Nanocellulose/nanocarbon composites are newly-emerging smart hybrid materials containing cellulose nanoparticles, such as nanofibrils and nanocrystals, and carbon nanoparticles, such as “classical” carbon allotropes (fullerenes, graphene, nanotubes and nanodiamonds), or other carbon nanostructures (carbon nanofibers, carbon quantum dots, activated carbon and carbon black). The nanocellulose component acts as a dispersing agent and homogeneously distribute the carbon nanoparticles in aqueous environment. Nanocellulose/nanocarbon composites can be prepared with many advantageous properties, such as high mechanical strength, flexibility, stretchability, tunable thermal and electrical conductivity, tunable optical transparency, photodynamic and photothermal activity, nanoporous character and high adsorption capacity. They are therefore promising for a wide range of industrial applications, such as energy generation, storage and conversion, water purification, food packaging, construction of fire retardants and shape memory devices. They also hold great promise for biomedical applications, such as radical scavenging, photodynamic and photothermal therapy of tumors and microbial infections, drug delivery, biosensorics, isolation of various biomolecules, electrical stimulation of damaged tissues (e.g. cardiac, neural), neural and bone tissue engineering, engineering of blood vessels and advanced wound dressing, e.g. with antimicrobial and antitumor activity. However, the potential cytotoxicity and immunogenicity of the composites and their components must also be taken into account.

- nanofibrillated cellulose

- cellulose nanocrystals

- fullerenes

- graphene

- carbon nanotubes

- diamond nanoparticles

- sensors

- drug delivery

- tissue engineering

- wound dressing

1. Introduction

Nanocellulose/nanocarbon composites are hybrid materials containing cellulose and carbon nanoparticles. Integration of nanocarbon materials with nanocellulose provides functionality of nanocarbons, using an eco-friendly, low-cost, strong, dimension-stable, nonmelting, nontoxic and nonmetal matrix or carrier, which alone has versatile applications in industry, biotechnology and biomedicine (for a review, see [1][2]). In addition to its advantageous combination with nanocarbon materials, nanocellulose is an appealing material for biomedical applications due to its tunable chemical properties, nonanimal origin, and resemblance to biological molecules in dimension, chemistry and viscoelastic properties, etc. [3][4][5][6].

2. Applications of Nanocellulose/Nanocarbon Composites: Focus on Biotechnology and Medicine

Cellulose nanomaterials include cellulose nanofibrils (CNFs) and cellulose nanocrystals (CNCs) [3]. CNFs are manufactured using either a bottom-up or a top-down approach. The bottom-up approach involves bacterial (Gluconacetobacter) biosynthesis to obtain bacterial cellulose (BC), while, in the top-down method, cellulosic biomass from plant fibers is disintegrated into smaller CNFs [7] that contain amorphous and crystalline regions [3]. The fibrillation of cellulose is achieved using mechanical forces, chemical treatments, enzymes or combinations of these. After fibrillation, the width of CNFs is typically between 3 and 100 nm, and the length can be several micrometers [8]. Separation of the crystalline parts from the amorphous regions of the fibers or fibrils to obtain CNCs typically requires acid hydrolysis, which destroys the amorphous regions [9]. Entangled CNFs are longer, while CNCs possess shorter needle- or rod-like morphology with a similar diameter and a more rigid molecule due to their higher crystallinity [3][9]. In general, the properties of nanocelluloses are variable and depend on their origin, type, processing, pretreatments and functionalization. Integration with other materials, as well as fabrication of the final product, further affects the properties of the resulting composite or hybrid structure.

