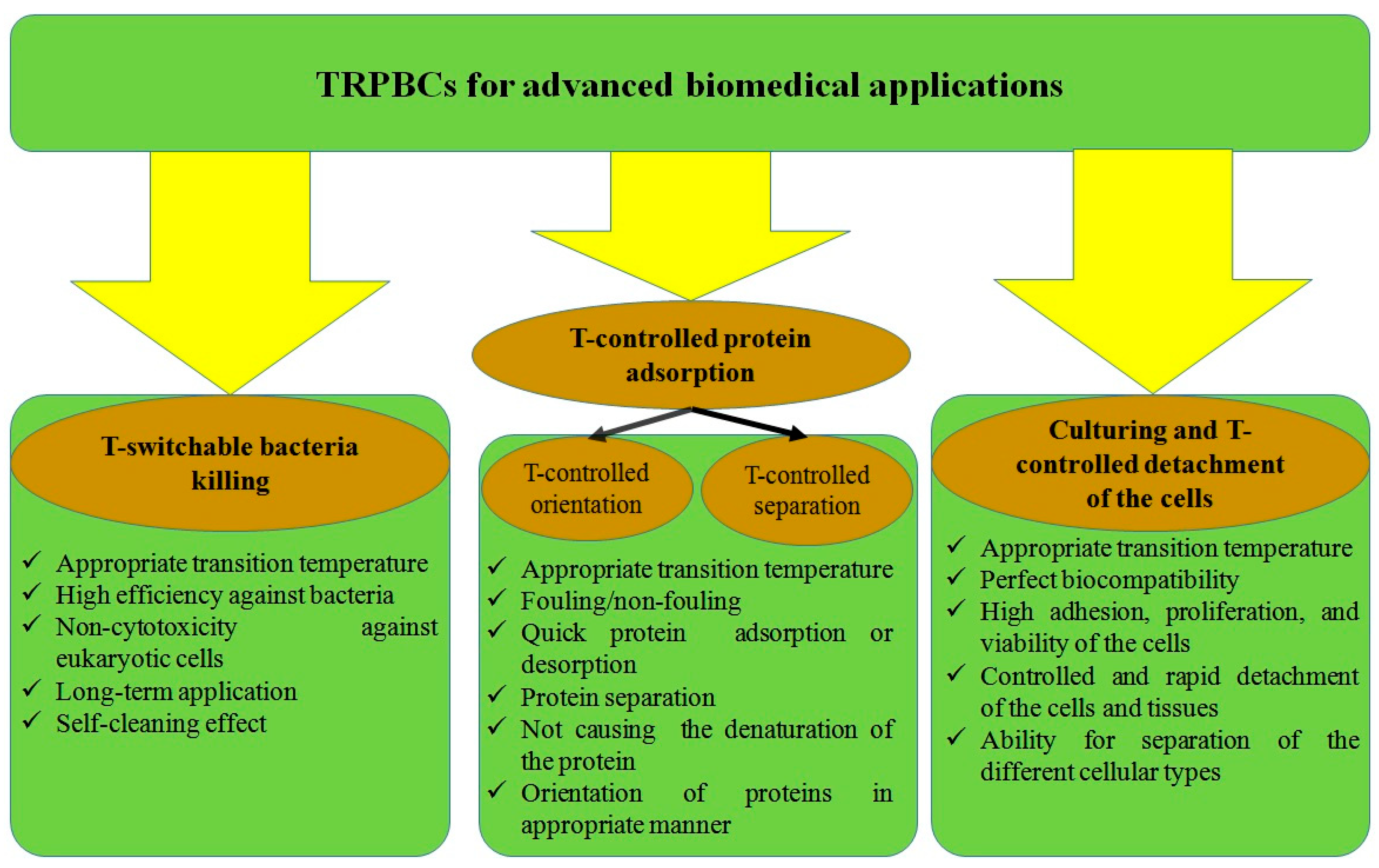

Modern biomedical technologies predict the application of materials and devices that not only can comply effectively with specific requirements, but also enable remote control of their functions. One of the most prospective materials for these advanced biomedical applications are materials based on temperature-responsive polymer brush coatings (TRPBCs). Despite progress in the development of such interesting materials, there are still some issues that need to be resolved, such as biocompatibility, high efficiency, selectivity of the action, stability, long-term and multiple-use, and the temperature of the transition close to physiological temperatures (appropriate transition temperature). The mechanisms of their temperature-induced reactions are one of the most crucial elements that affect the characteristics of temperature-sensitive grafted brush coatings. The TRPBCs exhibit the response to temperature governed by different mechanisms attributed to intermolecular interactions of the macromolecular chains between themselves and with the environment. The mechanism responsible for the temperature-dependent properties of polymer brushes is strongly dependent on the chemical nature of the macromolecular chains.

