Your browser does not fully support modern features. Please upgrade for a smoother experience.

Please note this is a comparison between Version 1 by Khaled Mashhor Salim and Version 3 by Dean Liu.

The result indicated that SOFCs (Solid Oxide Fuel Cells) have better implications for environmental performance, as well as being the least cost-effective option for commercially competitive purposes.

- SOFC

- life cycle sustainability assessment (LCSA)

- life cycle costing

1. Introduction

Over the last decade, large electrical energy consumption globally has increased electricity price fees. It has also negatively impacted the environment, causing global warming, acid rain, and urban smog [1]. Extensive efforts have been carried out to improve renewable energy source (RES) utilization and cost-efficiency strategy whilst meeting environmental goals [2]. Biomass resources have the potential to provide over 25% of worldwide primary energy in the year 2050 [3]. Biomass resources consist of solid biomass, biogas, and organic municipal solid waste (MSW). Electricity is generated from biomass resources by directly firing or co-firing in either electricity alone or a combined high degree of heat and power (CHP) [1]. A high-temperature fuel cell generates high-quality heat [4], especially from the developed version, the SOFC [3].

The SOFC is an efficient renewable energy technology that generates electrical voltage from the chemical reaction between hydrogen and oxygen [5]. SOFCs reduce methane gas emission pollution and use the biogas captured for fuel substitution, electricity production, and revenue generation [6]. An SOFC is economically feasible due to its steam pre-reforming catalyst and the creative design of internal recycling [7]. Furthermore, it has greater temperature scores and efficiency, which are optimal for hybrid power and power generation applications, while producing less pollutants, including NOx, SOx, CO, and particulate matter [8].

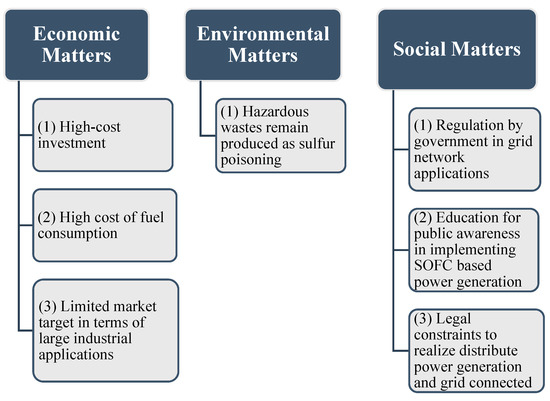

Despite the numerous benefits of the SOFC as a sustainable technology, it is mainly used in developed countries, especially European ones. The application of SOFCs across developing countries is scarce [9] due to the common thought about the high investment cost of new sustainable technology. In addition, transferring SOFC technology from laboratory scale to public scale can cause numerous issues (i.e., economic, environmental, and social opinions) [5] without any tangible benefits except being environmentally and socially compatible. Figure 1 shows the economic, environmental, and social issues in applying SOFCs.

Tackling these issues requires a systematic assessment, which provides accurate data for policymakers and consumers based on life cycle impacts and their effect on economic, environmental, and social sustainability, and feasible solutions [7]. The life cycle sustainability assessment approach (LCSA) can provide sustainability evaluation during the life cycle. It comprises three principal pillars, namely life cycle costing (or LCC), life cycle assessment (or LCA), and social life cycle (or SLC). The LCSA was applied to gather several aspects from the related research on SOFCs, such as scope and goals, the life cycle inventory (or LCI) modeling, and the assessment of impact [7]. The major purposes of LCSA research on SOFCs are (1) identifying the materials and processes that can motivate the economic and environmental influences of an SOFC application and the impact improvement opportunity options and (2) sustainability comparison involving economic and environmental assets of other alternative energy supply in reducing cost-effective option and environmental impacts [9][10][9,10].

LCSA is a comprehensive model aiming to achieve the product’s highest performance [11]. LCSA calculates and estimates the raw material, final products, and environmental impacts of a product in its full life cycle, “i.e., manufacture, use, maintenance, and disposal”, including the resource inputs used for manufacturing the product. It provides numerous criteria that describe various strategic choices to improve decision-making and align with economic, environmental, and social sustainability [12]. LCC, LCA, and SLC measured the LCSA for this study. Prior studies utilized different tools to evaluate the SOFC economically, such as the current cash flow net present value or economic criteria [6][8][6,8]. Most of these studies found that the SOFC was scored as the least cost-effective technology [9]. However, LCC is the most reliable economic assessment of design alternatives [7]. LCC provides valuable information for relevant decision-making, such as assessing and choosing alternatives during the product design phase [13]. It evaluates the total costs during the financial lifetime of products. LCC can calculate aggregate costs of alternative products and processes, including investment, capital, operating, energy, maintenance, and disposal costs across the project lifetime or the product with present value indicators [14].

