where it is expected that increasing the circularity of a product will decrease emissions as well. The fourth requirement considers the substitution of virgin resources with renewable and recycled resources. This is also included in the CE strategies of Jerome et al. (2022) as changing material composition looking either at recycled or renewable content [

2.1. Reduce Reliance on Fossil Resources

Transitioning from fossil resources to renewable resources such as biomass is an important aspect of the circular economy. The biobased economy covers a wide variety of products and industrial sectors, such as plastics, chemicals, pharmaceuticals, packaging, construction, textiles, and bioenergy [26][13]. Energy and transport fuels from fossil resources can largely be replaced by renewable energy and hydrogen, which are non-carbon-based solutions. In order to phase out the use of fossil feedstock in other sectors, there is requirement for renewable carbon [31][45]. Here, use of biomass is indispensable to meet the carbon demand of materials and chemicals that cannot be supplied with renewable energy (solar, wind, hydro and geothermal). This integral role of biogenic carbon for the circular economy was realized and recently coined with the term “biobased circular carbon economy”. For heavy transport, shipping and aviation fuels, biomass use is currently needed until other sustainable solutions become available [32][46]. As defined in the Dutch government wide Circular Economy program [33][47], “in case new raw materials are necessary, fossil-based, critical and non-sustainably produced raw materials must be replaced by sustainably produced, renewable and generally available raw materials.” As the decarbonization of the energy sector advances, it is considered that bioenergy and biofuels for light road transport will be phased out in the future and the released biomass can be used to supply the demand of the chemicals and materials sector [32][46]. Biomass will therefore be essential in meeting carbon-based non-food demands in industry and reduce dependence on fossil resources. The only other (virgin) alternative to fossil-based resources is through carbon capture and utilization which is still at an early stage of development [34][48].

2.2. Use Resources Efficiently (Including Biorefining)

As the demand for biomass increases, not only for food and feed but also for fuel, chemicals and materials, increasing competition for biomass, land and other natural resources will occur [35][49]. Although trade-offs exist, there is a possibility to have resource-efficient valorization of biomass with multi-output production where different products are attained from different components. Biomass components are fibers (cellulose, hemicellulose and lignin), carbohydrates (starch, sugars), oil, protein, minerals and high-added-value ingredients (such as pigments, aromatics). The composition of these components largely varies in different biomass sources. For the purpose of utilizing biomass in the bioeconomy, it is important to link these biomass components with the suitable applications [36][50].

Multi-output production is key for resource efficiency that is achieved through biorefining of biomass into a spectrum of biobased products (food, feed, chemicals, materials) and bioenergy (biofuels, power and/or heat) [37][51]. This considers an increased valorization of biomass components through the connection of additional processes and new technologies in an integrated way for an expanded range of products. This allows reducing waste formation as the side and residual streams arising are turned into products for various market sectors. An example is the Roquette Lestrem biorefinery, which was a simple starch mill that was gradually developed, and the product spectrum increased to native and modified starches, proteins, polyols, organic acids and specialty chemicals [38][52]. There is also increased development of biorefinery concepts that utilize resources that are not food crops (i.e., sugar, starch and oil crops). These include biorefineries that use lignocellulosic biomass (wood, forestry and agricultural residues, energy crops), aquatic biomass, natural fibers (e.g., hemp) and municipal solid waste [38][52].

Currently, biorefineries are energy-driven, where the main products are biofuels, power and heat, owing to the existing biofuel-related policy targets supporting the use of biomass for bioenergy production [39][53]. No such directive exists yet for the use of biomass for chemicals/materials. However, the principles of the circular economy favor the use as a material over energy use. Accordingly, it is desirable that future biorefineries transition towards a more product-driven (materials and chemicals) approach [32][46]. The transition from a fuel to a material focus could, for example, be achieved in existing biorefineries by diverting bioethanol from fuel use towards chemical use, and the use of sugars to produce other chemicals through chemical conversion or fermentation. Similarly, also use of fatty acid methyl esters for production of fatty alcohols, for example in the production of surfactants instead of use as biodiesel fuel. This shift will also reduce demand for additional biomass to be used in the production of biobased products.

A potential to alleviate pressure on fertile soil and competition with food/feed production is to grow biomass on polluted or contaminated lands for non-food applications. This ideally also improves the quality of contaminated soil over the long term [40][54]. However, some non-food applications may still be problematic as the resulting products can contain high pollution levels, which can still end up in the environment or remain a threat to humans [41][55]. For example, if biomass polluted with high levels of heavy metal is converted into a biofuel, this requires specific pre-treatment to render the contaminants and prevent them entering into the environment during the conversion [42][56].