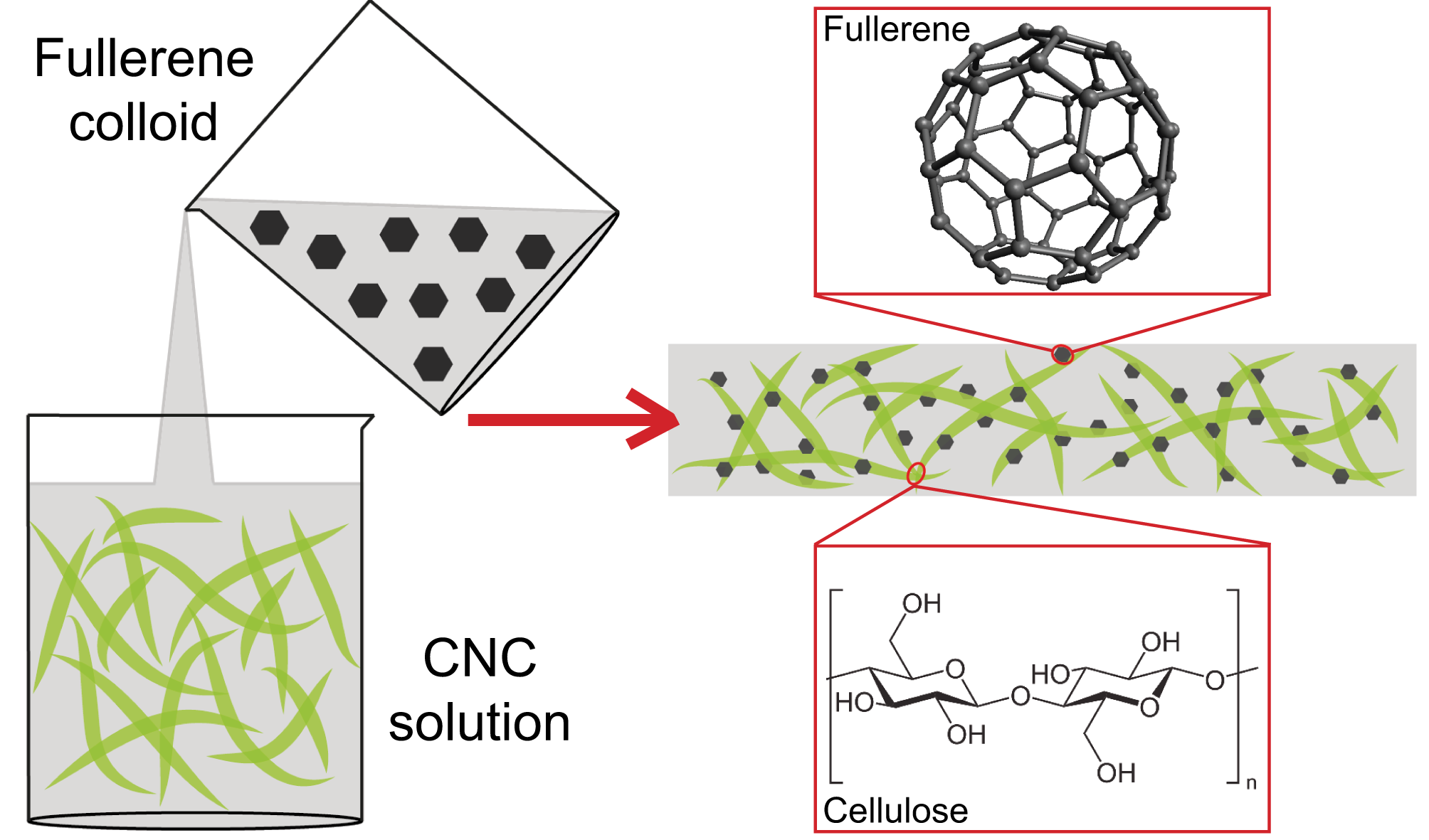

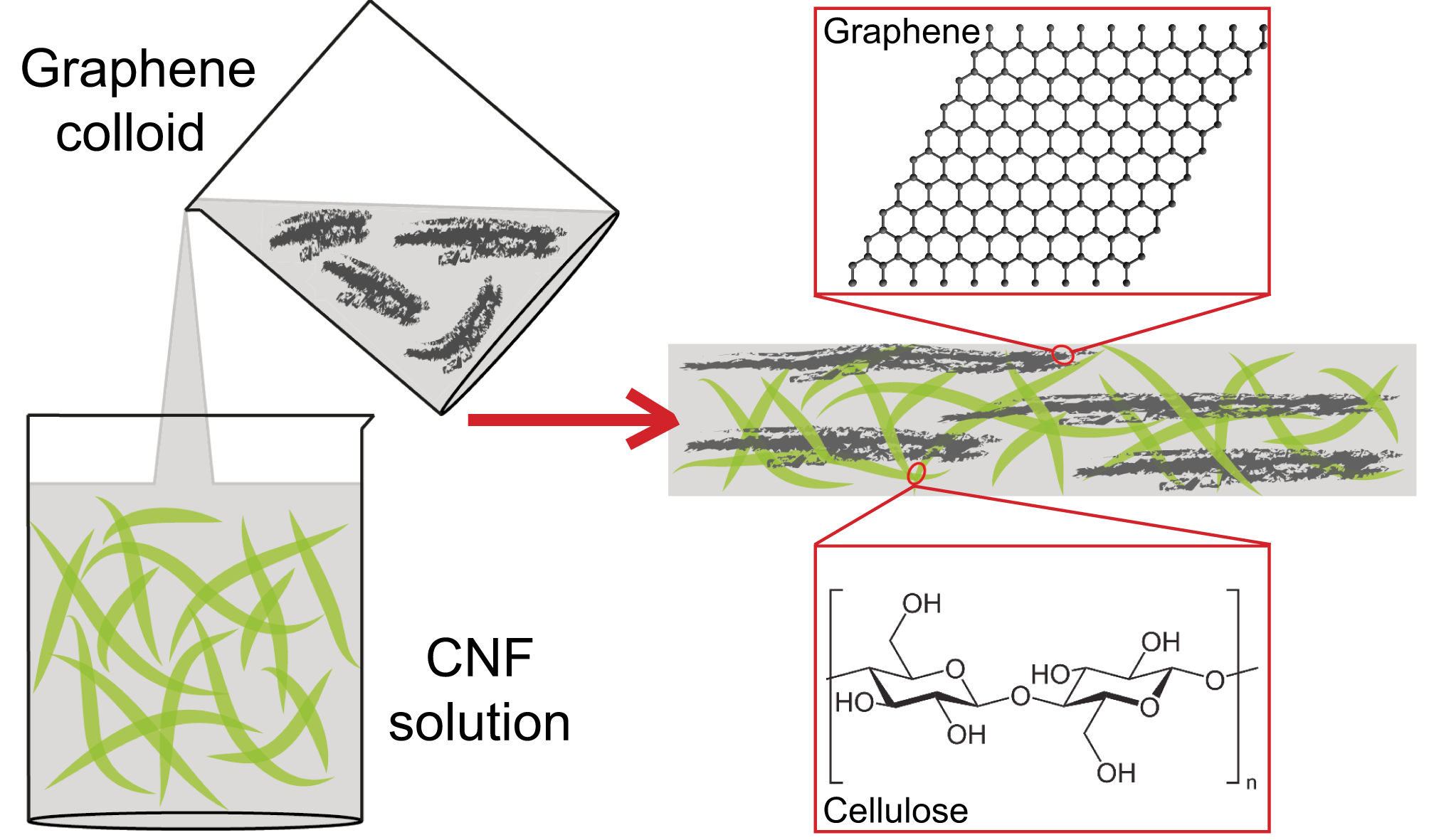

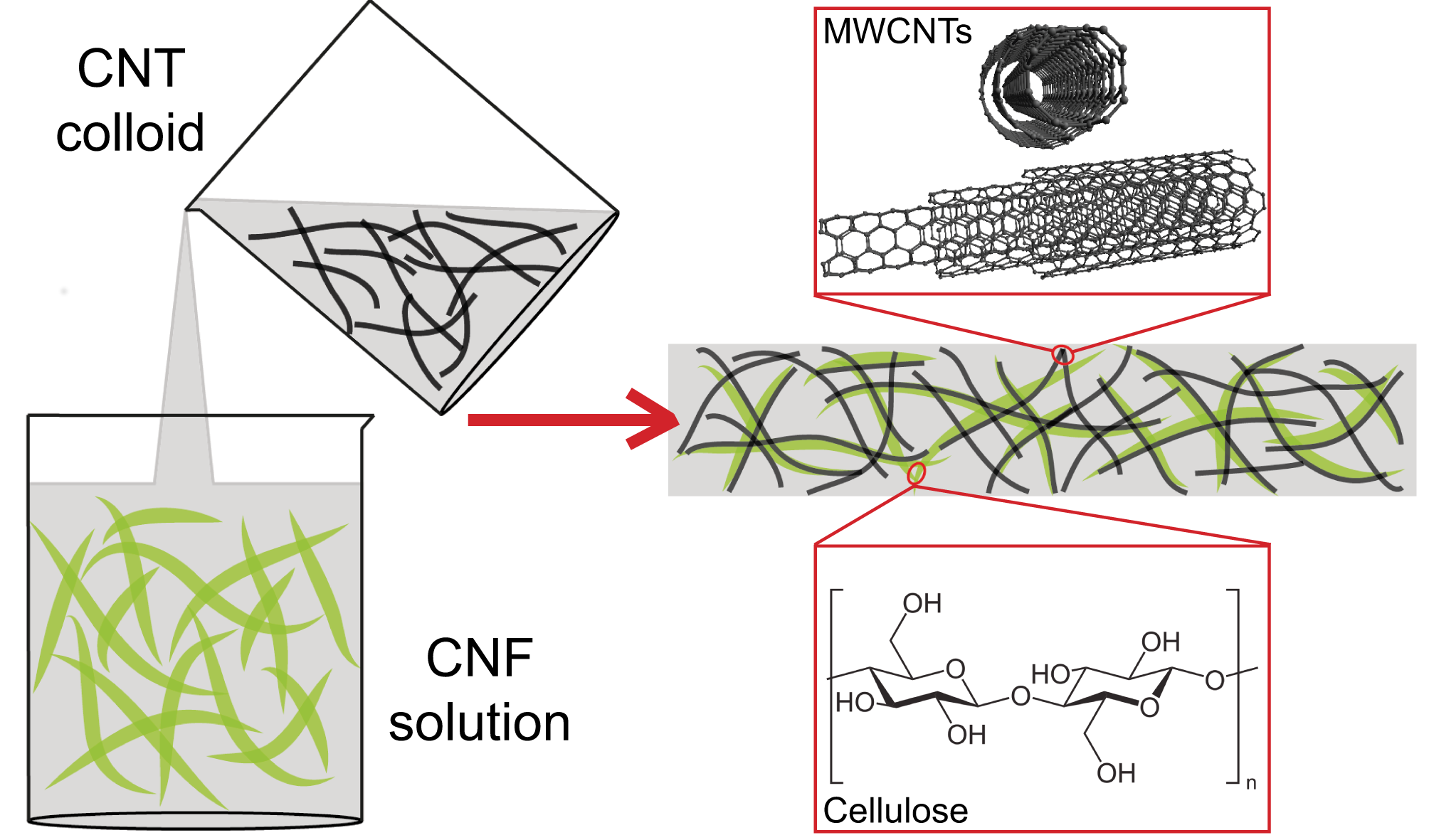

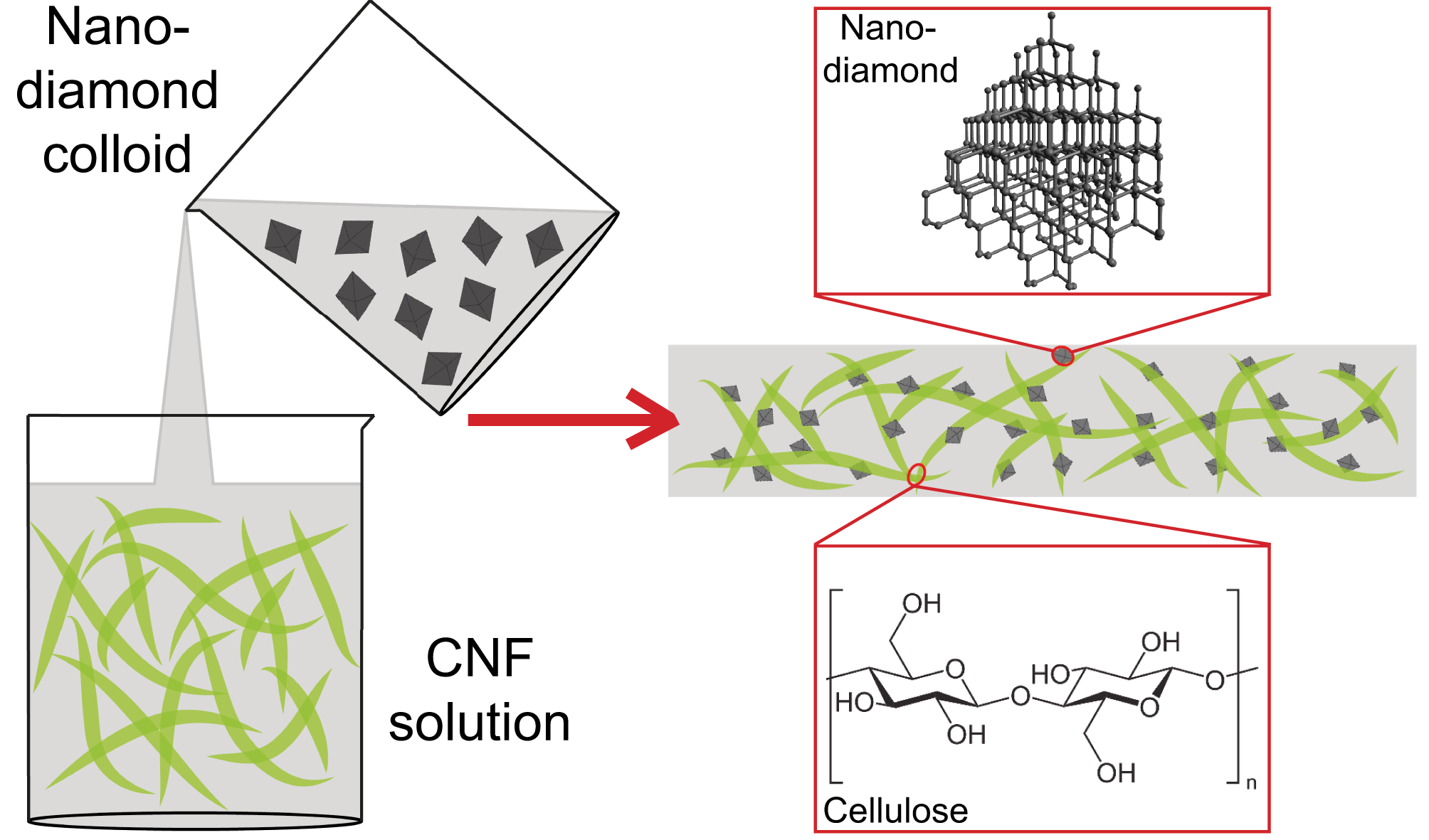

Carbon nanoparticles include fullerenes (usually C60), graphene-based particles (graphene, graphene oxide, reduced graphene oxide, graphene quantum dots), nanotubes (single-walled, double-walled, few-walled or multi-walled) and nanodiamonds (for a review, see [10][11][12][13][14][15][16][17][18][19][20]). The most frequently used nanocellulose/nanocarbon composites contain graphene or carbon nanotubes, while composites of nanocellulose with nanodiamond, and particularly with fullerenes, are less frequently used (Figures 1-4). Other carbon nanostructures, which are less frequently used in nanocellulose/nanocarbon composites, at least for biomedical applications, include carbon nanofibers [21][22][23][24][25], carbon quantum dots [26][27][28], activated carbon [29][30] and carbon black [31][32][33].

Figure 1. Scheme of the preparation and structure of nanocellulose/fullerene C60 composites

Figure 2. Scheme of the preparation and structure of nanocellulose/graphene composites

Figure 3. Scheme of the preparation and structure of nanocellulose/carbon nanotube composites

Figure 4. Scheme of the preparation and structure of nanocellulose/nanodiamond composites

Nanocellulose/nanocarbon composites can be prepared in one-dimensional (1D), two-dimensional (2D) or three-dimensional (3D) forms. 1D composites are represented, for example, by C60 fullerenes grafted onto cellulose nanocrystals that have undergone amination or oxidation [34][35]. 2D composites are represented by films, which can be self-standing or supported, i.e., in the form of free-standing membranes [29][36][37][38][39][40][41] or in the form of coatings deposited on bulk materials [33][42]. The films can be formed by depositing carbon nanoparticles on a nanocellulose layer [43][44]. More frequently, however, they are fabricated from aqueous dispersions of nanocellulose and carbon nanoparticles [39][42]. It should be pointed out that cellulose nanoparticles are excellent dispersive agents for carbon nanoparticles, as they prevent the aggregation of these nanoparticles and maintain them in long-term stable homogeneous suspensions without the need to subject them to chemical functionalization [45][46]. Suspensions of cellulose and carbon nanoparticles are also starting materials for the creation of 3D nanocellulose/nanocarbon composites in the form of aerogels, foams or sponges [45][47][48][49][50]. In addition, composite 3D scaffolds, especially for tissue engineering and for regenerative medicine, can be fabricated by 3D printing using bioinks based on cellulose and carbon nanoparticles [51][52]. Both 2D composites and 3D composites can also be created by adding carbon nanoparticles to cultures of cellulose-producing bacteria, such as Gluconacetobacter xylinus. These nanoparticles are then incorporated into bacterial nanocellulose in situ during its growth [53][54][55][56][57]. Another approach is via the electrospinning or wet spinning of solutions containing cellulose and carbon nanoparticles [58][59][60].

Nanocellulose/nanocarbon composites exhibit several more advantageous properties than materials containing only cellulose nanoparticles or only carbon nanoparticles. Adding carbon nanoparticles to nanocellulose materials can further increase their mechanical strength [59][61]. At the same time, the presence of nanocellulose promotes the flexibility and stretchability of the materials [52][62][63]; for a review, see [64]. Adding graphene, carbon nanotubes or boron-doped diamond nanoparticles endows nanocellulose materials with electrical conductivity [39][50][57][65][66]. Other advantageous properties of nanocellulose/nanocarbon composites include their thermal stability [67][68][69], tunable thermal conductivity and optical transparency [48][57][70], intrinsic fluorescence and luminescence [26][71][72] photothermal activity [56], hydrolytic stability [61], nanoporous character and high adsorption capacity [49][61]. Nanocellulose/nanocarbon composites can therefore be used in a wide range of industrial and technological applications, such as water purification [22][29][43][49][54][56][61][73][74][75][76], the isolation and separation of various molecules [22][74][77][78][79], energy generation, storage and conversion [21][23][44][47][64][80][81][82][83][84][85], biocatalysis [86], food packaging [67][68][69][87], construction of fire retardants [48], heat spreaders [70] and shape memory devices [38][88][89][90]. These composites are also used as fillers for various materials, usually polymers, in order to improve their mechanical, electrical and other physical and chemical properties [67][68][69][87][91].

