Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 2 by Conner Chen and Version 3 by Conner Chen.

The double-tube heat exchanger is one of the most common designs of heat exchangers used in commercial and industrial applications. It is the simplest and one in which hot and cold fluids move in same or opposite directions. Various methods are presented to improve a double-tube heat exchanger. The impact of nanoparticles on nanofluid properties is discussed by analyzing factors such as the concentration, size, and shape of nanoparticles. The nanofluid thermophysical properties and the flow rate are also observed in the heat transfer coefficient and the pressure drop of a double-tube heat exchanger.

- nanofluids

- nanoparticles

- double-pipe heat exchanger

- pressure drop

1. Introduction

The double-tube heat exchanger is one of the most common designs of heat exchangers used in commercial and industrial applications. It is the simplest and one in which hot and cold fluids move in same or opposite directions [1]. A great advantage of the double-tube heat exchanger is the ability to process products with particles without any blockage risk.

The chemical, food, oil, and gas industries use double-pipe heat exchangers to perform tasks such as pasteurization, sterilization, reheating, preheating, digester heating, and effluent heating processes [2], for example, heating and/or cooling in sanitary and pharmaceutical applications. Moreover, the double-tube heat exchanger has been widely used in different renewable energy systems, such as solar energy, waste heat recovery, geothermal, combustion, latent heat energy storage, and air conditioning, due to its simple construction, easy cleaning, and low cost [3].