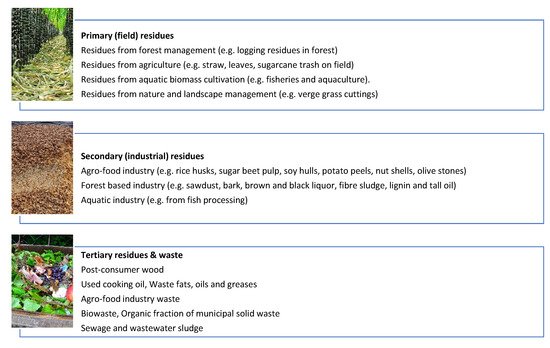

2.3. Valorize Wastes and Residues

The production, conversion and use of biomass results in various residues and wastes. While resource use efficiency (second principle) requires minimizing waste, it cannot be fully eliminated. Thereby the possibility to valorize the residues and waste is important for the circular economy [28][14]. Distinction is made between primary, secondary, and tertiary residual flows (see Figure 24). The primary resides are parts of plants that are left on the field or in the forest after harvesting of the biomass. The secondary residues are all forms of biomass that arise from processing of the biomass in industry (such as agro-food, woodworking) where the production of the residue was not the purpose of the process. There are also tertiary residues or wastes that have already had a use (post-consumer) that consist partly or fully of biological material such as organic household waste, food waste, sewage sludge [43][57]. More effective use of biogenic waste and residues for feed and as feedstock for the chemical, material and energy applications (see Figure 35, 3rd cycle) can reduce the need for additional primary biomass production for these applications.

Figure 24.

Biomass residues and wastes (source: Authors’ own elaboration).

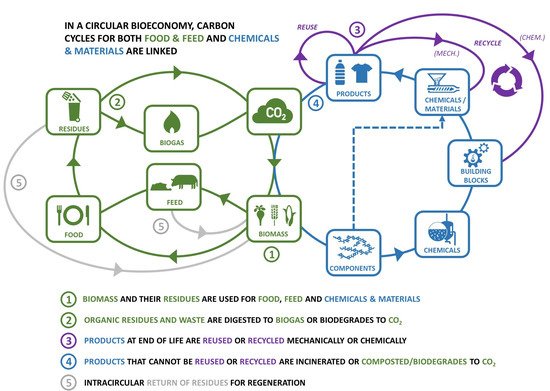

Figure 35. The cycles to optimize and extend to improve the circularity of biomass use in bioeconomy (source: Bos and Broeze (2020) [21]).

The cycles to optimize and extend to improve the circularity of biomass use in bioeconomy (source: Bos and Broeze (2020) [38]).

This categorization of residues is relevant because different sustainability considerations are relevant for the different types as well as in which applications they can be used for [44][58]. For primary residues, it is important to consider the soil quality and the sustainable harvest levels of the residues to maintain soil health and biodiversity. For tertiary residues, most have the status of waste in a legal sense and are subject to the EU Waste Framework Directive where the waste hierarchy must be followed [28][14] Therefore, it favors the food, feed, material and chemical applications over energy recovery. The tertiary residues and wastes also include biowaste that can be composted and serve as a valuable source of organic matter to return to soil (related to the fourth principle, regenerate). One strategy is to prioritize the use of biomass for human consumption and recycling any by-products for use in the economy [35][49]. Applications of food waste in the bioeconomy are increasing very strongly [28][45][14,59], such as the conversion of bread waste to succinic or lactic acid. Food processing residues can also be an interesting source of oil, which can have high value applications, such as avocado oil from rejected fruits, fish oil from lean fish and fish processing residues [46][60]. These and other examples are catalogued in the Power4Bio project [47][61].

