1. Introduction

Analysis of energy consumption in the processes of crushing and grinding mineral feeds indicate relatively low energy consumption rates by intermediate (0.3–0.5 kWh/t) and fine (0.8–1.2 kWh/t) crushing and high by fine (18–20 kWh/t) and ultra-fine (80 kWh/t and above) grinding

[1][2][3][1,2,44]. In the concentration processes of mineral feeds, the central role of disintegration is to complete unlocking of mineral intergrowth with the liberation of mineral grains for their subsequent separation according to their physical and physicochemical properties. The transition to selective disintegration is to manage the process in such a way that disintegration occurs not along the random directions of compressive forces, but along the boundaries of mineral grains as a result of the development of shear and tensile loads at their boundaries

[1][2][4][5][6][7][1,2,3,4,5,10]. These requirements are met in dynamic autogenous mills, vibroinertial cone crushers, gas-jets, spring mills for fine and ultrafine grinding (by Mekhanobr−tekhnika, Russia), and high-pressure roller mills (roller presses)

[1][2][8][9][10][1,2,8,9,45], providing energy and resource savings, higher mineral recovery, and high-grade products.

To achieve the most complete disclosure of finely disseminated mineral complexes of ferrous, non-ferrous, rare, and precious metals, non-mechanical energy impact-based methods appear to be highly promising, contributing to the selective disintegration of minerals along interfacial boundaries through the formation of microcracks and breakdown channels without excessive regrinding, and thus minimal energy consumption. In their pioneering studies, I.N. Plaksin and other researchers at ICEMR RAS and the Siberian Branch of the Russian Academy of Sciences demonstrated that ionizing effects (accelerated electrons, neutrons, gamma rays, etc.) do affect the physical, mechanical, and physicochemical properties of minerals

[1][4][5][6][11][12][13][14][15][16][1,3,4,5,12,13,35,46,47,48].

2. Applications of Accelerated Electron Energy in the Concentration Processes of Polymetallic Ores

The use of energy from accelerated electrons for the intensification of ore pretreatment and primary mineral processing is of high practical relevance

[3][17][18][24,25,44]. Radiation technology based on the use of electron accelerators in the energy range of 0.2–2.5 MeV

[19][49] is characterized by high process safety, energy efficiency, high processing rates, reduction of thermal and chemical pollution, reduction of production areas, long service life of the process equipment, high product grades, and high process availability

[3][19][44,49].

When semiconductor minerals (sulfides, oxides) and dielectrics (quartz, calcite) are exposed to a concentrated energy flow of accelerated electrons, the main factor determining the efficiency of mineral complex weakening and disclosure is the difference in the ability to accumulate and release charge by semiconductor minerals and dielectric minerals

[20][21][22][50,51,52]. Conductive minerals are characterized by the predominance of the charge drain over the charging process, or the establishment of an equilibrium between the influx and the drain of the charge, where no charge accumulation occurs. In a mineral substance with specific conductivity

σ > 10

−8 S/m, the charge is distributed over the particle surfaces, while in a low-conductivity environment, the charge is distributed in the volume of the particle itself

[20][50].

In high-resistance dielectrics excess charge is accumulated and then discharged, and the electrical discharge propagates along the breakdown channels in a self-oscillating (pulsating) mode

[20][21][22][50,51,52], causing the formation of microcracks that propagate in the mineral with each discharge pulse. This leads to a decrease in the strength of the mineral matrix material by two to three orders of magnitude.

As a result of preliminary (prior to grinding) treatment of ferruginous quartzites, polymetallic and gold-bearing ores with an accelerated electron flow, a 1.2- to 2-fold increase in the ore’s grinding performance was achieved with a 2-fold reduction in energy consumption and a simultaneous improvement in the intergrowth disclosure performance

[3][17][18][23][24,25,44,53]. Irradiation with accelerated electrons in the range of 0.2–0.8 Mrad of refractory pyrite-arsenopyrite gold-bearing gravity concentrate (particle size less than 500 μm) obtained from the Nezhdanino ore in Yakutia, Russia, led to an increase in gold and silver recovery in the sorption cyanidation circuit by 23.3% and 26.8%, respectively, and an absolute recovery of 74.5% and 48.6%, respectively

[24][26]. Treating the concentrate with water or acid before irradiation activated the disintegration process of the mineral complexes by accelerated electrons, bringing an increase in the recovery of precious metals by 7.7% (Au) and 5.7% (Ag) compared to dry feed

[24][26].

