1. Cool Roofs Pros and Cons and Its Relationship with the Weather

In the design stage of roofing systems, the energy savings and risk of condensation are important. The moisture-related problems can lead to deterioration of roofing materials and affect negatively the thermal performance by means of reduction in overall thermal resistance and service life of the roofing systems. This can lead as well to mold growth in those systems and affect the indoor air quality (IAQ) and the occupants’ health and comfort

[1][2][3][4][5][6][7][8][9][14,15,76,77,78,79,80,81,82].

The roof surface reflectivity can affect the quantity of the absorbed short-wave energy of the roof. Since the short-wave solar radiation has the capacity during the summer and daytime to dry out the roof, the solar reflectivity becomes an important parameter for the selection of roofing materials

[1][2][10][11][12][13][6,14,15,36,39,83]. The characteristic of the cool roofs is to maintain surface temperatures lower than those from the black roof (dark) because of its low short-wave solar absorption coefficient. This may lead to moisture-related problems in cold climate zones

[14][84] as such observed for both black and cool roofs

[1][2][14,15]. Several studies have investigated the moisture-related problems due to the colour of the roofing membrane in commercial buildings with a low slope such as in

[15][85] research. Their study was done for cold climate with the focus on single-ply roofing systems with highly reflective materials, white TPO/PVC and black membranes, where they are attached mechanically on low slope roofs (≤2:12). In this research

study, hygrothermal simulations were conducted for a one-year period on those roofing systems for the following cities in the USA: Boston, Albany, Chicago, Cleveland and Detroit. Two cases were studied: (i) 10% short-wave solar reflectivity for black roofs, and (ii) 70% short-wave solar reflectivity for white roofs. Since those systems are mechanically attached to the metal deck and to account for the leakage due to the attachment, the vapour permeance of metal was taken at 0.75 perms. The results showed that even there is condensation below the membrane TPO/PVC in the winter, all roofs have dried out in the summer.

Hygrothermal simulations were conducted

[16][86] for a 5-year period. They explored the moisture accumulation in different roofing systems (i.e., white with 80% short-wave solar reflectivity and black roofs with 12%) for different cities in the USA and Germany (Phoenix, AZ, Chicago, IL, Anchorage, AK, and Holzkirchen, Germany). The results of this

res

earchtudy showed that the white roofs have more moisture accumulation than the black ones. Three roofing systems cases, dark, bright and shaded flat roofs, have been studied by

[17][87] for their hygrothermal performance with initial construction moisture. In the summer, the results showed that the bright roofs have the lowest surface temperatures with a smaller drying potential than the two other roofing systems. The highest surface temperature and humidity fluctuations were shown in the dark roofs with high heat fluxes. The roof with shaded surfaces has shown as well a low temperature and drying potential.

Hygrothermal simulations on white and black Modified-Bitumen (MOD-BIT) roofing systems have been conducted by

[1][2][14,15]) to evaluate their energy and moisture accumulation for different climate zones in North America based on their Heating-Degree-Days (HDD) such as Toronto (ON), Montreal (QC), St. John’s (NL), Saskatoon (SK), Seattle (WA), Wilmington (AZ), and Phoenix (AZ). In the cities of St. John’s and Saskatoon, the white roofs showed the highest moisture accumulation over time than the black ones which could lead to moisture damage. On the contrary, there is no risk for the black roofs. The simulation results for Toronto, Montreal, Seattle, Wilmington, and Phoenix, showed that the white roofs have a low risk of experiencing moisture damage. The yearly heating loads of the white roof were slightly higher than that of the black roof. Conversely, the yearly cooling loads of the black roof were much important than the white roof. Thus, buildings with white roofs in these locations are predicted to result in net yearly energy savings compared to buildings with black roofs.

Most recently, several researchers

[1][2][3][4][5][6][7][8][9][13][14][15][16][17][18][19][20][21][22][23][14,15,16,72,73,74,75,76,77,78,79,80,81,82,83,84,85,86,87,88] conducted several studies to investigate the performance of cool and black roofs in terms of energy and moisture when they were subjected to different hot and humid climates in GCC countries. These studies covered several thicknesses of roof insulation material and surface solar reflectivity. These roofing systems showed no risk of condensation, thus, no risk of mold growth and roofs with high solar reflectivity showed significant energy savings. For the Eastern Province of Saudi Arabia and Kuwait City, respectively, the highest hourly surface temperatures of the black roofs were found to be 93.2 °C and 84.0 °C compared to 65.4 °C and 61.5 °C for a white roof at no cleaning condition, and 52.7 °C and 52.6 °C for white roofs at weekly cleaning conditions. The full results of that study that include material characterizations, installing guidelines, cleaning procedures, test results, three-dimensional numerical results, etc., are available in

[24][25][69,70].