2.4. Regenerate (Maintain Carbon and Nutrient Cycles)

It is required to ensure that the biomass production system remains healthy. As the Ellen MacArthur foundation prescribes, we need to “preserve and enhance natural capital by controlling finite stocks and balancing renewable resources flows” [29][43]. This concerns maintaining the essential soil carbon and nutrient cycles (see Figure 35, first two cycles). The soil carbon cycle concerns leaving enough crop residues in the field to maintain the soil organic matter content and valorize the excess in the biobased economy [48][62]. The soil carbon cycle also concerns converting organic wastes to compost and returning to soil. This can allow additional crop residues to become available for the bioeconomy. The nutrient cycle considers effective nutrient management to reduce losses and minimize dependence on artificial fertilizers by bringing manure to the required farmlands as well as regenerative agricultural practices such as crop rotations and use of cover crops [21][29][38,43]. Application of digestate (by-product from anaerobic digestion) as a fertilizer is another consideration here. Mineral-rich biomass sources such as manure, organic waste and wastewater sludge can go into anaerobic digestion, which generates biogas and digestate [49][63]. Biogas can be applied directly for energy use, or it can be upgraded to biomethane and used for energy or transport fuel thereafter. The by-product digestate contains minerals and organic material that can be used as a fertilizer returning carbon and nutrients to soil [36][50]. This enables the replacement of industrially produced mineral fertilizers [50][64].

For nutrient management, bringing manure or nutrient-rich residual streams in appropriate places and amounts is needed [20][6]. It is often seen that supply and uptake are not balanced, where both the surplus and deficit of nutrients cause problems. The excessive use will result in run-off to water bodies, causing eutrophication, whereas deficit will reduce soil fertility [18][36].

2.5. Recirculate

In the bioeconomy there are different possibilities of recycling. Biobased products can contribute to organic recycling (related to the fourth principle, regenerate) through industrially compostable biobased products as well as in-situ biodegradation, such as with biodegradable mulching films [51][52][65,66]. The European EN 13,432 “Packaging: requirements for packaging recoverable through composting and biodegradation” is the standard to comply to for treatment in industrial composting facilities. Applying the digestate from anaerobic digestion is also part of organic recycling (see Figure 46, point 2). The third cycle in Figure 35 also depicts the return of carbon and nutrients after various utilization pathways of biomass in the economy.

Biomass also enters the technical cycle (see Figure 46, blue cycle) and is used in the production of chemicals, plastics and materials. The biobased products can be kept in the technical cycle (see Figure 35, fourth cycle) through reuse and recycling mechanically or chemically (see Figure 46, purple lines). It is preferred to keep the cycles tighter (e.g., reuse rather than recycle) to preserve the value, which is referred to as the power of inner cycle [54][67]. It should also be aimed to maximize the number of consecutive cycles and/or the time spent in each cycle by extending the product life [55][68].

Recycling is very well established for paper products, which can be recycled several times [56][69]. Wood fibers can be recycled (mechanically) five to seven times before the quality becomes too low (fiber becomes too short) to produce new paper products due to physical degradation from repulping and processing. For biobased plastics and other materials made using biobased chemicals, there are two main categories: drop-in and dedicated [57][70]. The drop-in chemicals are chemically identical to currently used petrochemicals, can feed into the established market and be recycled using the same system in place [20][6]. For example, polyethylene (PE) and polyethylene terephthalate (PET) produced from biomass can be reused and mechanically recycled together with fossil-based PE and PET with no additional effort [58][71]. For dedicated chemicals, no directly identical fossil-based counterparts exist (i.e., PLA). For their associated products, the waste management system needs to be adapted to achieve efficient recycling of these products.

2.6. Extend the High-Quality Use of Biomass (Including Cascading Use)

It should be aimed to keep the biomass in use as long and at as high a grade as possible. Therefore, it is preferred to preserve the quality while recycling. However, the secondary material attained from recycling is often at a lower quality than the original material due to degradation and contamination [59][73]. This is called downcycling, which should be minimized. Retaining the highest utility in recirculation is very much dependent on the effectiveness of the collection system and the quality and purity of secondary material. Therefore, products should be designed to enable reuse and high-grade recycling as much as possible. Furthermore, the waste management and recycling systems should focus on providing high-quality recycled material to the economy [60][74]. Integrating circular economy principles at the design stage (circular by design) will facilitate high-value recovery after use [61][75].

Furthermore, chemical recycling can be a good approach to avoid downgrading. Chemical recycling allows us to recover building blocks or monomers that plastics are made of and has the advantage of being able to preserve the quality (yields polymer at identical quality to the virgin polymer) [60][74]. In this way, the cycle gets longer, with additional processing required to acquire to the product from monomers, but the original quality can be preserved. There are many research activities and start-ups working on developing this further [62][63][64][65][76,77,78,79].