For this energy impact treatment, the energy consumption is from 5 to 10 kWh⋅per ton of concentrate (particle size less than 500 μm), or ~1.1 kWh per 1 g of additionally recovered gold. This is 1.7 to 2.5 times lower than during mechanical grinding to a particle size class of -50 μm

[4][5][3,4].

Radiation thermal effect (RTE) treatment of minerals, such as granite, quartz, and magnetite create alternating temperature stresses, which, upon reaching the ultimate strength of a mineral, cause their softening and disintegration

[23][25][53,54]. Simultaneously, during RTE, the action of accelerated electrons on sulfide ores and minerals is combined with low-temperature (≤300 °C) phase transformations of iron-bearing sulfides into magnetic oxides—hematite and magnetite

[26][27][55,56]. RTE treatment of polymetallic pyrite ore from the Rubtsovo deposit (Fe-16.8%, particle size less than 3 mm, Altai Territory, Russia) at a temperature of 400 °C (electron accelerator ILU-10 with an electron energy of up to 3–5 MeV and a power output of up to 50 kW), resulted in magnetic fraction yields at the subsequent dry magnetic separation stage of 47.4%, compared to as low as ~2% under conventional thermal heating. Recovery of non-ferrous metals (Cu, Pb, Zn) into the magnetic fraction was 85–90%

[28][57].

RTE treatment (ILU-6, electron energy up to 2.5 MeV) of ferruginous bauxite samples from the Vezhayu-Vorykva deposit (Komi, Russia), resulted in ferromagnetic phases forming in bauxites, which can significantly improve the magnetic separation performance of the aluminum and iron components and improve the selectivity of the recovery of rare and rare earth elements

[29][58].

Exposure to accelerated electrons stimulates oxidative processes on the surface of iron-containing sulfides, as evidenced by a positive change in the potential and a decrease in sulfur on the surface of pyrite particles

[21][51]. Pretreatment of arsenopyrite increased flotation activity and xanthate sorption

[21][51]. For pyrite and arsenopyrite, the optimal doses of radiation were found in

[30][59], which ensured the selectivity of flotation of iron and arsenic sulfides with a difference in recovery of about 50%.

3. Applications of Microwave Energy in Mineral Processing

Sources of high-power pulsed microwave radiation are capable of creating extremely strong electromagnetic fields (on the order of 1 MeV/cm) in the accelerating units of electron-positron linear colliders

[31][32][27,29]. The pulsed nature of microwave radiation (as a heat source with the density

q, W/m

2) can significantly affect the structure and properties of heterogeneous materials and, in particular, earth materials (minerals, rocks, ores) consisting of components with very different mechanical, electrical, and thermal properties (for example, rocks with a high linear expansion coefficient and a low Young’s modulus).

When exposed to microwaves, the disintegration of mineral feeds occurs due to quick (~10

−5–10

−3 s) and non-homogeneous heating of samples from ambient temperature to hundreds of degrees; therefore, microwave treatment is classified as thermal exposure. At the same time, significant thermomechanical stresses arise at the interfaces, exceeding the ultimate strength of the mineral and leading to cracking of the ore

[31][32][33][34][35][27,28,29,30,33]. During conventional mechanical grinding energy is spent to a large extent on the breakdown of gangue, when a mineral feed treated by microwaves is ground, breakage occurs along the interfaces, impurities, intergrowths, and other defects. Also, the effect of weakening as a result of microwave exposure can be achieved through rapid evaporation of the water contained in the pores of the rock, when the saturated vapor pressure inside the pores exceeds the ultimate strength of the rock

[31][36][37][27,60,61].