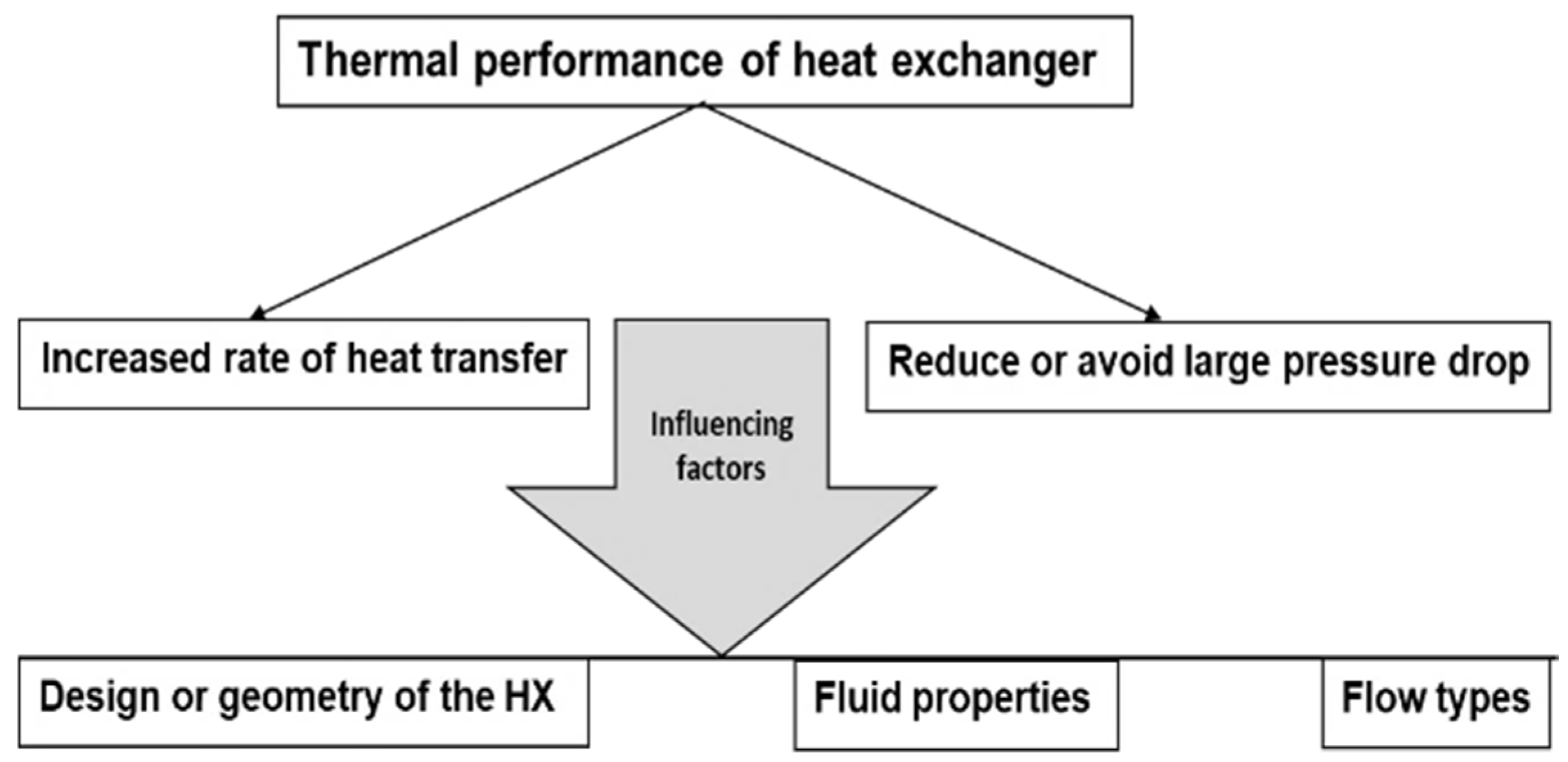

The heat transfer improvement in exchangers is usually accompanied by a pressure drop increase and, as a consequence, it requires higher pumping power. Therefore, any gains from improved heat transfer should be balanced against the associated pressure drop cost [4][5]. In this way, the main reasons for research work on heat exchangers are (i) to enhance their heat transfer rate, consequently reducing the heat exchanger’s overall size, saving initial cost and space, and (ii) to minimize or avoid a large pressure drop, allowing pumping power to be reduced and saving operating costs. Therefore, knowledge about the pressure drop and convective heat transfer characteristics in heat exchangers is essential for adopting this technology into marketable products. Therefore, several techniques are scrutinized in order to enhance heat pipe performance, such as new structure configurations, designs, and technologies or their modification, the integration of heat pipes with other systems such as solar concentrators, improving the working fluid type, or employing heat storage systems [6].

In the recent decade, many scientists have worked to improve performance in heat exchangers using nanofluids as heat transfer fluids. Kavitha et al. experimentally used the CuO-water nanofluid as a heat transfer fluid to enhance a double-pipe heat exchanger [7]. Jassim et al. experimentally assessed TiO2 and Al2O3 nanofluids on heat exchanger performance by considering nanofluids replacing conventional fluid, resulting in performance improvements from 13% to 23% with a concentration of 3% [8]. Ding et al. carried out a numerical simulation of TiO2-water nanofluids in a double-pipe heat exchanger considering various flow rates and TiO2 mass fractions. The results demonstrated that the heat transfer capacities of all mass fractions of TiO2-water nanofluids were higher than those of deionized water, but they also increased the flow resistance in a corrugated pipe [9]. Akbar et al. achieved excellent results employing a hybrid nanofluid (Al2O3+TiO2-water) to improve the heat transfer and pressure drop through horizontal tubes with diameter sizes of 30 to 45 nm. The results proved that the thermophysical properties of the hybrid nanofluid were enhanced from 7 to 13% compared to water, increasing the Nusselt number by approximately 30%, with a slight (5%) increase in pressure drop along a horizontal heated tube and a heat transfer highly appropriate for practical and industrial applications [10]. Jassim et al. experimentally assessed Al2O3 and Cu nanofluids on performance and heat leak in a double-pipe heat exchanger, showing that the Nusselt number was enhanced at all volume concentrations of Cu and Al2O3 nanofluids when compared to the base fluid (water). The Nusselt number was directly proportional to the Reynolds number for all cases. The use of nanoparticles in the base fluid causes an increment in exchanger effectiveness [11]. Mansoury et al. experimentally studied the heat transfer and flow characteristics of an Al2O3-water nanofluid in various heat exchangers on counter flow with a 20 nm nanoparticle size and turbulent flow. The double-pipe heat exchanger presented a 60% enhancement in the heat transfer coefficient, while the plate heat exchanger reflected an 11% increment in the heat transfer coefficient. However, the smallest percentage of pressure drop of 27% was reported in the plate heat exchanger, compared to the double-pipe heat exchanger at 85% [12].