- temperature-responsive polymers

- brushes

- coatings

1. Introduction

2. Mechanisms of the Temperature-Induced Transition of TRPBCs

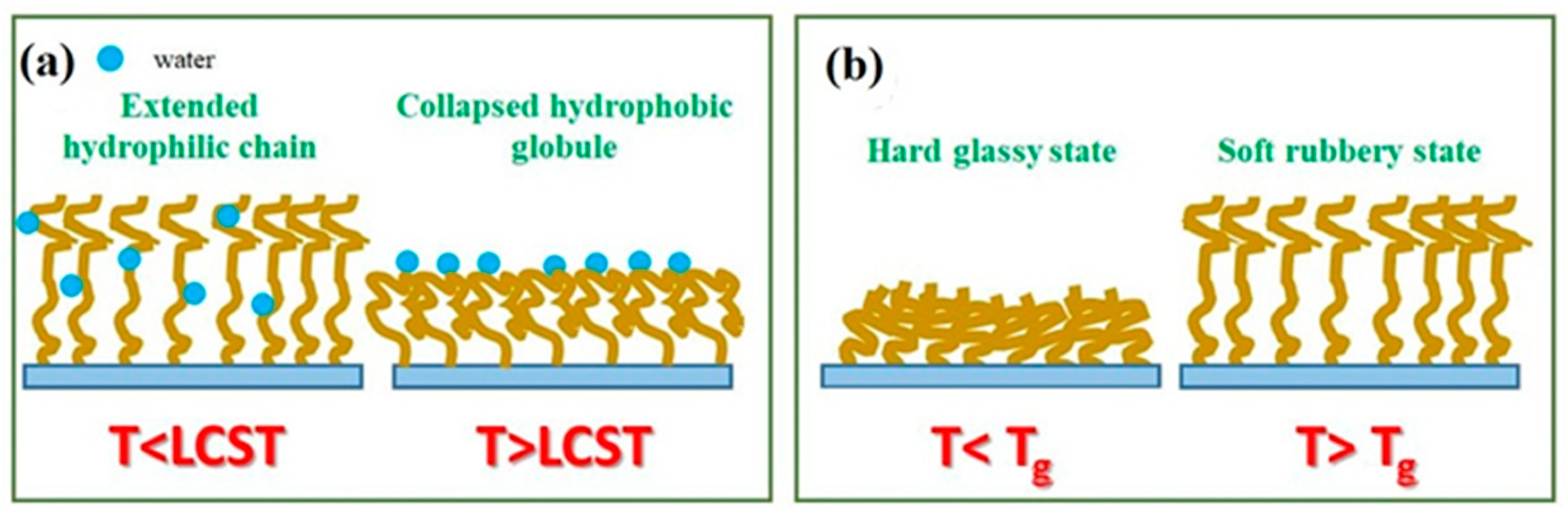

The TRPBCs exhibit the response to temperature governed by different mechanisms attributed to intermolecular interactions of the macromolecular chains between themselves and with the environment [1,25,30,31][1][25][30][31]. The mechanism responsible for the temperature-dependent properties of polymer brushes is strongly dependent on the chemical nature of the macromolecular chains. The first group of transitions is related to critical solution temperatures (Upper and Lower Critical Solution Temperatures (UCST and LCST)) and cannot be realized without surrounding solvents [32,33,34][32][33][34]. For advanced biomedical applications, TRPBSs with LCST based on NIPAM, oligo(ethylene glycol)ethyl ether methacrylate with Mw = 246 (OEGMA246), di(ethylene glycol)methyl ether methacrylate (other names 2-(2-methoxyethoxy)ethyl methacrylate or OEGMA188) (DEGMA) and their copolymers with various monomers are manufactured and exploited [1]. The second group of transitions is related to temperature-induced changes in the physical state of polymers, where the presence of solvent is not required (glass–glass, glass-rubber (Tg), nematic-isotropic temperature transitions in polymers) [35]. In this preseaper, werch, researchers focus on transitions based on LCST and Tg, which are most suitable for fabrication of the biomedical devices. These transitions are schematically sketched in Figure 2.