The microwave method offers several advantages

[31][32][33][34][38][27,28,29,30,62]: volumetric transformation of the applied microwave energy into thermal and mechanical energy with a penetration depth of 0.1–1 m in the meter wavelength range; the possibility of processing mineral feeds with a particle size of more than 2–3 mm; a high heating rate up to 10

6–10

8 °C/s at high power levels at the optimum frequency, providing thermal shock and the transition from ductile fractures to more energetically favorable brittle fractures; low energy losses due to friction and heat removal to the surrounding structures; availability of industrial-grade generators and other high power equipment (50–300 kW and higher), capable of providing an hourly throughput of up to 10–50 tons of mineral feed; non-contact delivery of fracture energy into the rock with high (up to 70%) efficiency. The microwave power transfer coefficient for a sample exposed to the electric field’s maximum is 95%

[36][38][60,62], making it possible to heat the sample to a temperature of several hundred degrees in a few seconds by applying microwave radiation with a power output of 600 W at a continuous magnetron operating frequency of 2.45 GHz.

Preliminary microwave treatment (especially in the pulse mode

[39][63]) significantly reduces the strength of mineral intergrowth, improving the unlocking performance of valuable minerals in the process of mechanical grinding and their recovery from refractory mineral feeds. Experiments on samples of sulfide copper-nickel ores from Norilsk Region, Russia, the effect of weakening mineral complexes when exposed to pulsed electromagnetic fields in the meter range with a field strength of 0.3 MW

[40][64] was established. For ores containing up to 8% of copper and nickel, the grinding time was reduced by 8–10%, and for low-grade ores (Cu, Ni 0.8%) by 24–34% combined with lower energy consumption for grinding and lower wear of the grinding mills. As a result of the research conducted at the Institute of Nuclear Physics and the Institute of Geology and Geophysics of the Academy of Sciences of Uzbekistan

[41][65], ICEMR (IPKON) RAS, and the Institute of Geosphere Dynamics RAS

[42][66], it was shown that microwave treatment of sulfide ores and middlings contributes to a significant increase in gold recovery by cyanidation and concentration.

The main disadvantages of this method are high power consumption (from 10 up to 100 kWh/t) and the negative impact of high temperatures, which, under certain processing parameters, cause the possible closure of microcracks and breakdown channels formed during the exposure. This sintering of mineral particles, due to melting, predetermines the insufficiently high concentration performance.

4. Laser Technology for Mineral Processing

In

[43][44][67,68], the effect of laser radiation in pulsed and continuous modes on finely disseminated mineral complexes of noble metals (aluminosilicates from alluvial deposits) was examined. The analysis of rapid thermal (thermodynamic) processes, structural phase transitions and the accompanying phenomena in earth materials when irradiated with a defocused laser beam with a diameter of 2–5 mm showed the possibility of unlocking, extracting, and coarsening valuable mineral particles and forming spherical agglomerates on the surface of gold minerals due to the thermocapillary mechanism

[45][69]. High-intensity electromagnetic exposure during laser treatment of mineral samples from anthropogenic products with ultrafine and colloid-ion gold inclusions (Gaifon deposit, Khabarovsk Territory, Russia) caused defragmentation of minerals due to high-speed melting and subsequent crystallization upon cooling. As a result of pulsed laser treatment, submillimeter spherical granules formed, and ultrathin gold films as a result of continuous treatment

[43][67]. In

[43][44][46][32,67,68], process designs were proposed for the concentration and recovery of submicron and ultrafine gold from technogenic placer products by using exposure to laser radiation.

The high-power fiber lasers from 3 to 10 kW leave other laser types behind in all commercially significant characteristics. According to

[46][32], high-power fiber lasers penetrate into mining process flows owing to low energy consumption, simple operation and high endurance.