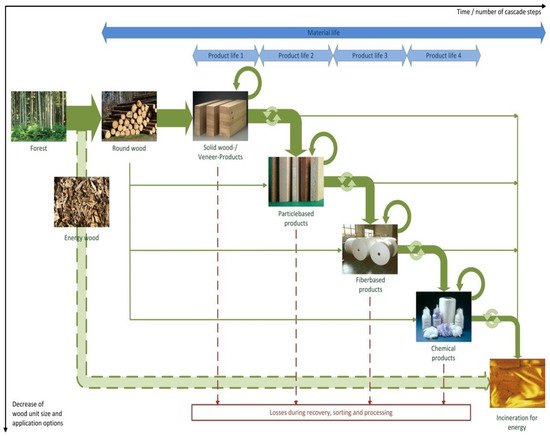

Optimizing the time spent in each cycle and the number of consecutive cycles is sought after (by minimizing the quality loss at each application) [66][80]. In this respect, cascading makes optimal use of biomass in consecutive products. The biomass is ideally used at the highest value and then reused or recycled for the same application as much as possible before moving to lower value applications in the following cascading steps (due to lowering of the quality of the secondary material). Value or quality refers to the functionality based on the inherent and intrinsic material properties such as structure and chemical composition [67][81].

In Figure 57, this is illustrated for wood. Wood is ideally first used for construction as beams, then can be used to make particle board, paper, chemicals and energy as consecutive products while at each stage maximizing closed loop recycling before moving down to lower quality applications [68][82]. It will be important to design the products and recycling systems so that it will be possible to extend the high-quality use of the biomass in such a way. Cascading use can provide substantial reduction in use of virgin resources by consecutively replacing virgin material needs with each application step and allow for highly resource-efficient use of biomass [69][70][83,84]. Cascading can be observed in current practice in the flow of materials between lumber, paper and energy sectors. There is potential for cascading also in use of textiles. They can be reused multiple times (second-hand apparel) for clothing, and when no longer suitable for this original application, they can be used as fiber-fill in upholstery in the furniture industry and then for insulation in the construction industry [54][71][67,85]. Each consecutive application substitutes an inflow of virgin materials into the economy.

Figure 57. Cascading use of biomass with the example of wood (source: Technical University Munich, 2017 [72]).

2.7. What Needs to Be Measured for Monitoring Circularity of Biobased Products

The measurement needs in order to evaluate the circularity performance of biobased products were identified (also included in Table 2). They are divided into two categories, as intrinsic and impact indicators.

The first category refers to indicators providing a measure of intrinsic circularity. This is about what needs to be measured in order to evaluate the circularity performance of biobased products with respect to the six CE principles defined. Linking with the first principle, people would like to minimize virgin fossil feedstock input and substitute the input needed with renewable resources such as biomass. Therefore, the first need concerns here the share of the feedstock that is renewable. Linking with the second and third principles, the second need is a measure of the efficiency of biomass utilization. This includes consideration of multi-output production with biorefining, reduction of waste and valorization of residual streams. The third need is linked with the fourth principle and concerns indicators that measure the degree of regeneration, looking at how well the soil carbon and nutrient cycles are maintained. This also considers organic recycling of biobased products. The fourth need addresses the degree of recirculation (linking with fifth principle), considering how well the loops are closed (by reuse or recycling), thereby minimizing incineration and landfilling. Then, the fifth need concerns measure of utility, which relates to ensuring products stay in the cycle as long as possible in as high a quality as possible (linking with the sixth principle). This also considers cascading use of biomass.

The second category refers to indicators concerning the evaluation of the impact of the transition to the circular economy. While circularity could contribute to improving sustainability, trade-offs exist that need to be addressed [73][74][87,88]. One issue is that along the cascade, products can accumulate hazardous substances. When using biobased materials, the presence of these hazardous substances should be considered, as well as their health and safety effects when closing loops. Accordingly, the sixth need is included, which considers measurement of risk of accumulation of hazardous substances (see Table 2). The use of biomass containing hazardous substances can lead to accumulation in biobased products or in the environment where the product is produced or used [40][41][54,55]. This can have severe impact on plant, animal or human health [75][76][89,90]. They can also enter and concentrate in the food chain [1][3]. It will therefore be appropriate to consider this as part of the overall assessment to measure such consequential toxicity risks and impacts.

Additionally, to be able to assess whether CE successfully supports sustainable development, all three dimensions of sustainability should be included [14][27]. Accordingly, the needs 7 to 9 are included in Table 2 to measure effects on environment, economy and society, respectively. As included in the definition by Kirchherr et al., a circular economy should aim at “simultaneously creating environmental quality, economic prosperity and social equity” [77][20].