In addition, nanocellulose/nanocarbon composites are promising for biomedical applications, though these applications are less frequent than industrial applications. Biomedical applications include radical scavenging [34][92], photothermal ablation of pathogenic bacteria [93], photodynamic and combined chemophotothermal therapy against cancer [35][94], drug delivery [16][28][65][72][95][96][97], biosensorics [31][32][33][63][66][71][91][98][99][100][101][102][103][104], and particularly tissue engineering and wound dressings. Hybrid materials containing nanocellulose and nanocarbons stimulated the growth and osteogenic differentiation of human bone marrow mesenchymal stem cells [37][59]. They provided good substrates for the attachment, growth and differentiation of SH-SHY5Y human neuroblastoma cells [51] and PC12 neural cells, particularly under electrical stimulation [105]. They enhanced the outgrowth of neurites from rat dorsal root ganglions in vitro and stimulated nerve regeneration in rats in vivo [106]. They also promoted the growth of vascular endothelial cells, enhanced angiogenesis and arteriogenesis in a chick chorioallantoic membrane model [107], and improved cardiac conduction when applied to surgically disrupted myocardium in dogs [52]. In addition, these materials supported the growth of human dermal fibroblasts [108] and mouse subcutaneous L929 fibroblasts [58][62], promoted wound healing in vivo in mice [109] and showed an antibacterial effect [30]. These materials are therefore promising for bone, neural and vascular tissue engineering, for creating cardiac patches and for advanced wound dressings. The biomedical applications of nanocellulose/nanocarbon composites are summarized in Table 1.

Table 1. Biomedical applications of nanocellulose/nanocarbon composites.

|

Application |

Nanocellulose/Nanocarbon Composites Containing: |

||||

|

Fullerenes |

Graphene |

CNTs |

Nanodiamonds |

Others |

|

|

Radical scavenging |

NH2-CNC/C60 [34]; CNC/C60(OH)30 [92] |

|

|

|

|

|

Photodynamic cancer therapy |

TEMPO-oxidized CNC/C60-NH2 [35] |

|

|

|

|

|

Photothermal, chemo-photothermal therapy |

|

Bacteria: [93] |

|

|

|

|

Cancer: [94] |

|

|

|

||

|

Drug delivery |

|

Anticancer drugs (doxorubicin) [72][95][96] |

Anticancer and other drugs [16] |

Anticancer drugs (doxorubicin) [97] |

Carbon quantum dots: Anticancer drugs (temozolomide) [28] |

|

(Bio)sensors |

|

Electrochemical: cholesterol [98]; glucose and bacteria [110]; avian leucosis virus [111]; organic liquids [112] |

Electrochemical: |

Electrochemical: Biotin [66] |

Carbon black: Electrochemical aptasensor for S. aureus [32]; electrochemical sensor for H2O2 [33] |

|

Piezoelectric: strain, human motion [63][99][113] |

Piezoresistance and thermoelectric-based: pressure and temperature [103]; pressure [17]; |

|

Carbon black: Strain, human motion [31][33] |

||

|

Optical: oxygen and temperature [115]; oxygen [116] |

Optical: |

|

|

Carbon quantum dots: optical sensor for biothiols [26] |

|

|

Acoustic: ammonia [101] |

|

|

|

||

|

Isolation of biomolecules |

|

Histidine-rich proteins, hemoglobin [77]; bovine serum albumin [79] |

|

|

|

|

Electrical stimulation of tissues |

|

|

Cardiac tissue [52]; neural tissue [106] |

|

|

|

Tissue engineering (TE) |

|

General cell biocompatibility [68][69][87]; |

Neural tissue engineering [51]; |

|

|

|

Wound dressing/healing |

Polysaccharides/ fullerene C60 derivatives [118][ |

Human dermal fibroblasts in vitro [108]; |

|

L929 fibroblasts in vitro [58][62]; HeLa cells in vitro, wound dressings delivering doxorubicin [97] |