5. Magnetic-Pulse Technology for the Softening and Disintegration of Ferruginous Quartzites

The magnetic-pulse treatment (MPT) to weaken ferruginous quartzites in the slurry feed, prior to mechanical grinding

[35][33] is based on using the phenomenon of magnetostriction in ferromagnetic mineral grains (magnetite) as a result of a high-intensity electromagnetic field

[35][47][33,34]. During magnetostriction, the shape of magnetite grains changes, which, in the presence of rigid bonds with neighboring components of the mineral complex, leads to mechanical stresses reaching their maximum at the boundaries of the intergrowth between magnetite and quartz, magnetite and hematite, etc. This contributes to the emergence and development of defects at the intergrowth boundaries of magnetite grains with neighboring grains and, as a result, leads to the weakening of the intergrowth. According to

[35][48][33,70] and estimates in

[49][71], MPT of ferruginous quartzites, although it does not completely destroy intergranular bonds between magnetite and quartz grains, causes softening of mineral complexes, which makes it possible to reduce energy consumption in the grinding of iron ore and improve the concentration performance.

The findings presented in

[50][72] indicate that magnetic pulse treatment practically did not change the particle size distribution of magnetite ore. However, despite this fact, the process performance of the subsequent magnetic separation of ore minerals and their intergrowth with rock-forming minerals improved: the recovery (grade) of iron increased from 81.3% (42.1%) before MPT to 87.7% (44.4%) after MPT.

During full-scale trials of a magnetic-pulse ore processing unit, before feeding the ore to the mill, the feed was treated by MPT by passing the slurry through a dielectric pipe segment with a system of electromagnetic coils installed, which generated alternating electromagnetic field pulses with a frequency of 1–12 Hz. The pulse duration was ~3 ms; high-frequency circuit discharge frequency ~5 kHz; radiation thermal power 1.5–2 kW; and power consumption of the MPT unit ~5 kW

[48][70]. The full-scale trials showed that MPT of ferruginous quartzites makes it possible to increase the grinding yield by 4.4% and, during the subsequent magnetic separation of the ground product, increase the recovery of iron by 2% without sacrificing the concentrate grade, and increase the overall separation performance by 3.3%

[48][70]. In general, for this energy impact treatment, the energy consumption is from 3 to 5 kWh/ton of ferruginous quartzites

[35][33].

6. Pulsed Power Technology for Mineral Processing

The most important direction in the development of advanced, cutting-edge processes is the pulsed power technology, based on the principle of converting the energy of an electric and/or a magnetic field into a pulsed form with the exposure of the mineral feed to dosed high-power pulsed electric and magnetic fields (as well as beams of charged particles, neutrons, and X-ray quanta). One of the applications of the pulsed power technology is the treatment of mineral feeds with ultra-strong pulsed electromagnetic fields.

In Russia, pulse power processes were first proposed by the Institute of High Current Electronics, Siberian Branch, Russian Academy of Sciences (IHCE SB RAS) Tomsk, the Institute of Electrophysics of the Ural Division of the Russian Academy of Sciences (IEP UD RAS), Yekaterinburg

[51][73], and the Northern Energetics Research Centre-Branch of the Federal Research Centre “Kola Science Centre of the Russian Academy of Sciences” (NERC KSC RAS)

[13][35].

When applied to the processes of breakage and disintegration of building materials, rocks, and ores, the performance of the pulsed power technology is determined by the manifestation of two main processes when a high voltage pulse is applied to a solid dielectric (semiconductor)

[7][13][52][10,35,36], which in the vast majority of cases is placed in a liquid medium

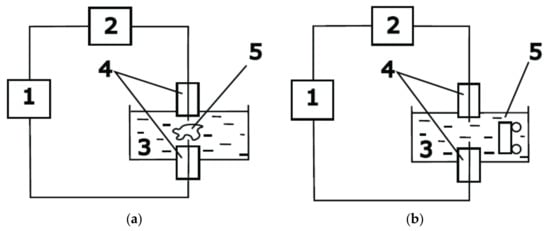

(Figure 1). These processes include electrodynamic fragmentation and electrohydraulic breakage (grinding).