2. Application and Maintenance of Cool Roofs

The application process of white roofing material requires technical knowledge as does the maintenance processes involved. Yet, the maintenance processes involved in white roofing materials must also be known from a marketing perspective. This is because emerging economies typically have limited resources available. At a granular level, however, entities that utilize white roofing materials as a means to reduce the cooling energy load of a structure, reduce environmental heat build-up and as well seek to control costs have to consider the post-application phase of the material. As mentioned, the technical application of the white roof depends upon the form of white roofing material selected. Likewise, maintenance is also dependent upon what material is selected. In effect, cost factors must also be considered with respect to ongoing maintenance of white roofs in developing markets.

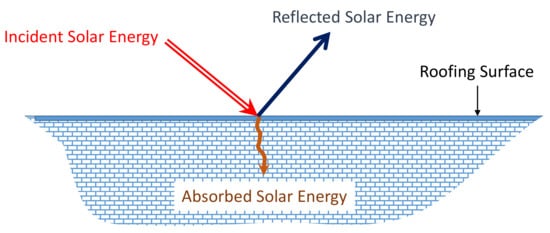

The exterior surface of the roofing system is exposed to dust/dirt, rain, snow, wind, cloud index, exterior temperature and relative humidity, etc. All these external conditions as well as the roofing systems specifications (components, dimensions, etc.) could affect the roofing system’s thermal and hygrothermal performance. As shown in Figure 14, when solar radiation hits the surface of a roofing system, a portion of this energy is reflected and the other portion is absorbed. Due to this energy absorption, the roof’s surface temperature increased, thus in the summer, the cooling energy load increased and in the winter, the heating energy load decreased. On the other hand, white roofing systems use surfaces with low short-wave solar absorption coefficient to show a significant portion of the incident short-wave solar radiation, and therefore, lowers the cooling energy load and as well the roof’s surface temperature compared to black roofing systems.

Figure 14.

Schematic of roofing surface subjected to incident solar energy.

The surface solar reflectivity can be affected negatively by the accumulation of dust or dirt on those surfaces, which can result in increasing solar heat gains. Several researchers

[26][27][28][29][30][29,30,33,34,35] have investigated the negative effect of the dust or dirt accumulation and weathering factors on the roofs’ thermal properties. Additionally, several cleaning processes of dust or dirt on roofing systems’ surfaces have been established to bring back roofing surfaces’ solar reflectivity to its original value such as in Levinson et al.

[29][34] studies on light-coloured roofing membranes’ solar heat gain.

In the

res

earchtudy [29][34], several roofing membranes with white or light gray polyvinyl chloride collected from different locations in the USA were tested. Black and inorganic carbon were found on the surface of the sample. These contaminants reduce the solar reflectivity of these membranes. To analyze the influence of several cleaning processes on the solar reflectivity values, the sample surfaces were firstly wiped to mimic the action of the wind action, then rinsed to mimic rain effect, and they were washed in the third step to simulate a homemade cleaning process using a phosphate-free dishwashing detergent. As a final step, all the surfaces were treated with sodium hydroxide and a mixture of sodium hypochlorite to mimic real cleaning processes. The outcomes of

res

earchtudy [29][34] showed that after washing and rinsing processes, almost all the dirt deposited on the surface was removed except for thin layers of organic carbon and some isolated dark spots of biomass. Bleaching processes cleared these last two contaminants recovering the loss of solar reflectivity.

Akbari et al.

[30][35] used an identical cleaning process established in

[29][34] on unweathered (i.e., new materials) and weathered single ply roofing membranes from several North American sites. In this research

study, 16 types of roofing materials were tested at Lawrence Berkeley National Laboratory (LBNL), following all the cleaning processes concerning the weathered samples surface treatment, and 25 other types were tested at the National Research Council of Canada, applying just wiping processes on the surface of the roofing material. The results showed that all types of cleaning recovered near 90% of their unweathered solar reflectivity and thus, showed their effectiveness.