Activated carbon: antibacterial wound dressing [30] |

|

Application |

Nanocellulose/Nanocarbon Composites Containing: |

||||

|

Fullerenes |

Graphene |

CNTs |

Nanodiamonds |

Others |

|

|

Radical scavenging |

NH2-CNC/C60 [34]; CNC/C60(OH)30 [92] |

|

|

|

|

|

Photodynamic cancer therapy |

TEMPO-oxidized CNC/C60-NH2 [35] |

|

|

|

|

|

Photothermal, chemo-photothermal therapy |

|

Bacteria: [93] |

|

|

|

|

Cancer: [94] |

|

|

|

||

|

Drug delivery |

|

Anticancer drugs (doxorubicin) [72][95][96] |

Anticancer and other drugs [16] |

Anticancer drugs (doxorubicin) [97] |

Carbon quantum dots: Anticancer drugs (temozolomide) [28] |

|

(Bio)sensors |

|

Electrochemical: cholesterol [98]; glucose and bacteria [110]; avian leucosis virus [111]; organic liquids [112] |

Electrochemical: |

Electrochemical: Biotin [66] |

Carbon black: Electrochemical aptasensor for S. aureus [32]; electrochemical sensor for H2O2 [33] |

|

Piezoelectric: strain, human motion [63][99][113] |

Piezoresistance and thermoelectric-based: pressure and temperature [103]; pressure [17]; |

|

Carbon black: Strain, human motion [31][33] |

||

|

Optical: oxygen and temperature [115]; oxygen [116] |

Optical: |

|

|

Carbon quantum dots: optical sensor for biothiols [26] |

|

|

Acoustic: ammonia [101] |

|

|

|

||

|

Isolation of biomolecules |

|

Histidine-rich proteins, hemoglobin [77]; bovine serum albumin [79] |

|

|

|

|

Electrical stimulation of tissues |

|

|

Cardiac tissue [52]; neural tissue [106] |

|

|

|

Tissue engineering (TE) |

|

General cell biocompatibility [68][69][87]; |

Neural tissue engineering [51]; |

|

|

|

Wound dressing/healing |

Polysaccharides/ fullerene C60 derivatives [118][ |

Human dermal fibroblasts in vitro [108]; |

|

L929 fibroblasts in vitro [58][62]; HeLa cells in vitro, wound dressings delivering doxorubicin [97] |

Activated carbon: antibacterial wound dressing [30] |

References

- Zhang, H.; Dou, C.; Pal, L.; Hubbe, M.A. Review of Electrically Conductive Composites and Films Containing Cellulosic Fibers or Nanocellulose. Bioresources 2019, 14.

- Lucie Bacakova; Julia Pajorova; Marketa Bacakova; Anne Skogberg; Pasi Kallio; Katerina Kolarova; Vaclav Svorcik; Versatile Application of Nanocellulose: From Industry to Skin Tissue Engineering and Wound Healing. Nanomaterials 2019, 9, 164, 10.3390/nano9020164.

- Zhang, Y.X.; Nypelo, T.; Salas, C.; Arboleda, J.; Hoeger, I.C.; Rojas, O.J. Cellulose Nanofibrils: From Strong Materials to Bioactive Surfaces. J Renew Mater 2013, 1, 195-211, doi:10.7569/Jrm.2013.634115.

- Ning Lin; Alain Dufresne; Nanocellulose in biomedicine: Current status and future prospect. European Polymer Journal 2014, 59, 302-325, 10.1016/j.eurpolymj.2014.07.025.

- Madhushree Bhattacharya; Melina M. Malinen; Patrick Laurén; Yan-Ru Lou; Saara W. Kuisma; Liisa Kanninen; Martina Lille; Anne Corlu; Christiane Guguen-Guillouzo; Olli Ikkala; Antti Laukkanen; Arto Urtti; Marjo Yliperttula; Nanofibrillar cellulose hydrogel promotes three-dimensional liver cell culture. Journal of Controlled Release 2012, 164, 291-298, 10.1016/j.jconrel.2012.06.039.

- Yan-Ru Lou; Liisa Kanninen; Tytti Kuisma; Johanna Niklander; Luke A. Noon; Deborah Burks; Arto Urtti; Marjo Yliperttula; The use of nanofibrillar cellulose hydrogel as a flexible three-dimensional model to culture human pluripotent stem cells.. Stem Cells and Development 2013, 23, 380-92, 10.1089/scd.2013.0314.

- Nurhidayatulllaili Muhd Julkapli; Samira Bagheri; Nanocellulose as a green and sustainable emerging material in energy applications: a review. Polymers for Advanced Technologies 2017, 28, 1583-1594, 10.1002/pat.4074.

- ISO/TS 20477:2017. In Nanotechnologies — Standard terms and their definition for cellulose nanomaterial.

- Youssef Habibi; Lucian A. Lucia; Orlando J. Rojas; Cellulose Nanocrystals: Chemistry, Self-Assembly, and Applications. Chemical Reviews 2010, 110, 3479-3500, 10.1021/cr900339w.

- Bacakova, L.; Grausova, L.; Vandrovcova, M.; Vacik, J.; Frazcek, A.; Blazewicz, S.; Kromka, A.; Vanecek, M.; Nesladek, M.; Svorcik, V. Carbon nanoparticles as substrates for cell adhesion and growth; Nova Science Publishers, Inc., Hauppauge, New York, USA: 2008; pp. 39-107; ISBN 978-1-60456-704-5

- Bacakova, L.; Grausova, L.; Vacik, J.; Kromka, A.; Biederman, H.; Choukourov, A.; Stary, V. Nanocomposite and nanostructured carbon-based films as growth substrates for bone cells; Intech, Open Access Publisher: 2011; pp 399-435, 2011; ISBN 978-953-307-202-9.

- Bacakova, L.; Kopova, I.; Vacik, J.; Lavrentiev, V. Interaction of fullerenes and metal-fullerene composites with cells; Nova Science Publishers, Inc., Hauppauge, New York, USA: 2014; pp 1-33; ISBN 978-1-63321-385-2.

- Lucie Bačáková; Ivana Kopova; Lubica Stankova; Jana Liskova; Jiri Vacík; Vasily Lavrentiev; Alexander Kromka; Štěpán Potocký; Denisa Stránská; Bone cells in cultures on nanocarbon-based materials for potential bone tissue engineering: A review. physica status solidi (a) 2014, 211, 2688-2702, 10.1002/pssa.201431402.

- Bacakova, L.; Filova, E.; Liskova, J.; Kopova, I.; Vandrovcova, M.; Havlikova, J. Nanostructured materials as substrates for the adhesion, growth, and osteogenic differentiation of bone cells. Appl Nanobiomater 2016, 4, 103-153, doi:10.1016/B978-0-323-42862-0.00004-3; ISBN 978-0-323-42862-0.

- Bacakova, L.; Broz, A.; Liskova, J.; Stankova, L.; Potocky, S.; Kromka, A. Application of nanodiamond in biotechnology and tissue engineering; IntechOpen, London, United Kingdom: 2016; doi:10.5772/61410, ISBN 978-953-51-2453-5.

- Bin Sheng Wong; Sia Lee Yoong; Anna Jagusiak; Tomasz Panczyk; Han Kiat Ho; Wee Han Ang; Giorgia Pastorin; Carbon nanotubes for delivery of small molecule drugs. Advanced Drug Delivery Reviews 2013, 65, 1964-2015, 10.1016/j.addr.2013.08.005.

- Miao Wang; Ilya V. Anoshkin; Albert G. Nasibulin; Juuso Korhonen; Jani Seitsonen; Jaakko Pere; Esko I. Kauppinen; Robin H. A. Ras; Olli Ikkala; Modifying Native Nanocellulose Aerogels with Carbon Nanotubes for Mechanoresponsive Conductivity and Pressure Sensing. Advanced Materials 2013, 25, 2428-2432, 10.1002/adma.201300256.

- Rui Yin; Tanupriya Agrawal; Usman Khan; Gaurav K Gupta; Vikrant Rai; Ying-Ying Huang; Michael R. Hamblin; Antimicrobial photodynamic inactivation in nanomedicine: small light strides against bad bugs. Nanomedicine 2015, 10, 2379-2404, 10.2217/nnm.15.67.

- Chengzhu Liao; Yuchao Li; S C Tjong; Graphene Nanomaterials: Synthesis, Biocompatibility, and Cytotoxicity. International Journal of Molecular Sciences 2018, 19, 3564, 10.3390/ijms19113564.

- Placha, D.; Jampilek, J. Graphenic Materials for Biomedical Applications. Nanomaterials (Basel) 2019, 9, doi:10.3390/nano9121758.