Figure 1. Schemes of (a) electropulse and (b) electrohydraulic technologies; presented in the paper [36]: 1—high-voltage pulse generator, 2—switchboard, 3—discharge chamber filled with liquid, 4—electrode system, 5—technology specimen. Adapted with permission from Ref. [36]. Copyright 2019, Publishing House of the Ural University.

In the former case, high-voltage breakdown

[53][54][74,75] of a condensed medium (geomaterial) is accompanied by the emergence of a plasma channel that disintegrates the material along the interfaces due to mechanical tensile stresses

[55][76]. In the latter case, solids are destroyed by shock displacements of the liquid (waves) arising during the development and collapse of cavitation pockets during the passage of an electric discharge through the liquid phase (the Yutkin effect

[56][77]). The breakage mechanism of processed samples, depending on the ratio between the electroplasma (EP) and electrohydraulic (EH) components of the electropulse breakdown process, is controlled by the electrical strength of the solid and liquid phases of the medium and the parameters of the pulsed action. The conditions for the transition from one type of breakage to another are determined by the steepness of the leading edge of the pulse (

τfr) and the pulse amplitude U

imp [13][35]: at

τfr ≤ 100 ns and U

imp ≥ 250–300 kV, the EP effect is observed; at

τfr > 100 ns and U

imp < 250–300 kV, the EG effect is observed.

6.1. Electrohydraulic Disintegration Process

Presently, of all the types of energy effects discussed in this

rpape

searchr and tested in practice, electrohydraulic disintegration (ED) of building materials, rocks, and ores is the one the most widely used globally, implemented as part of high-throughput plants

[13][57][58][35,78,79], and full-scale commercial applications

[59][80].

Electrohydraulic (ED) mineral processing, so-called selective crushing, is based on the action of shock waves generated during the electrical breakdown of a liquid on solids (dielectrics, semiconductors, and conductors) placed in the liquid

[56][77]. Brittle intercrystalline fracture of mineral complexes occurs along the boundaries of intergrowths between valuable minerals and the rock-forming matrix due to alternating compression and tension forces formed in solids when shock waves are reflected from solid-liquid interfaces

[60][81]. Under ED exposure, the following forces arise

[13][52][35,36]: a powerful shock pulse with a discharge energy of up to 80 J, volumetric cavitation microexplosions

[61][82], ultrasonic and electromagnetic radiation, changes in the chemical composition of the medium due to erosion of the electrode material, and the destruction of water molecules in the discharge channel. In the case of cavitation breakage of polymineral intergrowths, the release of nano- and microparticles of noble metals occurs as a result of the interaction of mineral particles with collapsing cavitation bubbles formed from shock loading of liquid heated to the boiling point, into which the particles were placed

[61][82].

The disintegration (crushing) process of the ground particles by shock waves arising from electrical breakdown of the liquid becomes efficient when the pulse duration (

τimp) is less than or equal to the double travel time of a sound wave with speed

v in a particle sized

d [60][81]:

τimp ≤ 0.5

d/

v;

d = 100 μm;

v = 8000 m/s (speed of sound in pyrite)

τimp~10

−9–10

−8 s, which indicates the need for high-voltage (50–250 kV) nanosecond pulses

[51][60][62][39,73,81]. In general, for this energy impact treatment, the energy consumption is from 3 to 5 kWh/ton of ores, concentrates, and tailings of enrichment.

In their detailed review, Wei Huang and Yumeng Chen

[7][10] concluded that the mechanisms of selective breakage (disintegration) of rocks and ores in the process of high voltage pulsed electrodynamic and electrohydraulic treatment, despite many years of research by Russian and international scientists, is still debatable and requires further scientific and process research.