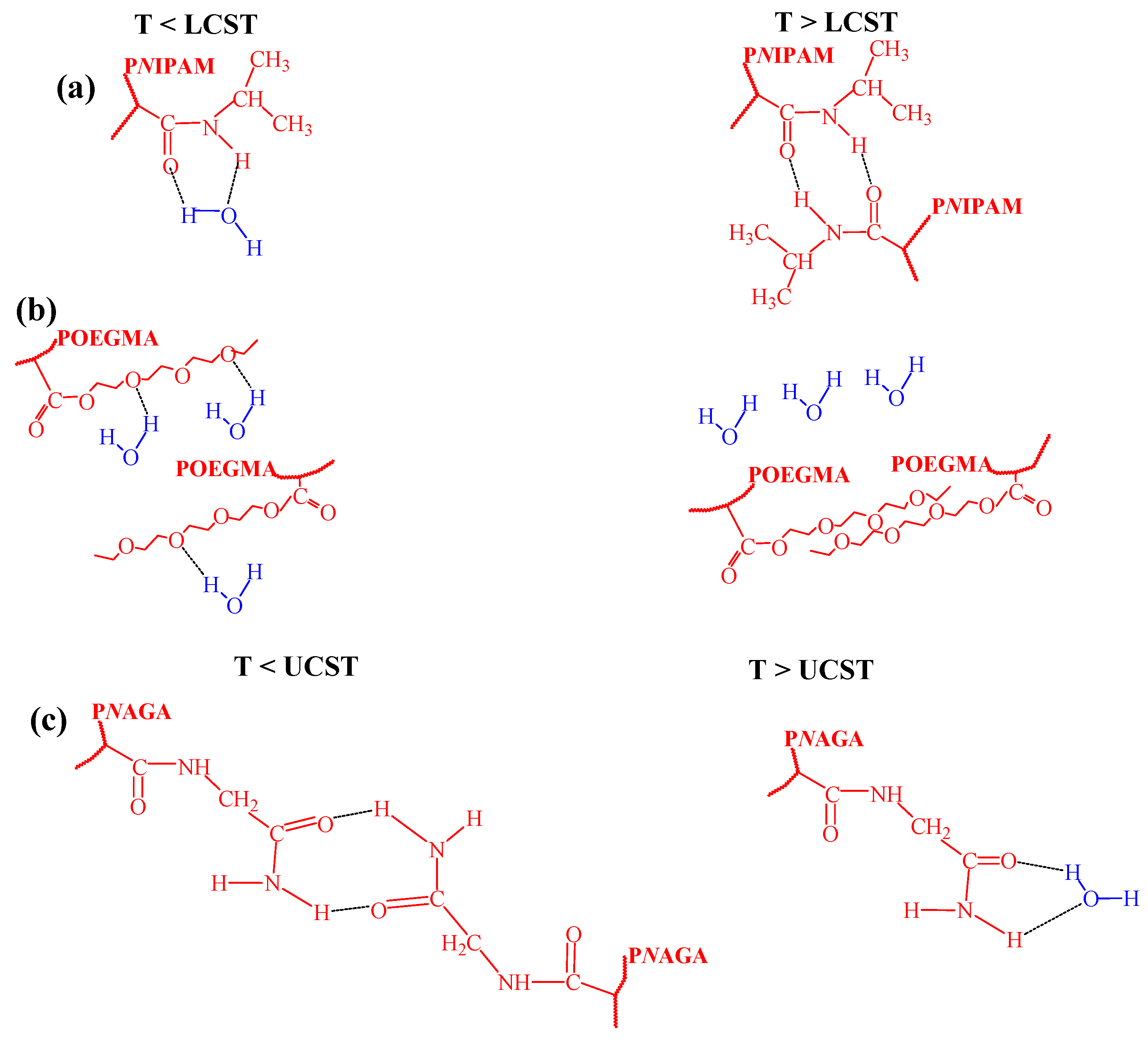

2.1. TRPBCs with Critical Solution Temperatures

The LCST (UCST) is the critical temperature below (above) which the components of a mixture are miscible for all concentrations. Transitions governed by LCST (and UCST) of polymers result in a change in the thickness and wettability of polymer brush coatings [1,36][1][36]. Below LCST, macromolecular chains are in an extended hydrophilic chain conformation, miscible with the environment [37]. When the temperature increases above the LCST, the macromolecules collapse and transform into collapsed hydrophobic globules weakly miscible with the environment [37]. This scenario is opposite for polymers with UCST, where the macromolecular chains are in the collapsed hydrophobic state below UCST and in the extended hydrophilic chain conformation above UCST [33,38,39,40,41,42][33][38][39][40][41][42]. In polymer chemistry, the phenomenon of the LCST is related to the systems based on polymer-solvent mixtures that are miscible below a given critical temperature and turn to two-phase unmixed systems above this critical temperature. The Gibbs free energy change (ΔG) related to the mixing of these two phases is negative below the LCST and positive above it, and the entropy change ΔS = −(dΔG/dT) is negative for the mixing process. This is in contrast to the more common and intuitive case, in which the entropy change promotes mixing because of the increased volume accessible to each component upon mixing. In general, the unfavorable entropy of mixing responsible for the LCST may have two physical origins. The first is related to interactions between the two components, such as strong polar interactions or hydrogen bonds, which prevent random mixing. The second physical factor that can lead to LCST is compressibility effects, especially in polymer-solvent systems [43,44][43][44]. In contrast to the LCST, the UCST is the critical temperature above which the components of a mixture are miscible in all proportions. Phase separation at the UCST is driven by unfavorable energetics; in particular, interactions between components favor a partially demixed state [43,44][43][44]. The TRPBCs most commonly used in biomedicine include OEGMA- or NIPAM-based polymer systems. The conformations of the macromolecular chains for these polymers are governed by hydrogen bonding, as sketched in Figure 3. For PNIPAM and copolymers with NIPAM fragments, hydrogen bonds between hydrophilic amide groups of NIPAM and water are established at T < LCST. Once the temperature increases above LCST, these bonds break, and other hydrogen bonds are established between the amide groups in the NIPAM chains [1,45,46,47][1][45][46][47] (Figure 3a). In case the of POEGMA, hydrogen bonds occur between the ether oxygen of poly(ethylene glycol) and water hydrogens at T < LCST, while at T > LCST the hydrogen bonds between the ethers in polymer chains are dominant (Figure 3b) [47,48,49,50][47][48][49][50]. Transitions are accompanied by changes in the volume and surface hydrophilicity. In the work [51], a series of dense water-swollen polymer brushes was studied using contact angle measurements, ellipsometry and quartz crystal microbalance. Diagrams of surface versus volume hydrophilicity of the brushes allow one to identify two types of behavior: strongly water-swollen brushes exhibit a progressive decrease in volume hydrophilicity with temperature, while surface hydrophilicity changes moderately; weakly water-swollen brushes have a close-to-constant volume hydrophilicity, while surface hydrophilicity decreases with temperature. Thermoresponsive brushes abruptly switch from one behavior to the other and do not exhibit an abrupt change of surface hydrophilicity throughout their collapse transition. In general, there is no direct correlation between surface hydrophilicity and volume hydrophilicity, because surface properties depend on the details of conformation and composition at the surface, while volume properties are averaged over a finite region within the brush [51]. In contrast to results reported in the work [51], ouresearchers' works [1,47,48,49][1][47][48][49] always showed strong changes in surface hydrophilicity at temperature-induced transitions. These differences may be related to the different structures of TRPBCs (thickness, grafting density, or other factors).