- Lina Ma; Rong Liu; Haijun Niu; Lixin Xing; Li Liu; Yudong Huang; Flexible and Freestanding Supercapacitor Electrodes Based on Nitrogen-Doped Carbon Networks/Graphene/Bacterial Cellulose with Ultrahigh Areal Capacitance. ACS Applied Materials & Interfaces 2016, 8, 33608-33618, 10.1021/acsami.6b11034.

- Zhaoyang Xu; Huan Zhou; Sicong Tan; Xiangdong Jiang; Weibing Wu; Jiangtao Shi; Peng Chen; Ultralight super-hydrophobic carbon aerogels based on cellulose nanofibers/poly(vinyl alcohol)/graphene oxide (CNFs/PVA/GO) for highly effective oil–water separation. Beilstein Journal of Nanotechnology 2018, 9, 508-519, 10.3762/bjnano.9.49.

- Wenyue Li; Nazifah Islam; Guofeng Ren; Shiqi Li; Zhaoyang Fan; AC-Filtering Supercapacitors Based on Edge Oriented Vertical Graphene and Cross-Linked Carbon Nanofiber. Materials 2019, 12, 604, 10.3390/ma12040604.

- Qianqian Shi; Dapeng Liu; Yan Wang; Yiwei Zhao; Xiaowei Yang; Jia Huang; High-Performance Sodium-Ion Battery Anode via Rapid Microwave Carbonization of Natural Cellulose Nanofibers with Graphene Initiator.. Small 2019, 15, e1901724, 10.1002/smll.201901724.

- Rachel L. Price; Karen Ellison; Karen M. Haberstroh; Thomas J. Webster; Nanometer surface roughness increases select osteoblast adhesion on carbon nanofiber compacts. Journal of Biomedical Materials Research 2004, 70, 129-138, 10.1002/jbm.a.30073.

- Samira Abbasi-Moayed; Hamed Golmohammadi; Arafeh Bigdeli; M. Reza Hormozi-Nezhad; A rainbow ratiometric fluorescent sensor array on bacterial nanocellulose for visual discrimination of biothiols. The Analyst 2018, 143, 3415-3424, 10.1039/c8an00637g.

- Li, L.; Wang, F.; Lv, Y.; Liu, J.; Bian, H.; Wang, W.; Li, Y.; Shao, Z. CQDs-Doped Magnetic Electrospun Nanofibers: Fluorescence Self-Display and Adsorption Removal of Mercury(II). ACS Omega 2018, 3, 4220-4230, doi:10.1021/acsomega.7b01969.

- Mojtaba Shamsipour; Amir Mohammad Mansouri; Pouran Moradipour; Temozolomide Conjugated Carbon Quantum Dots Embedded in Core/Shell Nanofibers Prepared by Coaxial Electrospinning as an Implantable Delivery System for Cell Imaging and Sustained Drug Release.. AAPS PharmSciTech 2019, 20, 259, 10.1208/s12249-019-1466-0.

- Mohammad Hassan; Ragab E. Abou-Zeid; Mohammad Hassan; Linn Berglund; Yvonne Aitomäki; Kristiina Oksman; Membranes Based on Cellulose Nanofibers and Activated Carbon for Removal of Escherichia coli Bacteria from Water. Polymers 2017, 9, 335, 10.3390/polym9080335.

- Mohammad Ashfaq; Nishith Verma; Suphiya Khan; Highly effective Cu/Zn-carbon micro/nanofiber-polymer nanocomposite-based wound dressing biomaterial against the P. aeruginosa multi- and extensively drug-resistant strains. Materials Science and Engineering: C 2017, 77, 630-641, 10.1016/j.msec.2017.03.187.

- Murilo Santhiago; Cátia C. Corrêa; Juliana S. Bernardes; Mariane P. Pereira; Letícia J. M. Oliveira; Mathias Strauss; Carlos C. Bof Bufon; Flexible and Foldable Fully-Printed Carbon Black Conductive Nanostructures on Paper for High-Performance Electronic, Electrochemical, and Wearable Devices. ACS Applied Materials & Interfaces 2017, 9, 24365-24372, 10.1021/acsami.7b06598.

- Saba Ranjbar; Saeed Shahrokhian; Design and fabrication of an electrochemical aptasensor using Au nanoparticles/carbon nanoparticles/cellulose nanofibers nanocomposite for rapid and sensitive detection of Staphylococcus aureus. Bioelectrochemistry 2018, 123, 70-76, 10.1016/j.bioelechem.2018.04.018.

- Qianming Li; Hu Liu; Shuaidi Zhang; Dianbo Zhang; X Liu; Yuxin He; Liwei Mi; Jiaoxia Zhang; Chuntai Liu; Changyu Shen; Zhanhu Guo; Superhydrophobic Electrically Conductive Paper for Ultrasensitive Strain Sensor with Excellent Anticorrosion and Self-Cleaning Property. ACS Applied Materials & Interfaces 2019, 11, 21904-21914, 10.1021/acsami.9b03421.

- Jinxian Lin; Zhijing Zhong; Qunling Li; Zhaoyi Tan; Tao Lin; Yi Quan; Ng Zhang; Facile Low-Temperature Synthesis of Cellulose Nanocrystals Carrying Buckminsterfullerene and Its Radical Scavenging Property in Vitro. Biomacromolecules 2017, 18, 4034-4040, 10.1021/acs.biomac.7b01095.

- A. Herreros Lopez; Marco Carini; Tatiana Da Ros; Tommaso Carofiglio; Carla Marega; Valeria La Parola; Valentina Rapozzi; Luigi Xodo; Ali A. Alshatwi; Caroline Hadad; Maurizio Prato; Nanocrystalline cellulose-fullerene: Novel conjugates. Carbohydrate Polymers 2017, 164, 92-101, 10.1016/j.carbpol.2017.01.068.

- Yeseul Kim; Hun-Sik Kim; Young Soo Yun; Hyeonseong Bak; Hyoung-Joon Jin; Ag-doped multiwalled carbon nanotube/polymer composite electrodes.. Journal of Nanoscience and Nanotechnology 2010, 10, 3571-3575, 10.1166/jnn.2010.2232.

- Lin Jin; Zhiping Zeng; Shreyas Kuddannaya; Dingcai Wu; Yilei Zhang; Zhenling Wang; Biocompatible, Free-Standing Film Composed of Bacterial Cellulose Nanofibers–Graphene Composite. ACS Applied Materials & Interfaces 2015, 8, 1011-1018, 10.1021/acsami.5b11241.

- Sunghan Kim; Rui Xiong; Vladimir V. Tsukruk; Probing Flexural Properties of Cellulose Nanocrystal–Graphene Nanomembranes with Force Spectroscopy and Bulging Test. Langmuir 2016, 32, 5383-5393, 10.1021/acs.langmuir.6b01079.

- Sanna Siljander; Pasi Keinänen; Anna Räty; Karthik Ram Ramakrishnan; Sampo Tuukkanen; Vesa Kunnari; A. Harlin; Jyrki Vuorinen; Mikko Kanerva; Effect of Surfactant Type and Sonication Energy on the Electrical Conductivity Properties of Nanocellulose-CNT Nanocomposite Films. International Journal of Molecular Sciences 2018, 19, 1819, 10.3390/ijms19061819.

- Jingquan Han; Siwei Wang; Sailing Zhu; Chaobo Huang; Yiying Yue; Changtong Mei; Xinwu Xu; Changlei Xia; Electrospun Core-Shell Nanofibrous Membranes with Nanocellulose-Stabilized Carbon Nanotubes for Use as High-Performance Flexible Supercapacitor Electrodes with Enhanced Water Resistance, Thermal Stability, and Mechanical Toughness.. ACS Applied Materials & Interfaces 2019, 11, 44624-44635, 10.1021/acsami.9b16458.

- Hoang Kha Nguyen; Jaehan Bae; Jaehyun Hur; Sang Joon Park; Min Sang Park; Il Tae Kim; Tailoring of Aqueous-Based Carbon Nanotube⁻Nanocellulose Films as Self-Standing Flexible Anodes for Lithium-Ion Storage.. Nanomaterials 2019, 9, 655, 10.3390/nano9040655.

- Mingzhe Jiang; Robert Seney; Paul Charles Bayliss; Christopher Kitchens; Carbon Nanotube and Cellulose Nanocrystal Hybrid Films.. Molecules 2019, 24, 2662, 10.3390/molecules24142662.

- Liu, P.; Zhu, C.; Mathew, A.P. Mechanically robust high flux graphene oxide - nanocellulose membranes for dye removal from water. J Hazard Mater 2019, 371, 484-493, doi:10.1016/j.jhazmat.2019.03.009.

- Qumrul Hasan; Jonathan Yuen; Gymama Slaughter; Carbon Nanotube-Cellulose Pellicle for Glucose Biofuel Cell. 2018 40th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC) 2018, null, 1-4, 10.1109/embc.2018.8513229.