To the best of the ouresearchers' knowledge, most (if not all) previous studies related to characterizing the impact of dust or dirt accumulation on the rooftops and its impact on cool roofs’ energy performance were conducted in non-dusty climates. As such, a new joint research study between the KSA’s Jubail University College (JUC) and Kuwait Institute for Scientific Research (KISR), called “JUC-KISR project” was initiated to address this issue in a dusty climate. Several roofing materials with different emissivity are currently being tested and numerically modelled under the dusty and polluted climate of KSA’s Jubail Industrial City. The objectives of JUC-KISR project include: (i) motioning the short-wave solar reflectivity’s variation of the tested materials, (ii) developing a technical guide for dust and dirt cleaning processes for the tested materials, and (iii) quantification the effect of dirt and dust accumulation of on the overall roofing systems’ energy and moisture performance. The developed technical guide will be proposed later to International Organizations such as ASTM or ASHRAE to develop an international standard for the cleaning procedure of different reflective materials for use in residential and commercial buildings when they are subjected to dusty and non-dusty climates.

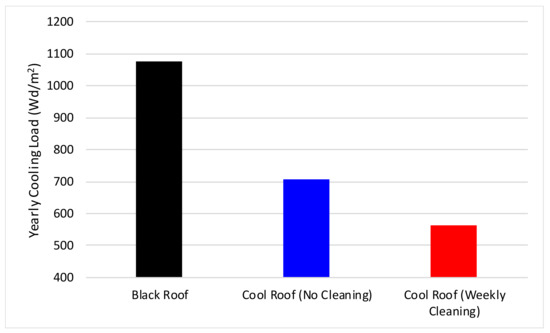

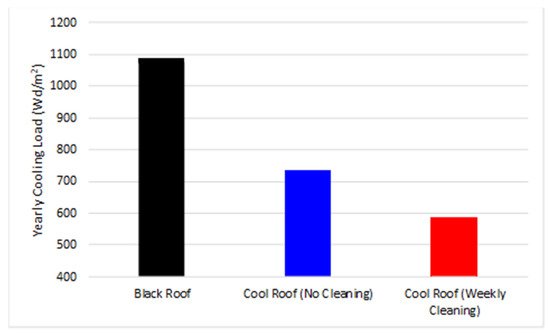

In the JUC-KISR project, one of the reflective coating materials was characterized and tested under the highly polluted and dusty weather of Jubail Industrial City. Thereafter, this reflective coating material was used in one of the most common roofing systems in GCC countries when it was exposed to Kuwait City and Eastern Province of Saudi Arabia’s environmental conditions. For Saudi Eastern Province climates, Figure 25 shows that the yearly cooling load (EC, Y) of the conventional/black roof (1077 Wd/m2) decreased to 706 Wd/m2 (i.e., a reduction in EC, Y by 53%) and 563 Wd/m2 (i.e., a reduction in EC, Y by 91%) as a result of installing reflective coating material at no cleaning condition and weekly cleaning condition, respectively. Furthermore, as shown in Figure 36 for Kuwait City climates, the yearly cooling load of the black roof (1091 Wd/m2) decreased to 730 Wd/m2 (i.e., a reduction in EC, Y by 49%) and 592 Wd/m2 (i.e., a reduction in EC, Y by 84%) as a result of installing reflective cooling material at no cleaning condition and weekly cleaning condition, respectively.

Figure 25. Comparison of the yearly cooling energy load of conventional/black roof and white roof based on no cleaning condition and weekly cleaning condition and subjected to Saudi Eastern Province climates

[19][31][71,72].

Figure 36. Comparison of the yearly cooling energy load of conventional/black roof and white roof based on no cleaning condition and weekly cleaning condition and subjected to Kuwait City climates

[19][31][71,72].

For the Eastern Province of Saudi Arabia and Kuwait City’s environmental conditions, respectively, the highest hourly black roofs’ surface temperatures were 93.2 °C and 84.0 °C compared to 65.4 °C and 61.5 °C for white roof at no cleaning condition, and 52.7 °C and 52.6 °C for white roofs at weekly cleaning conditions. The full results of the JUC-KISR project that include material characterizations, installing guidelines, cleaning procedures, test results, three-dimensional numerical results, etc., are available in

[19][31][71,72].

In summary, a logical step towards achieving energy-efficient buildings in cities with extreme climatic conditions is to design roofing systems with simultaneous energy savings, no condensation and less risk of moisture problems. The main parameters affecting the energy and moisture performance of roofing systems are a type of roof, environmental conditions, amount of insulation and the solar reflectivity of the roofing surfaces. Several cleaning processes have been used to increase the solar reflectivity to reach approximately its initial value in case there is dust/dirt accumulation on the roofing surface.