The following technological results demonstrate the possibilities of using the ED method for pre-treatment of refractory mineral raw materials. At IEP UD RAS, a unit was developed for electrohydraulic processing of mineral feeds by nanosecond pulses of positive polarity with an amplitude of up to 250 kV, a pulse repetition rate of 300 Hz, an energy in the discharge channel of 3 J, and a power consumption of 5 J/pulse

[60][81]. As a result of nanosecond breakdown of water containing suspended gold-bearing pyrite particles from the Uchaly tailings storage facility (D90 74 μm, Au 2.2 g/t), gold recovery was 60% higher (from 17% to 87%) with an energy consumption of ~4 kWh/t

[60][63][81,83].

Pre-treatment in continuous mode (pilot laboratory machine throughput up to 120 kg/h of solid mineral feed) of refractory gold ore from the Albazino deposit (Au 13 g/t, sample particle size –0.2 + 0.1 mm) by a series of electrohydraulic shocks (total 40 EH pulses) with an energy of 3.2 kJ/dm

3 in an acidic 2% solution of H

2SO

4 followed by thiourea leaching made it possible to improve gold recovery from 65–75% in control runs to 95% after ED treatment

[64][84].

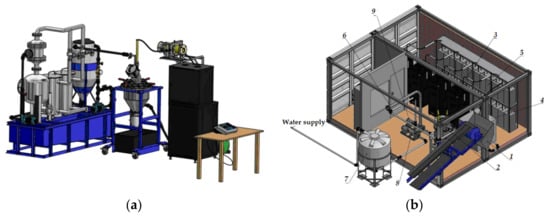

One of the most significant recent developments in Russia is the electrohydraulic plants by the ElectroHydroDynamika Group (NPF EGD, St. Petersburg): EGDL-10 for processing mineral samples up to 10 kg on a lab scale

(Figure 2a), and the modular EGD-10 for pretreatment of ore and anthropogenic mineral feeds prior to concentration in a full-scale industrial setting

[58](Figure 2b) [79].

Figure 2. Electrohydraulic installations of the ElectroHydroDynamika Group (St. Petersburg, Russia): (a) laboratory installation EGDL-10 and (b) industrial modular installation EGD-10 [79]: 1—feed unit, 2—reactor, 3—pulse current generators, 4—air discharger, 5—capacitor unit, 6—material sampling unit, 7—water buffer tank, 8—water supply pump, 9—slurry pump. Reprinted with permission from Ref. [79]. Copyright 2017–2021, ElectroHydroDynamics.

The full-scale EGD-10 plant is composed of

[58] (Figure 2b) [79] feed unit (

1), reactor (

2), pulse current generators (

3), air discharger (

4), capacitor unit (

5), material sampling unit (

6), water buffer tank (

7), water supply pump (

8), slurry pump (

9). The plant supports continuous loading and processing of feeds with a maximum grain size of 5 mm at a S:L ratio of no more than 1:2 with a throughput of up to 9 t/h. A closed-loop hydraulic system with circulating process water ensures low water consumption. Maximum installed power is 7 kW/t, and maximum power consumption is 63 kW.

Among global developments, commercial lab scale equipment SELFRAG Lab by SELFRAG, Switzerland, for the selective fragmentation of composite materials, mineralogical and geological samples using high-power high-voltage electric discharges in a liquid medium is worth noting

[57][78].

In general, the disadvantages of the ED method include significant limitations in the processing of fine mineral products with a particle size of less than 100 micron and a relatively high energy consumption. The need for a liquid medium at a S:L ratio of 1:1 reduces process performance and increases energy consumption. In practice, the uncontrolled change in the ionic composition of the aqueous phase of the slurry causes the formation of oxidation by-products (iron hydroxide films) on the surface of mineral particles, which creates additional energy barriers that prevent the selective disintegration and opening of mineral aggregates and subsequent recovery of valuable minerals.

6.2. Advanced Pulsed Power Technology for Dry Mineral Processing

Presently, both global and Russian practice of ore pretreatment and concentration is dominated by the so-called “wet” methods of concentration; for example, flotation, gravity processes, electrohydraulic breakage. Despite the continuous improvements in process management, ore concentration process flows have not undergone radical changes over the past decades. Wet concentration methods, for all their performance, due to the shortage of water all over the world, have the following significant disadvantages

[65][85]: high water consumption, the need for water-sludge circuits, high irretrievable energy costs of moving large water volume, the need for auxiliary energy-intensive equipment, large capital costs involved in the construction and operation of concentrators.