Similarly, LCA is an analytical methodology used to analyze the environmental effect through the whole product life cycle, service, or process [13]. LCA analyzes the entire or individual process from raw material consumption through manufacturing, usage, and disposal/recycling [8]. The LCA process comprises the “definition of a goal and scope”, “inventory analysis”, “impact assessment”, and “interpretation of the results” [14]. It aims to facilitate and quantify the environmental issues across the life cycle of resource-based SOFC systems [15]. LCA provides comprehensive information on resource usage, emissions, and waste generation from different technologies used for generating electricity [16]. LCA in SOFC is used to identify the material environmental assessment effects, the potential influence of mitigation of these effects, and the assessment of energy sources [17]. SLC is established according to the United Nations (UN) environmental program to investigate the sociological and social factors of products and their effect across the entire life cycle. SLC generally consists of a group of stages for socially calculating a product's impacts. It uses data from dedicated databases on countries and sectors, utilizing both general and site-specific data. SLC uses approaches and systems to collect and manipulate the data [18]. While LCA involves physical quantities associated with the product system, SLC includes quantitative and qualitative information on organization-related aspects [19].

Despite the rising trend of research on the usage of LCA on SOFCs, there are a few substantial gaps identified in this research [9]. Most studies focused on the environmental impact assessment [6], whereas the studies assessing the economic and social impact associated with SOFC are rarely reported. The authors of [14][15][14,15] conducted a review study focused on LCA usage on SOFCs consisting of 55 articles during the period from 1999 to 2018. Thirty-five of those articles focused merely on environmental LCA. Whereas 15 focused on implementing a combined environmental data and economic analysis, the remaining studies concentrated on the socio-economic efficiency by means of LCC evaluation. While identifying indicators for the environmental assessment using LCA is crucial for providing relevant and reliable data to the stakeholders for environment and biodiversity evaluation [9], identifying indicators associated with economic and social impact assessment utilizing LCC and SLC can improve decision-making. An indicator derived from the LCC model provides in-depth cost analysis, comparison, and commercial level contrast between the SOFC and a conventional system [7]. Further, indicators designed for SLC can show the benefits of the SOFC for people, such as job creation [20].

Second, previous studies assessed LCA using single or very few indicators. Few indicators may not sufficiently assess the sustainability impact of SOFCs, since products and processes might have a small influence on certain indicators such as climate change impacts (less CO2 emission). Still, they may have a harmful or high influence on acidification impacts due to the increased emission of SO2 and NOX [9]. Accordingly, developing a framework based on the LCSA methodology is recommended to integrate the environmental impact assessment alongside the economy and society into the work for better sustainability evaluation [16][17][16,17]. More specifically, a wide-ranging dynamic multi-criteria sustainability impact analysis, consisting of environmental, economic, and social indicators, is required to make a robust comparison of sustainability assessment results of SOFC applications.