Likewise, several studies confirmed simultaneous improvements in heat exchangers and solar collectors using a nanofluid as one of their heat transfer fluids. Vincely et al. performed an experimental investigation of solar flat plate collector performance using a graphene oxide–water nanofluid under forced circulation connected to a concentric-tube heat exchanger. It was observed that the collector efficiency was enhanced with increasing concentrations and flow rates. The heat transfer coefficient increments for the nanofluid in a laminar flow with concentrations of 0.005, 0.01, and 0.02 were 8.03%, 10.93%, and 11.50%, respectively [13]. Similarly, Henein et al. utilized a MgO/MWCNT-water hybrid nanofluid as a working fluid to enhance the thermal performance of a heat-pipe evacuated-tube solar collector with a 0.02% concentration at various volume flow rates ranging from 1 to 3 L/min. The results showed an enhancement in the energy and exergy efficiencies with an increase in the weight ratios of the MWCNT nanoparticles and the volume flow rate. The energy and exergy efficiency enhancements for the collector were 55.83% and 77.14%, respectively, for the MgO/MWCNT (50:50) hybrid nanofluid [14].

2. Heat Exchanger Performance

Different methodologies were investigated to improve heat exchanger performance. Examples of active and passive methods are summarized in Table 1. For active methods, external forces are required for heat transfer performance in double-tube heat exchangers. Generally, the main external forces used were mechanical forces, ultrasound, and magnetic fields [3]. As can be seen in Table 1, high-power and sophisticated devices were applied to improve the heat transfer rate by active methods. Contrastingly, passive methods did not require a powerful force. In that case, simple techniques were used to improve the heat transfer coefficient. Helical wires and porous media were two techniques considered with a greater percentage of pressure drop. However, this pressure drop could be compensated with a percentage of heat transfer improvement. Passive techniques were better when compared to active techniques because of their simplicity, low cost, and certain level of enhancement with a tolerable pressure drop [15]. The use of nanoparticles has been one of the most promising ways among the passive methods to improve heat exchanger performance.Table 1. Examples of methods used to improve the double-pipe heat exchanger.

| Methods | Improvement Approach | Observations (by Percentage, %) | Ref. |

|---|---|---|---|

| Active | Using air bubble injection | The percentage improvement of the overall heat transfer coefficient can be from 10.30% to 149.50%. | [16] |

| Using surface vibrations | Heat transfer coefficient enhancement of 9% | [17] | |

| Using magnetic field | Heat transfer enhancement up to 320% and a slight increase in pressure drop | [18] | |

| Using ultrasonic vibration | Heat transfer is enhanced by about 60%. | [19] | |

| Passive | Porous media | Enhanced heat transfer of 44% with larger pressure drops | [20] |

| Using fins | Heat transfer rate enhancement of around 90–98%. Pressure drops for finned tube also increased. | [21] | |

| Helical wires | Augments Nusselt number by up to 2.64 fold. Increases friction factor by about 2.74 fold. | [22] | |

| Twisted tape | Significant (15%) enhancement in heat transfer rate. Friction factor increased by 10%. | [23] | |

| Metal foam | Nusselt number enhanced by 57.21%. | [24] | |

| Nanofluids (MgO-ethylene glycol) | Heat transfer coefficient enhancement of 27% for wt.% = 0.3 and 35% pressure drop at wt.% = 0.3. | [25] |