In this context, “dry” concentration processes can become the preferred solution for a number of mineral feeds (“mineral processing technologies of the future”)

[65][66][67][85,86,87]. Promising dry concentration processes, include gravity concentration, magnetic separation

[66][67][86,87], X-ray radiometric separation (large-sized ore sorting

[65][85]; this technology is planned to be implemented at more than 300 deposits), electrical separation (separation of fine fractions)

[65][67][85,87], weakening and structural-chemical modification of mineral feeds by high-power nanosecond electromagnetic pulses

[1][4][5][6][68][69][70][71][72][73][74][75][1,3,4,5,17,18,19,20,21,22,37,38], low-temperature dielectric barrier discharge plasma

[76][77][78][79][80][81][14,15,16,41,42,43], and other methods

[3][17][18][43][44][49][65][66][67][24,25,44,67,68,71,85,86,87].

Currently, research is carried out on the use of high-power sources of electromagnetic radiation

[51][82][73,88] for

nonthermal impacts on natural and engineered environments of various nature

[83][89]. Research is underway at the Kotelnikov Institute of Radioengineering and Electronics (IRE) Russian Academy of Sciences in Moscow and IHCE SB RAS in Tomsk on nonthermal impacts on biological objects, including living organisms, of high-power nanosecond microwave pulses (radio pulses)

[84][90]. In

[85][91], a mechanism of resonant action for virus inactivation is proposed, based on the transformation of electromagnetic oscillations into acoustic ones. In

[86][92], a hypothesis was put forward about the possibility of using high-power nanosecond electromagnetic pulses with specific frequencies in the microwave range for pondermotor action on bacteria and viruses to destroy biological objects with known morphological features in the form of nanoprotrusions and nanopoints.

Energy impacts of this type belong to the so-called

nonthermal impacts, since the energy of each pulse is not capable of significantly changing the overall temperature of the object. In

[83][89], the conditions of nonthermal impact of HPEMP on natural and engineered environments of various nature are presented:

- (1)

-

The temperature,

T, of the environment as a whole, as well as the temperature of its characteristic relatively homogeneous elements, practically does not change,

Taverage (before the treatment) ≅

Taverage (after the treatment).

-

- (2)

-

The strength amplitude of the electric field of the pulse

E is much greater than the static breakdown amplitude,

Emax. imp. >>

Estat.

-

- (3)

-

Pulse duration,

Δt, is much less than the thermal relaxation time of the medium, Δ

t << Δ

ttherm.rel.. During a time, much shorter than the typical time to establish the thermophysical properties of the materials making up the environment, local temperature during the impact can be high

[83][87][89,93].

-

The method of

nonthermal exposure to high-power nanosecond electromagnetic pulses

[1][4][5][6][74][75][1,3,4,5,37,38] is used in the processing of refractory, gold-bearing, and polymetallic ores and their concentration products. It is an effective solution for overcoming the physical resistance of ore by unlocking finely disseminated mineral complexes of non-ferrous, rare, and noble metals; thus, increasing the recovery of valuable components in cyanidation

[4][5][74][75][88][3,4,37,38,94], gravity separation

[49][71], and acid leaching circuits

[89][90][91][92][95,96,97,98]. It also increases the contrast of the properties of semiconductor ore minerals (sulfides, oxides) and improves their subsequent separation during flotation due to the formation of hydrophobic and hydrophilic nanoparticles on their surface

[1][5][6][68][69][70][71][72][73][93][94][1,4,5,17,18,19,20,21,22,23,99].

In the preparation of mineral feeds for concentration, the effectiveness of high-power electromagnetic pulses in the processes of selective disintegration is regulated by the following conditions and limitations: predominantly dry or wet (S:L from 5:1 to 3:1) ground feed is processed; the range of change in the mineral particle size is from 100 microns to 2–5 mm.