2. Environmental Impact Assessment Indicators Using LCA

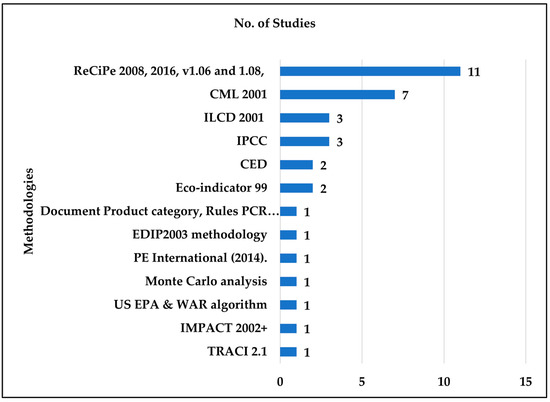

The impact categories, consisting of endpoint and midpoint LCA indicators, reflect the environmental aspects of SOFC technology in electricity generation [7]. Midpoint categories are closely related to low uncertainty and environmental flows. Categorization indicators at the midpoint level are available across the pathway of impact, reducing the correlation between uncertainties and assessing the potential environmental damages [21][34]. On the other hand, endpoint categories provide direct data on the environmental flows’ environmental significance but are less clear than the midpoint characterization factors [22][35]. Characterization elements at the endpoint level consist of three zones of protection, which are ecosystem quality, health, and natural resources [23][36]. The key variances between the two levels are “comprehensiveness and gaps, uncertainty (model and parameter), relevance (or scenario uncertainty), transparency, value-choices, and an understanding of the limited panel-based weighting methods across impact categories comparison” [24][37]. Most prior studies have used certain midpoint impact categories to assess the environmental impacts of SOFC application. Few studies used the endpoint level [25][38]. Nevertheless, midpoint and endpoint indicators should be applied together within a consistent framework [24][37]. The transparency level related to midpoint indicators may be regarded as greater than endpoint methods. However, when comparing the impact categories, the indirect associations among the midpoint and endpoint effects remain unclear or represented in an unorganized way. This may affect the overall quality of the results and weighting exercise [24][37]. In terms of the methodologies for the environmental impact, 13 different methods and approaches were used in the prior studies, as shown in Figure 2. Eleven articles used ReCiPe approaches, seven used CML methods, three used both IPCC factors and ILCD methods, and two used Eco-indicator 99 and CED methods. Only one article used the CED, TRACI, Impact 2002+ US EPA & WAR algorithm, Monte Carlo analysis, PE International (2014), EPID2003 and document product category, Rules PCR 2007:08 method [6][7][8][26][27][6,7,8,39,40]. Detailed information about these methodologies is discussed in the following subsection.

Figure 2.

Environmental impact approaches used in LCA SOFC-related applications.

3. Economic Impact Assessment Indicators Using LCC

For optimal strategy, various objectives must be considered in SOFC applications. Economic aspects are one of these objectives that ought to be considered [5]. Most of the customers in energy technology acquisition often build up their decision based on profit-driven, cost-effective analysis [33][67]. Accordingly, identifying the economic feasibility of the entire system is necessary for all stakeholders to make their correct choices [34][68]. Prior studies used different economic impact assessment methodologies for calculating the feasibility of the SOFC application, such as the LCC, the net present value, the net present cost, environmental cost, payback period, profitability index, and gross operative margins (GOM) [5][6][7][35][36][5,6,7,69,70]. The LCC method is chosen as the focus in this review. The LCC system comprises capital, fuel, operating, salvage value, and maintenance. Additionally, it comprises the utility expenses in the case utilities offer a building electricity and thermal energy [35][69]. Effective LCC usage of a system is necessary for a complicated decision-making process. Reference [7] identified that the cost of natural gas fuel feed is a major contribution to the life cycle. SOFC application shows a smaller overall LCC than microturbines in home applications. SOFC is a good alternative to the traditional system when the sustainability of investment costs is determined. On the contrary, [36][70] revealed that wind power plants make up 68.35% of total capital investment of GBP 2,468,093. SOFC/gas turbine (GT) technology costs about 50% of power to gas (P2G), with 67.1% electrical efficiency operation through multiple safety constraints. Accordingly, SOFC/GT technology shows financial and technical feasibility options for investors in a renewable-powered P2G model. Apart from that, investors are concerned about recovering the investment cost or “payback period” [37][71], which influences their decision on SOFC investment. The payback period occurs once the actual capitalized expense and the yearly saving amounts are more than the lifespan of the overall installation [33][67]. From the economic perspective, the acceptable payback period is preferred to be between 7 and 10 years [38][72] or 10 and 15 years [39][57], Reference [40][73] as the lifespan of an SOFC is 40,000–80,000 h. Reference [41][74] analyzed the impact of recovering the key energy in municipal solid waste produced in Port Harcourt through the SOFC system in a single platform. It is found that the cost stands evaluated at USD 227.8 million. The cost of energy and recovery of the initial investment were 0.018 USD/kWh and 7.5 years, respectively. In [42][75], it was found that the capital investment for integrated gasification and anaerobic digestion to transform waste from agricultural to refrigeration and electrical power in a combined multiple generation plan could be repaid after 7.5 years and was USD 3.75 million. On the other hand, the recommended payback period for commercially competitive purposes is 3–5 years. Government subsidization at half of the system costs for a trigeneration model is enough for the break-even point to be less than 6 years [38][72]. Reference [29][42] compares the economic impact of SOFC usage fueled with biogas among individual and centralized systems across Malaysian palm oil mills. The individual system required a lower cost than the central system with RM 2.56 per kWh and RM 7.04 per kWh, respectively, including incentives and government financial support. Reference [43][76] emphasized financial satisfaction with a small payback period in the presence of subsidization reaching less than 12 months. The period may need to be 36.46 months in the deficiency of any subsidy. The reduced operation costs increase the cash inflows and the likelihood of ideal payback, as shown in Equation (1).Payback period =

Payback period =

Investment Cost / Annual cash inflows

Annual cash inflows