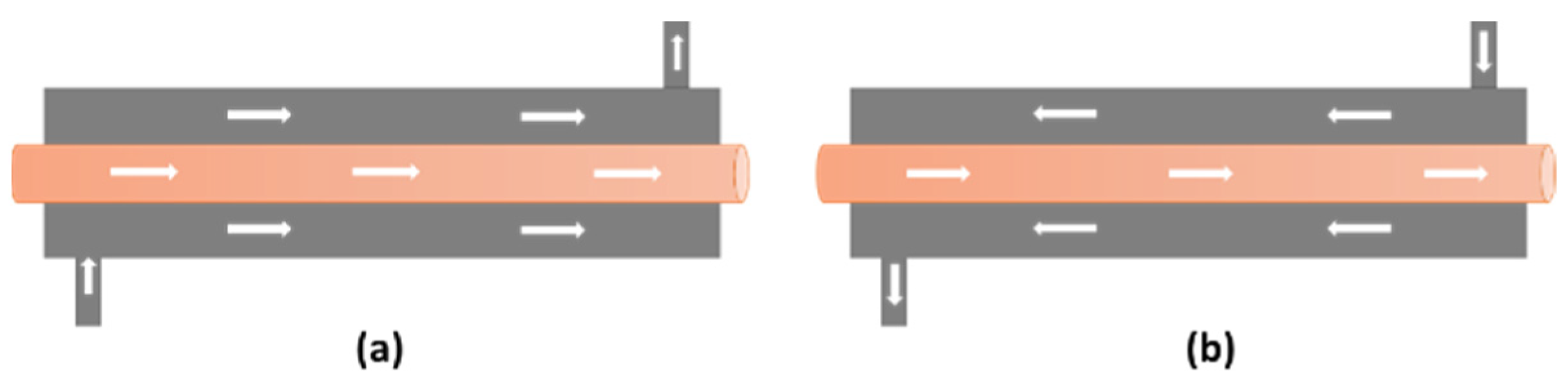

Figure 1. Double-pipe heat exchangers using (a) parallel flow and (b) counter flow [3].

Figure 2. Scheme showing factors influencing heat exchanger performance.

References

- Rao, V.N.; Sankar, B.R. Heat transfer and friction factor investigations of CuO nanofluid flow in a double pipe U-bend heat exchanger. Mater. Today Proc. 2019, 18, 207–218.

- Omidi, M.; Farhadi, M.; Jafari, M. A comprehensive review on double pipe heat exchangers. Appl. Therm. Eng. 2017, 110, 1075–1090.

- Li, H.; Wang, Y.; Han, Y.; Li, W.; Yang, L.; Guo, J.; Liu, Y.; Zhang, J.; Zhang, M.; Jiang, F. A comprehensive review of heat transfer enhancement and flow characteristics in the concentric pipe heat exchanger. Powder Technol. 2021, 397, 117037.

- Cengel, Y. Heat and Mass Transfer. A Practical Approach, 3rd ed.; McGraw-Hill/Interamericana Editores, S.A.: Mexico City, Mexico, 2013; pp. 1689–1699.

- Bergman, T.L.; Lavine, A.S.; Incropera, F.P. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2011; Available online: https://books.google.cl/books?id=5cgbAAAAQBAJ (accessed on 20 August 2022).

- Alshukri, M.J.; Hussein, A.K.; Eidan, A.A.; Alsabery, A.I. A review on applications and techniques of improving the performance of heat pipe-solar collector systems. Sol. Energy 2022, 236, 417–433.

- Kavitha, R.; Algani, Y.M.A.; Kulkarni, K.; Gupta, M. Heat transfer enhancement in a double pipe heat exchanger with copper oxide nanofluid: An experimental study. Mater. Today Proc. 2021, 56, 3446–3449.

- Jassim, E.I.; Ahmed, F. Assessment of nanofluid on the performance and energy-environment interaction of Plate-Type-Heat exchanger. Therm. Sci. Eng. Prog. 2021, 25, 100988.

- Ding, Z.; Qi, C.; Luo, T.; Wang, Y.; Tu, J.; Wang, C. Numerical simulation of nanofluids forced convection in a corrugated double-pipe heat exchanger. Can. J. Chem. Eng. 2021, 100, 1954–1964.

- Akbar, H.M.; Mohammed, A.S.; Ezzat, S.B. Hybrid nanofluid to improve heat transfer and pressure drop through horizontal tube. Mater. Today Proc. 2021, 42, 1885–1888.

- Jassim, E.I.; Ahmed, F. Experimental assessment of Al2O3 and Cu nanofluids on the performance and heat leak of double pipe heat exchanger. Heat Mass Transf. 2020, 56, 1845–1858.