2.2. TRPBCs with Tg

The glass-rubber transitions of the polymers or α-relaxation influence the elasticity of the polymeric surface [25,31,35,65,66,67][25][31][35][65][66][67]. Below the glass-rubber transition temperature, the polymer is in the hard glassy state; above the glass-rubber transition temperature, the polymer is in the soft rubbery state. In the glassy state, the neighboring macromolecules interact quite strongly, tending to link together. Above the glass-rubber transition, the neighboring macromolecules interact weaker. This also affects the morphology of the polymer grafted brush coatings, which are strongly transformed from highly rough and structured at T < Tg to relatively smooth at T > Tg. It should be noted that temperature-induced transitions, such as glass–glass transitions or β-relaxation might have a weak influence on surface elasticity while showing a considerable influence on wettability, heat capacity, and refractive index [35,66,67][35][66][67]. Glass–glass transitions can be attributed to a particular molecular rearrangement in the glassy polymer state, significantly less expressed than in the glass-rubber transition. Liquid crystalline polymers form orientationally ordered anisotropic liquid crystalline phases in a well-defined temperature range [35,66,67,68,69][35][66][67][68][69]. Polymers that undergo these transitions are used for temperature-controlled orientation of proteins [25], aligning of liquid crystals [66], and are promising materials for temperature-stimulated cell detachment [31,67][31][67]. The glass transition was reported for poly(butyl methacrylate) (PBMA) TRPBCs [31], where it is shown that Tg is depends on the thickness of the brush coating. The dependence of transition temperature on the thickness of the coatings was also demonstrated for poly(methyl methacrylate) and polystyrene TRPBCs [70,71,72][70][71][72].References

- Stetsyshyn, Y.; Raczkowska, J.; Harhay, K.; Gajos, K.; Melnyk, Y.; Dąbczyński, P.; Shevtsova, T.; Budkowski, A. Temperature-Responsive and Multi-Responsive Grafted Polymer Brushes with Transitions Based on Critical Solution Temperature: Synthesis, Properties, and Applications. Colloid. Polym. Sci. 2020, 299, 363–383.

- Brunato, S.; Mastrotto, F.; Bellato, F.; Garofalo, M.; Göddenhenrich, T.; Mantovani, G.; Alexander, C.; Gross, S.; Salmaso, S.; Caliceti, P. Thermosensitive “Smart” Surfaces for Biorecognition Based Cell Adhesion and Controlled Detachment. Macromol. Biosci. 2021, 21, 2000277.

- Azzaroni, O.; Szleifer, I. Polymer and Biopolymer Brushes: For Materials Science and Biotechnology; John Wiley & Sons: Hoboken, NJ, USA, 2017; pp. 1–780.

- Peng, S.; Bhushan, B. Smart Polymer Brushes and Their Emerging Applications. RSC Adv. 2012, 2, 8557–8578.

- Budkowski, A.; Klein, J.; Fetters, L.J. Brush Formation by Symmetric and Highly Asymmetric Diblock Copolymers at Homopolymer Interfaces. Macromolecules 1995, 28, 8571–8578.

- Li, Z.; Tang, M.; Liang, S.; Zhang, M.; Biesold, G.M.; He, Y.; Hao, S.M.; Choi, W.; Liu, Y.; Peng, J.; et al. Bottlebrush Polymers: From Controlled Synthesis, Self-Assembly, Properties to Applications. Prog. Polym. Sci. 2021, 116, 101387.