- Mahiar Max Hamedi; Alireza Hajian; Andreas B. Fall; Karl Håkansson; Michaela Salajkova; Fredrik Lundell; Lars Wågberg; Lars A. Berglund; Highly Conducting, Strong Nanocomposites Based on Nanocellulose-Assisted Aqueous Dispersions of Single-Wall Carbon Nanotubes. ACS Nano 2014, 8, 2467-2476, 10.1021/nn4060368.

- Alireza Hajian; Stefan Lindstrom; Torbjörn Pettersson; Mahiar Max Hamedi; Lars Wågberg; Understanding the Dispersive Action of Nanocellulose for Carbon Nanomaterials. Nano Letters 2017, 17, 1439-1447, 10.1021/acs.nanolett.6b04405.

- Mahiar Max Hamedi; Erdem Karabulut; Andrew Marais; Anna Herland; Gustav Nyström; Lars Wågberg; Nanocellulose Aerogels Functionalized by Rapid Layer-by-Layer Assembly for High Charge Storage and Beyond. Angewandte Chemie 2013, 125, 12260-12264, 10.1002/ange.201305137.

- Bernd Wicklein; A. Kocjan; German Salazar-Alvarez; Federico Carosio; Giovanni Camino; Markus Antonietti; Lennart Bergström; Thermally insulating and fire-retardant lightweight anisotropic foams based on nanocellulose and graphene oxide. Nature Nanotechnology 2014, 10, 277-283, 10.1038/nnano.2014.248.

- Nariman Yousefi; Kerwin K. W. Wong; Zeinab Hosseinidoust; Henning Osholm Sørensen; Stefan Bruns; Yi Zheng; Nathalie Tufenkji; Hierarchically porous, ultra-strong reduced graphene oxide-cellulose nanocrystal sponges for exceptional adsorption of water contaminants. Nanoscale 2018, 10, 7171-7184, 10.1039/c7nr09037d.

- Sanna Siljander; Pasi Keinänen; Anastasia Ivanova; Jani Lehmonen; Sampo Tuukkanen; Mikko Kanerva; Tomas Björkqvist; Conductive Cellulose based Foam Formed 3D Shapes—From Innovation to Designed Prototype. Materials 2019, 12, 430, 10.3390/ma12030430.

- Volodymyr Kuzmenko; Erdem Karabulut; Elin Pernevik; Peter Enoksson; Paul Gatenholm; Tailor-made conductive inks from cellulose nanofibrils for 3D printing of neural guidelines. Carbohydrate Polymers 2018, 189, 22-30, 10.1016/j.carbpol.2018.01.097.

- Dawn M. Pedrotty; Volodymyr Kuzmenko; Erdem Karabulut; Alan M. Sugrue; Christopher Livia; Vaibhav R. Vaidya; Christopher J. McLeod; Samuel J. Asirvatham; Paul Gatenholm; Suraj Kapa; Three-Dimensional Printed Biopatches With Conductive Ink Facilitate Cardiac Conduction When Applied to Disrupted Myocardium.. Circulation: Arrhythmia and Electrophysiology 2019, 12, e006920, 10.1161/CIRCEP.118.006920.

- Nasrullah Shah; Mazhar Ul-Islam; Waleed Ahmad Khattak; Joong Kon Park; Overview of bacterial cellulose composites: A multipurpose advanced material. Carbohydrate Polymers 2013, 98, 1585-1598, 10.1016/j.carbpol.2013.08.018.

- Ting Xu; Qisheng Jiang; Deoukchen Ghim; Keng-Ku Liu; Hongcheng Sun; Hamed Gholami Derami; Zheyu Wang; Sirimuvva Tadepalli; Young-Shin Jun; Dianbo Zhang; Srikanth Singamaneni; Catalytically Active Bacterial Nanocellulose-Based Ultrafiltration Membrane. Small 2018, 14, 1704006, 10.1002/smll.201704006.

- Young-Shin Jun; Xuanhao Wu; Deoukchen Ghim; Qisheng Jiang; Sisi Cao; Srikanth Singamaneni; Photothermal Membrane Water Treatment for Two Worlds. Accounts of Chemical Research 2019, 52, 1215-1225, 10.1021/acs.accounts.9b00012.

- Qisheng Jiang; Deoukchen Ghim; Sisi Cao; Sirimuvva Tadepalli; Keng-Ku Liu; Hyuna Kwon; Jingyi Luan; Yujia Min; Young-Shin Jun; Srikanth Singamaneni; Photothermally Active Reduced Graphene Oxide/Bacterial Nanocellulose Composites as Biofouling-Resistant Ultrafiltration Membranes. Environmental Science & Technology 2018, 53, 412-421, 10.1021/acs.est.8b02772.

- Deyaa Abol-Fotouh; Bernhard Dörling; Osnat Zapata-Arteaga; Xabier Rodríguez-Martínez; Andrés Gómez; J. Sebastian Reparaz; Anna Laromaine; Anna Roig; Mariano Campoy-Quiles; Farming thermoelectric paper. Energy & Environmental Science 2019, 12, 716-726, 10.1039/c8ee03112f.

- Mina Mahdavi; Nafiseh Mahmoudi; Farzad Rezaie Anaran; Abdolreza Simchi; Electrospinning of Nanodiamond-Modified Polysaccharide Nanofibers with Physico-Mechanical Properties Close to Natural Skins. Marine Drugs 2016, 14, 128, 10.3390/md14070128.

- Liu, X.; Shen, H.; Song, S.; Chen, W.; Zhang, Z. Accelerated biomineralization of graphene oxide - incorporated cellulose acetate nanofibrous scaffolds for mesenchymal stem cell osteogenesis. Colloids Surf B Biointerfaces 2017, 159, 251-258, doi:10.1016/j.colsurfb.2017.07.078.

- Sooyeon Cho; Hayoung Yu; Junghoon Choi; Hohyung Kang; Seoungwoong Park; Ji-Soo Jang; Hye-Jin Hong; Il-Doo Kim; Seoung-Ki Lee; Hyeon Su Jeong; Hee-Tae Jung; Continuous Meter-Scale Synthesis of Weavable Tunicate Cellulose/Carbon Nanotube Fibers for High-Performance Wearable Sensors.. ACS Nano 2019, 13, 9332-9341, 10.1021/acsnano.9b03971.

- Chuantao Zhu; Peng Liu; Aji P Mathew; Self-Assembled TEMPO Cellulose Nanofibers: Graphene Oxide-Based Biohybrids for Water Purification. ACS Applied Materials & Interfaces 2017, 9, 21048-21058, 10.1021/acsami.7b06358.

- Fatemeh Ostadhossein; Nafiseh Mahmoudi; Gabriel Morales-Cid; Elnaz Tamjid; Francisco Javier Navas-Martos; Belén Soriano-Cuadrado; José Manuel López Paniza; Abdolreza Simchi; Development of Chitosan/Bacterial Cellulose Composite Films Containing Nanodiamonds as a Potential Flexible Platform for Wound Dressing. Materials 2015, 8, 6401-6418, 10.3390/ma8095309.

- Chunxiao Zheng; Jingquan Han; Lu Gan; Xinwu Xu; Changtong Mei; Jingquan Han; Highly Stretchable and Self-Healing Strain Sensors Based on Nanocellulose-Supported Graphene Dispersed in Electro-Conductive Hydrogels.. Nanomaterials 2019, 9, 937, 10.3390/nano9070937.

- Jinghao Xing; Peng Tao; Zhengmei Wu; Chuyue Xing; Xiaoping Liao; ShuangXi Nie; Nanocellulose-graphene composites: A promising nanomaterial for flexible supercapacitors. Carbohydrate Polymers 2019, 207, 447-459, 10.1016/j.carbpol.2018.12.010.

- Zhijun Shi; G O Phillips; Guang Yang; Nanocellulose electroconductive composites. Nanoscale 2013, 5, 3194-3201, 10.1039/c3nr00408b.

- Alyah Buzid; Phyllis E. Hayes; Jeremy D. Glennon; John Luong; Captavidin as a regenerable biorecognition element on boron-doped diamond for biotin sensing.. Analytica Chimica Acta 2019, 1059, 42-48, 10.1016/j.aca.2019.01.058.

- Fang Li; Hou-Yong Yu; Yan-Yan Wang; Ying Zhou; Heng Zhang; Ju-Ming Yao; Somia Yassin Hussain Abdalkarim; Michael Tam; Natural Biodegradable Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) Nanocomposites with Multifunctional Cellulose Nanocrystals/Graphene Oxide Hybrids for High-Performance Food Packaging.. Journal of Agricultural and Food Chemistry 2019, 67, 10954-10967, 10.1021/acs.jafc.9b03110.

- Nidhi Pal; Somesh Banerjee; Partha Roy; Kaushik Pal; Melt‐blending of unmodified and modified cellulose nanocrystals with reduced graphene oxide into PLA matrix for biomedical application. Polymers for Advanced Technologies 2019, 30, 3049-3060, 10.1002/pat.4736.