As a result of the impact of HPEMP on refractory ores and middlings containing finely disseminated particles of noble metals, a sustainable improvement of 5–10% in the recovery of precious metals was achieved, with a decrease in energy consumption and a decrease in the cost of finished products

[4][5][74][75][88][3,4,37,38,94]. Electropulse treatment of a wet feed intensifies the process of intergrowth unlocking and, depending on the type of mineral feed, provides an increase in the recovery of precious metals between 2% and 40% while reducing the energy consumption

[4][75][95][3,38,100].

According to

[4][5][75][3,4,38], for a gravitational concentrate of ore from the Nezhdaninskoye deposit exposed to HPEMP, a rather high gain in precious metal recovery was obtained with a minimum energy expenditure of just 3–4 kWh/ton of concentrate being processed and 0.2–0.25 kWh/g of additionally recovered gold. Energy consumption in a process involving the mechanical grinding of ore from 500 μm to 50 μm was about 20–25 kWh/ton of ore and 0.9 kWh/g of additionally recovered gold. This fact indicates that the HPEMP effect provides highly efficient breaking-up of resistant ore products, primarily owing to the partial destruction of mineral complexes and the generation of breakdown channels promoting the access of lixiviant to gold and silver particles.

Plasma treatment of ores, ore concentrates, and mineral feeds is used most often to improve the separation performance of ore minerals and non-metallic gangue, as well as for the “plasma grinding” of ores and processing products to reduce the time of subsequent mechanical grinding and energy costs. The practical application of plasma for directed modification of the structural-chemical and process properties of geomaterials (among other factors) is largely associated with the use of a process (plasma-forming) gas. The power consumption of a plasma-technological reactor with a capacity of 120 kg/h for processing of tin-lead, molybdenum ores and concentrates with a low-temperature plasma flow varies in the range of 50–100 kW

[11][12].

The central role of low-temperature oxygen (Ar-O

2) plasma in processing sulfide minerals with similar physicochemical surface properties, is selective plasma-induced surface oxidation of sulfides from a natural mixture of disseminated mineral particles

[11][76][77][12,14,15]. Exposure to plasma leads to a stepwise change in the chemical state of atoms and structural phase transformations on the surface of minerals, the appearance of surface films of oxides (hydroxides) and microdefects, and the reduction and thermal removal of sulfur causing a directed change in the process properties of sulfides and improves their flotation performance

[76][77][96][97][98][14,15,101,102,103]. As applied to full-scale production of zirconium oxide (fluoride), oxygen plasma can be used to clean the surface of zircon from organic films and modify its flotation properties

[99][104]. It is also proposed to use oxygen plasma treatment of tantalum oxide films to control their electrical and dielectric properties

[100][105].

Non-equilibrium, low-temperature plasma of dielectric barrier discharge, characterized by high pressure (hundreds of Torr and higher), high electron temperatures (average electron temperatures can reach several electron volts), and low temperature of the process gas (close to the temperature of dielectric barriers)

[101][40] is considered the most precise, efficient, and safe tool for modifying the composition, structure, and properties of the surfaces of various materials, including geomaterials

[77][78][79][80][81][92][102][103][104][105][15,16,41,42,43,98,106,107,108,109]. A dielectric barrier discharge occurs in a gas under the action of an alternating voltage applied to the conducting electrodes, provided that at least one electrode is covered with a dielectric layer on the side of the discharge gap. The discharge can be carried out in oxygen or air at atmospheric pressure, room temperature, and natural air humidity

[101][106][40,110], i.e., under normal conditions (NIST) and without the use of a special plasma gas. The parameters of HV generators for DBD plasma producing are generally in the range of power 0.5–10 kW, pulses repetition rate initiating discharge—5–50 kHz, pulse voltage—5–20 kV; for effective materials surface treatment, the discharge energy in the range of 0.5–1.5 kJ/m

2 should be provided

[101][106][40,110].