- Xia, Y.; Adibnia, V.; Huang, R.; Murschel, F.; Faivre, J.; Xie, G.; Olszewski, M.; De Crescenzo, G.; Qi, W.; He, Z.; et al. Biomimetic Bottlebrush Polymer Coatings for Fabrication of Ultralow Fouling Surfaces. Angew. Chem. Int. Ed. 2019, 58, 1308–1314.

- Zhang, R.; Liu, Y.; He, M.; Su, Y.; Zhao, X.; Elimelech, M.; Jiang, Z. Antifouling Membranes for Sustainable Water Purification: Strategies and Mechanisms. Chem. Soc. Rev. 2016, 45, 5888–5924.

- Mei, H.; Mah, A.H.; Hu, Z.; Li, Y.; Terlier, T.; Stein, G.E.; Verduzco, R. Rapid Processing of Bottlebrush Coatings through UV-Induced Cross-Linking. ACS Macro Lett. 2020, 9, 1135–1142.

- Mah, A.H.; Mei, H.; Basu, P.; Laws, T.S.; Ruchhoeft, P.; Verduzco, R.; Stein, G.E. Swelling Responses of Surface-Attached Bottlebrush Polymer Networks. Soft Matter 2018, 14, 6728–6736.

- Mei, H.; Laws, T.S.; Mahalik, J.P.; Li, J.; Mah, A.H.; Terlier, T.; Bonnesen, P.; Uhrig, D.; Kumar, R.; Stein, G.E.; et al. Entropy and Enthalpy Mediated Segregation of Bottlebrush Copolymers to Interfaces. Macromolecules 2019, 52, 8910–8922.

- Miyagi, K.; Mei, H.; Terlier, T.; Stein, G.E.; Verduzco, R. Analysis of Surface Segregation of Bottlebrush Polymer Additives in Thin Film Blends with Attractive Intermolecular Interactions. Macromolecules 2020, 53, 6720–6730.

- Roeven, E.; Kuzmyn, A.R.; Scheres, L.; Baggerman, J.; Smulders, M.M.J.; Zuilhof, H. PLL-Poly(HPMA) Bottlebrush-Based Antifouling Coatings: Three Grafting Routes. Langmuir 2020, 36, 10187–10199.

- Gao, Q.; Yu, M.; Su, Y.; Xie, M.; Zhao, X.; Li, P.; Ma, P.X. Rationally Designed Dual Functional Block Copolymers for Bottlebrush-like Coatings: In Vitro and in Vivo Antimicrobial, Antibiofilm, and Antifouling Properties. Acta Biomater. 2017, 51, 112–124.

- Nakayama, M.; Okano, T.; Winnik, F. Poly(N-Isopropylacrylamide)-Based Smart Surfaces for Cell Sheet Tissue Engineering. Mater. Matters 2010, 5, 5.

- Kano, K.; Yamato, M.; Okano, T. Ectopic Transplantation of Hepatocyte Sheets Fabricated with Temperature-Responsive Culture Dishes. Hepatol. Res. 2008, 38, 1140–1147.

- Wei, T.; Tang, Z.; Yu, Q.; Chen, H. Smart Antibacterial Surfaces with Switchable Bacteria-Killing and Bacteria-Releasing Capabilities. ACS Appl. Mater. Interfaces 2017, 9, 37511–37523.

- Li, X.; Wu, B.; Chen, H.; Nan, K.; Jin, Y.; Sun, L.; Wang, B. Recent Developments in Smart Antibacterial Surfaces to Inhibit Biofilm Formation and Bacterial Infections. J. Mater. Chem. B 2018, 6, 4274–4292.

- Huber, D.L.; Manginell, R.P.; Samara, M.A.; Kim, B.I.I.; Bunker, B.C. Programmed Adsorption and Release of Proteins in a Microfluidic Device. Science 2003, 301, 352–354.

- Wei, T.; Qu, Y.; Zou, Y.; Zhang, Y.; Yu, Q. Exploration of Smart Antibacterial Coatings for Practical Applications. Curr. Opin. Chem. Eng. 2021, 34, 100727.

- Elashnikov, R.; Ulbrich, P.; Vokatá, B.; Pavlíčková, V.S.; Švorčík, V.; Lyutakov, O.; Rimpelová, S. Physically Switchable Antimicrobial Surfaces and Coatings: General Concept and Recent Achievements. Nanomaterials 2021, 11, 3083.

- Chen, C.; Atif, M.; He, K.; Zhang, M.; Chen, L.; Wang, Y. A Binary Mixed Polymer Brush Coating with Adjusted Hydrophobic Property to Control Protein Adsorption. Mater. Adv. 2021, 2, 2120–2131.

- Psarra, E.; König, U.; Ueda, Y.; Bellmann, C.; Janke, A.; Bittrich, E.; Eichhorn, K.J.; Uhlmann, P. Nanostructured Biointerfaces: Nanoarchitectonics of Thermoresponsive Polymer Brushes Impact Protein Adsorption and Cell Adhesion. ACS Appl. Mater. Interfaces 2015, 7, 12516–12529.