- Nidhi Pal; Somesh Banerjee; Partha Roy; Kaushik Pal; Reduced graphene oxide and PEG-grafted TEMPO-oxidized cellulose nanocrystal reinforced poly-lactic acid nanocomposite film for biomedical application.. Materials Science and Engineering: C 2019, 104, 109956, 10.1016/j.msec.2019.109956.

- Na Song; Siqi Cui; Xingshuang Hou; Peng Ding; Liyi Shi; Significant Enhancement of Thermal Conductivity in Nanofibrillated Cellulose Films with Low Mass Fraction of Nanodiamond. ACS Applied Materials & Interfaces 2017, 9, 40766-40773, 10.1021/acsami.7b09240.

- Celia Ruiz-Palomero; Sandra Benítez-Martínez; M.Laura Soriano; Miguel Valcárcel; Fluorescent nanocellulosic hydrogels based on graphene quantum dots for sensing laccase. Analytica Chimica Acta 2017, 974, 93-99, 10.1016/j.aca.2017.04.018.

- Siamak Javanbakht; Hassan Namazi; Doxorubicin loaded carboxymethyl cellulose/graphene quantum dot nanocomposite hydrogel films as a potential anticancer drug delivery system. Materials Science and Engineering: C 2018, 87, 50-59, 10.1016/j.msec.2018.02.010.

- T.S. Anirudhan; J.R. Deepa; Nano-zinc oxide incorporated graphene oxide/nanocellulose composite for the adsorption and photo catalytic degradation of ciprofloxacin hydrochloride from aqueous solutions. Journal of Colloid and Interface Science 2017, 490, 343-356, 10.1016/j.jcis.2016.11.042.

- Zhaoyang Xu; Huan Zhou; Xiangdong Jiang; Jianyu Li; Fang Huang; Facile synthesis of reduced graphene oxide/trimethyl chlorosilane-coated cellulose nanofibres aerogel for oil absorption. IET Nanobiotechnology 2017, 11, 929-934, 10.1049/iet-nbt.2017.0063.

- Qiufang Yao; Bitao Fan; Ye Xiong; Chunde Jin; Qingfeng Sun; Chengmin Sheng; 3D assembly based on 2D structure of Cellulose Nanofibril/Graphene Oxide Hybrid Aerogel for Adsorptive Removal of Antibiotics in Water. Scientific Reports 2017, 7, 45914, 10.1038/srep45914.

- Moien Alizadehgiashi; Nancy Khuu; Amir Khabibullin; Andria Henry; Moritz Tebbe; Toyoko Suzuki; Eugenia Kumacheva; Nanocolloidal Hydrogel for Heavy Metal Scavenging. ACS Nano 2018, 12, 8160-8168, 10.1021/acsnano.8b03202.

- Yixun Liang; Jiawei Liu; Lili Wang; Yi Wan; Jiwei Shen; Quan Bai; Metal affinity-carboxymethyl cellulose functionalized magnetic graphene composite for highly selective isolation of histidine-rich proteins. Talanta 2019, 195, 381-389, 10.1016/j.talanta.2018.11.074.

- Haixiang Sun; Cheng Ma; Tao Wang; Yanyan Xu; Bingbing Yuan; Peng Li; Ying Kong; Preparation and Characterization of C60-Filled Ethyl Cellulose Mixed-Matrix Membranes for Gas Separation of Propylene/Propane. Chemical Engineering & Technology 2014, 37, 611-619, 10.1002/ceat.201300667.

- S. Vetrivel; M. Sri Abirami Saraswathi; D. Rana; Alagumalai Nagendran; Fabrication of cellulose acetate nanocomposite membranes using 2D layered nanomaterials for macromolecular separation. International Journal of Biological Macromolecules 2018, 107, 1607-1612, 10.1016/j.ijbiomac.2017.10.027.

- Nicklas Blomquist; Thomas Wells; Britta Andres; Joakim Bäckström; Sven Forsberg; Hakan Olin; Metal-free supercapacitor with aqueous electrolyte and low-cost carbon materials. Scientific Reports 2017, 7, 39836, 10.1038/srep39836.

- Xuezhu Xu; You-Lo Hsieh; Aqueous exfoliated graphene by amphiphilic nanocellulose and its application in moisture-responsive foldable actuators.. Nanoscale 2019, 11, 11719-11729, 10.1039/c9nr01602c.

- Qisheng Jiang; Limei Tian; Keng‐Ku Liu; Sirimuvva Tadepalli; Ramesh Raliya; Pratim Biswas; Rajesh R. Naik; Srikanth Singamaneni; Bilayered Biofoam for Highly Efficient Solar Steam Generation. Advanced Materials 2016, 28, 9400-9407, 10.1002/adma.201601819.

- Xinpu Li; Chuang Shao; Bing Zhuo; Sheng Yang; Zhenyu Zhu; Chuwang Su; Quanping Yuan; The use of nanofibrillated cellulose to fabricate a homogeneous and flexible graphene-based electric heating membrane. International Journal of Biological Macromolecules 2019, 139, 1103-1116, 10.1016/j.ijbiomac.2019.08.081.

- Michal Kizling; Sylwia Draminska; Krzysztof Stolarczyk; Petter Tammela; Zhaohui Wang; Leif Nyholm; Renata Bilewicz; Biosupercapacitors for powering oxygen sensing devices. Bioelectrochemistry 2015, 106, 34-40, 10.1016/j.bioelechem.2015.04.012.

- Andrey Generalov; I V Anoshkin; M Erdmanis; Dmitri Lioubtchenko; V Ovchinnikov; Albert G. Nasibulin; Antti Räisänen; Carbon nanotube network varactor. Nanotechnology 2015, 26, 45201, 10.1088/0957-4484/26/4/045201.

- Shamoon Asmat; Qayyum Husain; Exquisite stability and catalytic performance of immobilized lipase on novel fabricated nanocellulose fused polypyrrole/graphene oxide nanocomposite: Characterization and application. International Journal of Biological Macromolecules 2018, 117, 331-341, 10.1016/j.ijbiomac.2018.05.216.

- Nidhi Pal; Poornima Dubey; P. Gopinath; Kaushik Pal; Combined effect of cellulose nanocrystal and reduced graphene oxide into poly-lactic acid matrix nanocomposite as a scaffold and its anti-bacterial activity. International Journal of Biological Macromolecules 2017, 95, 94-105, 10.1016/j.ijbiomac.2016.11.041.

- L. Valentini; M. Cardinali; Elena Fortunati; Jose M. Kenny; Nonvolatile memory behavior of nanocrystalline cellulose/graphene oxide composite films. Applied Physics Letters 2014, 105, 153111, 10.1063/1.4898601.

- Laifu Song; Yuqi Li; Zhongqiang Xiong; Lulu Pan; Qiyun Luo; Xu Xu; Shaorong Lu; Water-Induced shape memory effect of nanocellulose papers from sisal cellulose nanofibers with graphene oxide. Carbohydrate Polymers 2018, 179, 110-117, 10.1016/j.carbpol.2017.09.078.

- Wu; Gu; Hou; Li; Ke; Xiao; Guanzheng Wu; Yanjia Gu; Xiuliang Hou; Ruiqing Li; Huizhen Ke; Xueliang Xiao; Hybrid Nanocomposites of Cellulose/Carbon-Nanotubes/Polyurethane with Rapidly Water Sensitive Shape Memory Effect and Strain Sensing Performance. Polymers 2019, 11, 1586, 10.3390/polym11101586.

- Li Zhu; Xin Zhou; Yuhang Liu; Qiang Fu; Highly Sensitive, Ultrastretchable Strain Sensors Prepared by Pumping Hybrid Fillers of Carbon Nanotubes/Cellulose Nanocrystal into Electrospun Polyurethane Membranes. ACS Applied Materials & Interfaces 2019, 11, 12968-12977, 10.1021/acsami.9b00136.

- Fatima Awan; Eli Bulger; Richard M. Berry; Michael Tam; Michael Tam; Enhanced radical scavenging activity of polyhydroxylated C60 functionalized cellulose nanocrystals. Cellulose 2016, 23, 3589-3599, 10.1007/s10570-016-1057-0.

- Jiwen Luo; Weijie Deng; Feng Yang; Zeqi Wu; Mantuo Huang; Mengyuan Gu; Gold nanoparticles decorated graphene oxide/nanocellulose paper for NIR laser-induced photothermal ablation of pathogenic bacteria. Carbohydrate Polymers 2018, 198, 206-214, 10.1016/j.carbpol.2018.06.074.

- T.S. Anirudhan; Chithra Sekhar V.; Shainy F.; Jefin P. Thomas; Effect of dual stimuli responsive dextran/nanocellulose polyelectrolyte complexes for chemophotothermal synergistic cancer therapy.. International Journal of Biological Macromolecules 2019, 135, 776-789, 10.1016/j.ijbiomac.2019.05.218.

- Monireh Rasoulzadeh; Hassan Namazi; Carboxymethyl cellulose/graphene oxide bio-nanocomposite hydrogel beads as anticancer drug carrier agent. Carbohydrate Polymers 2017, 168, 320-326, 10.1016/j.carbpol.2017.03.014.