- Mansoury, D.; Doshmanziari, F.I.; Kiani, A.; Chamkha, A.J.; Sharifpur, M. Heat Transfer and Flow Characteristics of Al2O3/Water Nanofluid in Various Heat Exchangers: Experiments on Counter Flow. Heat Transf. Eng. 2019, 41, 220–234.

- Vincely, D.A.; Natarajan, E. Experimental investigation of the solar FPC performance using graphene oxide nanofluid under forced circulation. Energy Convers. Manag. 2016, 117, 1–11.

- Henein, S.M.; Abdel-Rehim, A.A. The performance response of a heat pipe evacuated tube solar collector using MgO/MWCNT hybrid nanofluid as a working fluid. Case Stud. Therm. Eng. 2022, 33, 101957.

- Rajesh Babu, C.; Kumar, P.; Roy, S.; Ganesan, R. A comprehensive review on compound heat transfer enhancement using passive techniques in a heat exchanger. Mater. Today Proc. 2021, 54, 428–436.

- Heyhat, M.M.; Abdi, A.; Jafarzad, A. Performance evaluation and exergy analysis of a double pipe heat exchanger under air bubble injection. Appl. Therm. Eng. 2018, 143, 582–593.

- Hosseinian, A.; Isfahani, A.H.M. Experimental study of heat transfer enhancement due to the surface vibrations in a flexible double pipe heat exchanger. Heat Mass Transf. 2017, 54, 1113–1120.

- Bezaatpour, M.; Goharkhah, M. Convective heat transfer enhancement in a double pipe mini heat exchanger by magnetic field induced swirling flow. Appl. Therm. Eng. 2020, 167, 114801.

- Setareh, M.; Saffar-Avval, M.; Abdullah, A. Experimental and numerical study on heat transfer enhancement using ultrasonic vibration in a double-pipe heat exchanger. Appl. Therm. Eng. 2019, 159, 113867.

- Akbarzadeh, M.; Rashidi, S.; Keshmiri, A.; Shokri, N. The optimum position of porous insert for a double-pipe heat exchanger based on entropy generation and thermal analysis. J. Therm. Anal. 2020, 139, 411–426.

- Baba, M.S.; Raju, A.S.R.; Rao, M.B. Heat transfer enhancement and pressure drop of Fe3O4 -water nanofluid in a double tube counter flow heat exchanger with internal longitudinal fins. Case Stud. Therm. Eng. 2018, 12, 600–607.

- Akpinar, E.K. Evaluation of heat transfer and exergy loss in a concentric double pipe exchanger equipped with helical wires. Energy Convers. Manag. 2006, 47, 3473–3486.

- Naphon, P. Heat transfer and pressure drop in the horizontal double pipes with and without twisted tape insert. Int. Commun. Heat Mass Transf. 2006, 33, 166–175.

- Shirvan, K.M.; Ellahi, R.; Mirzakhanlari, S.; Mamourian, M. Enhancement of heat transfer and heat exchanger effectiveness in a double pipe heat exchanger filled with porous media: Numerical simulation and sensitivity analysis of turbulent fluid flow. Appl. Therm. Eng. 2016, 109, 761–774.

- Arya, H.; Sarafraz, M.M.; Pourmehran, O.; Arjomandi, M. Heat transfer and pressure drop characteristics of MgO nanofluid in a double pipe heat exchanger. Heat Mass Transf. 2019, 55, 1769–1781.

- Okonkwo, E.C.; Wole-Osho, I.; Almanassra, I.W.; Abdullatif, Y.M.; Al-Ansari, T. An updated review of nanofluids in various heat transfer devices. J. Therm. Anal. 2021, 145, 2817–2872.

- Ambreen, T.; Kim, M.-H. Heat transfer and pressure drop correlations of nanofluids: A state of art review. Renew. Sustain. Energy Rev. 2018, 91, 564–583.

- Gupta, M.; Singh, V.; Kumar, R.; Said, Z. A review on thermophysical properties of nanofluids and heat transfer applications. Renew. Sustain. Energy Rev. 2017, 74, 638–670.

More