- Kikuchi, A.; Okano, T. Intelligent Thermoresponsive Polymeric Stationary Phases for Aqueous Chromatography of Biological Compounds. Prog. Polym. Sci. 2002, 27, 1165–1193.

- Awsiuk, K.; Stetsyshyn, Y.; Raczkowska, J.; Lishchynskyi, O.; Dabczyński, P.; Kostruba, A.; Ohar, H.; Shymborska, Y.; Nastyshyn, S.; Budkowski, A. Temperature-Controlled Orientation of Proteins on Temperature-Responsive Grafted Polymer Brushes: Poly(Butyl Methacrylate) vs Poly(Butyl Acrylate): Morphology, Wetting, and Protein Adsorption. Biomacromolecules 2019, 20, 2185–2197.

- Jain, A.; Trindade, G.F.; Hicks, J.M.; Potts, J.C.; Rahman, R.; Hague, R.J.M.; Amabilino, D.B.; Pérez-García, L.; Rawson, F.J. Modulating the Biological Function of Protein by Tailoring the Adsorption Orientation on Nanoparticles. J. Colloid Interface Sci. 2021, 587, 150–161.

- Idota, N.; Ebara, M.; Kotsuchibashi, Y.; Narain, R.; Aoyagi, T. Novel Temperature-Responsive Polymer Brushes with Carbohydrate Residues Facilitate Selective Adhesion and Collection of Hepatocytes. Sci. Technol. Adv. Mater. 2012, 13, 064206.

- Li, L.; Wu, J.; Gao, C. Gradient Immobilization of a Cell Adhesion RGD Peptide on Thermal Responsive Surface for Regulating Cell Adhesion and Detachment. Colloid. Surf. B. Biointerfaces 2011, 85, 12–18.

- Desseaux, S.; Klok, H.A. Temperature-Controlled Masking/Unmasking of Cell-Adhesive Cues with Poly(Ethylene Glycol) Methacrylate Based Brushes. Biomacromolecules 2014, 15, 3859–3865.

- Chen, T.; Ferris, R.; Zhang, J.; Ducker, R.; Zauscher, S. Stimulus-Responsive Polymer Brushes on Surfaces: Transduction Mechanisms and Applications. Prog. Polym. Sci. 2010, 35, 94–112.

- Stetsyshyn, Y.; Raczkowska, J.; Lishchynskyi, O.; Awsiuk, K.; Zemla, J.; Dąbczyński, P.; Kostruba, A.; Harhay, K.; Ohar, H.; Orzechowska, B.; et al. Glass Transition in Temperature-Responsive Poly(Butyl Methacrylate) Grafted Polymer Brushes. Impact of Thickness and Temperature on Wetting, Morphology, and Cell Growth. J. Mater. Chem. B 2018, 6, 1613–1621.

- Barker, J.A.; Fock, W. Theory of upper and lower critical solution temperatures. Discuss. Faraday Soc. 1953, 15, 188–195.

- Seuring, J.; Agarwal, S. Polymers with Upper Critical Solution Temperature in Aqueous Solution: Unexpected Properties from Known Building Blocks. ACS Macro Lett. 2013, 2, 597–600.

- Cook, M.T.; Haddow, P.; Kirton, S.B.; Mcauley, W.J.; Cook, M.T.; Haddow, P.; Kirton, S.B.; Mcauley, W.J. Polymers Exhibiting Lower Critical Solution Temperatures as a Route to Thermoreversible Gelators for Healthcare. Adv. Funct. Mater. 2021, 31, 2008123.

- Van Krevelen, D.W.; Te Nijenhuis, K. Properties of Polymers; Elsevier: Amsterdam, The Netherlands, 2009.

- Kostruba, A.; Stetsyshyn, Y.; Mayevska, S.; Yakovlev, M.; Vankevych, P.; Nastishin, Y.; Kravets, V. Composition, Thickness and Properties of Grafted Copolymer Brush Coatings Determined by Ellipsometry: Calculation and Prediction. Soft Matter 2018, 14, 1016–1025.

- Zhang, Q.; Weber, C.; Schubert, U.S.; Hoogenboom, R. Thermoresponsive Polymers with Lower Critical Solution Temperature: From Fundamental Aspects and Measuring Techniques to Recommended Turbidimetry Conditions. Mater. Horiz. 2017, 4, 109–116.

- Xue, X.; Thiagarajan, L.; Braim, S.; Saunders, B.R.; Shakesheff, K.M.; Alexander, C. Upper Critical Solution Temperature Thermo-Responsive Polymer Brushes and a Mechanism for Controlled Cell Attachment. J. Mater. Chem. B 2017, 5, 4926–4933.

- Jia, X.; Ji, H.; Zhang, G.; Xing, J.; Shen, S.; Zhou, X.; Sun, S.; Wu, X.; Yu, D.; Wyman, I. Smart Self-Cleaning Membrane via the Blending of an Upper Critical Solution Temperature Diblock Copolymer with PVDF. ACS Appl. Mater. Interfaces 2021, 13, 38712–38721.