- Xiangdong Wang; Kexin Yu; Ran An; Linglin Han; Yulin Zhang; Lingying Shi; Rong Ran; Self-assembling GO/modified HEC hybrid stabilized pickering emulsions and template polymerization for biomedical hydrogels. Carbohydrate Polymers 2019, 207, 694-703, 10.1016/j.carbpol.2018.12.034.

- Xiaogang Luo; Hao Zhang; Zhenni Cao; Ning Cai; Yanan Xue; Faquan Yu; A simple route to develop transparent doxorubicin-loaded nanodiamonds/cellulose nanocomposite membranes as potential wound dressings. Carbohydrate Polymers 2016, 143, 231-238, 10.1016/j.carbpol.2016.01.076.

- T.S. Anirudhan; J.R. Deepa; Binussreejayan; Electrochemical sensing of cholesterol by molecularly imprinted polymer of silylated graphene oxide and chemically modified nanocellulose polymer. Materials Science and Engineering: C 2018, 92, 942-956, 10.1016/j.msec.2018.07.041.

- Wanlin Fu; Yunqian Dai; Xiangyu Meng; Wanlin Xu; Jie Zhou; Zhen-Guo Liu; Wei-Bing Lu; Shimei Wang; Chaobo Huang; Yueming Sun; Weibin Lu; Wang Shimei; Electronic textiles based on aligned electrospun belt-like cellulose acetate nanofibers and graphene sheets: portable, scalable and eco-friendly strain sensor. Nanotechnology 2018, 30, 045602, 10.1088/1361-6528/aaed99.

- Yu-Xiu Zou; Yinling Zhang; Yiting Xu; Yiqin Chen; Siqi Huang; Yifan Lyu; Huigao Duan; Zhuo Chen; Weihong Tan; Portable and Label-Free Detection of Blood Bilirubin with Graphene-Isolated-Au-Nanocrystals Paper Strip. Analytical Chemistry 2018, 90, 13687-13694, 10.1021/acs.analchem.8b04058.

- Yongtang Jia; Hui Yu; Yumei Zhang; Fengchun Dong; Zhe Li; Cellulose acetate nanofibers coated layer-by-layer with polyethylenimine and graphene oxide on a quartz crystal microbalance for use as a highly sensitive ammonia sensor. Colloids and Surfaces B: Biointerfaces 2016, 148, 263-269, 10.1016/j.colsurfb.2016.09.007.

- Ting Xue; Yingying Sheng; Jingkun Xu; Yingying Li; Xinyu Lu; Yifu Zhu; Xuemin Duan; Yangping Wen; In-situ reduction of Ag+ on black phosphorene and its NH2-MWCNT nanohybrid with high stability and dispersibility as nanozyme sensor for three ATP metabolites. Biosensors and Bioelectronics 2019, 145, 111716, 10.1016/j.bios.2019.111716.

- Minhyun Jung; Kyungkwan Kim; Bumjin Kim; Kwang-Jae Lee; Jae-Wook Kang; Sanghun Jeon; Vertically stacked nanocellulose tactile sensor. Nanoscale 2017, 9, 17212-17219, 10.1039/C7NR03685J.

- Penghui Zhu; Yu Liu; Zhiqiang Fang; Yudi Kuang; Yazeng Zhang; Congxing Peng; Gang Chen; Flexible and Highly Sensitive Humidity Sensor Based on Cellulose Nanofibers and Carbon Nanotube Composite Film. Langmuir 2019, 35, 4834-4842, 10.1021/acs.langmuir.8b04259.

- Chuntao Chen; Ting Zhang; Qi Zhang; Xiao Chen; Chunlin Zhu; Yunhua Xu; Jiazhi Yang; Jian Liu; Dongping Sun; Biointerface by Cell Growth on Graphene Oxide Doped Bacterial Cellulose/Poly(3,4-ethylenedioxythiophene) Nanofibers. ACS Applied Materials & Interfaces 2016, 8, 10183-10192, 10.1021/acsami.6b01243.

- Yi Sun; Qi Quan; Haoye Meng; Yu-Dong Zheng; Jiang Peng; Yaxin Hu; Zhaoxuan Feng; Xiao Sang; Kun Qiao; Wei He; Xiaoqi Chi; Liang Zhao; Enhanced Neurite Outgrowth on a Multiblock Conductive Nerve Scaffold with Self-Powered Electrical Stimulation.. Advanced Healthcare Materials 2019, 8, e1900127, 10.1002/adhm.201900127.

- S. Chakraborty; T. Ponrasu; S. Chandel; M. Dixit; V. Muthuvijayan; Reduced graphene oxide-loaded nanocomposite scaffolds for enhancing angiogenesis in tissue engineering applications. Royal Society Open Science 2018, 5, 172017, 10.1098/rsos.172017.

- Xiang Yi Chen; Hao Ran Low; Xin Yi Loi; Laura Merel; Mohd Amin Mohd Cairul Iqbal; Fabrication and evaluation of bacterial nanocellulose/poly(acrylic acid)/graphene oxide composite hydrogel: Characterizations and biocompatibility studies for wound dressing. Journal of Biomedical Materials Research Part B: Applied Biomaterials 2019, 107, 2140-2151, 10.1002/jbm.b.34309.

- Yiwei Wang; Liujun Shi; Haoping Wu; Qingyang Li; Wei Hu; Zhenbao Zhang; Langhuan Huang; Jingxian Zhang; Dengjie Chen; Suiping Deng; Shaozao Tan; Zhenyou Jiang; Graphene Oxide-IPDI-Ag/ZnO@Hydroxypropyl Cellulose Nanocomposite Films for Biological Wound-Dressing Applications.. ACS Omega 2019, 4, 15373-15381, 10.1021/acsomega.9b01291.

- S.L. Burrs; M. Bhargava; R. Sidhu; J. Kiernan-Lewis; C. Gomes; J.C. Claussen; Eric S. McLamore; A paper based graphene-nanocauliflower hybrid composite for point of care biosensing. Biosensors and Bioelectronics 2016, 85, 479-487, 10.1016/j.bios.2016.05.037.

- Chao Liu; Jing Dong; Geoffrey Waterhouse; Ziqiang Cheng; Shiyun Ai; Electrochemical immunosensor with nanocellulose-Au composite assisted multiple signal amplification for detection of avian leukosis virus subgroup J. Biosensors and Bioelectronics 2018, 101, 110-115, 10.1016/j.bios.2017.10.007.

- Jie Cao; Xinxing Zhang; Xiaodong Wu; Shuman Wang; Canhui Lu; Cellulose nanocrystals mediated assembly of graphene in rubber composites for chemical sensing applications. Carbohydrate Polymers 2016, 140, 88-95, 10.1016/j.carbpol.2015.12.042.

- Chaoyi Yan; Jiangxin Wang; Wenbin Kang; Mengqi Cui; Xu Wang; Ce Yao Foo; Kenji Jianzhi Chee; Pooi See Lee; Highly Stretchable Piezoresistive Graphene-Nanocellulose Nanopaper for Strain Sensors. Advanced Materials 2013, 26, 2022-2027, 10.1002/adma.201304742.

- Shuman Wang; Xinxing Zhang; Xiaodong Wu; Canhui Lu; Tailoring percolating conductive networks of natural rubber composites for flexible strain sensors via a cellulose nanocrystal templated assembly. Soft Matter 2016, 12, 845-852, 10.1039/c5sm01958c.

- Carlos Baleizão; Stefan Nagl; Michael Schäferling; Mario Berberan-Santos; Otto S. Wolfbeis; Dual Fluorescence Sensor for Trace Oxygen and Temperature with Unmatched Range and Sensitivity. Analytical Chemistry 2008, 80, 6449-6457, 10.1021/ac801034p.

- Sven Kochmann; Carlos Baleizão; Mario Berberan-Santos; Otto S. Wolfbeis; Sensing and Imaging of Oxygen with Parts per Billion Limits of Detection and Based on the Quenching of the Delayed Fluorescence of13C70Fullerene in Polymer Hosts. Analytical Chemistry 2013, 85, 1300-1304, 10.1021/ac303486f.

- Yu Luo; Shige Wang; Mingwu Shen; Ruiling Qi; Yi Fang; Rui Guo; Hongdong Cai; Xueyan Cao; Helena Tomás; Meifang Zhu; Xiangyang Shi; Carbon nanotube-incorporated multilayered cellulose acetate nanofibers for tissue engineering applications. Carbohydrate Polymers 2013, 91, 419-427, 10.1016/j.carbpol.2012.08.069.

- Simon Duri; April L. Harkins; Anna J. Frazier; Chieu Tran; Composites Containing Fullerenes and Polysaccharides: Green and Facile Synthesis, Biocompatibility, and Antimicrobial Activity. ACS Sustainable Chemistry & Engineering 2017, 5, 5408-5417, 10.1021/acssuschemeng.7b00715.