- Zhou, Q.; Palanisamy, A.; Albright, V.; Sukhishvili, S.A. Enzymatically Degradable Star Polypeptides with Tunable UCST Transitions in Solution and within Layer-by-Layer Films. Polym. Chem. 2018, 9, 4979–4983.

- Niskanen, J.; Tenhu, H. How to Manipulate the Upper Critical Solution Temperature (UCST)? Polym. Chem. 2016, 8, 220–232.

- Albright, V.; Palanisamy, A.; Zhou, Q.; Selin, V.; Sukhishvili, S.A. Functional Surfaces through Controlled Assemblies of Upper Critical Solution Temperature Block and Star Copolymers. Langmuir 2019, 35, 10677–10688.

- Aseyev, V.; Tenhu, H.; Winnik, F.M. Non-Ionic Thermoresponsive Polymers in Water in Self Organized Nanostructures of Amphiphilic Block Copolymers II, Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2010; pp. 29–89.

- Sanchez, I.C.; Lacombe, R.H. Statistical Thermodynamics of Polymer Solutions; John Wiley & SONS, Inc.: New York, NY, USA, 2000; Volume 1.

- Chen, G.; Hoffman, A.S. Graft Copolymers That Exhibit Temperature-Induced Phase Transitions over a Wide Range of pH. Nature 1995, 373, 49–52.

- Xia, F.; Feng, L.; Wang, S.; Sun, T.; Song, W.; Jiang, W.; Jiang, L.; Song, W.; Jiang, W.; Jiang, L.; et al. Dual-Responsive Surfaces That Switch between Superhydrophilicity and Superhydrophobicity. Adv. Mater. 2006, 18, 432–436.

- Stetsyshyn, Y.; Zemla, J.; Zolobko, O.; Fornal, K.; Budkowski, A.; Kostruba, A.; Donchak, V.; Harhay, K.; Awsiuk, K.; Rysz, J.; et al. Temperature and pH Dual-Responsive Coatings of Oligoperoxide-Graft-Poly(N-Isopropylacrylamide): Wettability, Morphology, and Protein Adsorption. J. Colloid. Interface Sci. 2012, 387, 95–105.

- Stetsyshyn, Y.; Fornal, K.; Raczkowska, J.; Zemla, J.; Kostruba, A.; Ohar, H.; Ohar, M.; Donchak, V.; Harhay, K.; Awsiuk, K.; et al. Temperature and pH Dual-Responsive POEGMA-Based Coatings for Protein Adsorption. J. Colloid. Interface Sci. 2013, 411, 247–256.

- Shymborska, Y.; Stetsyshyn, Y.; Raczkowska, J.; Awsiuk, K.; Ohar, H.; Budkowski, A. Impact of the Various Buffer Solutions on the Temperature-responsive Properties of POEGMA-grafted Brush Coatings. Colloid. Polym. Sci. 2022, 300, 487–495.

- Lutz, J.F.; Weichenhan, K.; Akdemir, Ö.; Hoth, A. About the Phase Transitions in Aqueous Solutions of Thermoresponsive Copolymers and Hydrogels Based on 2-(2-Methoxyethoxy)Ethyl Methacrylate and Oligo(Ethylene Glycol) Methacrylate. Macromolecules 2007, 40, 2503–2508.

- Zhuang, P.; Dirani, A.; Glinel, K.; Jonas, A.M. Temperature Dependence of the Surface and Volume Hydrophilicity of Hydrophilic Polymer Brushes. Langmuir 2016, 32, 3433–3444.

- Dong, Z.; Wei, H.; Mao, J.; Wang, D.; Yang, M.; Bo, S.; Ji, X. Synthesis and Responsive Behavior of Poly(N,N-Dimethylaminoethyl Methacrylate) Brushes Grafted on Silica Nanoparticles and Their Quaternized Derivatives. Polymers 2012, 53, 2074–2084.

- Raczkowska, J.; Stetsyshyn, Y.; Awsiuk, K.; Zemła, J.; Kostruba, A.; Harhay, K.; Marzec, M.; Bernasik, A.; Lishchynskyi, O.; Ohar, H.; et al. Temperature-Responsive Properties of Poly(4-Vinylpyridine) Coatings: Influence of Temperature on the Wettability, Morphology, and Protein Adsorption. RSC Adv. 2016, 6, 87469–87477.

- Raczkowska, J.; Ohar, M.; Stetsyshyn, Y.; Zemła, J.; Awsiuk, K.; Rysz, J.; Fornal, K.; Bernasik, A.; Ohar, H.; Fedorova, S.; et al. Temperature-Responsive Peptide-Mimetic Coating Based on Poly(N-Methacryloyl-l-Leucine): Properties, Protein Adsorption and Cell Growth. Colloid. Surf. B Biointerfaces 2014, 118, 270–279.

- Liu, Z.; Hu, J.; Sun, J.; He, G.; Li, Y.; Zhang, G. Preparation of Thermoresponsive Polymers Bearing Amino Acid DiamideDerivatives via RAFT Polymerization. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 3573–3586.

- Stetsyshyn, Y.; Raczkowska, J.; Budkowski, A.; Kostruba, A.; Harhay, K.; Ohar, H.; Awsiuk, K.; Bernasik, A.; Ripak, N.; ZemŁa, J. Synthesis and Postpolymerization Modification of Thermoresponsive Coatings Based on Pentaerythritol Monomethacrylate: Surface Analysis, Wettability, and Protein Adsorption. Langmuir 2015, 31, 9675–9683.

- Seuring, J.; Bayer, F.M.; Huber, K.; Agarwal, S. Upper Critical Solution Temperature of Poly(N-Acryloyl Glycinamide) in Water: A Concealed Property. Macromolecules 2012, 45, 374–384.

- Plunkett, K.N.; Zhu, X.; Moore, J.S.; Leckband, D.E. PNIPAM Chain Collapse Depends on the Molecular Weight and Grafting Density. Langmuir 2006, 22, 4259–4266.

- Morgese, G.; Shaghasemi, S.; Causin, V.; Zenobi-Wong, M.; Ramakrishna, S.N.; Reimhult, E.; Benetti, E.M. Next-Generation Polymer Shells for Inorganic Nanoparticles Are Highly Compact, Ultra-Dense, and Long-Lasting Cyclic Brushes. Angew. Chem. Int. Ed. 2017, 56, 4507–4511.

- Morgese, G.; Trachsel, L.; Romio, M.; Divandari, M.; Ramakrishna, S.N.; Benetti, E.M. Topological Polymer Chemistry Enters Surface Science: Linear versus Cyclic Polymer Brushes. Angew. Chem. Int. Ed. 2016, 55, 15583–15588.

- Flemming, P.; Fery, A.; Münch, A.S.; Uhlmann, P. Does Chain Confinement Affect Thermoresponsiveness? A Comparative Study of the LCST and Induced UCST Transition of Tailored Grafting-to Polyelectrolyte Brushes. Macromolecules 2022, 55, 6775–6786.

- Koenig, M.; Rodenhausen, K.B.; Rauch, S.; Bittrich, E.; Eichhorn, K.J.; Schubert, M.; Stamm, M.; Uhlmann, P. Salt Sensitivity of the Thermoresponsive Behavior of PNIPAAm Brushes. Langmuir 2018, 34, 2448–2454.

- Otulakowski, Ł.; Kasprów, M.; Strzelecka, A.; Dworak, A.; Trzebicka, B. Thermal Behaviour of Common Thermoresponsive Polymers in Phosphate Buffer and in Its Salt Solutions. Polymers 2020, 13, 90.

- Shevtsova, T.; Cavallaro, G.; Lazzara, G.; Milioto, S.; Donchak, V.; Harhay, K.; Korolko, S.; Budkowski, A.; Stetsyshyn, Y. Temperature-Responsive Hybrid Nanomaterials Based on Modified Halloysite Nanotubes Uploaded with Silver Nanoparticles. Colloids Surf. A Physicochem. Eng. Asp. 2022, 641, 128525.

- Hill, A.J.; Tant, M.R. The Structure and Properties of Glassy Polymers (ACS Symposium Series, 710); American Chemical Society: Washington, DC, USA, 1999.

- Stetsyshyn, Y.; Raczkowska, J.; Budkowski, A.; Awsiuk, K.; Kostruba, A.; Nastyshyn, S.; Harhay, K.; Lychkovskyy, E.; Ohar, H.; Nastishin, Y. Cholesterol-Based Grafted Polymer Brushes as Alignment Coating with Temperature-Tuned Anchoring for Nematic Liquid Crystals. Langmuir 2016, 32, 11029–11038.

- Raczkowska, J.; Stetsyshyn, Y.; Awsiuk, K.; Lekka, M.; Marzec, M.; Harhay, K.; Ohar, H.; Ostapiv, D.; Sharan, M.; Yaremchuk, I.; et al. Temperature-Responsive Grafted Polymer Brushes Obtained from Renewable Sources with Potential Application as Substrates for Tissue Engineering. ApSS 2017, 407, 546–554.

- McKeen, L.W. Fatigue and Tribological Properties of Plastics and Elastomers; William Andrew: Amsterdam, The Netherlands, 2016; pp. 125–170.

- Shibaev, V. Liquid Crystalline Polymers. Polym. Sci. A Compr. 2012, 1, 259–285.

- Yamamoto, S.; Tsujii, Y.; Fukuda, T. Glass Transition Temperatures of High-Density Poly(Methyl Methacrylate) Brushes. Macromolecules 2002, 35, 6077–6079.

- Zuo, B.; Zhang, S.; Niu, C.; Zhou, H.; Sun, S.; Wang, X. Grafting Density Dominant Glass Transition of Dry Polystyrene Brushes. Soft Matter 2017, 13, 2426–2436.

- Tsui, O.K.C.; Russell, T.P.; Hawker, C.J. Effect of Interfacial Interactions on the Glass Transition of Polymer Thin Films. Macromolecules 2001, 34, 5535–5539.